Your Ultimate Guide to Sourcing Schaefer Group

Introduction: Navigating the Global Market for schaefer group

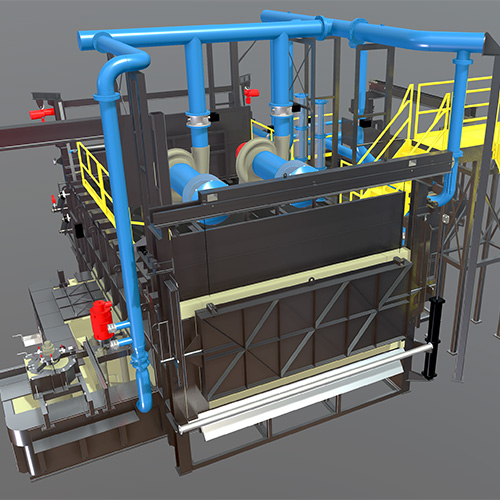

Navigating the complexities of the global market requires strategic partnerships and informed decisions, particularly for B2B buyers seeking reliable suppliers like the Schaefer Group. Known for its innovative solutions in industrial furnaces, refractory sales, and advanced control systems, the Schaefer Group stands out as a pivotal player in enhancing manufacturing efficiency and operational excellence. Their expertise not only streamlines production processes but also significantly reduces energy consumption, providing a competitive edge in various industries.

This comprehensive guide is designed to empower international B2B buyers from Africa, South America, the Middle East, and Europe, including regions like Mexico and the UAE. It covers essential aspects of sourcing from the Schaefer Group, including types of products offered, materials used, manufacturing and quality control standards, and supplier insights. In addition, it delves into cost considerations and market dynamics, equipping buyers with the knowledge needed to make informed decisions.

By navigating through the guide, buyers will gain clarity on the Schaefer Group’s offerings, enhancing their ability to source efficiently and effectively. The insights provided will facilitate smarter procurement strategies, ensuring that businesses can leverage the full potential of Schaefer Group’s solutions to drive growth and profitability in their operations.

Understanding schaefer group Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automated Storage | High-density storage systems with robotic retrieval | Warehousing, Distribution Centers | Pros: Maximizes space efficiency; reduces labor costs. Cons: High initial investment; complexity in maintenance. |

| Cold Storage | Temperature-controlled environments for perishable goods | Food & Beverage, Pharmaceuticals | Pros: Preserves product quality; compliance with health standards. Cons: Energy-intensive; requires regular maintenance. |

| Warehouse Management Systems (WMS) | Software solutions for inventory and operations management | Retail, E-commerce, Manufacturing | Pros: Enhances operational efficiency; real-time data tracking. Cons: Requires training; can be costly to integrate. |

| Pallet Racking | Modular shelving systems for heavy loads | Manufacturing, Industrial Warehousing | Pros: Flexible configurations; easy access to products. Cons: Limited to static storage; may require additional safety measures. |

| Automated Guided Vehicles (AGVs) | Mobile robots for transporting goods within facilities | Manufacturing, Logistics, Warehousing | Pros: Increases efficiency; reduces risk of workplace injuries. Cons: Initial setup costs; may require infrastructure changes. |

Automated Storage

Automated storage systems utilize advanced robotics and software to optimize space and streamline retrieval processes. These systems are particularly suited for high-volume warehouses and distribution centers where maximizing floor space is critical. B2B buyers should consider the initial investment versus long-term savings in labor and operational efficiency. Regular maintenance and updates are essential to ensure seamless operation and prevent downtime.

Illustrative Image (Source: Google Search)

Cold Storage

Cold storage solutions are designed to maintain specific temperature ranges, making them ideal for industries dealing with perishable goods, such as food and pharmaceuticals. These systems help businesses comply with health regulations while preserving product quality. Buyers must weigh the benefits of quality preservation against the higher energy costs and maintenance requirements associated with such facilities.

Warehouse Management Systems (WMS)

WMS software is crucial for managing inventory, tracking shipments, and optimizing warehouse operations. It is applicable across various industries, including retail, e-commerce, and manufacturing. Buyers should evaluate the scalability of WMS solutions and the training required for their teams to effectively utilize these systems. The investment in WMS can lead to significant efficiency gains and improved customer satisfaction.

Pallet Racking

Pallet racking systems provide a versatile and efficient way to store heavy goods in warehouses. Their modular nature allows businesses to adapt storage solutions to changing inventory levels. While these systems are cost-effective and easy to access, buyers must consider safety regulations and potential space limitations when designing their warehouse layouts.

Automated Guided Vehicles (AGVs)

AGVs are innovative mobile robots designed to transport materials within manufacturing and warehousing environments. They enhance operational efficiency by automating the movement of goods, reducing labor costs, and minimizing workplace injuries. However, buyers should be aware of the initial setup costs and potential need for infrastructure modifications to accommodate these vehicles.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of schaefer group

| Industry/Sector | Specific Application of Schaefer Group | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated Storage and Retrieval Systems (ASRS) | Increases efficiency and reduces labor costs in warehousing | Compatibility with existing systems and infrastructure |

| Food & Beverage | Cold Chain Storage Solutions | Ensures product integrity and compliance with safety standards | Regulatory compliance and temperature control capabilities |

| Automotive | Pallet Racking and Conveying Systems | Optimizes space utilization and enhances workflow efficiency | Load capacity and material handling requirements |

| Pharmaceuticals | Warehouse Management Software (WAMAS) | Improves inventory accuracy and order fulfillment speed | Integration with ERP systems and scalability options |

| Retail | Omnichannel Fulfillment Solutions | Enhances customer satisfaction through efficient order processing | Flexibility to adapt to various sales channels and inventory types |

Manufacturing

In the manufacturing sector, the Automated Storage and Retrieval Systems (ASRS) provided by Schaefer Group are crucial for optimizing warehouse operations. These systems automate the storage and retrieval processes, significantly increasing efficiency and reducing labor costs. International buyers, particularly from regions with growing manufacturing bases like Africa and South America, should consider how these systems can integrate with existing infrastructure and what specific automation needs they have to streamline operations.

Food & Beverage

The Cold Chain Storage Solutions offered by Schaefer Group are essential for the food and beverage industry, where maintaining product integrity is paramount. These solutions help ensure compliance with safety standards while preserving the quality of perishable goods. B2B buyers from the Middle East and Europe must prioritize regulatory compliance and the effectiveness of temperature control systems when sourcing these solutions to meet stringent local and international food safety regulations.

Automotive

In the automotive industry, Pallet Racking and Conveying Systems are designed to optimize space utilization and improve workflow efficiency. Schaefer Group’s solutions facilitate the seamless movement of parts and materials throughout the production process. Buyers, especially those from regions with a robust automotive manufacturing presence like Europe and South America, should evaluate load capacity and material handling requirements to ensure that the systems can support their specific production scales.

Pharmaceuticals

The Warehouse Management Software (WAMAS) is a critical component for the pharmaceutical sector, enhancing inventory accuracy and speeding up order fulfillment. This software integrates seamlessly with various enterprise resource planning (ERP) systems, making it a versatile choice for international buyers. Companies in Africa and the Middle East should focus on the scalability of the software and its ability to adapt to changing regulatory requirements in the pharmaceutical industry.

Retail

For the retail sector, Schaefer Group’s Omnichannel Fulfillment Solutions significantly enhance customer satisfaction by streamlining order processing across multiple sales channels. These solutions provide flexibility and adaptability to varying inventory types and sales strategies. Retailers in Europe and Latin America should consider how these solutions can integrate with their existing systems and the degree of flexibility they require to meet dynamic consumer demands.

Related Video: SSI Orbiter provides automated pallet handling & maximizes channel storage efficiency | SSI SCHAEFER

Strategic Material Selection Guide for schaefer group

When selecting materials for the products offered by the Schaefer Group, international B2B buyers must consider several factors, including the specific application requirements, material properties, and compliance with regional standards. Below, we analyze four common materials used in Schaefer Group applications, focusing on their key properties, advantages, disadvantages, and considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Steel

Key Properties:

Steel is renowned for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Steel also has good corrosion resistance when treated or alloyed.

Pros & Cons:

The primary advantage of steel is its strength and versatility, allowing it to be used in various applications, from structural components to storage systems. However, steel can be heavy and susceptible to corrosion if not properly coated or treated, which may increase maintenance costs over time.

Impact on Application:

Steel is compatible with various media, including chemicals and heavy loads, making it ideal for manufacturing and storage solutions. Its strength ensures that it can handle the demands of industrial environments.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM in the U.S. or DIN in Europe. Corrosion-resistant coatings may be necessary in humid or corrosive environments, common in regions like the Middle East.

2. Aluminum

Key Properties:

Aluminum is lightweight yet strong, with excellent corrosion resistance. It has a lower melting point than steel, which can be advantageous in specific applications.

Pros & Cons:

The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. However, it is generally more expensive than steel and may not be suitable for high-load applications without reinforcement.

Impact on Application:

Aluminum is often used in applications requiring lightweight structures, such as automated guided vehicles (AGVs) and shelving systems. Its corrosion resistance makes it ideal for environments exposed to moisture.

Considerations for International Buyers:

Aluminum products must meet specific standards, such as JIS in Japan or EN in Europe. Buyers should also consider the cost implications of aluminum versus steel, especially in regions with fluctuating metal prices.

3. Refractory Materials

Key Properties:

Refractory materials are designed to withstand high temperatures and thermal shock. They typically have excellent thermal insulation properties and can resist chemical corrosion.

Pros & Cons:

The main advantage of refractory materials is their ability to maintain structural integrity at elevated temperatures, making them essential for furnace applications. However, they can be brittle and may require careful handling during installation.

Impact on Application:

Refractory materials are critical in applications involving molten metal and high-temperature processes, such as aluminum furnaces. Their thermal properties ensure efficient energy use and safety in operations.

Considerations for International Buyers:

Compliance with local thermal and safety standards is crucial. Buyers should also be aware of the specific refractory material types suitable for their application, as different materials may have varying performance characteristics.

4. Composite Materials

Key Properties:

Composite materials combine two or more constituent materials to achieve superior properties, such as enhanced strength-to-weight ratios and improved corrosion resistance.

Pros & Cons:

The primary advantage of composites is their versatility and tailored properties, which can be optimized for specific applications. However, they can be more complex to manufacture and may require specialized knowledge for installation.

Impact on Application:

Composites are often used in applications where weight reduction is critical, such as in AGVs and ergonomic workstations. Their resistance to corrosion makes them suitable for various environments.

Considerations for International Buyers:

Buyers should verify compliance with local standards and consider the availability of skilled labor for installation. The initial cost may be higher than traditional materials, but the long-term benefits can justify the investment.

| Material | Typical Use Case for Schaefer Group | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, storage systems | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Automated guided vehicles, shelving systems | Lightweight and corrosion-resistant | Higher cost than steel | High |

| Refractory Materials | Furnaces, high-temperature applications | Excellent thermal resistance | Brittle and requires careful handling | Medium |

| Composite Materials | Ergonomic workstations, AGVs | Tailored properties and lightweight | Complex manufacturing and installation | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions aligned with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for schaefer group

The manufacturing processes and quality assurance measures employed by the Schaefer Group reflect a commitment to excellence and reliability, which is crucial for B2B buyers looking to engage with a reputable supplier. Here’s an in-depth examination of these processes, designed to provide actionable insights for international buyers from regions such as Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Main Stages of Manufacturing

-

Material Preparation

– Sourcing: High-quality raw materials are sourced from verified suppliers. This often includes metals, refractory materials, and components for automation systems.

– Inspection: Incoming materials undergo rigorous inspection to verify compliance with specifications. This includes checking for defects and ensuring materials meet relevant international standards. -

Forming

– Techniques: Techniques such as casting, machining, and welding are commonly used. For instance, aluminum melting furnaces are typically manufactured using advanced casting processes that ensure precision and durability.

– Technology: The use of CNC (Computer Numerical Control) machines allows for high precision in forming components, ensuring they meet stringent specifications. -

Assembly

– Modular Approach: The assembly process often follows a modular design, allowing for flexibility and efficiency. This includes the integration of various systems such as automation and control software.

– Skilled Labor: Highly trained technicians oversee the assembly process, ensuring that each component is correctly integrated and functioning as intended. -

Finishing

– Surface Treatment: Finishing processes, including coating and polishing, enhance the durability and aesthetic appeal of products. This is particularly important in industries such as automotive and electronics.

– Final Inspection: Before leaving the factory, products undergo a final inspection to ensure they meet quality and safety standards.

Key Techniques in Manufacturing

- Automation: The integration of automated guided vehicles (AGVs) and robotic systems enhances efficiency and accuracy in the manufacturing process.

- Lean Manufacturing: The Schaefer Group employs lean principles to minimize waste and optimize productivity, which is essential for maintaining competitive pricing.

- Advanced Software Solutions: The use of WAMAS® warehouse management software facilitates real-time tracking and management of inventory, ensuring operational efficiency.

Quality Assurance

International Standards

- ISO 9001: The Schaefer Group adheres to ISO 9001 standards, ensuring a systematic approach to quality management. This certification signifies a commitment to continuous improvement and customer satisfaction.

- CE Marking: Products are often marked with the CE symbol, indicating compliance with European health, safety, and environmental protection standards.

- API Standards: For industries like oil and gas, adherence to American Petroleum Institute (API) standards ensures that products meet industry-specific requirements.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Materials are inspected upon arrival to ensure they meet quality specifications before being used in production. -

In-Process Quality Control (IPQC)

– Continuous monitoring during the manufacturing process helps identify any defects early. This includes regular checks at various stages of assembly. -

Final Quality Control (FQC)

– Comprehensive testing of finished products is conducted to verify that they meet all specified standards before delivery.

Common Testing Methods

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and radiographic testing are employed to evaluate the integrity of materials without causing damage.

- Performance Testing: Products undergo performance evaluations to ensure they operate correctly under expected conditions.

Verification of Supplier Quality Control

For B2B buyers, especially those from diverse regions, ensuring the quality of suppliers is critical. Here are effective strategies to verify the Schaefer Group’s quality control processes:

- Audits: Conducting regular audits of the manufacturing facilities can provide insights into the operational practices and adherence to quality standards.

- Quality Reports: Request detailed quality reports that outline the results of inspections and tests conducted at various checkpoints.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the quality management processes in place.

Quality Certification Nuances for International Buyers

Understanding the nuances of quality certifications is vital for international B2B buyers. Here are key considerations:

- Regional Standards: Be aware that different regions may have varying standards and regulations. For example, while CE marking is crucial in Europe, other regions may prioritize different certifications.

- Documentation: Ensure that all quality certifications are documented and easily accessible. This is crucial for compliance and traceability.

- Cultural Sensitivity: Recognize that communication styles and business practices may differ across regions. Establishing clear expectations regarding quality standards can help prevent misunderstandings.

Conclusion

The Schaefer Group’s meticulous approach to manufacturing and quality assurance not only enhances product reliability but also instills confidence in B2B buyers. By understanding the intricacies of their processes and quality control measures, international buyers can make informed decisions, fostering successful partnerships that contribute to their business success.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for schaefer group Sourcing

When considering sourcing from the Schaefer Group, understanding the comprehensive cost structure and pricing strategy is essential for international B2B buyers. The following analysis breaks down the key components that influence costs and pricing, providing actionable insights for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The cost of raw materials is a significant factor in the overall pricing structure. Schaefer Group utilizes high-quality materials to ensure durability and performance. Prices can fluctuate based on market conditions, which may impact the final cost to buyers.

-

Labor: Labor costs vary by region and can significantly influence total expenses. Schaefer Group’s commitment to skilled labor is reflected in their pricing, as they prioritize quality and efficiency in production.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Buyers should be aware that manufacturing overhead may vary depending on the location of production facilities.

-

Tooling: Tooling costs are critical, especially for customized solutions. The initial investment in tooling can be substantial, but it is amortized over production runs, affecting unit pricing for larger orders.

-

Quality Control (QC): Schaefer Group invests in stringent QC processes to ensure that all products meet industry standards. While this may add to the cost, it enhances reliability and reduces the risk of defects.

-

Logistics: Transportation and handling costs can vary widely, particularly for international shipments. Factors such as distance, mode of transport, and local regulations will influence logistics costs.

-

Margin: The profit margin applied by the Schaefer Group will depend on market dynamics and competitive positioning. Understanding their margin strategy can help buyers gauge pricing flexibility.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Higher volumes typically lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom solutions often come with additional costs. The more specific the requirements, the higher the initial setup and tooling costs may be.

-

Materials: The choice of materials not only affects quality but also the price. Premium materials will increase costs, while alternative options may provide savings.

-

Quality/Certifications: Products that meet stringent international quality standards may carry a premium price. Certifications can enhance trust and perceived value, justifying higher costs.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers like Schaefer Group may command higher prices due to their proven track record.

-

Incoterms: The terms of shipment (Incoterms) will impact the total landed cost. Buyers should negotiate terms that minimize risks and unexpected expenses.

Buyer Tips

-

Negotiate Wisely: Leverage your purchasing power, especially if you can commit to higher volumes. This can lead to better pricing and favorable terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, operational costs, and potential savings over the product’s lifecycle.

-

Understand Pricing Nuances: Be aware of how local market conditions in your region can influence the cost of materials and logistics. Buyers from Africa, South America, the Middle East, and Europe should factor in currency fluctuations and trade tariffs that could affect pricing.

-

Build Strong Relationships: Establishing a good relationship with suppliers can lead to better terms and flexibility in pricing, especially for long-term partnerships.

Disclaimer

Prices and cost structures are indicative and can vary based on specific project requirements, regional factors, and market conditions. It is advisable for buyers to conduct thorough due diligence and obtain detailed quotes tailored to their needs.

Spotlight on Potential schaefer group Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘schaefer group’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for schaefer group

When engaging with the Schaefer Group, understanding essential technical properties and industry terminology is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances communication with suppliers and partners.

Key Technical Properties

-

Material Grade

– Definition: This refers to the specific type of material used in manufacturing, such as aluminum, steel, or refractory materials.

– B2B Importance: Knowing the material grade helps buyers assess the quality, durability, and suitability of products for their specific applications. For instance, high-grade aluminum is essential for industries requiring lightweight and corrosion-resistant materials. -

Tolerance

– Definition: Tolerance indicates the permissible limit of variation in a physical dimension or measurement of a component.

– B2B Importance: In precision industries, such as manufacturing and construction, understanding tolerances is vital to ensure compatibility and performance of components. Tight tolerances can enhance the reliability and efficiency of systems, reducing the need for costly rework. -

Load Capacity

– Definition: This property defines the maximum weight that a storage or handling system can support safely.

– B2B Importance: Buyers must match load capacities with their operational needs to prevent equipment failure and ensure safety. Overloading can lead to accidents and damage, significantly impacting operational costs. -

Energy Efficiency

– Definition: This refers to the effectiveness of a system or component in using energy to perform its intended function.

– B2B Importance: With growing energy costs and environmental concerns, energy-efficient products can lead to significant savings and a lower carbon footprint. Buyers should seek solutions that align with sustainability goals while reducing operational expenses. -

Automation Compatibility

– Definition: This property assesses whether a system can integrate with automated processes and technologies.

– B2B Importance: As industries move towards automation, understanding compatibility with existing systems is crucial. Buyers should prioritize solutions that can seamlessly integrate into their workflows, enhancing productivity and reducing labor costs.

Common Trade Terms

- OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is key for buyers seeking quality assurance and after-sales support. Collaborating with reputable OEMs can enhance product reliability.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing MOQs helps buyers plan their purchases and manage inventory effectively. This is especially important for smaller businesses that may not have the capacity to purchase in large volumes. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers.

– Importance: An RFQ allows buyers to compare pricing and terms from multiple suppliers, ensuring they get the best deal. It’s a critical step in the procurement process, particularly for large-scale purchases. -

Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk transfer, and cost implications. This knowledge is essential for effective negotiation and contract management. -

Lead Time

– Definition: The time taken from the initiation of an order to the delivery of the product.

– Importance: Understanding lead times is crucial for planning and inventory management. Buyers should factor lead times into their operational timelines to avoid delays in production or service delivery.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can enhance their interactions with the Schaefer Group, ensuring that they make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the schaefer group Sector

Market Overview & Key Trends

The Schaefer Group operates within a dynamic landscape characterized by evolving global drivers and innovative technologies. Key market trends indicate a rising demand for automation and efficiency in manufacturing and logistics. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking integrated solutions that enhance operational efficiency while reducing costs. This shift is largely driven by the need for agility in supply chains, particularly in response to global disruptions.

Emerging technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and advanced robotics are transforming the sector. These technologies facilitate real-time data analytics and predictive maintenance, allowing companies to optimize their operations. For example, SSI SCHAEFER’s WAMAS® software integrates seamlessly with hardware to provide visibility and control over warehouse operations, thereby enhancing productivity.

Additionally, international buyers are looking for suppliers that can offer scalable solutions tailored to their specific market needs. As companies expand their operations into new regions, the ability to customize solutions to fit local market dynamics becomes increasingly important. This trend is particularly relevant in regions like Mexico and the UAE, where rapid economic growth is prompting increased investment in logistics and manufacturing capabilities.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical focus for businesses, influencing purchasing decisions and supply chain management practices. The Schaefer Group is committed to minimizing its environmental impact through sustainable practices. This includes the utilization of energy-efficient manufacturing processes and the development of products that reduce waste and enhance recycling capabilities.

Ethical sourcing is equally vital, as B2B buyers are increasingly prioritizing suppliers that uphold ethical labor practices and transparency in their supply chains. Companies are now more inclined to partner with organizations that can demonstrate compliance with international standards for labor rights and environmental stewardship. For instance, certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming prerequisites for many buyers.

Furthermore, the use of ‘green’ materials and recyclable components in product offerings not only appeals to environmentally conscious consumers but also helps companies comply with stringent regulations. By aligning with these sustainability goals, suppliers can enhance their appeal to a broader customer base while contributing to a more sustainable future.

Brief Evolution/History

The Schaefer Group has a rich history marked by innovation and strategic partnerships. Established through the merger of two companies, the group has evolved into a leader in the manufacturing of industrial furnaces and refractory services. Over the years, the company has expanded its portfolio through strategic acquisitions and collaborations, such as the recent partnership with Sanken Sangyo Furnace Co. This collaboration allows the Schaefer Group to offer advanced melting technologies, enhancing their product offerings and meeting the growing demand for energy-efficient solutions.

Today, the Schaefer Group stands as a testament to the integration of technology and expertise in the industrial sector, providing comprehensive solutions from design to installation and ongoing support. This evolution positions the group favorably for future growth, particularly in emerging markets where demand for efficient manufacturing solutions is on the rise.

Related Video: The Shadow World: Inside the Global Arms Trade

Frequently Asked Questions (FAQs) for B2B Buyers of schaefer group

-

What criteria should I use to vet suppliers from the Schaefer Group?

When vetting suppliers from the Schaefer Group, consider their industry experience, product quality, and customer reviews. Request certifications such as ISO 9001 for quality management and check if they meet international standards relevant to your market. Engage in direct communication to assess their responsiveness and willingness to provide references. Additionally, inquire about their operational capabilities, including production capacity and technology used, to ensure they align with your needs. -

Can the Schaefer Group customize products to meet my specific needs?

Yes, the Schaefer Group offers customization options for many of its products. Engage directly with their sales team to discuss your specific requirements, including design specifications and functional features. They have a history of working closely with clients to tailor solutions that enhance operational efficiency. Ensure you communicate your needs clearly to facilitate the customization process and discuss any potential implications on lead times and costs. -

What are the minimum order quantities (MOQ) and lead times for Schaefer Group products?

Minimum order quantities can vary based on the specific product and customization requirements. Generally, standard products may have lower MOQs, while customized solutions might require larger orders. Lead times also depend on production schedules, complexity, and shipping logistics. It’s advisable to clarify these details early in discussions to align your procurement timelines with your project needs. -

What payment terms does the Schaefer Group offer for international buyers?

The Schaefer Group typically offers flexible payment terms, which may include options such as letter of credit, bank transfers, or installment payments depending on the size of the order. It’s essential to discuss payment options during the negotiation phase to ensure they align with your financial processes. Additionally, be aware of any currency exchange implications if purchasing from outside your local market. -

How does the Schaefer Group ensure quality assurance and compliance with international standards?

The Schaefer Group implements rigorous quality assurance processes throughout their production and delivery phases. They adhere to international standards, such as ISO certifications, and conduct thorough testing on their products. Request documentation of their quality control measures, including inspection reports and compliance certificates, to ensure that the products meet your expectations and local regulations. -

What logistics support does the Schaefer Group provide for international shipping?

The Schaefer Group has established logistics partnerships that facilitate efficient international shipping. They typically assist with customs clearance, freight forwarding, and provide guidance on shipping regulations specific to your country. It is beneficial to inquire about the shipping options available, including estimated transit times and costs, to make informed decisions regarding delivery schedules. -

How can I resolve disputes with the Schaefer Group if they arise?

To resolve disputes, start by directly communicating your concerns with your designated account manager or customer service representative. Document all correspondence and agreements to support your case. If necessary, refer to the terms outlined in your contract, which may specify mediation or arbitration processes. Establishing a clear line of communication can often lead to a satisfactory resolution without escalating the matter further. -

What after-sales support does the Schaefer Group offer?

The Schaefer Group provides comprehensive after-sales support, including installation assistance, maintenance services, and training for your staff on product usage. They also offer technical support to address any operational issues that may arise post-purchase. Engaging with their support team early in the procurement process can help you understand the full range of services available and ensure smooth operation of the purchased systems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for schaefer group

In conclusion, strategic sourcing with the Schaefer Group presents a myriad of opportunities for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. The company’s extensive portfolio, which includes innovative solutions in industrial furnaces, refractory sales, and automated logistics, underscores its commitment to enhancing operational efficiency and reducing costs. By leveraging Schaefer’s advanced technologies, buyers can streamline their supply chains and improve their competitive edge in the marketplace.

Key Takeaways:

– Comprehensive Solutions: Schaefer offers tailored solutions that cater to diverse industries, ensuring that buyers can find products that meet their specific needs.

– Sustainability Focus: The introduction of energy-efficient systems, such as the Sanken tower melters, highlights Schaefer’s dedication to sustainability, which is increasingly important for modern businesses.

– Global Reach: With a solid international presence, Schaefer is well-positioned to support buyers in navigating the complexities of global supply chains.

As we look to the future, it is crucial for B2B buyers to engage with Schaefer Group to explore partnerships that foster innovation and growth. Embrace the opportunity to enhance your operations with Schaefer’s expertise—reach out today to discuss how they can help you achieve your strategic sourcing goals.