Your Ultimate Guide to Sourcing Rayes Boiler

Introduction: Navigating the Global Market for rayes boiler

Navigating the global market for rayes boilers presents a pivotal opportunity for businesses striving to enhance operational efficiency across various sectors, including manufacturing, energy production, and food processing. As industries globally face mounting pressures to optimize energy use, reduce emissions, and comply with stringent environmental regulations, the role of advanced boiler systems becomes increasingly critical. The rayes boiler, recognized for its innovative design and adaptability, stands out as a strategic investment that can significantly drive down operational costs while ensuring compliance with international standards.

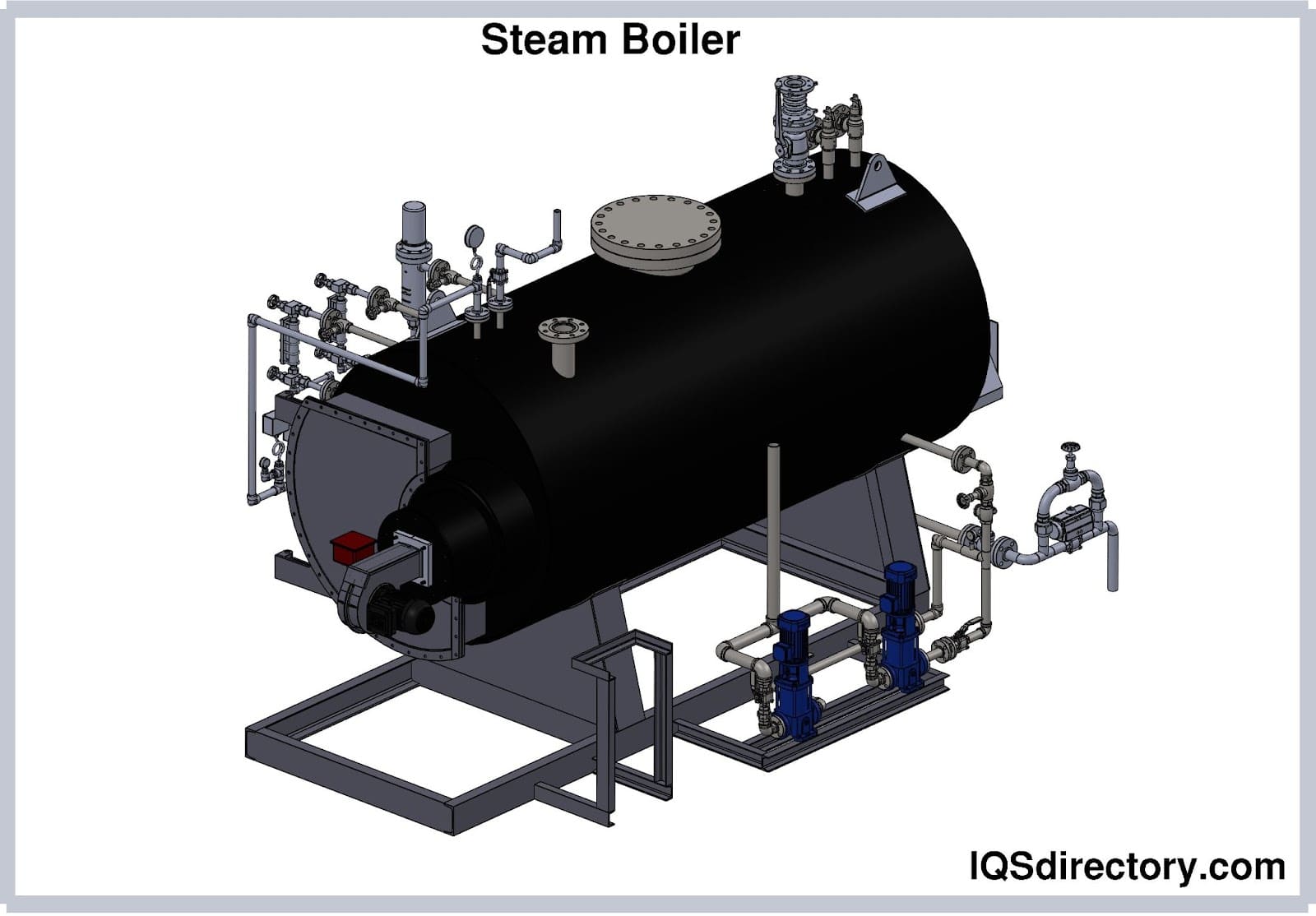

Illustrative Image (Source: Google Search)

This guide serves as a comprehensive resource for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, including key markets like Italy and Vietnam. It delves into essential topics such as boiler classifications, highlighting the operational strengths of various types; core components and materials, emphasizing their impact on performance; and manufacturing and quality control practices that ensure reliability. Additionally, it offers insights on supplier evaluation, enabling buyers to assess and partner with reputable manufacturers effectively.

By understanding cost structures and market trends, buyers can navigate pricing drivers and total cost of ownership, while the frequently asked questions section addresses common concerns to streamline the procurement process. Equipped with this knowledge, international B2B buyers will be empowered to make informed sourcing decisions that not only enhance their operational capabilities but also position them strategically in an evolving global marketplace.

Understanding rayes boiler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fire-Tube Boiler | Combustion gases flow through tubes surrounded by water; compact design | Food processing, textiles, small power plants | Affordable, easy maintenance; limited to low-medium pressure jobs |

| Water-Tube Boiler | Water circulates in tubes heated externally by hot gases; scalable | Power generation, petrochemicals, heavy industry | High efficiency and pressure; higher cost, needs skilled operators |

| Modular Boiler | Composed of multiple smaller units operating together; adaptive system | Hospitals, manufacturing with variable loads | Flexible, scalable, easy maintenance; higher upfront customization |

| Heat Recovery Steam Generator (HRSG) | Captures waste heat from processes to produce steam | Combined cycle plants, desalination, cement | Maximizes energy recovery, eco-friendly; complex integration |

| Electric Boiler | Uses electricity as a heat source; compact, minimal emissions | Labs, hospitals, light industrial uses | Clean, simple install; higher energy cost, capacity limitations |

Fire-Tube Boiler

Fire-tube boilers are characterized by their simple design, where hot gases pass through tubes surrounded by water. This makes them an excellent choice for industries like food processing and textiles, where operational costs are a primary concern. Buyers should consider their limited pressure capabilities and ensure that maintenance schedules are adhered to, as these systems generally require regular upkeep to maintain efficiency.

Water-Tube Boiler

Water-tube boilers circulate water within tubes heated externally, allowing them to achieve higher pressures and temperatures. This design is ideal for demanding applications in power generation and petrochemicals, particularly in regions experiencing rapid industrial growth. Buyers must be prepared for a higher initial investment and the need for skilled operators to manage these more complex systems, as well as robust water treatment processes to ensure longevity.

Modular Boiler

Modular boilers consist of smaller, interconnected units that can operate independently or collectively, providing flexibility for varying steam demands. This adaptability is particularly beneficial for hospitals and diverse manufacturing facilities. B2B buyers should evaluate the integration capabilities of these systems and consider the potential for future expansion, as well as the maintenance advantages of servicing individual modules without shutting down the entire operation.

Heat Recovery Steam Generator (HRSG)

HRSGs are designed to capture waste heat from industrial processes, converting it into steam for further use. This technology is especially relevant in combined cycle power plants and energy-intensive industries looking to enhance efficiency and reduce emissions. Buyers should assess the complexity of integrating HRSGs into existing operations and ensure they have the technical support needed for optimal performance.

Electric Boiler

Electric boilers utilize electricity as a heat source, offering a compact solution with minimal emissions. They are particularly suited for light industrial applications and facilities like laboratories and hospitals where space is at a premium. However, potential buyers must weigh the higher operational costs associated with electricity against the benefits of a cleaner, more straightforward installation process.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of rayes boiler

| Industry/Sector | Specific Application of rayes boiler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Steam generation for turbines | Enhances energy output and operational efficiency | Compliance with local energy regulations, fuel type compatibility |

| Food Processing | Steam supply for cooking, sterilization, and cleaning | Ensures food safety and operational efficiency | Quality certifications, ease of maintenance, energy efficiency |

| Chemical Manufacturing | Heat source for chemical reactions | Improves reaction rates and product quality | Material compatibility, pressure requirements, safety standards |

| Textile Industry | Steam generation for dyeing and finishing processes | Boosts production speed and product quality | Reliability, scalability, and local service support |

| Desalination Plants | Heat source for water treatment processes | Increases freshwater production and operational reliability | Integration with existing systems, energy consumption, and emissions standards |

Power Generation

In the power generation sector, rayes boilers are primarily utilized for steam generation to drive turbines. These boilers enhance energy output and operational efficiency by providing high-pressure steam essential for turbine operation. International buyers must ensure compliance with local energy regulations and consider the compatibility of the boiler with available fuel types, as this can significantly impact performance and cost-effectiveness.

Food Processing

Rayes boilers play a critical role in the food processing industry by supplying steam for cooking, sterilization, and cleaning processes. This application is vital for ensuring food safety and improving operational efficiency. Buyers should prioritize quality certifications and energy efficiency ratings, as these factors influence both operational costs and compliance with health regulations. Additionally, ease of maintenance is essential to minimize downtime in production.

Chemical Manufacturing

In chemical manufacturing, rayes boilers serve as a heat source for various chemical reactions, enabling precise temperature control and enhancing reaction rates. This leads to improved product quality and consistency. B2B buyers need to consider material compatibility with the chemicals processed, as well as the specific pressure requirements of their operations. Adherence to safety standards is also crucial to mitigate risks associated with high-temperature operations.

Textile Industry

The textile industry utilizes rayes boilers for steam generation in dyeing and finishing processes. This application significantly boosts production speed and enhances the quality of the final products. Buyers should focus on the reliability and scalability of the boiler systems, ensuring they can accommodate fluctuating production demands. Additionally, local service support is important for maintaining operational continuity and addressing any technical issues swiftly.

Desalination Plants

In desalination plants, rayes boilers provide the necessary heat for water treatment processes. This application is increasingly critical in regions facing water scarcity, as it enhances freshwater production and ensures operational reliability. Buyers must consider the integration of the boiler with existing systems, the energy consumption of the setup, and compliance with emissions standards. These factors will ultimately influence the sustainability and cost-effectiveness of the desalination process.

Related Video: How a Firetube Boiler Works

Strategic Material Selection Guide for rayes boiler

When selecting materials for the construction of rayes boilers, it is crucial for international B2B buyers to consider the unique properties and applications of various materials. Here, we analyze four common materials used in boiler manufacturing, focusing on their performance characteristics, advantages and disadvantages, and implications for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

Carbon Steel

Key Properties:

Carbon steel is known for its excellent strength and toughness, making it suitable for high-pressure applications. It typically has a temperature rating up to 400°C (752°F) and can withstand significant pressure, making it a popular choice for boiler construction.

Pros & Cons:

The durability of carbon steel is a significant advantage, as it can endure harsh operating conditions. However, it is prone to corrosion, especially in high-moisture environments, which can lead to maintenance challenges. The cost of carbon steel is relatively low, but the need for protective coatings can increase overall expenses.

Impact on Application:

Carbon steel is compatible with various media, including water and steam. However, its susceptibility to corrosion means that it may not be suitable for applications involving aggressive chemicals or high-salinity water.

Considerations for International Buyers:

Buyers in regions with high humidity or corrosive environments, such as parts of Africa or the Middle East, should prioritize corrosion-resistant coatings or consider alternative materials. Compliance with standards like ASTM A106 or equivalent local standards is essential for ensuring quality and safety.

Stainless Steel

Key Properties:

Stainless steel offers superior corrosion resistance and can handle higher temperatures (up to 800°C or 1472°F) and pressures compared to carbon steel. Its composition typically includes chromium, which enhances its resistance to oxidation.

Pros & Cons:

The primary advantage of stainless steel is its longevity and reduced maintenance requirements due to its corrosion resistance. However, it is significantly more expensive than carbon steel, which may impact budget considerations for larger projects. Additionally, the manufacturing complexity can lead to longer lead times.

Impact on Application:

Stainless steel is ideal for applications involving corrosive fluids or high-temperature steam, making it suitable for chemical processing and power generation. Its compatibility with a wide range of media enhances its versatility.

Considerations for International Buyers:

Buyers should ensure that the stainless steel grades used comply with international standards like ASTM A312 or EN 1.4401. In regions like Europe, where environmental regulations are stringent, stainless steel may be preferred for its sustainability credentials.

Alloy Steel

Key Properties:

Alloy steel is engineered to enhance specific properties, including strength, hardness, and corrosion resistance. Its temperature and pressure ratings can vary widely based on the alloying elements used, often exceeding those of carbon steel.

Pros & Cons:

The adaptability of alloy steel allows for tailored performance in demanding applications. However, the complexity of manufacturing and the potential for higher costs can be drawbacks. The initial investment may be justified by reduced operational costs and extended service life.

Impact on Application:

Alloy steel is suitable for high-pressure steam applications and environments where strength and durability are critical. It is often used in power generation and heavy industrial applications.

Considerations for International Buyers:

Buyers should verify that the alloy steel used meets relevant standards, such as ASTM A335 or DIN 17175. In regions like South America, where mining and energy sectors are booming, alloy steel may be essential for high-performance applications.

Cast Iron

Key Properties:

Cast iron is known for its excellent thermal conductivity and ability to withstand high temperatures. It typically has a lower pressure rating than steel and is often used in lower-pressure applications.

Pros & Cons:

The durability of cast iron is a significant advantage, providing a long service life with minimal maintenance. However, it is brittle and can fracture under extreme conditions, limiting its use in high-pressure applications. Cast iron is generally more affordable than steel options.

Impact on Application:

Cast iron is suitable for applications that require good thermal efficiency, such as heating systems and low-pressure steam boilers. Its compatibility with water and steam makes it a reliable choice for many industries.

Considerations for International Buyers:

Buyers should be aware of the limitations of cast iron in high-pressure applications. Compliance with standards like ASTM A48 is crucial for ensuring quality, particularly in regions with stringent regulations.

Summary Table

| Material | Typical Use Case for rayes boiler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Low to medium pressure boilers | Affordable and durable | Prone to corrosion | Low |

| Stainless Steel | High-temperature and corrosive applications | Superior corrosion resistance | High cost and manufacturing complexity | High |

| Alloy Steel | High-pressure steam applications | Tailored performance | Higher initial investment | Medium |

| Cast Iron | Heating systems and low-pressure boilers | Excellent thermal conductivity | Brittle and limited pressure rating | Low |

This strategic material selection guide provides B2B buyers with insights into the properties, advantages, and considerations for selecting materials for rayes boilers, ensuring informed decision-making tailored to their regional requirements and operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for rayes boiler

Manufacturing Processes for Rayes Boiler

The manufacturing of Rayes boilers involves several critical stages that ensure the final product meets the high standards required for efficiency, safety, and durability. Understanding these processes not only helps international B2B buyers make informed decisions but also allows them to assess the capabilities and reliability of potential suppliers.

1. Material Preparation

The foundation of any boiler’s performance lies in the quality of its materials. For Rayes boilers, the selection process includes:

- Raw Materials: High-quality steel and alloy materials are sourced based on specific performance requirements, such as pressure and temperature ratings. Common materials include carbon steel, stainless steel, and special alloys for high-temperature applications.

- Material Testing: Before production, materials undergo rigorous testing to verify their properties. Common tests include tensile strength, hardness, and impact resistance to ensure they can withstand operational demands.

- Inventory Management: Efficient inventory systems are crucial for managing raw materials, ensuring that only the best and most suitable materials are available for production.

2. Forming

Once the materials are prepared, they undergo several forming processes:

- Cutting: Steel sheets and plates are cut to size using plasma cutting, laser cutting, or water jet cutting technologies. This precision ensures that components fit together seamlessly during assembly.

- Bending and Shaping: Techniques such as press braking and rolling are employed to shape the materials into the desired forms, including tubes and plates essential for the boiler structure.

- Welding: Advanced welding techniques, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, are utilized to join components. The welding process is meticulously controlled to maintain structural integrity and prevent defects.

3. Assembly

The assembly stage is where the various components come together to form the complete boiler:

- Sub-Assembly: Components such as burners, heat exchangers, and control systems are assembled separately before being integrated into the main boiler structure. This modular approach allows for easier maintenance and replacement.

- Final Assembly: The sub-assemblies are then integrated into the boiler framework. This stage involves significant attention to detail, ensuring that all parts are correctly aligned and secured.

- Installation of Safety Features: Safety valves, pressure gauges, and control systems are installed to ensure compliance with international safety standards. These features are crucial for operational safety and efficiency.

4. Finishing

The finishing touches on a Rayes boiler enhance both aesthetics and functionality:

- Surface Treatment: Processes such as sandblasting, painting, or coating are applied to protect against corrosion and wear. The choice of coating materials can significantly impact the longevity of the boiler, especially in harsh environments.

- Insulation: Proper insulation is added to reduce heat loss and improve energy efficiency. This is particularly important for boilers operating in extreme temperatures or climates.

- Final Inspection: A thorough inspection ensures that all components meet the design specifications and quality standards before leaving the manufacturing facility.

Quality Assurance for Rayes Boiler

Quality assurance is a critical component of the manufacturing process for Rayes boilers, ensuring that each unit meets the highest standards of performance and safety. B2B buyers must understand the relevant quality control measures to evaluate potential suppliers effectively.

International Standards

Rayes boilers comply with various international standards, which are essential for ensuring safety and reliability:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality throughout their processes.

- CE Marking: Required in the European market, CE marking signifies compliance with health, safety, and environmental protection standards.

- API Standards: For boilers used in oil and gas applications, adherence to American Petroleum Institute (API) standards is critical for safety and efficiency.

Quality Control Checkpoints

The quality control process for Rayes boilers includes several key checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This step is crucial for preventing defects in the final product.

- In-Process Quality Control (IPQC): Regular inspections occur at various stages of production to monitor adherence to specifications. This includes checking weld quality, dimensional accuracy, and assembly integrity.

- Final Quality Control (FQC): After assembly, the complete boiler undergoes rigorous testing to ensure it meets performance and safety standards. This may include pressure testing, leak testing, and functionality checks.

Common Testing Methods

Several testing methods are employed during the quality assurance phase:

- Hydrostatic Testing: This test involves filling the boiler with water and pressurizing it to check for leaks and structural integrity.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and radiographic testing are used to detect internal flaws without damaging the boiler.

- Performance Testing: The boiler is tested under simulated operating conditions to ensure it meets efficiency and output specifications.

Verifying Supplier Quality Control

B2B buyers should adopt a proactive approach to verifying the quality control processes of their suppliers:

- Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards and identify areas for improvement.

- Documentation Review: Requesting quality control documentation, including inspection reports and testing certifications, provides insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control practices and product reliability.

Regional Considerations for International Buyers

When sourcing Rayes boilers from different regions, buyers must be aware of specific quality control nuances:

- Africa and South America: Buyers should focus on suppliers with experience in local regulations and environmental conditions, ensuring compliance with regional safety and quality standards.

- Middle East: Given the extreme operating conditions, it’s essential to verify that suppliers have robust quality assurance processes for high-temperature and high-pressure applications.

- Europe (e.g., Italy, Germany): European buyers should prioritize suppliers with CE marking and other relevant certifications, emphasizing the importance of rigorous quality assurance in meeting EU regulations.

By understanding the manufacturing processes and quality assurance measures for Rayes boilers, international B2B buyers can make informed sourcing decisions that align with their operational needs and regulatory requirements. This knowledge will not only enhance procurement strategies but also foster long-term partnerships with reliable suppliers.

Related Video: Cochran – Boiler Manufacturing Process

Comprehensive Cost and Pricing Analysis for rayes boiler Sourcing

Understanding the cost structure and pricing factors involved in sourcing rayes boilers is crucial for international B2B buyers aiming to make informed decisions. This analysis covers the key components of cost, the influences on pricing, and offers practical tips for negotiation and procurement.

Cost Components of Rayes Boiler Sourcing

-

Materials: The primary materials used in rayes boiler construction include steel, insulation, and specialized components like burners and heat exchangers. The choice of materials significantly affects both initial costs and long-term performance. Higher quality materials may incur greater upfront costs but can lead to lower maintenance and operational expenses.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and installation. Regions with higher labor costs may see increased boiler prices. However, investing in skilled labor can enhance the quality and efficiency of the product, ultimately leading to better operational outcomes.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Tooling costs vary based on the complexity of the boiler design. Custom tooling for specific boiler configurations can increase initial expenses but may be essential for meeting unique buyer specifications.

-

Quality Control (QC): Quality assurance processes are crucial for ensuring the reliability and safety of boilers. Rigorous QC can add to costs but is necessary for compliance with international standards (e.g., ASME, CE certifications).

-

Logistics: Transporting boilers from the manufacturer to the buyer involves significant logistics costs, including freight, handling, and insurance. The distance, mode of transport, and local customs regulations can all impact these expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics and competitive landscape can help buyers gauge whether a margin is reasonable.

Price Influencers

Several factors can influence the pricing of rayes boilers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to bulk discounts, making it more cost-effective for buyers. Negotiating favorable terms for higher volumes can significantly reduce per-unit costs.

-

Specifications/Customization: Custom features or specifications can elevate costs. Buyers should clearly define their requirements to prevent unexpected expenses during production.

-

Materials: Fluctuations in material costs, influenced by global supply chains, can directly affect boiler pricing. Buyers should stay informed about market trends in material pricing.

-

Quality/Certifications: Compliance with international quality standards may increase costs but ensures safety and efficiency. Buyers should weigh the importance of certifications against potential price increases.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge a premium for their experience and service level.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk transfer, impacting the overall cost.

Buyer Tips for Cost-Efficiency

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Establishing a long-term partnership can also lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the TCO, which includes installation, maintenance, and operational costs over the boiler’s lifespan. This holistic view can lead to better purchasing decisions.

-

Pricing Nuances: For buyers from Africa, South America, the Middle East, and Europe, understanding local market conditions, currency fluctuations, and import duties is crucial. Tailoring procurement strategies to these factors can enhance cost-efficiency.

Disclaimer

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential rayes boiler Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘rayes boiler’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for rayes boiler

Key Technical Properties of Rayes Boilers

When considering the procurement of rayes boilers, understanding critical technical specifications is essential for making informed decisions. Here are some key specifications to focus on:

-

Material Grade: The construction materials of a rayes boiler, typically carbon steel or stainless steel, influence durability, heat resistance, and corrosion resistance. High-grade materials ensure longevity, which is vital for minimizing operational downtime and maintenance costs.

-

Pressure Rating: This specification indicates the maximum pressure the boiler can safely handle. For B2B buyers, selecting a boiler with an appropriate pressure rating is crucial, as it determines the boiler’s suitability for specific applications, such as power generation or industrial processing.

-

Heat Transfer Efficiency: This metric measures how effectively the boiler converts fuel into steam. A higher efficiency rating not only reduces fuel costs but also supports sustainability goals by lowering emissions. Buyers should prioritize boilers with high heat transfer efficiency to enhance operational profitability.

-

Steam Output Capacity: This defines the amount of steam the boiler can produce per hour, measured in kilograms or tons. Understanding the required steam output helps buyers select a boiler that meets their production needs without over-investing in unnecessary capacity.

-

Fouling Resistance: This refers to the boiler’s ability to resist buildup of deposits on heat exchange surfaces. A boiler with high fouling resistance minimizes maintenance frequency and enhances operational efficiency, which is particularly beneficial in industries with hard water or high particulate loads.

-

Control System Features: Modern rayes boilers often come equipped with advanced control systems that automate operation and optimize performance. Features like real-time monitoring, data analytics, and remote control capabilities are essential for enhancing operational efficiency and reducing human error.

Common Trade Terminology

Understanding industry jargon is equally important for navigating the procurement process. Here are some commonly used terms relevant to rayes boilers:

-

OEM (Original Equipment Manufacturer): This term refers to the company that designs and manufactures the boiler. For buyers, partnering with a reputable OEM ensures access to quality products, reliable support, and compliance with industry standards.

-

MOQ (Minimum Order Quantity): This specifies the smallest order size that a supplier is willing to accept. Knowing the MOQ is crucial for budgeting and ensuring that the buyer’s needs align with supplier capabilities, especially when sourcing large industrial equipment.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for a specific product or service. By issuing an RFQ, buyers can compare offers and negotiate better terms, making it a key step in the procurement process.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and insurance obligations.

-

Lead Time: This refers to the time taken from placing an order to receiving the product. Understanding lead times is critical for project planning, as longer lead times can impact production schedules and operational efficiency.

-

Warranty Period: This specifies the duration for which the manufacturer guarantees the boiler’s performance and covers repairs or replacements. A longer warranty period can indicate higher product quality and provides buyers with peace of mind regarding their investment.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing rayes boilers, ensuring they select the right equipment for their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rayes boiler Sector

Market Overview & Key Trends

The global rayes boiler market is currently experiencing significant transformation driven by various factors, including rising energy costs, regulatory pressure for emissions reductions, and advancements in technology. One of the key trends is the shift towards modular and scalable boiler systems that allow companies to optimize energy use and reduce operational costs. This trend is particularly pertinent for international buyers in rapidly industrializing regions like Africa and South America, where energy infrastructure is still developing. Modular systems offer flexibility, allowing for phased investments in capacity that align with business growth.

Another notable trend is the increasing adoption of smart technology in boiler systems. Innovations such as IoT-enabled sensors and AI-driven analytics facilitate real-time monitoring and predictive maintenance, enhancing operational efficiency and minimizing downtime. B2B buyers from Europe, especially countries like Italy, are particularly interested in these technologies to comply with stringent EU regulations and improve competitiveness.

Additionally, sustainability remains a cornerstone of procurement strategies. There is a marked shift towards sourcing boilers that utilize alternative fuels, including biomass and biogas, aligning with global sustainability goals. Buyers must stay informed about the evolving market dynamics, such as fluctuating raw material prices and geopolitical factors that may affect supply chains, particularly in the Middle East and South America.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes increasingly critical in procurement strategies, international buyers must prioritize ethical sourcing and the environmental impact of their boiler systems. The rayes boiler sector is no exception, as manufacturers are increasingly focusing on reducing carbon footprints and enhancing energy efficiency. This commitment is reflected in the development of boilers designed to operate with lower emissions and higher thermal efficiency.

Buyers should seek out suppliers who possess green certifications such as ISO 14001 or ENERGY STAR, as these indicators can help ensure that the products meet rigorous environmental standards. Utilizing materials with lower environmental impact, such as recycled steel or eco-friendly insulation, can further contribute to a sustainable supply chain.

Moreover, engaging with suppliers committed to transparent labor practices and ethical sourcing can enhance a company’s reputation and meet the growing consumer demand for responsible business practices. By investing in sustainable and ethically sourced rayes boilers, companies can not only comply with regulations but also align with their corporate social responsibility goals.

Brief Evolution/History

The evolution of rayes boilers can be traced back to traditional steam boiler designs, which have undergone significant advancements over the decades. Initially focused on coal and oil as primary fuel sources, the industry has adapted to include a broader range of energy options, including natural gas and renewable resources.

In recent years, the introduction of advanced materials and digital technologies has transformed boiler efficiency and operational reliability. This evolution has allowed manufacturers to meet the increasing demand for energy efficiency and lower emissions, particularly in regions facing stringent regulatory environments. For B2B buyers, understanding this historical context is essential for making informed decisions about the most suitable boiler systems that align with both operational needs and sustainability goals.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of rayes boiler

-

What key factors should I consider when vetting suppliers for rayes boilers?

When vetting suppliers, prioritize their experience in boiler manufacturing and their reputation in international markets. Look for certifications such as ASME and CE, which indicate compliance with global standards. Additionally, assess their financial stability and customer references. It’s beneficial to visit their facilities or request virtual tours to evaluate their production capabilities. Lastly, inquire about their after-sales support and warranty terms, as these can be critical in maintaining operational efficiency. -

Can rayes boilers be customized to meet specific operational needs?

Yes, rayes boilers can typically be customized to suit the unique requirements of various industries. Buyers should communicate their specific needs regarding capacity, pressure, fuel type, and operational conditions. Collaborating closely with the manufacturer during the design phase ensures that the boiler will meet local regulatory standards and efficiency goals. Customization may involve longer lead times, so it’s advisable to discuss timelines early in the procurement process. -

What are the minimum order quantities (MOQ) and lead times for rayes boilers?

The MOQ for rayes boilers often varies depending on the supplier’s production capabilities and the customization required. Standard models may have lower MOQs, while custom configurations could necessitate larger orders. Lead times can range from a few weeks to several months, depending on the complexity of the order and the supplier’s current workload. To avoid delays, it’s crucial to clarify these details upfront and plan procurement timelines accordingly. -

What payment terms are typically offered for international purchases of rayes boilers?

Payment terms for international purchases of rayes boilers can vary widely. Common arrangements include upfront deposits (usually 30-50%) with the balance due upon shipment or installation. Some suppliers may offer letter of credit options, which can provide additional security for both parties. It’s essential to negotiate payment terms that align with your cash flow needs while ensuring adequate protection against risks associated with international trade. -

What quality assurance processes and certifications should I expect from rayes boiler manufacturers?

Reputable rayes boiler manufacturers should adhere to rigorous quality assurance processes. Look for certifications such as ISO 9001, which indicates a commitment to quality management systems. Additionally, inquire about their testing procedures, including pressure testing and performance validation. Manufacturers should also provide documentation proving compliance with international standards, ensuring that the product meets safety and operational efficiency requirements. -

How do I manage logistics when sourcing rayes boilers internationally?

Managing logistics for international boiler procurement involves several key steps. First, confirm the delivery terms (Incoterms) with the supplier, as this will define responsibilities for shipping, insurance, and customs clearance. Partner with a reliable freight forwarder who understands the complexities of transporting heavy machinery. Additionally, factor in local regulations regarding import duties and certifications needed for installation to avoid delays upon arrival. -

What steps can I take to resolve disputes with rayes boiler suppliers?

To mitigate disputes, establish clear communication channels and document all agreements, including specifications, timelines, and payment terms. In case of a disagreement, engage in open dialogue with the supplier to seek an amicable resolution. If necessary, refer to the contract for dispute resolution mechanisms, which may include mediation or arbitration. Maintaining a professional relationship and understanding cultural differences can also facilitate smoother negotiations.

Illustrative Image (Source: Google Search)

- What are the best practices for maintenance and operational efficiency of rayes boilers?

Regular maintenance is essential for ensuring the efficiency and longevity of rayes boilers. Establish a maintenance schedule that includes routine inspections, cleaning, and parts replacement. Utilize monitoring technologies to track performance metrics and identify potential issues early. Training your staff on operational best practices will also enhance efficiency. Additionally, keep a log of maintenance activities to inform future decisions and ensure compliance with safety regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rayes boiler

In summary, the strategic sourcing of rayes boilers presents a pivotal opportunity for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. Understanding the nuances of boiler types—such as fire-tube, water-tube, modular, and HRSG—enables buyers to align their procurement strategies with operational needs and regional energy requirements.

Key takeaways include the importance of evaluating suppliers based on quality certifications, production processes, and total cost of ownership. A well-informed selection process not only enhances operational efficiency but also ensures compliance with international standards, thereby fostering sustainability and reducing long-term costs.

As industries worldwide increasingly prioritize energy efficiency and environmental responsibility, the demand for advanced boiler technologies will continue to grow. International B2B buyers are encouraged to leverage these insights to forge partnerships with reputable manufacturers and capitalize on innovative solutions that drive productivity.

Take action now to assess your boiler needs and explore sourcing opportunities that will position your business for future success in an evolving global market.