Your Ultimate Guide to Sourcing Appleton Papers Appvion

Introduction: Navigating the Global Market for appleton papers appvion

Navigating the global market for Appleton Papers Appvion presents a unique opportunity for B2B buyers seeking high-quality, sustainable paper solutions. With over a century of expertise, Appvion stands as a leader in direct thermal and specialty coating solutions, providing essential products that drive efficiency and performance across various industries, including retail, healthcare, and logistics. Their commitment to sustainability through innovations like the EarthChem™ product line not only enhances product functionality but also aligns with the increasing demand for environmentally responsible sourcing.

This comprehensive guide will delve into the multifaceted aspects of Appleton Papers Appvion, covering crucial topics such as product types, materials used, manufacturing and quality control processes, supplier networks, and cost structures. It will also address market trends and provide answers to frequently asked questions, equipping international B2B buyers, especially from Africa, South America, the Middle East, and Europe, with the insights needed for informed sourcing decisions.

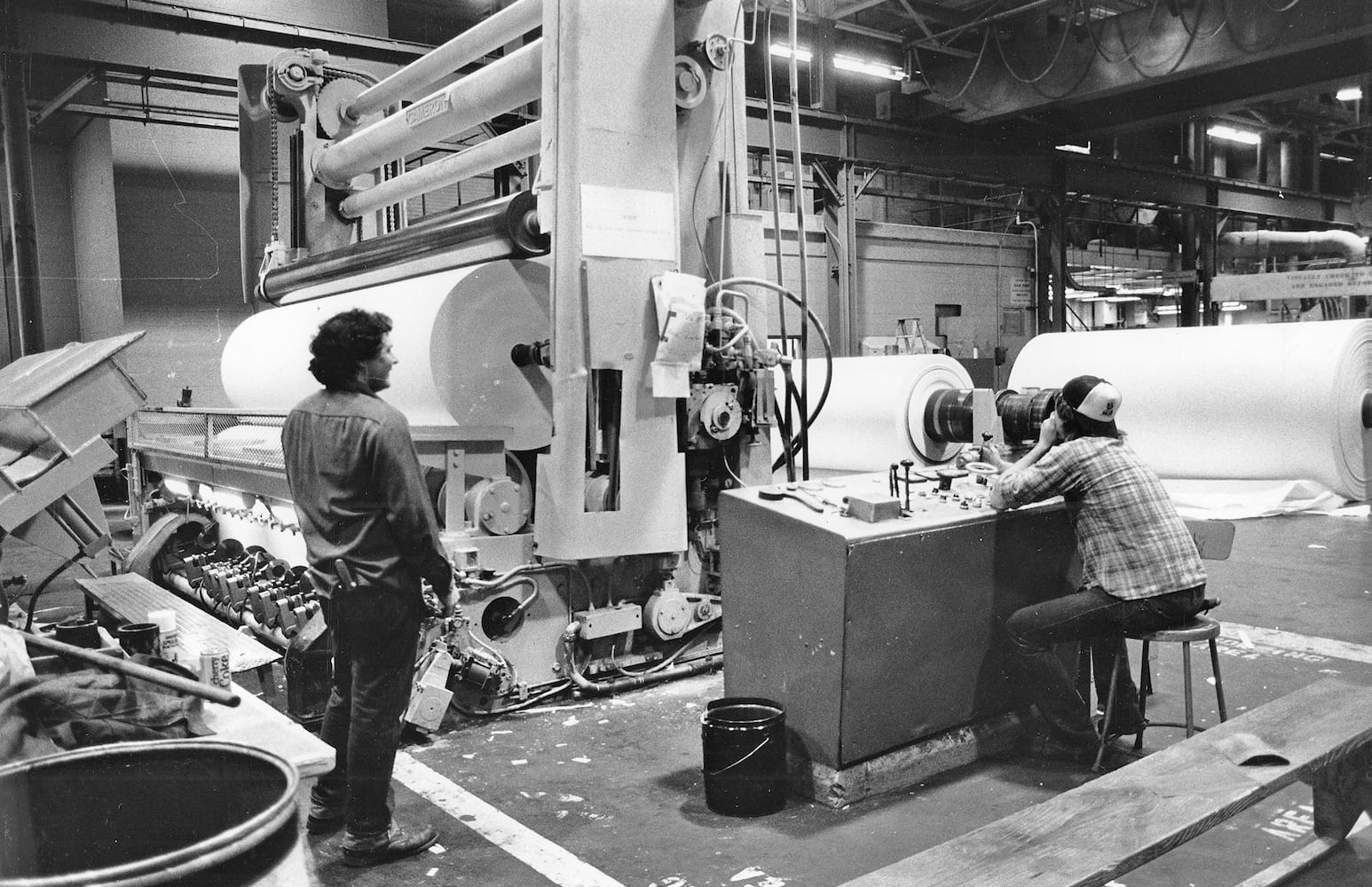

Illustrative Image (Source: Google Search)

By understanding the nuances of Appvion’s offerings, buyers can navigate the complexities of the global paper market effectively. This guide empowers you to make strategic decisions that enhance operational efficiency while fulfilling sustainability commitments—an essential consideration in today’s competitive landscape. Whether you are looking to optimize supply chains or explore innovative packaging solutions, this resource is designed to support your business needs in a rapidly evolving market.

Understanding appleton papers appvion Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| EarthChem™ | Sustainable, phenol-free direct thermal products, emphasizing environmental stewardship. | Retail labels, logistics, and packaging. | Pros: Eco-friendly, innovative. Cons: May be pricier than traditional options. |

| Résiste® 165 E | Top-coated direct thermal label facestock with enhanced durability and print quality. | Package delivery, logistics, and shipping labels. | Pros: High performance, reliable. Cons: Limited to specific thermal printers. |

| Water-Based Coatings | Versatile coatings that enhance printability and durability on various substrates. | Food packaging, healthcare, and retail products. | Pros: Environmentally friendly, adaptable. Cons: May require specific application processes. |

| Specialty Films | Innovative films designed for unique applications such as gaming and high-visibility labels. | Gaming tickets, event passes, and specialty labels. | Pros: Tailored solutions, high visibility. Cons: Niche market may limit availability. |

| Direct Thermal Paper | Direct thermal paper that eliminates the need for ribbons or inks, simplifying printing. | Retail receipts, shipping labels, and tags. | Pros: Cost-effective, easy to use. Cons: Limited lifespan and exposure to heat can affect legibility. |

EarthChem™

EarthChem™ represents Appvion’s commitment to sustainability, featuring products that are both innovative and environmentally friendly. This line of direct thermal products is designed to reduce environmental impact while maintaining high performance standards. B2B buyers, especially those from regions prioritizing sustainability, should consider EarthChem™ for applications in retail labels and logistics, as it aligns with growing eco-conscious consumer demands.

Illustrative Image (Source: Google Search)

Résiste® 165 E

The Résiste® 165 E is a premium choice for businesses looking for durability and high-quality print results. Its top-coated surface is designed to withstand the rigors of package delivery and logistics, ensuring that labels remain clear and legible throughout their lifecycle. Buyers should evaluate their specific thermal printing equipment compatibility, as this product may not work with all printers, but its reliability and performance make it a strong contender for shipping and logistics applications.

Water-Based Coatings

Appvion’s water-based coatings offer versatility across various substrates, enhancing printability and durability. These coatings are particularly advantageous for food packaging and healthcare applications, where safety and compliance are paramount. B2B buyers should consider the specific requirements of their products and the application processes involved, as these coatings can provide significant benefits while also being environmentally responsible.

Specialty Films

Specialty films from Appvion are designed for unique applications, such as gaming tickets or high-visibility labels. These products offer tailored solutions that meet the specific needs of niche markets, providing high visibility and durability. Buyers should assess their market requirements and potential volume needs, as these films can be an excellent investment for businesses looking to stand out in competitive environments.

Direct Thermal Paper

Direct thermal paper simplifies the printing process by eliminating the need for ribbons or inks, making it a cost-effective solution for various applications, including retail receipts and shipping labels. However, buyers should be aware of the limitations regarding lifespan and exposure to heat, which can affect the legibility of printed information. This type of paper is ideal for businesses seeking efficiency and ease of use in their printing operations.

Related Video: Diffusion Models | Paper Explanation | Math Explained

Key Industrial Applications of appleton papers appvion

| Industry/Sector | Specific Application of appleton papers appvion | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Direct Thermal Labels for Price Tagging | Enhances pricing accuracy and reduces labor costs | Ensure compatibility with existing printing systems; evaluate sustainability certifications. |

| Healthcare | Patient Identification Wristbands | Improves patient safety and reduces identification errors | Focus on materials that are hypoallergenic and comply with health regulations. |

| Transportation | Shipping Labels for Logistics | Streamlines package tracking and enhances supply chain efficiency | Verify durability under various environmental conditions; consider lead times for international shipping. |

| Food Packaging | Direct Thermal Labels for Food Products | Ensures compliance with labeling regulations and enhances product visibility | Assess thermal resistance and safety for food contact; prioritize eco-friendly materials. |

| Gaming | Custom Ticketing Solutions for Events | Increases operational efficiency and enhances customer experience | Look for customizable options; check for bulk order discounts and delivery timelines. |

In the retail sector, Appvion’s direct thermal labels are widely used for price tagging. These labels enhance pricing accuracy and streamline inventory management, ultimately reducing labor costs associated with manual tagging. International buyers should ensure that the labels are compatible with their existing printing systems and evaluate the sustainability certifications of the products, especially as consumers increasingly demand eco-friendly options.

In healthcare, Appvion provides patient identification wristbands that significantly improve patient safety by reducing identification errors. These wristbands are designed to be hypoallergenic, making them suitable for diverse patient populations. Buyers in this sector should focus on sourcing materials that comply with health regulations and ensure that the products are durable enough to withstand various hospital environments.

For the transportation industry, Appvion’s shipping labels are critical for logistics operations, facilitating efficient package tracking and enhancing supply chain efficiency. These labels must be durable enough to withstand various environmental conditions, so international buyers should verify their performance under different climates. Additionally, considering lead times for international shipping is essential to avoid delays in operations.

In the food packaging industry, direct thermal labels are used for food products to ensure compliance with labeling regulations and enhance product visibility. Buyers should assess the thermal resistance of the labels and confirm that they are safe for food contact. Prioritizing eco-friendly materials is also crucial as consumer awareness around sustainability increases.

Lastly, in the gaming sector, Appvion offers custom ticketing solutions for events that enhance operational efficiency and improve the customer experience. Buyers should look for customizable options that meet their specific needs and check for bulk order discounts, as well as delivery timelines, to ensure smooth operations. These applications highlight Appvion’s versatility and commitment to providing tailored solutions across diverse industries.

Related Video: What Can You Do with Python? – The 3 Main Applications

Strategic Material Selection Guide for appleton papers appvion

When selecting materials for products from Appvion, international B2B buyers must consider various factors that influence performance, cost, and compliance. Below is an analysis of four common materials used in Appvion’s offerings, focusing on their properties, advantages and disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Direct Thermal Paper

Key Properties:

Direct thermal paper is designed to react to heat, creating images without the need for ink. It typically operates effectively within a temperature range of -20°C to 70°C and is sensitive to light and moisture.

Pros & Cons:

The primary advantage of direct thermal paper is its cost-effectiveness and ease of use, as it eliminates the need for ink cartridges. However, it has limitations in durability, as exposure to heat and light can degrade the print quality over time, making it less suitable for long-term labeling.

Impact on Application:

This material is ideal for applications such as shipping labels, receipts, and tickets, where short-term visibility is essential. However, it may not be suitable for environments with extreme temperatures or prolonged exposure to sunlight.

Considerations for International Buyers:

Buyers should ensure compliance with local standards, such as ASTM D645 or DIN 16552, which govern the quality of thermal papers. Additionally, understanding regional preferences for labeling durability is crucial, particularly in hot climates.

2. Résiste® 165 E

Key Properties:

Résiste® 165 E is a phenol-free direct thermal label facestock designed for enhanced performance in package delivery and logistics. It features high print quality and resistance to smudging and scratching.

Pros & Cons:

The key advantage of Résiste® 165 E is its superior durability compared to standard direct thermal papers, making it suitable for various applications. However, it may come at a higher price point, which could be a consideration for cost-sensitive buyers.

Impact on Application:

This material is particularly effective for logistics and shipping labels that require clear, lasting prints even in challenging conditions. Its enhanced performance ensures that labels remain readable throughout the supply chain.

Considerations for International Buyers:

Buyers should verify that the product meets local regulations regarding chemical content, especially in regions with strict environmental laws. Understanding the local market’s demand for sustainable materials can also influence purchasing decisions.

3. Water-Based Coatings

Key Properties:

Water-based coatings are eco-friendly solutions that provide excellent adhesion and flexibility. They are generally resistant to moisture and UV light, making them suitable for various applications.

Pros & Cons:

These coatings are advantageous due to their low environmental impact and ability to enhance the durability of printed materials. However, they may require more complex manufacturing processes, which can increase production times and costs.

Impact on Application:

Water-based coatings are ideal for food packaging and other applications where safety and environmental concerns are paramount. Their moisture resistance also makes them suitable for products exposed to humidity.

Considerations for International Buyers:

Buyers should consider compliance with food safety standards such as FDA regulations in the U.S. or EFSA guidelines in Europe. Additionally, understanding local preferences for eco-friendly products can drive purchasing decisions.

4. Specialty Films

Key Properties:

Specialty films offer high clarity, strength, and moisture resistance. They can withstand a wide range of temperatures and are often used in demanding environments.

Pros & Cons:

The primary advantage of specialty films is their versatility and durability, making them suitable for both consumer and industrial applications. However, they can be more expensive than traditional paper products, which may deter some buyers.

Impact on Application:

These films are commonly used in packaging solutions that require high visibility and protection, such as food packaging and retail displays. Their strength ensures that they can handle the rigors of shipping and handling.

Considerations for International Buyers:

Buyers should ensure that specialty films comply with local packaging regulations, particularly in food safety. Additionally, understanding the regional market’s willingness to pay for higher-quality materials can inform procurement strategies.

Summary Table

| Material | Typical Use Case for appleton papers appvion | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Direct Thermal Paper | Shipping labels, receipts, tickets | Cost-effective, easy to use | Limited durability under heat/light | Medium |

| Résiste® 165 E | Logistics and shipping labels | Superior durability | Higher price point | High |

| Water-Based Coatings | Food packaging, eco-friendly applications | Low environmental impact | Complex manufacturing process | Medium |

| Specialty Films | Retail displays, food packaging | Versatile and durable | Higher cost than paper products | High |

This guide provides actionable insights for B2B buyers to make informed decisions regarding material selection for Appvion products, ensuring compliance and suitability for diverse applications across different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for appleton papers appvion

Appvion has established itself as a leader in the manufacturing of specialty coating solutions, particularly in the realm of direct thermal papers and films. Understanding their manufacturing processes and quality assurance protocols is crucial for international B2B buyers looking to engage with this supplier. Below is a detailed overview of the typical manufacturing stages, key techniques employed, and the quality assurance measures that Appvion adheres to.

Manufacturing Processes

The manufacturing of Appvion’s products involves several key stages, each critical to ensuring the final product meets stringent quality standards.

1. Material Preparation

In this initial stage, raw materials such as paper substrates and specialized coatings are sourced. Appvion places a strong emphasis on sustainability, opting for renewable materials whenever possible. The preparation phase involves:

- Sourcing: Materials are acquired from vetted suppliers who comply with environmental and quality standards.

- Testing: Incoming materials undergo rigorous testing to ensure they meet specific criteria for purity and performance.

2. Forming

Once the materials are prepared, they move to the forming stage, where the paper substrate is coated with various specialty layers. Key techniques include:

- Coating Application: This involves applying water-based coatings using advanced techniques such as gravure or flexographic printing. These methods ensure even distribution and optimal adhesion of the coating to the substrate.

- Drying: The coated substrates are dried using heated rollers or infrared systems, which helps in achieving the desired finish and performance characteristics.

3. Assembly

In the assembly stage, the coated paper is cut into specified dimensions and formats. This can include rolls, sheets, or specific labels. Important considerations include:

- Precision Cutting: Automated cutting machines ensure that the product meets the exact specifications required by customers.

- Labeling and Packaging: Finished products are labeled for easy identification and packaged to ensure protection during transit.

4. Finishing

The final stage of manufacturing focuses on enhancing the product’s usability and performance. This includes:

- Final Coating: Additional coatings may be applied to enhance features like scratch resistance or water repellency.

- Quality Checks: Before dispatch, products undergo final quality checks to confirm adherence to specifications.

Quality Assurance

Quality assurance is integral to Appvion’s operations, ensuring that every product meets international standards and customer expectations.

Relevant International Standards

Appvion adheres to various international quality standards, including:

- ISO 9001: This standard ensures a robust quality management system that focuses on continuous improvement and customer satisfaction.

- CE Marking: For products intended for the European market, CE marking is crucial as it indicates compliance with health, safety, and environmental protection standards.

Industry-Specific Standards

In addition to ISO, Appvion may also comply with industry-specific certifications such as:

- API (American Petroleum Institute): Relevant for products used in the oil and gas sectors.

- FDA Compliance: For products that may come into contact with food packaging, ensuring safety for consumer use.

Quality Control Checkpoints

Appvion employs several quality control checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Tests raw materials upon arrival to confirm they meet predefined specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect any deviations from standards.

- Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet all quality standards before shipment.

Common Testing Methods

Testing methods utilized include:

- Physical Testing: Assessing strength, thickness, and durability.

- Chemical Analysis: Evaluating the composition of coatings to ensure compliance with safety regulations.

- Performance Testing: Simulating real-world conditions to test product efficacy, such as heat and moisture resistance.

Verifying Supplier Quality Control

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are actionable steps to ensure supplier credibility:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into operational processes and adherence to quality standards.

- Request Quality Reports: Suppliers should provide comprehensive quality control reports, including testing results and certifications.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance practices.

Quality Control and Certification Nuances

For buyers in diverse markets, understanding the nuances of quality control and certification is vital:

- Regional Regulations: Familiarize yourself with local regulations and standards that may impact product acceptance. For example, some countries have specific import regulations that necessitate additional certifications.

- Cultural Considerations: Recognize that perceptions of quality may vary by region, influencing how products are received in different markets. Engaging local experts can help navigate these complexities.

In conclusion, understanding the manufacturing processes and quality assurance measures at Appvion equips B2B buyers with the necessary knowledge to make informed purchasing decisions. By focusing on quality, sustainability, and compliance with international standards, Appvion positions itself as a reliable partner in the global market for specialty coating solutions.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for appleton papers appvion Sourcing

When sourcing products from Appvion, understanding the comprehensive cost structure and pricing strategies is crucial for international B2B buyers. This analysis covers the key cost components, price influencers, and practical tips for maximizing value in procurement, particularly for businesses in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The cost of raw materials significantly impacts the overall pricing. Appvion utilizes high-quality, often sustainable materials in their products, such as their EarthChem™ portfolio. Sustainable sourcing may incur higher initial costs but can lead to long-term savings and improved brand reputation.

-

Labor: Labor costs encompass the wages of skilled workers who handle manufacturing processes. Appvion’s commitment to innovation may require specialized labor, which can elevate costs. However, efficient labor practices can enhance productivity and reduce the per-unit cost.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, depreciation of equipment, and facility maintenance. A well-optimized manufacturing process can help lower these overheads, allowing for competitive pricing.

-

Tooling: Tooling costs relate to the equipment and technology used in production. Custom tooling for specific orders can drive up costs, while standardized tooling can offer economies of scale.

-

Quality Control (QC): Ensuring product quality is paramount, especially for thermal paper and coatings that demand precision. The costs associated with QC processes can vary based on the complexity and specifications of the product.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Factors such as distance, shipping method, and customs duties can significantly affect total costs. Understanding Incoterms is essential for managing these logistics costs effectively.

-

Margin: The profit margin set by Appvion reflects the company’s positioning in the market. Buyers should be aware that higher margins may be applied to specialized or high-demand products, impacting overall pricing.

Price Influencers

-

Volume/MOQ: Purchasing in bulk often leads to lower unit prices. Understanding minimum order quantities (MOQ) can help buyers strategize their purchasing to maximize savings.

-

Specifications/Customization: Custom products usually carry a premium due to the additional resources required for development and production. Buyers should assess whether customization is essential for their needs or if standard products can suffice.

-

Materials and Quality Certifications: Products that require specific certifications for safety, sustainability, or performance may cost more. Buyers should evaluate the necessity of these certifications against their budget and product requirements.

-

Supplier Factors: The supplier’s market position, reputation, and stability can influence pricing. Established suppliers like Appvion may offer reliability and quality assurance, justifying higher prices.

-

Incoterms: Understanding shipping terms is vital for managing costs. Different Incoterms (e.g., FOB, CIF) can affect who bears the cost of shipping, insurance, and risk during transit.

Buyer Tips

-

Negotiation: Engage in open discussions with Appvion representatives to explore pricing flexibility. Highlighting potential long-term partnerships can be advantageous during negotiations.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the upfront costs. Consider factors like durability, performance, and potential savings from reduced waste or improved efficiency in your operations.

-

Pricing Nuances for International Buyers: Be mindful of currency fluctuations, tariffs, and import duties that can impact overall costs. Building a relationship with local logistics partners can help navigate these complexities.

-

Sample Requests: Don’t hesitate to request samples before committing to large orders. This practice ensures that the product meets your specifications and quality standards.

Disclaimer

Prices and cost structures are subject to change based on market conditions, currency fluctuations, and specific buyer requirements. Always consult directly with Appvion for the most accurate pricing information tailored to your needs.

Spotlight on Potential appleton papers appvion Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘appleton papers appvion’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for appleton papers appvion

Understanding the technical properties and trade terminology associated with Appvion’s products is crucial for B2B buyers, particularly those operating in international markets. Below is a comprehensive overview of essential specifications and common industry terms that will aid decision-makers in making informed purchasing choices.

Key Technical Properties

-

Material Grade

– Definition: The classification of paper based on its chemical and physical properties, such as fiber composition and coating type.

– Importance: Selecting the right material grade ensures the paper meets specific application requirements, such as durability, print quality, and environmental sustainability. For instance, Appvion’s EarthChem™ products are designed for eco-conscious consumers. -

Basis Weight

– Definition: The weight of a specific area of paper, usually measured in grams per square meter (gsm).

– Importance: Basis weight affects the paper’s thickness and rigidity, influencing printing performance and end-use applications. B2B buyers should choose the right basis weight to ensure compatibility with their printing equipment and product requirements.

-

Coating Type

– Definition: The specific formulation applied to the surface of the paper, which can enhance printability and durability.

– Importance: Different coating types, such as water-based or phenol-free, provide various benefits, including moisture resistance and improved image quality. For example, the Résiste® 165 E features phenol-free chemistry, making it a safer option for diverse applications. -

Heat Resistance

– Definition: The ability of the paper to withstand elevated temperatures without degrading or losing print quality.

– Importance: Heat resistance is critical for applications involving thermal printing, such as labels and tags in logistics. Understanding this property helps buyers ensure that the paper will perform reliably in their operational environments. -

Printability

– Definition: The capability of the paper to produce high-quality images and text when printed.

– Importance: Good printability is vital for branding and communication purposes. B2B buyers should consider this property to ensure that their labels and packaging stand out and convey the right message to consumers.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Usage: In the context of Appvion, OEMs may use their coated papers in producing labels, tags, or packaging for various industries. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Usage: Understanding MOQ is crucial for B2B buyers to manage inventory costs and ensure they meet their production needs without overcommitting to large quantities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Usage: B2B buyers should issue RFQs to multiple suppliers, including Appvion, to compare pricing, lead times, and terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in international transactions.

– Usage: Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk management, and cost implications when sourcing products from suppliers across borders. -

Sustainability Certifications

– Definition: Acknowledgments that a product meets specific environmental standards and practices.

– Usage: Buyers should look for sustainability certifications when selecting paper products, as these can enhance brand reputation and align with eco-friendly initiatives.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing Appvion’s products, ultimately improving their supply chain efficiency and product quality.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the appleton papers appvion Sector

The appleton papers appvion sector is experiencing notable market dynamics influenced by a variety of global drivers and emerging trends. As the demand for sustainable products increases, international B2B buyers are prioritizing suppliers that can demonstrate environmental responsibility. The rise of e-commerce and logistics has spurred growth in demand for direct thermal papers and specialty coatings, particularly in sectors like retail, healthcare, and transportation. Additionally, advancements in digital technologies are reshaping sourcing practices, with buyers increasingly leveraging e-procurement platforms to enhance efficiency and transparency.

Emerging trends include the integration of automation and artificial intelligence in supply chain management, which allows for better inventory tracking and demand forecasting. Buyers from Africa, South America, the Middle East, and Europe should focus on suppliers that not only offer innovative products but also demonstrate agility in adapting to changing market conditions. Understanding local regulations and certifications related to product safety and environmental impact is crucial for making informed sourcing decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability is not just a trend; it has become a fundamental expectation among B2B buyers. The appleton papers appvion sector is committed to minimizing environmental impact through innovative practices like the EarthChem™ portfolio, which offers sustainable thermal products. This shift towards eco-friendly solutions reduces the carbon footprint associated with paper production and aligns with global sustainability goals.

Ethical sourcing is equally important. Buyers should prioritize suppliers who maintain transparent supply chains and adhere to ethical labor practices. Certifications such as Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) are indicators of responsible sourcing that can enhance a company’s reputation in the market. By choosing products with these certifications, international buyers can contribute to sustainable forestry practices and ensure they are supporting responsible manufacturing processes.

Brief Evolution/History

Appvion has a rich history spanning over 115 years, initially recognized for its advancements in carbonless and microencapsulation technologies. Over the decades, the company has evolved to become a leader in direct thermal and specialty coating solutions, focusing on innovation and sustainability. This evolution reflects a commitment to meeting the needs of diverse markets such as retail, healthcare, and food packaging, while also addressing the growing demand for environmentally friendly products. As a global player headquartered in Appleton, Wisconsin, Appvion continues to influence the industry by leveraging its extensive expertise in materials science and environmental stewardship.

Related Video: The Shadow World: Inside the Global Arms Trade

Frequently Asked Questions (FAQs) for B2B Buyers of appleton papers appvion

-

What should I consider when vetting Appvion as a supplier?

When vetting Appvion as a supplier, it’s crucial to assess their industry reputation, experience, and product range. Investigate their compliance with international standards and certifications, such as ISO. Additionally, inquire about their sustainability practices and commitment to environmental stewardship, particularly relevant to buyers in regions prioritizing eco-friendly products. Engaging in discussions with current clients can also provide insights into their reliability and service quality. -

Can Appvion customize products to meet specific needs?

Yes, Appvion offers customization options tailored to meet the unique requirements of their clients. This includes variations in size, coating types, and performance characteristics of their thermal papers and films. To initiate customization, buyers should provide detailed specifications and discuss their specific application needs with Appvion’s sales team. This collaborative approach ensures that the final product aligns perfectly with your operational requirements. -

What are the minimum order quantities (MOQ) and lead times for international orders?

Appvion typically has minimum order quantities that vary by product line and customization level. For standard products, the MOQ may be lower, while customized orders may require larger quantities. Lead times can range from a few weeks to several months, depending on production schedules and shipping logistics. It is advisable to discuss your specific needs with their sales team to get accurate MOQ and lead time information tailored to your order. -

What payment options are available for international buyers?

Appvion offers various payment options to accommodate international buyers, including wire transfers, letters of credit, and other secure payment methods. It’s essential to clarify payment terms during negotiations, especially regarding deposits and balance payments. Buyers should also ensure they are familiar with any currency conversion and international transaction fees that may apply, which can affect the total cost. -

How does Appvion ensure quality assurance and certifications?

Appvion adheres to strict quality assurance protocols and holds several industry certifications, ensuring that their products meet high performance and safety standards. Buyers can request documentation of these certifications, such as ISO and environmental compliance certificates, to verify quality. Regular audits and testing are part of their quality management system, providing further assurance of product integrity and reliability. -

What logistics options does Appvion provide for international shipping?

Appvion collaborates with reputable logistics partners to offer flexible shipping options for international buyers. They can facilitate both air and sea freight, depending on urgency and budget considerations. It’s advisable to discuss shipping preferences during order placement, including delivery timelines, customs clearance, and any import regulations specific to your country to avoid delays. -

What should I do in case of disputes or issues with my order?

In case of disputes or issues with your order, it is important to contact Appvion’s customer service team promptly. They typically have a structured complaint resolution process in place. Provide detailed documentation of the issue, including order numbers and any relevant communications. Open communication will help in resolving issues efficiently, whether it involves product quality, delivery delays, or billing discrepancies. -

How can I stay updated on new products and innovations from Appvion?

To stay informed about Appvion’s latest products and innovations, consider subscribing to their newsletter or following them on social media platforms. They also maintain a blog that features updates on new product launches, industry trends, and sustainability initiatives. Engaging with their content can provide valuable insights that may benefit your business decisions and enhance your sourcing strategies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for appleton papers appvion

In summary, strategic sourcing from Appvion offers international B2B buyers a unique opportunity to enhance operational efficiency while embracing sustainability. By leveraging innovative products such as the EarthChem™ portfolio and the phenol-free Résiste® 165 E, businesses can align their procurement strategies with environmental stewardship, a growing demand in global markets.

Key Takeaways:

- Sustainability Focus: Appvion prioritizes eco-friendly solutions, enabling buyers to meet their sustainability goals without compromising on quality.

- Diverse Applications: Their extensive range of products serves various sectors, including retail, healthcare, and transportation, ensuring that buyers can find tailored solutions for their specific needs.

- Market Leadership: As a leading provider in North America, Appvion’s expertise and innovation position them as a reliable partner for international sourcing.

Looking ahead, buyers from Africa, South America, the Middle East, and Europe are encouraged to engage with Appvion to explore how their strategic sourcing initiatives can not only reduce costs but also contribute to a sustainable future. Embrace this opportunity to forge partnerships that empower your business and support global sustainability efforts.