Your Ultimate Guide to Sourcing Monoflo International Inc

Introduction: Navigating the Global Market for monoflo international inc winchester

In today’s competitive global landscape, Monoflo International Inc. of Winchester, Virginia, emerges as a pivotal player in the packaging and logistics sector. Renowned for its superior-quality, injection-molded plastic products, Monoflo offers innovative solutions tailored for various industries, including food, bakery, automotive, and manufacturing. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding Monoflo’s capabilities is essential for optimizing supply chain efficiency and ensuring product integrity.

This comprehensive guide delves into the myriad offerings of Monoflo International, highlighting key product categories such as automation trays, bulk containers, and pallet systems. It explores the materials used in manufacturing, stringent quality control processes, and the diverse supplier network that supports Monoflo’s operations. Additionally, buyers will find insights into pricing structures, market trends, and frequently asked questions, equipping them with the knowledge necessary to make informed sourcing decisions.

By leveraging this guide, international B2B buyers can navigate the complexities of global procurement with confidence. Whether you are a distributor in Kenya or a manufacturer in the UK, the strategic insights provided herein will empower your organization to select the right packaging solutions, ultimately enhancing operational efficiency and market competitiveness.

Understanding monoflo international inc winchester Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Attached Lid Nestable Totes & Dollies | Stackable, secure lids, space-efficient design | Food distribution, warehousing | Pros: Maximizes space, secure closure; Cons: Limited load capacity. |

| Automation Trays | Designed for automated systems, durable | Manufacturing, logistics, automation | Pros: Enhances efficiency, compatible with automation; Cons: Higher initial investment. |

| Bakery Trays & Dollies | Specialized for bakery products, easy to clean | Bakery distribution, retail | Pros: Food-safe materials, optimized for bakery goods; Cons: May not fit all product sizes. |

| Bulk Containers | Large capacity, heavy-duty construction | Industrial storage, bulk transport | Pros: Cost-effective for large volumes; Cons: Requires more storage space. |

| Collapsible Containers | Foldable design for easy storage | E-commerce, seasonal inventory management | Pros: Space-saving, versatile; Cons: Less durable than rigid containers. |

Attached Lid Nestable Totes & Dollies

These containers feature secure lids and a design that allows for stacking, making them ideal for food distribution and warehousing operations. Their nestable design helps save space when not in use. When purchasing, B2B buyers should consider the specific size and weight limitations of these totes, as they may not be suitable for heavier items. Additionally, ensuring compliance with food safety regulations is crucial for businesses in the food sector.

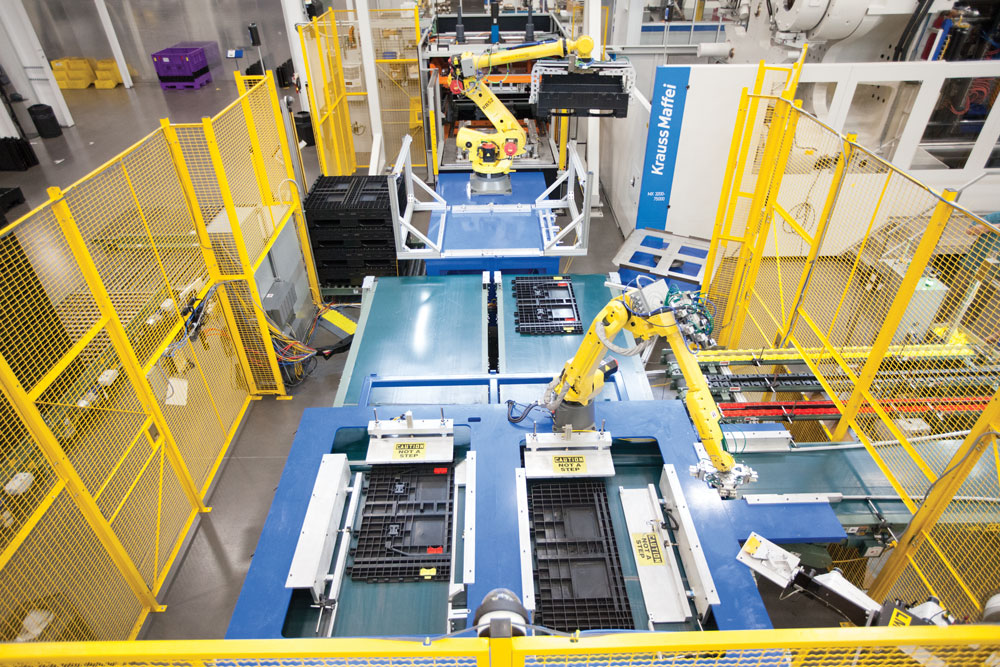

Automation Trays

Automation trays are engineered for seamless integration into automated systems, providing a robust solution for manufacturing and logistics. Their durability and design enhance operational efficiency, making them a preferred choice in automated environments. Buyers should assess the compatibility of these trays with existing automation equipment and consider the initial investment costs against potential long-term savings in labor and efficiency.

Bakery Trays & Dollies

Designed specifically for the bakery industry, these trays and dollies facilitate the transport of baked goods while ensuring product integrity. They are made from food-safe materials and are easy to clean, which is essential for maintaining hygiene standards. Buyers should evaluate the dimensions and weight capacity of these trays to ensure they meet their specific product handling needs, as well as consider seasonal demand fluctuations.

Bulk Containers

Bulk containers are heavy-duty storage solutions that provide substantial capacity for industrial applications. They are ideal for transporting large quantities of goods and are often used in manufacturing and logistics settings. When considering bulk containers, buyers should focus on the trade-off between cost-effectiveness and the space required for storage, as well as ensure that the containers meet any relevant safety and compliance standards.

Collapsible Containers

These versatile containers can be folded down when not in use, providing significant space savings for seasonal inventory or e-commerce applications. They are ideal for businesses needing flexible storage solutions. Buyers should consider the durability of these containers, especially if they are used frequently, as well as the potential trade-offs in strength compared to rigid options.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of monoflo international inc winchester

| Industry/Sector | Specific Application of Monoflo International Inc Winchester | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Bakery | Attached Lid Nestable Totes & Dollies | Enhanced food safety and efficiency in storage and transport | Compliance with food safety regulations, durability in cold environments |

| Manufacturing & Automotive | Collapsible Containers | Space-saving design that reduces shipping costs | Material strength, compatibility with automated systems |

| Distribution | Automation Trays | Streamlined logistics and improved inventory management | Customization options, ease of integration with existing systems |

| Poultry & Dairy | Poultry & Dairy Containers | Optimized handling and transportation of perishable goods | Temperature control features, ease of cleaning and sanitization |

| Custom Applications | Custom Molded Solutions | Tailored solutions that meet specific business needs | Flexibility in design, lead times, and production capabilities |

Detailed Applications

Food & Bakery

Monoflo International’s Attached Lid Nestable Totes & Dollies are ideal for the food and bakery sector. These containers ensure safe transportation of baked goods while maintaining hygiene standards. The design allows for efficient stacking and nesting, minimizing storage space. For international buyers, especially those in regions like Africa and Europe, compliance with local food safety regulations is critical. Buyers should prioritize durability and resistance to temperature variations to ensure product integrity.

Manufacturing & Automotive

In the manufacturing and automotive industries, Monoflo’s Collapsible Containers provide a robust solution for parts and materials handling. Their space-saving design is particularly beneficial for businesses looking to reduce shipping costs. International buyers should consider the material strength to withstand heavy loads and the containers’ compatibility with automation systems. This can lead to enhanced operational efficiency and reduced labor costs.

Distribution

Automation Trays from Monoflo are pivotal in the distribution sector, facilitating seamless logistics. These trays are designed to fit perfectly in automated systems, improving inventory management and order fulfillment processes. For companies in South America and the Middle East, sourcing these trays requires attention to customization options that align with specific distribution needs and existing workflows, ensuring maximum efficiency.

Poultry & Dairy

Monoflo’s Poultry & Dairy Containers are designed to optimize the handling and transportation of perishable goods. Their construction allows for effective temperature control, essential for maintaining product freshness. Buyers from regions with stringent health regulations, like the UK, should focus on features that enhance cleaning ease and compliance with hygiene standards to ensure food safety throughout the supply chain.

Custom Applications

Monoflo also offers custom molded solutions tailored to specific business requirements. This flexibility allows companies to address unique challenges, whether in design or function. Buyers should evaluate lead times and production capabilities when considering custom solutions, ensuring they align with project timelines and operational needs. This adaptability can provide a significant competitive advantage in diverse markets across Africa, South America, the Middle East, and Europe.

Related Video: Monoflo Stack Only 6040-270-G2 Welded Base Automation Containers

Strategic Material Selection Guide for monoflo international inc winchester

When selecting materials for products offered by Monoflo International Inc. in Winchester, several factors must be considered, especially for international B2B buyers. The choice of material affects product performance, durability, cost, and compliance with regional standards. Below, we analyze four common materials used in Monoflo’s product range, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Polypropylene (PP)

Key Properties: Polypropylene is known for its excellent chemical resistance, lightweight nature, and high melting point (around 160°C). It is also resistant to moisture and has good tensile strength.

Pros & Cons: The durability of polypropylene makes it suitable for various applications, including food packaging and industrial containers. However, it can be less resistant to UV light, leading to degradation over time when exposed to sunlight. The manufacturing process is relatively straightforward, but the cost can vary based on the grade of polypropylene used.

Impact on Application: Polypropylene is compatible with a wide range of media, including food products, making it ideal for bakery trays and food storage solutions.

Considerations for International Buyers: Buyers should ensure that the polypropylene used complies with food safety standards such as FDA regulations in the U.S. or EFSA guidelines in Europe. Additionally, understanding local recycling capabilities is crucial, as polypropylene is recyclable but may not be accepted in all regions.

High-Density Polyethylene (HDPE)

Key Properties: HDPE boasts high impact resistance, low moisture absorption, and a melting point of approximately 120°C. It is also resistant to many solvents, making it suitable for various industrial applications.

Pros & Cons: The primary advantage of HDPE is its strength-to-density ratio, providing excellent durability at a relatively low cost. However, its lower temperature resistance compared to other plastics can limit its use in high-heat applications. The manufacturing process is efficient, but sourcing HDPE can sometimes be challenging in remote regions.

Impact on Application: HDPE is widely used in bulk containers and pallets, especially in logistics and distribution sectors, due to its strength and lightweight nature.

Considerations for International Buyers: Compliance with standards such as ASTM D3350 for HDPE is essential. Buyers should also be aware of local regulations regarding plastic use and disposal, particularly in regions with stringent environmental laws.

Polyvinyl Chloride (PVC)

Key Properties: PVC is known for its excellent chemical resistance, rigidity, and versatility. It can withstand temperatures up to 60°C and is often used in applications requiring a strong, durable material.

Pros & Cons: PVC is highly durable and can be manufactured in various forms, including flexible and rigid options. However, it can be more expensive than other plastics and may require additives to improve its properties. The complexity of the manufacturing process can also increase costs.

Impact on Application: PVC is commonly used in automation containers and trays due to its structural integrity and resistance to various chemicals.

Considerations for International Buyers: Buyers should check compliance with international standards such as ISO 1163 for PVC products. Additionally, awareness of the environmental impact of PVC, including its recyclability, is crucial in regions focused on sustainability.

Polycarbonate (PC)

Key Properties: Polycarbonate is known for its high impact resistance, optical clarity, and ability to withstand temperatures up to 135°C. It is also resistant to UV light, making it suitable for outdoor applications.

Pros & Cons: The primary advantage of polycarbonate is its strength and durability, which makes it ideal for heavy-duty applications. However, it is more expensive than other plastics and can be prone to scratching unless treated with a hard coating.

Impact on Application: Polycarbonate is often used in applications requiring transparency and strength, such as bakery trays that need to withstand high temperatures during baking.

Considerations for International Buyers: Compliance with safety standards such as ASTM D256 for impact resistance is essential. Buyers should also consider the cost implications of sourcing polycarbonate, particularly in regions with limited access to high-quality materials.

| Material | Typical Use Case for Monoflo International Inc. Winchester | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Bakery trays, food storage containers | Excellent chemical resistance | UV degradation over time | Medium |

| High-Density Polyethylene | Bulk containers, pallets | High impact resistance | Limited high-temperature use | Low |

| Polyvinyl Chloride | Automation containers, trays | Versatile and durable | Higher cost and complex manufacturing | Medium |

| Polycarbonate | Heavy-duty bakery trays | High impact resistance and clarity | Higher cost, prone to scratching | High |

This strategic material selection guide provides critical insights for international B2B buyers, enabling informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for monoflo international inc winchester

Monoflo International, Inc. in Winchester, Virginia, is recognized for its advanced manufacturing processes and stringent quality assurance practices, essential for B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. Understanding these processes can significantly enhance procurement decisions for international buyers.

Manufacturing Processes

Monoflo’s manufacturing operations can be categorized into four main stages: material preparation, forming, assembly, and finishing. Each stage employs specific techniques and technologies that ensure the production of high-quality, injection-molded plastic products.

-

Material Preparation

– Selection of Raw Materials: Monoflo utilizes high-grade thermoplastics, which are sourced from reputable suppliers. The quality of raw materials is critical, as it directly impacts the durability and performance of the final products.

– Material Testing: Before production, materials undergo rigorous testing to verify their compliance with specifications. This step may include assessing the physical and chemical properties to ensure they meet industry standards. -

Forming

– Injection Molding: The primary technique employed is injection molding, which allows for precise control over the product design and dimensions. This method is efficient for producing large volumes of consistent, high-quality products.

– Advanced Machinery: Monoflo invests in state-of-the-art machinery that enhances production efficiency and accuracy. Regular maintenance of these machines ensures minimal downtime and consistent output quality. -

Assembly

– Automated Assembly Lines: Where applicable, automation is integrated into the assembly process to increase speed and reduce human error. This is particularly beneficial for large-scale production runs.

– Manual Inspection: For certain products, skilled workers perform manual assembly tasks, ensuring that each item meets quality expectations before moving to the next stage. -

Finishing

– Surface Treatment: Products may undergo surface treatments to enhance their aesthetics and performance, such as UV coating or texturing.

– Final Inspection: Each product is subjected to a final inspection, where it is evaluated against predefined quality criteria before packaging.

Quality Assurance

Monoflo International adheres to rigorous quality assurance protocols to ensure that its products meet both international standards and customer expectations.

-

International Standards Compliance

– ISO 9001 Certification: Monoflo’s commitment to quality management is underscored by its ISO 9001 certification. This standard emphasizes a process-based approach to quality management, ensuring consistency and continual improvement.

– Industry-Specific Standards: Depending on the application, products may also comply with additional certifications such as CE marking for safety in European markets or API standards for the oil and gas industry. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This phase involves the inspection of raw materials and components upon arrival. Any materials that do not meet specifications are rejected and returned to the supplier.

– In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor production parameters and product quality. This step helps to identify and rectify any deviations in real-time.

– Final Quality Control (FQC): Before products are packaged and shipped, they undergo a comprehensive final inspection to ensure they meet all quality standards and specifications. -

Common Testing Methods

– Mechanical Testing: Products are tested for strength, durability, and flexibility using standardized methods.

– Dimensional Inspection: Automated and manual measurement techniques ensure that products adhere to design specifications.

– Environmental Testing: Products may be subjected to temperature and humidity tests to ascertain their performance under various conditions.

Verifying Supplier Quality Control

B2B buyers from international markets can take several steps to verify the quality control practices of Monoflo International:

-

Supplier Audits: Conducting regular audits of the manufacturing facility can provide insights into their quality management systems and operational practices. This is particularly important for buyers from regions like Africa and South America, where supply chain transparency may vary.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports, including results from IQC, IPQC, and FQC. These documents provide a clear picture of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can help verify the quality of products before shipment. This practice is especially beneficial for buyers in the Middle East and Europe, where regulatory compliance is stringent.

Illustrative Image (Source: Google Search)

- Understanding Certification Nuances: International buyers should familiarize themselves with the certifications relevant to their markets. For instance, understanding CE certification requirements is crucial for European buyers, while API certifications may be more relevant for those in the oil and gas sector.

Conclusion

The manufacturing processes and quality assurance practices at Monoflo International, Inc. are designed to meet the highest standards of quality and efficiency. By understanding these processes, international B2B buyers can make informed decisions, ensuring they source reliable and high-quality products tailored to their specific needs. As markets evolve, maintaining a strong focus on quality will remain essential for sustaining competitiveness in the global marketplace.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for monoflo international inc winchester Sourcing

To effectively engage with Monoflo International Inc. in Winchester, a comprehensive understanding of the cost structure and pricing nuances is vital for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Cost Structure Breakdown

Understanding the cost components involved in sourcing products from Monoflo is essential for calculating overall expenses and optimizing procurement strategies. Here’s a detailed breakdown:

-

Materials: The choice of materials significantly impacts pricing. Monoflo uses high-quality, injection-molded plastics, which can vary in cost based on market fluctuations, especially for raw materials like polypropylene and polyethylene.

-

Labor: Labor costs in the U.S. are higher than in many developing countries. However, Monoflo’s focus on efficiency and automation may mitigate some of these costs, contributing to competitive pricing.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility management. Monoflo’s advanced facilities in Winchester and Leon, Mexico, help optimize overhead through economies of scale.

-

Tooling: Tooling costs for custom molds can be significant, particularly for specialized containers. Buyers should factor in these costs when considering custom solutions.

-

Quality Control (QC): Monoflo emphasizes quality assurance, which includes rigorous testing and compliance with industry standards. This commitment may increase initial costs but can lead to long-term savings by reducing defects and returns.

-

Logistics: Shipping costs can vary widely based on destination and shipping method. Proximity to major transport hubs in the U.S. can provide logistical advantages for European buyers, while buyers from Africa and South America may face higher freight costs.

-

Margin: Monoflo’s pricing strategy also includes a profit margin that reflects its brand value and product quality. Understanding this can help buyers gauge the competitiveness of the pricing.

Price Influencers

Several factors can influence the pricing structure:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs. Buyers should assess their requirements and negotiate accordingly.

-

Specifications/Customization: Custom products generally incur additional costs. Buyers should clarify their needs early in discussions to understand the implications on pricing.

-

Materials and Quality Certifications: The use of certified materials can add to costs but ensures compliance with safety and quality standards, which is especially crucial in regulated industries.

-

Supplier Factors: The supplier’s reliability, production capacity, and historical performance can influence pricing. Engaging in long-term relationships may also yield better pricing structures.

-

Incoterms: Understanding shipping terms is critical. Different Incoterms (e.g., FOB, CIF) can shift costs and responsibilities between buyer and supplier, impacting overall costs.

Buyer Tips for Cost-Efficiency

-

Negotiation: Approach negotiations with a clear understanding of your budget and requirements. Leverage volume purchasing to negotiate better pricing.

-

Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with maintenance, shipping, and potential downtime due to quality issues.

-

Pricing Nuances: Be aware that pricing can fluctuate based on market conditions, raw material availability, and geopolitical factors. Keeping abreast of these changes can help in budgeting effectively.

-

Regional Considerations: Buyers from Africa and South America should account for additional tariffs, duties, and shipping delays, which can significantly impact the final cost.

-

Request Quotes: Utilize Monoflo’s request for quotes feature to get precise pricing tailored to your needs. Ensure that all specifications are clearly communicated to avoid surprises.

Conclusion

Understanding the comprehensive cost and pricing structure of Monoflo International Inc. is crucial for international B2B buyers. By focusing on the outlined cost components, price influencers, and actionable tips, buyers can make informed decisions that align with their business objectives. Always remember that the prices provided are indicative and subject to change based on numerous factors discussed above.

Spotlight on Potential monoflo international inc winchester Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘monoflo international inc winchester’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for monoflo international inc winchester

Key Technical Properties of Monoflo International Inc. Products

When engaging with Monoflo International Inc. for your packaging needs, understanding the following critical specifications will facilitate better decision-making and enhance your procurement process.

-

Material Grade: Monoflo primarily uses high-density polyethylene (HDPE) and polypropylene (PP) for its products. These materials are known for their durability, chemical resistance, and recyclability. B2B buyers should consider material grade carefully, as it directly affects product lifespan, safety, and environmental impact.

-

Tolerance: This refers to the allowable deviation from a specified dimension. For instance, Monoflo’s containers may have tight tolerances for stacking and fitting with automated systems. Understanding tolerances is crucial for ensuring compatibility with existing logistics and storage systems, particularly in automated environments.

-

Load Capacity: Each product comes with a specified load capacity, which indicates the maximum weight it can safely hold. This specification is vital for buyers to assess the suitability of a product for their specific applications, whether for food distribution or industrial use.

-

Temperature Resistance: Many Monoflo products are designed to withstand varying temperature ranges, which is essential for applications in food processing and storage. Knowing the temperature resistance helps buyers ensure their products can operate effectively in their specific environments without compromising integrity.

-

Recyclability: Monoflo emphasizes sustainability in its design, with many products being fully recyclable. This property is increasingly important for international buyers who must comply with environmental regulations and sustainability goals in their regions.

-

Stackability: This characteristic is essential for optimizing space during storage and transport. Products designed for efficient stackability can significantly reduce shipping costs and improve warehouse management.

Common Trade Terminology

Familiarity with industry jargon will empower B2B buyers to communicate effectively and make informed purchasing decisions.

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers navigate supply chains and ensure they are sourcing quality components.

-

MOQ (Minimum Order Quantity): This represents the smallest amount of a product that a supplier is willing to sell. Being aware of the MOQ helps buyers plan their purchasing strategy and manage inventory costs effectively.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. For international buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing logistics, shipping costs, and risk allocation.

-

Lead Time: This term refers to the amount of time from placing an order to its delivery. For B2B buyers, understanding lead times is critical for planning inventory and ensuring that operations run smoothly.

-

Custom Applications: This phrase describes products that are tailored to meet specific customer requirements. Recognizing the potential for custom applications allows buyers to explore unique solutions that fit their operational needs.

By familiarizing yourself with these technical properties and trade terms, you will be better equipped to engage with Monoflo International Inc. and make strategic purchasing decisions that align with your business objectives.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the monoflo international inc winchester Sector

Market Overview & Key Trends

The global market for injection-molded plastic products is experiencing robust growth, driven by increasing demand across various sectors, including food and beverage, automotive, and logistics. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping this landscape.

Digital Transformation is at the forefront, with companies embracing automation and IoT technologies to enhance efficiency. Buyers should consider suppliers like Monoflo International that invest in automation trays and containers, which streamline supply chain processes. Additionally, the shift towards e-commerce necessitates advanced packaging solutions that ensure product safety during transit, making Monoflo’s collapsible containers and bulk containers particularly relevant.

Sustainability is another crucial driver. Increasing regulatory pressure and consumer demand for eco-friendly practices compel companies to adopt sustainable sourcing strategies. As buyers from regions like the UK or Kenya seek suppliers with a commitment to environmental stewardship, those offering reusable, recyclable, or biodegradable products will hold a competitive advantage.

Furthermore, regional dynamics such as trade agreements and tariffs are also influencing sourcing decisions. For instance, buyers in South America may benefit from Monoflo’s production facility in Mexico, which can reduce lead times and shipping costs while adhering to regional compliance.

Sustainability & Ethical Sourcing in B2B

Sustainability is not just a trend but a fundamental aspect of modern B2B operations. The environmental impact of plastic waste has prompted businesses to prioritize ethical sourcing and sustainable materials. For Monoflo International, this means a focus on reusable and recyclable products, which help minimize waste and promote a circular economy.

Ethical supply chains are increasingly important for buyers looking to align with suppliers who share their values. Monoflo’s commitment to sustainability can be evidenced through its use of eco-friendly materials and processes. Buyers should inquire about certifications such as ISO 14001 (Environmental Management) and other green certifications that indicate a supplier’s adherence to sustainable practices.

Moreover, the adoption of ‘green’ materials—such as recycled plastics—can enhance a company’s reputation and customer loyalty. International buyers should actively seek partnerships with manufacturers that prioritize sustainability, as this not only meets regulatory requirements but also resonates with environmentally conscious consumers.

Brief Evolution/History

Founded in 1989, Monoflo International has established itself as a leader in the injection-molded plastic products sector. Initially focused on the North American market, the company has expanded its reach globally, with production facilities in Mexico to cater to Latin American clients.

Over the years, Monoflo has evolved its product offerings to include a wide range of innovative solutions, such as automated containers and collapsible totes. This strategic diversification has positioned the company well within various industries, allowing it to adapt to changing market demands and sustainability trends. As a result, Monoflo continues to be a trusted partner for B2B buyers seeking quality and reliability in their supply chains.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of monoflo international inc winchester

-

What should I consider when vetting Monoflo International Inc as a supplier?

When vetting Monoflo International Inc, focus on their industry experience, product quality, and customer feedback. Evaluate their certifications, such as ISO standards, which indicate compliance with international quality management. Request references from other international buyers, particularly those in your region, to gauge their reliability. Additionally, assess their production capacity and ability to meet your specific needs, including customization and scalability. Conducting a site visit, if possible, can also provide valuable insights into their operational processes. -

Can Monoflo International Inc customize products for my specific needs?

Yes, Monoflo International Inc offers customization options for various products. They understand that different industries have unique requirements, and they can tailor their solutions accordingly. When discussing customization, provide detailed specifications about dimensions, materials, and functionalities needed. Engaging with their design team early in the process can help streamline the customization journey and ensure that the final product meets your expectations. -

What are the minimum order quantities (MOQ) and lead times for international orders?

Minimum order quantities (MOQ) and lead times vary based on the product type and customization requirements. Generally, Monoflo International Inc may have a standard MOQ for their products, but flexibility can be negotiated for larger or repeat orders. Lead times for production can range from a few weeks to several months, depending on the complexity of the order and current production schedules. It’s advisable to communicate your timeline needs upfront to establish a clear understanding of what is feasible. -

What payment options are available for international buyers?

Monoflo International Inc typically accepts various payment methods, including wire transfers, letters of credit, and credit cards, depending on the order size and buyer relationship. For international transactions, it’s crucial to clarify the payment terms upfront to avoid misunderstandings. Additionally, consider discussing terms such as deposits or payment upon delivery, as these can impact cash flow and financial planning. -

How does Monoflo International Inc ensure quality assurance and certification?

Monoflo International Inc places a strong emphasis on quality assurance throughout their manufacturing process. They employ rigorous testing and inspection procedures to ensure that all products meet industry standards. Certifications such as ISO 9001 can indicate their commitment to quality management. International buyers should request specific quality assurance documentation and product certifications that may be required in their local markets to ensure compliance. -

What logistics options are available for shipping products internationally?

Monoflo International Inc provides several logistics solutions for international shipping. They can coordinate freight forwarding, customs clearance, and delivery to your specified location. Understanding your shipping requirements, such as preferred carriers and delivery timelines, is essential. Additionally, inquire about packaging options that ensure products arrive safely and in good condition. Establishing clear communication regarding logistics will help mitigate potential delays. -

What steps should I take if a dispute arises during the purchasing process?

In the event of a dispute, it’s important to first communicate directly with Monoflo International Inc to address the issue. Document all correspondence and agreements made during the purchasing process. If a resolution cannot be reached, refer to the contract terms, which should outline procedures for dispute resolution, including arbitration or mediation options. Maintaining a professional demeanor and seeking a mutually beneficial solution can often lead to a satisfactory resolution for both parties. -

What support does Monoflo International Inc offer after the sale?

Monoflo International Inc provides ongoing support to international buyers post-sale, including technical assistance and product training. They may also offer warranty services and maintenance support, depending on the product. It’s beneficial to clarify the extent of post-sale services during the initial discussions, as this can impact your long-term relationship with the supplier. Establishing a clear line of communication for support needs ensures that issues can be addressed promptly and effectively.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for monoflo international inc winchester

As international B2B buyers navigate the complexities of sourcing quality products, Monoflo International Inc. in Winchester stands out as a reliable partner. Their extensive range of injection-molded plastic products, including automation trays and bulk containers, caters to diverse industries such as food and bakery, manufacturing, and automotive. By leveraging Monoflo’s commitment to quality and innovation, buyers can streamline their supply chains and enhance operational efficiency.

Key Takeaways:

- Strategic Sourcing Benefits: Engaging with Monoflo offers access to superior-quality products that can significantly reduce costs and improve logistics.

- Customization and Support: Monoflo’s ability to provide tailored solutions ensures that businesses in various regions, including Africa, South America, the Middle East, and Europe, can find products that meet their specific needs.

- Sustainability Focus: Their emphasis on reusable packaging aligns with the growing global demand for environmentally friendly solutions.

Looking ahead, international buyers are encouraged to consider Monoflo International as a strategic partner. By prioritizing quality sourcing, you not only secure better products but also position your business for sustainable growth in a competitive landscape. Contact Monoflo today to explore how their innovative solutions can transform your supply chain.