Your Ultimate Guide to Sourcing Emi Filter

Introduction: Navigating the Global Market for emi filter

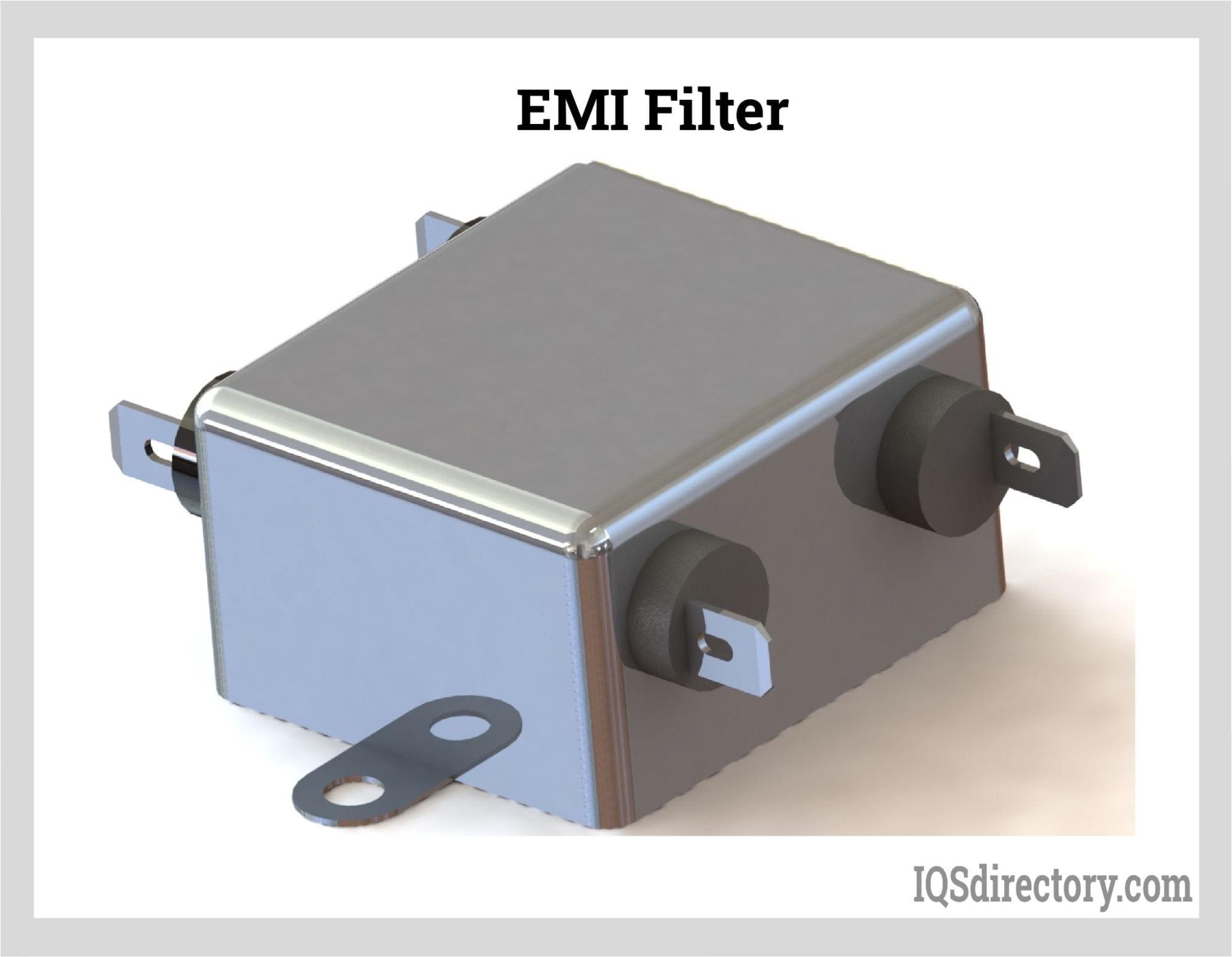

Navigating the global market for EMI filters is essential for international B2B buyers looking to ensure the reliability and efficiency of their electronic systems. As electromagnetic interference (EMI) becomes increasingly prevalent, the role of EMI filters in mitigating unwanted signals and maintaining electromagnetic compatibility (EMC) cannot be overstated. These filters are critical in a variety of sectors, including industrial automation, telecommunications, and medical devices, where the integrity of electrical signals is paramount.

This comprehensive guide will delve into the various types of EMI filters available, including their configurations and materials, to help buyers make informed decisions. It will cover essential manufacturing and quality control practices to ensure product reliability, alongside insights into leading suppliers across different regions. Additionally, we will explore cost considerations and market trends that impact sourcing strategies.

With a focus on empowering B2B buyers from Africa, South America, the Middle East, and Europe, this guide aims to equip decision-makers with the knowledge needed to navigate the complexities of the EMI filter market. By understanding the nuances of EMI filtering technology and its applications, buyers can enhance their procurement processes, optimize equipment performance, and ultimately achieve greater operational efficiency.

Understanding emi filter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Power Filters | Designed for AC applications, typically low-pass | Industrial machinery, HVAC systems | Pros: Effective for general EMI suppression; Cons: May require specific tuning for optimal performance. |

| DC Power Filters | Specialized for DC circuits; includes capacitors | Renewable energy systems, battery management | Pros: Essential for battery protection; Cons: Limited to DC applications. |

| Common Mode Filters | Blocks common-mode noise; uses inductive components | Telecommunications, data centers | Pros: High efficiency in noise reduction; Cons: More complex design may increase costs. |

| Differential Mode Filters | Focuses on differential signals; simpler design | Audio equipment, consumer electronics | Pros: Generally lower cost and easier to implement; Cons: Less effective against common-mode noise. |

| Integrated EMI Filters | Combines multiple functions in a single package | Compact electronic devices, automotive | Pros: Space-saving and cost-effective; Cons: May compromise on individual filter performance. |

AC Power Filters

AC Power Filters are primarily designed to mitigate electromagnetic interference in alternating current (AC) applications. They are crucial in environments like industrial machinery and HVAC systems, where high power levels can lead to significant EMI issues. When purchasing, buyers should consider the filter’s cut-off frequency and insertion loss, as these parameters determine the filter’s effectiveness in specific applications. Additionally, the need for customization based on the specific load and source impedance is an important factor.

DC Power Filters

DC Power Filters are tailored for direct current applications, often found in renewable energy systems and battery management systems. These filters are vital for protecting sensitive electronics from voltage spikes and noise that can arise from power conversion processes. Buyers should assess the filter’s voltage rating and current handling capabilities, as well as its efficiency in suppressing unwanted signals. The selection of suitable components, particularly capacitors, is essential for optimizing performance in DC circuits.

Common Mode Filters

Common Mode Filters are designed to eliminate common-mode noise, which can be particularly problematic in telecommunications and data centers. These filters utilize inductive components to effectively reduce interference from both incoming and outgoing signals. For B2B buyers, understanding the filter’s impedance characteristics and its ability to handle high-frequency noise is critical. While they offer high efficiency in noise reduction, the complexity of their design may lead to higher costs, necessitating careful budget considerations.

Differential Mode Filters

Differential Mode Filters focus on filtering differential signals and are typically easier to implement than their common-mode counterparts. They are widely used in consumer electronics and audio equipment, where EMI can degrade performance. Buyers should evaluate the filter’s frequency response and insertion loss to ensure compatibility with their applications. While these filters are generally lower in cost, they may not provide sufficient protection against common-mode noise, which should be taken into account during the selection process.

Integrated EMI Filters

Integrated EMI Filters combine multiple filtering functions into a single compact package, making them ideal for space-constrained applications like automotive and compact electronic devices. They simplify the design process and can reduce overall system costs. However, buyers should be aware that while these filters are convenient, they may compromise on performance compared to standalone filters. Evaluating the specific filtering needs and the filter’s performance metrics is essential to ensure it meets the demands of the application.

Related Video: Denoising Diffusion Probabilistic Models | DDPM Explained

Key Industrial Applications of emi filter

| Industry/Sector | Specific Application of EMI Filter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Automation | Filtering for Variable Frequency Drives (VFDs) | Enhances equipment longevity and reduces downtime | Ensure compatibility with motor specifications and harmonics. |

| Telecommunications | EMI protection for communication devices | Ensures signal integrity and reliability | Check for compliance with international standards. |

| Medical Devices | Protection in diagnostic and monitoring equipment | Safeguards sensitive data and operational safety | Prioritize filters with high attenuation levels for sensitive applications. |

| Renewable Energy | Filtering for solar inverters and wind turbines | Improves system efficiency and reduces noise emissions | Evaluate for environmental resilience and operational stability. |

| Automotive Electronics | EMI filtering in electric vehicle components | Enhances performance and compliance with safety regulations | Consider size, weight, and integration capabilities. |

Industrial Automation

In the realm of industrial automation, EMI filters are crucial for Variable Frequency Drives (VFDs), which control motor speed and torque. These drives often generate significant electromagnetic noise, leading to potential equipment failures and operational disruptions. By integrating EMI filters, businesses can enhance the longevity of their machinery and minimize downtime, ultimately improving productivity. Buyers should consider the specific motor specifications and the harmonic distortion levels to ensure compatibility and effectiveness.

Telecommunications

Telecommunication equipment, such as routers and switches, is particularly sensitive to EMI, which can disrupt signal integrity and communication reliability. EMI filters are employed to suppress unwanted noise, ensuring uninterrupted service and high-quality data transmission. For international buyers, it is essential to source filters that comply with regional standards and regulations to avoid operational issues and ensure reliable performance in diverse environments.

Illustrative Image (Source: Google Search)

Medical Devices

In the medical field, EMI filters are critical for safeguarding sensitive diagnostic and monitoring equipment. These filters protect against electromagnetic interference that could compromise patient data or device functionality, thereby ensuring operational safety. Buyers in this sector must prioritize filters with high attenuation levels, as well as certifications that demonstrate compliance with strict health regulations, to maintain patient safety and device reliability.

Renewable Energy

EMI filters are increasingly important in renewable energy applications, particularly in solar inverters and wind turbines. These systems can produce high-frequency noise that affects their efficiency and reliability. By utilizing EMI filters, businesses can improve energy conversion efficiency and reduce noise emissions, fostering a more sustainable operation. Buyers should evaluate filters for their resilience to environmental factors and their ability to maintain performance under varying operational conditions.

Automotive Electronics

As electric vehicles (EVs) become more prevalent, EMI filtering in automotive electronics is essential for ensuring the performance of components such as battery management systems and electric motors. Effective EMI filters help mitigate interference that could lead to safety issues or regulatory non-compliance. Buyers should consider factors such as size, weight, and integration capabilities to ensure that the filters meet the specific requirements of their automotive applications while maintaining optimal performance.

Related Video: Introduction to Electromagnetic Interference (EMI) Filter or Power Line Filter!

Strategic Material Selection Guide for emi filter

When selecting materials for EMI filters, international B2B buyers must consider various factors, including the specific application requirements, environmental conditions, and regulatory standards. Below is an analysis of four common materials used in EMI filters, focusing on their properties, advantages, disadvantages, and implications for buyers in regions such as Africa, South America, the Middle East, and Europe.

1. Ferrite Cores

Ferrite materials are widely used in EMI filters due to their magnetic properties, which are effective in suppressing high-frequency noise.

- Key Properties: Ferrites exhibit high magnetic permeability and low electrical conductivity, making them suitable for high-frequency applications. They can operate effectively at temperatures up to 150°C.

- Pros & Cons: Ferrite cores are lightweight and cost-effective, providing good performance for a wide range of frequencies. However, they can be brittle and may require careful handling during manufacturing and assembly.

- Impact on Application: Ferrite materials are particularly effective in filtering out high-frequency noise in power electronics and communication systems.

- Considerations for Buyers: Compliance with international standards such as ASTM and JIS is crucial. Buyers should also consider the local availability of ferrite materials and manufacturers’ capabilities to meet specific performance requirements.

2. Capacitors (Ceramic and Film)

Capacitors are essential components in EMI filters, often used in conjunction with inductors to form low-pass filters.

- Key Properties: Ceramic capacitors have high dielectric strength and stability, while film capacitors offer excellent frequency response and low loss characteristics. Both types can operate at high temperatures (up to 125°C for ceramics and 85°C for films).

- Pros & Cons: Ceramic capacitors are compact and cost-effective, while film capacitors provide better performance at higher frequencies. However, ceramic capacitors can be sensitive to voltage spikes, and film capacitors may be bulkier and more expensive.

- Impact on Application: These capacitors are critical in suppressing both common-mode and differential-mode noise, enhancing the overall performance of electronic devices.

- Considerations for Buyers: International buyers should ensure capacitors meet relevant safety and performance standards, such as IEC and UL certifications. Regional preferences for capacitor types may also influence sourcing decisions.

3. Inductors

Inductors are another critical component in EMI filtering, used to block high-frequency signals while allowing lower frequencies to pass.

- Key Properties: Inductors can handle high currents and are available in various configurations, including toroidal and axial. They typically operate well in temperatures up to 130°C.

- Pros & Cons: Inductors are highly effective in EMI suppression and can be designed for specific frequency ranges. However, they can be larger and more expensive than other components, and their performance can be affected by core saturation.

- Impact on Application: Inductors are essential in applications requiring high current handling and low-frequency signal integrity, such as in power supplies and motor drives.

- Considerations for Buyers: Buyers should evaluate the manufacturing capabilities of suppliers to ensure inductors meet the required specifications for their applications. Understanding local market conditions and supply chain logistics is also crucial.

4. Metal Enclosures

Metal enclosures provide physical protection and electromagnetic shielding for EMI filters, enhancing their effectiveness.

- Key Properties: Metals such as aluminum and steel offer excellent conductivity and durability, with good resistance to environmental factors like moisture and corrosion.

- Pros & Cons: Metal enclosures provide robust protection and are relatively easy to manufacture. However, they can add weight and cost to the final product, and their effectiveness can be influenced by design factors such as grounding.

- Impact on Application: Enclosures are vital for protecting sensitive electronic components from external EMI and ensuring compliance with regulatory standards.

- Considerations for Buyers: Buyers must consider local regulations regarding material use and environmental impact, especially in regions with strict compliance requirements. Understanding the supply chain for metal components is also essential for timely delivery.

Summary Table

| Material | Typical Use Case for EMI Filter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ferrite Cores | High-frequency noise suppression | Lightweight and cost-effective | Brittle and requires careful handling | Low |

| Capacitors | Common-mode and differential-mode noise | Compact and effective | Sensitive to voltage spikes | Medium |

| Inductors | Power supplies and motor drives | High current handling | Larger and can be expensive | Medium |

| Metal Enclosures | Electromagnetic shielding | Robust protection | Adds weight and cost | High |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in EMI filters, enabling informed decisions that align with their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for emi filter

The manufacturing processes and quality assurance protocols for EMI filters are critical in ensuring that these components perform reliably in various applications. B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be informed about the stages involved in manufacturing EMI filters, as well as the quality control measures that guarantee their effectiveness.

Manufacturing Processes

Material Preparation

The first step in the manufacturing of EMI filters involves the selection and preparation of materials. Key materials typically include:

- Capacitors: Made from dielectric materials such as ceramic or polymer.

- Inductors: Often constructed using ferrite cores and copper wire.

- Enclosures: These may be made from metal or plastic, designed to shield the internal components from external electromagnetic interference.

Materials must be sourced from reliable suppliers who provide certifications for quality and compliance with international standards.

Forming

Once materials are prepared, the forming process begins. This phase involves shaping the components into the desired forms. Techniques include:

- Winding: For inductors, wires are wound around a core to create the necessary inductance.

- Molding: Capacitors may be molded into specific shapes, ensuring consistent performance across units.

- Machining: Precision machining is used for creating enclosures and other structural elements to ensure a tight fit and effective shielding.

Each of these techniques must be executed with precision to avoid defects that could compromise performance.

Assembly

The assembly stage is where the individual components come together to form the EMI filter. This typically involves:

- Soldering: Components are soldered together using automated machines or manual processes, depending on the complexity of the design.

- Integration: The assembled components are integrated into the filter housing, which is designed to minimize electromagnetic leakage.

Quality during assembly is paramount; any misalignment or improper connections can lead to failure in the field.

Finishing

The final stage involves finishing processes that enhance the performance and durability of the EMI filters. Key activities include:

- Coating: Applying protective coatings to prevent corrosion and enhance insulation.

- Testing: Each unit undergoes rigorous testing to ensure it meets performance specifications before it is packaged for distribution.

Finishing touches not only protect the filter but also improve its longevity in demanding environments.

Quality Assurance

Quality assurance in the manufacturing of EMI filters is crucial to meet international standards and ensure reliability. The following aspects are essential for B2B buyers to consider:

Relevant International Standards

To maintain high-quality production, manufacturers must comply with various international standards, including:

- ISO 9001: This standard ensures that organizations meet customer and regulatory requirements through a systematic approach to quality management.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: For filters used in oil and gas applications, adherence to American Petroleum Institute (API) standards is critical.

Quality Control Checkpoints

Quality control checkpoints throughout the manufacturing process include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring the production process to catch defects early. This includes visual inspections and functional testing of components.

- Final Quality Control (FQC): Conducting thorough testing on finished products to ensure they meet performance specifications.

Common Testing Methods

Testing methods utilized in quality assurance for EMI filters include:

- Insertion Loss Testing: Evaluating how much signal is lost as it passes through the filter.

- Impedance Testing: Ensuring that the filter maintains the correct impedance levels for its intended application.

- Temperature and Humidity Testing: Assessing performance under various environmental conditions to ensure reliability.

Verifying Supplier Quality Control

B2B buyers should adopt several strategies to verify the quality control measures of their suppliers:

- Audits: Conducting regular audits of suppliers’ manufacturing facilities to assess adherence to quality standards.

- Reports: Requesting detailed quality control reports, including testing results and compliance documentation.

- Third-Party Inspections: Engaging independent inspectors to evaluate the manufacturing processes and product quality.

QC/Cert Nuances for International B2B Buyers

International buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control and certification:

- Cultural Expectations: Understanding the local business culture can aid in navigating supplier relationships and quality expectations.

- Regulatory Variances: Different regions may have unique regulations affecting product certification. Buyers should familiarize themselves with these to ensure compliance.

- Communication: Clear communication regarding quality expectations and standards is essential to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance practices for EMI filters, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific needs.

Related Video: How To Make EMI Filter | What Is An EMI Filter

Comprehensive Cost and Pricing Analysis for emi filter Sourcing

When sourcing EMI filters, understanding the comprehensive cost structure and pricing influences is essential for international B2B buyers. The cost components typically involved in the production of EMI filters include:

Cost Components

-

Materials: The primary raw materials for EMI filters include capacitors, inductors, and housing materials. The choice of materials greatly influences the overall cost, with high-quality components often leading to higher prices but enhanced performance and reliability.

-

Labor: Labor costs can vary significantly based on geographic location and the complexity of the manufacturing process. Skilled labor is often required for assembly and quality control, particularly in regions with stringent regulatory requirements.

-

Manufacturing Overhead: This encompasses utilities, equipment depreciation, and indirect labor costs. In regions with high energy costs, manufacturing overhead can become a significant portion of the total cost.

-

Tooling: Initial tooling costs can be substantial, especially for custom or specialized EMI filters. Buyers should consider these costs when evaluating suppliers, as they can impact the price for low-volume orders.

-

Quality Control (QC): Effective QC measures are crucial for ensuring product reliability, especially in industries like aerospace and medical. The costs associated with testing and certification can vary, impacting the final price.

-

Logistics: Shipping, handling, and customs duties are critical components of the total cost. These can vary based on the distance from the supplier to the buyer, as well as the chosen shipping method.

-

Margin: Supplier profit margins can range from 10% to 30%, depending on market competition, product complexity, and brand reputation. Understanding the margin can help buyers negotiate more effectively.

Price Influencers

Several factors can influence the pricing of EMI filters:

-

Volume/MOQ: Larger orders typically yield better pricing due to economies of scale. Buyers should assess their needs and negotiate minimum order quantities (MOQs) with suppliers.

-

Specifications/Customization: Customized EMI filters tailored to specific applications can significantly increase costs. Buyers should clearly outline their requirements to avoid unexpected expenses.

-

Materials: The choice between standard and premium materials can affect pricing. High-performance materials may be necessary for critical applications but will increase costs.

-

Quality/Certifications: Filters that meet international standards (like ISO or IEC certifications) may command a higher price due to the assurance of quality and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can impact cost. Established suppliers may charge more, but they often provide better support and quality assurance.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can affect logistics costs. Buyers should understand how terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) influence total costs.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing. Highlight your long-term potential as a buyer to leverage better terms.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes initial costs, operational costs, and potential downtime. A lower initial price may lead to higher long-term costs if quality is compromised.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and local economic conditions. These factors can affect pricing and should be factored into budgeting.

-

Disclaimer for Indicative Prices: Pricing can vary widely based on the factors mentioned above. Buyers should request quotes from multiple suppliers to get a clearer picture of the market.

By understanding these cost structures and pricing influences, B2B buyers can make informed sourcing decisions that align with their operational needs and budget constraints.

Spotlight on Potential emi filter Manufacturers and Suppliers

This section looks at several manufacturers active in the ’emi filter’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for emi filter

Key Technical Properties of EMI Filters

Understanding the technical specifications of EMI filters is crucial for international B2B buyers. Here are some essential properties to consider:

-

Cut-off Frequency

This is the frequency at which the filter begins to attenuate the signal. It is critical for defining the operational range of the filter. For B2B buyers, selecting a filter with the appropriate cut-off frequency ensures that the desired signals pass through while unwanted noise is suppressed. This is particularly important in industries like telecommunications and medical devices, where signal integrity is paramount. -

Insertion Loss

This term refers to the amount of signal power lost when the filter is inserted into the circuit. It is typically measured in decibels (dB). A lower insertion loss means better performance, which is vital for maintaining the efficiency of electronic systems. Buyers should look for filters with minimal insertion loss to optimize the performance of their equipment. -

Common-Mode Rejection Ratio (CMRR)

CMRR measures the filter’s ability to reject common-mode noise, which is essential in environments with significant electromagnetic interference. A high CMRR indicates that the filter can effectively block unwanted noise while allowing the desired signal to pass. This property is particularly beneficial for industrial applications where multiple devices may generate interference. -

Rated Voltage and Current

These specifications indicate the maximum voltage and current that the filter can handle without failure. Selecting a filter with appropriate ratings is crucial for ensuring long-term reliability and safety in applications. Buyers must consider the operational conditions of their equipment to avoid premature filter failure. -

Temperature Range

EMI filters operate best within specific temperature ranges. Understanding this range is essential for applications in extreme environments, such as industrial or outdoor settings. Choosing a filter that can withstand the expected temperature fluctuations will enhance durability and performance.

- Size and Form Factor

The physical dimensions of the filter can impact its integration into existing systems. Buyers should consider the available space in their equipment and ensure that the chosen filter fits without compromising performance. Compact designs are often preferred in modern electronics to save space and reduce weight.

Common Trade Terminology in EMI Filtering

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding whether a filter is an OEM product can help assess quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. For B2B buyers, knowing the MOQ can impact inventory management and cash flow, especially when testing new products or technologies. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Buyers should provide detailed specifications to receive accurate quotes, facilitating better comparisons across suppliers. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery. Understanding Incoterms is crucial for international transactions, as they dictate who is liable for shipping costs, risks, and insurance during transit. -

EMC (Electromagnetic Compatibility)

EMC refers to the ability of equipment to function as intended in its electromagnetic environment without causing or being affected by interference. This term is critical for buyers to ensure that their devices comply with regulatory standards and operate reliably. -

Transient Response

This term describes how quickly a filter can respond to changes in input signals. A filter with a good transient response is essential for applications that experience rapid changes in voltage or current, such as in industrial automation.

By understanding these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make more informed decisions when selecting EMI filters for their applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the emi filter Sector

Market Overview & Key Trends

The global EMI filter market is experiencing significant growth, driven by increasing demand for electronic devices and stringent regulatory compliance regarding electromagnetic interference. With the rapid expansion of industries such as automotive, telecommunications, and consumer electronics, the need for effective EMI filtering solutions has never been more critical. Key trends impacting international B2B buyers include the rise of smart technologies, where interconnected devices require robust EMI solutions to maintain performance and safety.

Emerging sourcing trends highlight the shift towards customized solutions, as businesses seek filters tailored to specific applications, particularly in sectors like renewable energy and industrial automation. Buyers from Africa, South America, the Middle East, and Europe should be aware of the growing presence of local manufacturers that offer competitive pricing and shorter lead times, facilitating easier access to EMI filters. Moreover, the increasing adoption of IoT devices is pushing companies to invest in advanced filtering technologies capable of managing both conducted and radiated emissions.

The dynamics of the EMI filter market are also influenced by evolving regulations, such as the IEC and CISPR standards, which mandate compliance with electromagnetic compatibility (EMC) requirements. International buyers must stay abreast of these regulations, as non-compliance can lead to significant penalties and product recalls. Additionally, the trend towards miniaturization in electronic components means that EMI filters must be compact yet effective, prompting innovation in filter design and materials.

Sustainability & Ethical Sourcing in B2B

As environmental concerns grow, sustainability has become a pivotal factor in the sourcing of EMI filters. The production and disposal of electronic components can lead to considerable environmental impact, including hazardous waste and energy consumption. Therefore, international B2B buyers should prioritize suppliers that demonstrate a commitment to sustainable practices. This includes the use of recyclable materials and energy-efficient manufacturing processes.

Ethical sourcing is equally vital. Companies are increasingly scrutinizing their supply chains to ensure that they adhere to ethical labor practices and environmental standards. Buyers can enhance their corporate social responsibility by choosing suppliers with certifications such as ISO 14001 (Environmental Management) or RoHS (Restriction of Hazardous Substances). These certifications not only assure compliance with environmental regulations but also reflect a commitment to minimizing ecological footprints.

Moreover, the demand for ‘green’ materials in EMI filter production is rising. Buyers should look for filters made from eco-friendly materials that reduce environmental impact without compromising performance. Investing in sustainable EMI filters not only fulfills regulatory requirements but also caters to the growing consumer preference for environmentally responsible products.

Brief Evolution/History

The development of EMI filters dates back to the mid-20th century, coinciding with the rapid advancement of electronic technology. Initially, these filters were primarily used in military and aerospace applications to ensure the reliability of sensitive equipment. As electronic devices became more prevalent in civilian sectors, the need for effective EMI filtering solutions expanded across industries.

Over the decades, the evolution of EMI filters has been marked by significant technological advancements. The introduction of digital filtering techniques and the integration of microelectronics have transformed traditional filtering methods, allowing for greater efficiency and performance. Today, EMI filters are integral to the functionality of a wide range of devices, from household appliances to sophisticated industrial equipment, reflecting their importance in maintaining electromagnetic compatibility in an increasingly interconnected world.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of emi filter

-

What criteria should I use to vet suppliers of EMI filters?

When vetting suppliers, prioritize their industry experience, certifications, and customer reviews. Look for manufacturers with ISO certifications, as these indicate adherence to quality management standards. Assess their technical capabilities, including R&D resources, to ensure they can meet your specific filtering requirements. Request samples to evaluate product quality and performance. Additionally, consider suppliers’ responsiveness and support services, as effective communication is crucial for successful partnerships. -

Can EMI filters be customized to meet my specific needs?

Yes, many manufacturers offer customization options for EMI filters. When discussing your requirements, provide detailed specifications, such as frequency range, voltage levels, and application environments. Custom designs can include adjustments in component values, sizes, and configurations to optimize performance for your specific application. Ensure to communicate your needs early in the procurement process to allow sufficient time for design and testing. -

What are the typical minimum order quantities (MOQs) and lead times for EMI filters?

MOQs for EMI filters can vary significantly based on the supplier and the complexity of the filter design. Generally, MOQs range from 50 to 500 units for standard products. Lead times typically span from 4 to 12 weeks, depending on whether the filters are off-the-shelf or custom-made. Always confirm these details upfront and consider negotiating terms that align with your project timelines and volume requirements. -

What payment terms are commonly offered for international purchases of EMI filters?

Payment terms can vary widely among suppliers. Common options include advance payment, letter of credit, and net payment terms (e.g., net 30 or 60 days). For first-time transactions, suppliers may prefer advance payment or partial payment upfront. Ensure to clarify payment terms before finalizing your order to avoid any misunderstandings. It’s also wise to consider using secure payment methods that provide protection for both parties. -

How can I ensure quality assurance and certifications for EMI filters?

Request copies of relevant quality certifications from your supplier, such as ISO 9001 or IEC standards, which ensure compliance with international quality management practices. Ask about their quality control processes, including testing methods for EMI performance and reliability. Some suppliers may also provide third-party testing results, which can further validate their product claims. Regular audits and inspections can also help maintain quality assurance in ongoing orders. -

What logistics considerations should I keep in mind when sourcing EMI filters internationally?

Logistics is a critical factor in international sourcing. Assess shipping options based on cost, speed, and reliability. Consider working with suppliers who have experience in your region to navigate customs regulations effectively. Be aware of potential tariffs and duties that could affect your overall costs. Additionally, ensure that the supplier can provide necessary shipping documentation, such as bills of lading and commercial invoices, to facilitate smooth customs clearance. -

What steps should I take if I encounter disputes with my EMI filter supplier?

In the event of a dispute, initiate communication with the supplier to discuss the issue directly. Document all communications and agreements for clarity. Many suppliers have established dispute resolution procedures, which may include mediation or arbitration. If necessary, refer to the contract terms to determine the appropriate course of action. Maintaining a professional and cooperative approach can often lead to a satisfactory resolution for both parties. -

How can I stay informed about the latest developments in EMI filter technology?

To keep abreast of advancements in EMI filter technology, subscribe to industry publications and newsletters, participate in relevant trade shows, and engage in professional networks. Many manufacturers also release white papers and case studies highlighting new products and technologies. Joining industry associations can provide access to valuable resources, including webinars and training sessions, which can enhance your knowledge and understanding of the evolving landscape of EMI filtering solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for emi filter

The integration of EMI filters into electronic systems is vital for ensuring operational reliability and compliance with regulatory standards. As highlighted, strategic sourcing of these filters not only addresses the need for electromagnetic compatibility but also enhances the overall performance of industrial and consumer electronics. By selecting high-quality EMI filters, businesses can mitigate risks associated with electromagnetic interference, thereby safeguarding sensitive equipment and prolonging its lifespan.

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, it is essential to prioritize suppliers who demonstrate expertise in EMI filter design and application. Engaging with manufacturers that understand local regulatory requirements and can offer tailored solutions will provide a competitive edge in your market.

Looking ahead, the demand for advanced EMI filtering solutions is expected to grow, driven by the increasing complexity of electronic systems and the proliferation of IoT devices. By investing in strategic sourcing now, companies can position themselves as leaders in their sectors, ready to leverage new technologies and meet the challenges of tomorrow. Take proactive steps today to ensure your operations are equipped with the best EMI filtering solutions available.

Illustrative Image (Source: Google Search)