Master Sourcing Dynaflex Exhaust Systems for Optimal

Introduction: Navigating the Global Market for dynaflex exhaust systems

In today’s competitive landscape, Dynaflex exhaust systems stand out as a crucial component for enhancing performance and compliance in various applications, from heavy-duty trucks to specialized industrial machinery. As international B2B buyers navigate the complexities of sourcing these systems, understanding the nuances of product offerings, manufacturing processes, and quality control becomes imperative. This guide serves as a comprehensive resource, providing insights into the diverse types of Dynaflex exhaust systems, the materials used, and the manufacturing standards that ensure reliability and efficiency.

Buyers from regions such as Africa, South America, the Middle East, and Europe (including markets like Mexico and Poland) will find valuable information regarding trusted suppliers, cost considerations, and market trends that influence purchasing decisions. The guide also addresses frequently asked questions, empowering buyers to make informed choices that align with their operational needs and regulatory requirements.

By equipping buyers with actionable insights and a clear understanding of the Dynaflex ecosystem, this resource not only facilitates effective sourcing but also fosters strategic partnerships with manufacturers. Whether optimizing for performance, reducing emissions, or enhancing durability, informed decision-making is key to unlocking the full potential of Dynaflex exhaust systems in your operations.

Understanding dynaflex exhaust systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monster Stacks | Tall, chrome-plated stacks with high visibility | Long-haul trucking, custom vehicles | Pros: High aesthetic appeal; Cons: May require more maintenance due to exposure. |

| OEM Replacement Kits | Direct replacements for original equipment | Fleet maintenance, repair shops | Pros: Ensures compatibility; Cons: Limited customization options. |

| Universal Exhaust Parts | Versatile components for various applications | Custom builds, aftermarket upgrades | Pros: Flexible fitment; Cons: May require additional modifications. |

| Emission Control Systems | Advanced designs for compliance with regulations | Industrial applications, fleet owners | Pros: Reduces emissions; Cons: Can be more expensive due to technology. |

| Silicone and Hose Parts | Flexible components for exhaust systems | Custom installations, repairs | Pros: Durable and heat-resistant; Cons: May not be suited for high-performance applications. |

Monster Stacks

Monster Stacks are characterized by their tall, chrome-plated design, making them a popular choice for long-haul trucking and custom vehicles. Their striking appearance can enhance the aesthetic of any truck, attracting attention at shows and on the road. When purchasing, buyers should consider the potential for increased maintenance needs due to their exposure to the elements. Additionally, while they offer significant visual appeal, buyers must ensure that they comply with local regulations regarding height and emissions.

OEM Replacement Kits

OEM Replacement Kits are designed to match the specifications of original equipment manufacturer parts. They are primarily used in fleet maintenance and repair shops, where consistency and reliability are paramount. The key advantage of these kits is their guaranteed compatibility with existing systems, reducing the risk of installation errors. However, buyers should note that customization options are limited, which may not suit businesses looking for unique solutions.

Universal Exhaust Parts

Universal Exhaust Parts provide flexibility for various applications, making them ideal for custom builds and aftermarket upgrades. These components can be adapted to fit a wide range of vehicles, appealing to businesses that prioritize versatility. While they allow for creative installations, buyers should be prepared for potential modifications to achieve a perfect fit. This adaptability can be a significant selling point, especially for businesses in dynamic markets.

Emission Control Systems

Emission Control Systems are engineered to meet stringent environmental regulations, making them essential for industrial applications and fleet owners focused on compliance. These systems utilize advanced technology to minimize emissions, thus contributing to sustainability efforts. Although they represent a higher upfront investment, the long-term benefits, including potential tax incentives and reduced environmental impact, can make them a valuable addition to any fleet. Buyers should evaluate the total cost of ownership, including maintenance and compliance costs.

Silicone and Hose Parts

Silicone and Hose Parts are crucial for creating flexible connections within exhaust systems. Their durability and heat resistance make them suitable for various applications, including custom installations and repairs. While these parts are essential for maintaining system integrity, they may not be ideal for high-performance setups where rigidity is required. Buyers should assess their specific needs, considering both the performance requirements and the environmental conditions in which these components will operate.

Related Video: What are Transformer Models and how do they work?

Key Industrial Applications of dynaflex exhaust systems

| Industry/Sector | Specific Application of dynaflex exhaust systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Heavy-duty trucks and trailers | Enhanced performance and reduced emissions | Compliance with local emissions regulations, durability under heavy loads |

| Agriculture | Agricultural machinery | Improved engine efficiency and reduced noise | Compatibility with various machinery brands, resistance to environmental factors |

| Construction | Construction vehicles and equipment | Increased operational efficiency and longevity | Availability of custom solutions, adherence to safety standards |

| Mining | Mining trucks and equipment | Enhanced safety through reduced exhaust emissions | Ability to withstand harsh environments, availability of parts for maintenance |

| Marine | Marine vessels | Compliance with maritime emissions regulations | Certification for marine applications, resistance to corrosion |

Transportation

In the transportation sector, dynaflex exhaust systems are primarily used in heavy-duty trucks and trailers. These systems significantly enhance vehicle performance while complying with stringent emissions regulations. For international buyers, particularly from regions like Africa and South America, it’s crucial to ensure that the exhaust systems meet local environmental standards. Buyers should also consider the durability of the products under heavy loads and long distances, ensuring that they do not compromise on performance or safety.

Agriculture

Dynaflex exhaust systems find vital applications in agricultural machinery, such as tractors and harvesters. These systems help in improving engine efficiency and reducing operational noise, which is beneficial for both productivity and environmental compliance. International buyers, particularly from the Middle East and Europe, must focus on sourcing exhaust systems that are compatible with various machinery brands and can withstand diverse environmental conditions, such as dust and moisture.

Construction

In the construction industry, dynaflex exhaust systems are integral to construction vehicles and equipment, ensuring increased operational efficiency and longevity. These systems help to minimize noise pollution, which is essential in urban construction sites. For B2B buyers in Europe and South America, it’s important to source products that adhere to local safety standards and can be customized for specific machinery needs, thus ensuring optimal performance.

Mining

Mining operations utilize dynaflex exhaust systems in their trucks and equipment to enhance safety by reducing harmful exhaust emissions. These systems are designed to withstand harsh mining environments, ensuring reliability and performance. Buyers from regions like Africa, where mining is a significant industry, should prioritize sourcing exhaust systems that offer maintenance support and parts availability to ensure uninterrupted operations.

Marine

In the marine sector, dynaflex exhaust systems are critical for compliance with maritime emissions regulations. They are used in various marine vessels to manage exhaust efficiently while reducing environmental impact. International buyers must ensure that the exhaust systems are certified for marine applications and are resistant to corrosion, given the harsh marine conditions. This focus on compliance and durability is essential for successful operations in this sector.

Related Video: Dynaflex 8″ with Curve exhaust kit installed on a 12′ Peterbilt 389 pt.2

Strategic Material Selection Guide for dynaflex exhaust systems

When selecting materials for Dynaflex exhaust systems, international B2B buyers must consider several factors that influence performance, durability, and compliance with regional standards. Here, we analyze four common materials used in exhaust systems, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance, and good mechanical properties. It can withstand temperatures up to 1,600°F (870°C) and is often rated for high-pressure applications.

Pros & Cons:

Stainless steel is highly durable and resistant to rust, making it suitable for harsh environments. However, it is more expensive than other materials, which can impact overall production costs. Manufacturing can be complex due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is ideal for exhaust systems that require high durability and resistance to corrosive elements, such as salt and moisture, often found in coastal regions.

Considerations for International Buyers:

Buyers must ensure compliance with standards such as ASTM A312 for seamless pipes and ASTM A240 for plates. In regions like Europe, adherence to EN standards is also crucial.

Aluminized Steel

Key Properties:

Aluminized steel features a coating of aluminum-silicon alloy, providing moderate corrosion resistance and good heat resistance, typically up to 1,200°F (650°C).

Pros & Cons:

This material is more cost-effective than stainless steel and offers good performance for general applications. However, it is less durable and can corrode more quickly in highly acidic environments, limiting its lifespan.

Impact on Application:

Aluminized steel is suitable for light-duty applications where cost is a significant factor, such as in passenger vehicles or light trucks.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding emissions and material standards. Compliance with ASTM A463 is essential for quality assurance.

Carbon Steel

Key Properties:

Carbon steel is a strong material with good tensile strength and can handle high pressures. However, it has lower corrosion resistance compared to stainless and aluminized steel.

Pros & Cons:

Carbon steel is relatively inexpensive and easy to manufacture, making it a popular choice for budget-conscious projects. Its main drawback is its susceptibility to rust and corrosion, particularly in humid or coastal environments.

Impact on Application:

Best suited for applications where cost is a primary concern and where the exhaust system is not exposed to extreme conditions.

Considerations for International Buyers:

Buyers should ensure that carbon steel components meet relevant standards, such as ASTM A36, and consider applying coatings for enhanced corrosion resistance.

Titanium

Key Properties:

Titanium is lightweight, has excellent strength-to-weight ratio, and boasts outstanding corrosion resistance, even in extreme environments.

Pros & Cons:

While titanium offers superior performance and longevity, it is significantly more expensive and requires specialized manufacturing techniques. This can increase the overall cost of the exhaust system.

Impact on Application:

Ideal for high-performance applications, especially in motorsports or luxury vehicles where weight savings and performance are critical.

Considerations for International Buyers:

Buyers must check compliance with international standards such as ASTM B348 for titanium bars and rods. The high cost may limit its use to niche markets.

Summary Table

| Material | Typical Use Case for dynaflex exhaust systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty trucks, high-performance vehicles | Excellent corrosion resistance | High cost and complex manufacturing | High |

| Aluminized Steel | Light-duty vehicles, general applications | Cost-effective | Lower durability | Medium |

| Carbon Steel | Budget-friendly exhaust systems | Low cost and easy to manufacture | Susceptible to rust | Low |

| Titanium | High-performance and motorsport applications | Lightweight and highly durable | Very high cost | High |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in Dynaflex exhaust systems, helping them make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dynaflex exhaust systems

The manufacturing process and quality assurance (QA) for Dynaflex exhaust systems are critical components that ensure high performance and compliance with international standards. This section provides a detailed overview of the typical stages involved in manufacturing, the techniques employed, and the quality assurance measures that international B2B buyers should consider.

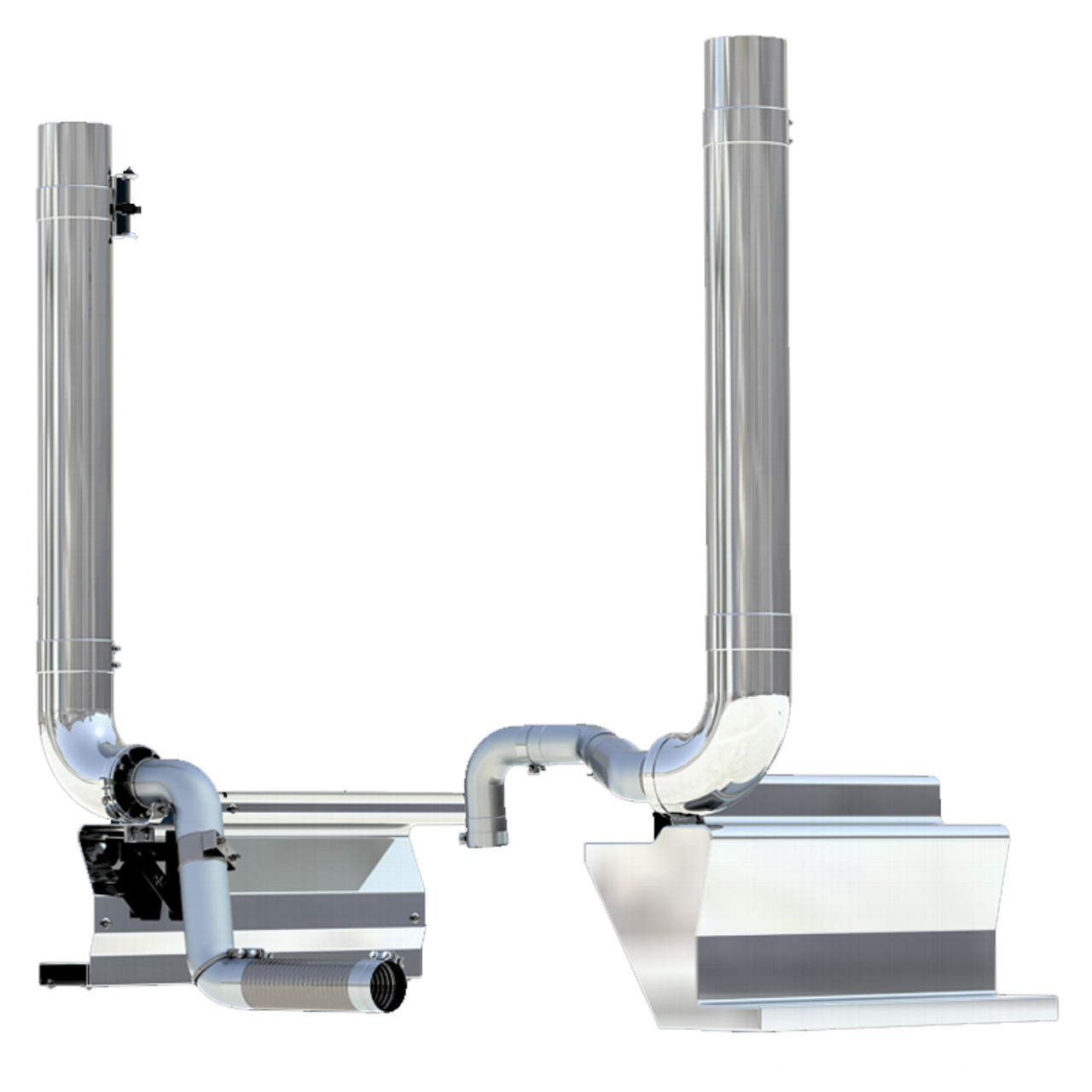

Illustrative Image (Source: Google Search)

Manufacturing Process

The manufacturing of Dynaflex exhaust systems encompasses several key stages, each designed to ensure product integrity and performance.

1. Material Preparation

The first step in the manufacturing process involves selecting high-quality raw materials, primarily metals such as stainless steel and aluminized steel, known for their durability and resistance to corrosion. The materials undergo a rigorous inspection to verify their compliance with specific international standards, such as ASTM and ISO.

- Key Techniques:

- Cutting: Utilizing laser cutting and plasma cutting technologies for precision.

- Bending: Employing CNC bending machines to shape the exhaust components accurately.

2. Forming

Once the materials are prepared, they are formed into specific shapes required for the exhaust system. This may involve processes like stamping, which creates complex geometries necessary for optimal performance.

- Key Techniques:

- Hydraulic Pressing: Used for creating bends and curves in the metal.

- Roll Forming: This technique is employed for continuous profiles, ensuring uniformity across components.

3. Assembly

After forming, the components are assembled. This stage is critical as it ensures that all parts fit together correctly to form a complete exhaust system.

- Key Techniques:

- Welding: MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are commonly used for joining components, ensuring strong and lasting connections.

- Bolting and Clamping: These methods are employed for parts that require disassembly or adjustment.

4. Finishing

The final stage involves finishing processes that enhance the appearance and functionality of the exhaust systems. This can include surface treatments, coatings, and polishing.

- Key Techniques:

- Coating: Powder coating or ceramic coating is often applied to improve corrosion resistance and aesthetics.

- Polishing: Ensuring a smooth surface finish, which can also reduce exhaust noise.

Quality Assurance

Quality assurance is paramount in the manufacturing of exhaust systems to meet both regulatory requirements and customer expectations. Dynaflex adheres to several international standards and employs a robust quality control framework.

International Standards

To ensure that products meet global quality benchmarks, Dynaflex follows internationally recognized standards such as:

- ISO 9001: This standard focuses on quality management systems and is essential for consistent product quality.

- CE Marking: Ensures that products meet EU safety, health, and environmental protection standards.

- API Standards: Relevant for exhaust systems used in industrial applications, ensuring compliance with safety and performance standards.

Quality Control Checkpoints

To maintain high-quality production, several key checkpoints are integrated into the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before processing.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to identify defects or deviations from specifications.

- Final Quality Control (FQC): A comprehensive review of the finished product to ensure it meets all specifications and quality standards before shipping.

Common Testing Methods

Dynaflex employs various testing methods to verify product performance and compliance:

- Hydrostatic Testing: Used to assess the integrity of the exhaust system under pressure.

- Vibration Testing: Ensures that the exhaust can withstand operational vibrations without failure.

- Emissions Testing: Verifies that the exhaust systems comply with environmental regulations.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, it is crucial to verify the quality control measures of potential suppliers. Here are some actionable steps:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control systems in place.

- Requesting Quality Reports: Suppliers should be able to provide documentation, including quality control reports and compliance certificates.

- Third-Party Inspections: Engaging third-party inspection agencies can ensure an unbiased assessment of the manufacturing and quality assurance processes.

- Certifications Verification: Buyers should verify the authenticity of any certifications claimed by suppliers, ensuring they are up to date and relevant.

Quality Control Nuances for International Buyers

International buyers must be aware of specific nuances that could affect quality assurance:

- Regulatory Differences: Different regions may have varying regulatory requirements, which can impact product specifications.

- Supply Chain Considerations: Fluctuations in raw material quality due to sourcing can affect the overall quality of the final product.

- Cultural Factors: Understanding cultural differences in business practices can help in establishing effective communication and expectations regarding quality standards.

Conclusion

The manufacturing processes and quality assurance measures for Dynaflex exhaust systems are comprehensive and designed to meet international standards. By understanding these processes, international B2B buyers can make informed decisions and ensure that they partner with reliable suppliers who prioritize quality and compliance. This knowledge is particularly valuable for buyers in regions like Africa, South America, the Middle East, and Europe, where diverse regulatory environments and market needs exist.

Related Video: Honda factory tour – Production in Japan plant

Comprehensive Cost and Pricing Analysis for dynaflex exhaust systems Sourcing

When sourcing Dynaflex exhaust systems, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. The costs associated with these systems can be broken down into several key components, each influencing the overall price.

Cost Components

-

Materials: The primary raw materials include high-quality metals and alloys used in exhaust system production. Prices can fluctuate based on global market conditions and the specific materials chosen, such as stainless steel versus mild steel.

-

Labor: Labor costs encompass skilled workers involved in manufacturing, assembly, and quality control. Regions with lower labor costs may offer competitive pricing, but it’s essential to balance cost savings with the expertise required for high-quality production.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these overheads, contributing to lower overall costs.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. Buyers should consider whether they require specialized tooling for unique specifications, which can increase the upfront investment.

-

Quality Control (QC): Ensuring that products meet stringent quality standards incurs additional costs. A robust QC process is vital for maintaining compliance with international regulations, especially for buyers in regions with strict emissions standards.

-

Logistics: Shipping costs, including freight and insurance, significantly impact the final price, especially for international shipments. Costs can vary based on the shipping method (air, sea, or land) and the distance to the destination.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary depending on their market position and the competitive landscape. Understanding this margin can help buyers negotiate better deals.

Price Influencers

Several factors can influence the pricing of Dynaflex exhaust systems:

-

Volume/MOQ: Larger orders often qualify for volume discounts. Establishing a minimum order quantity (MOQ) can also affect pricing structures.

-

Specifications/Customization: Custom-designed exhaust systems tailored to specific vehicle models or performance requirements may incur higher costs due to the additional engineering and production complexities.

-

Materials: The choice of materials can significantly impact pricing. Premium materials that offer enhanced durability and performance may come at a higher cost.

-

Quality and Certifications: Systems certified to meet specific international standards (e.g., ISO, EPA regulations) may command higher prices due to the associated compliance costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products based on their track record of quality and service.

-

Incoterms: Understanding the terms of trade (Incoterms) is critical for determining who bears the shipping costs and risks, which can affect the total cost of acquisition.

Buyer Tips

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiate: Engage in open discussions with suppliers to negotiate pricing based on your specific needs, potential volume, and long-term partnership opportunities.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational efficiency, and potential savings from quality products that reduce downtime.

-

Understand Pricing Nuances: Be aware of regional pricing variations and currency fluctuations that could impact costs. Establish relationships with multiple suppliers to compare pricing effectively.

-

Leverage Local Regulations: Familiarize yourself with local regulations and standards that may affect the choice of exhaust systems, as compliance can lead to long-term savings and reduced risk of penalties.

Disclaimer

Prices and costs presented in this analysis are indicative and may vary based on market conditions, specific supplier agreements, and other factors. Always consult with suppliers for the most accurate and current pricing information.

Spotlight on Potential dynaflex exhaust systems Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dynaflex exhaust systems’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dynaflex exhaust systems

Key Technical Properties of Dynaflex Exhaust Systems

Understanding the technical specifications of Dynaflex exhaust systems is crucial for international B2B buyers. Here are some essential properties:

-

Material Grade:

Dynaflex exhaust systems are typically constructed from high-grade stainless steel or aluminized steel. The choice of material significantly impacts durability, resistance to corrosion, and overall lifespan. Stainless steel offers superior resistance to rust and heat, making it ideal for heavy-duty applications. For buyers in regions with harsh climates, investing in higher-grade materials can reduce long-term maintenance costs. -

Tolerance Levels:

Tolerances refer to the permissible limits of variation in a physical dimension. In exhaust systems, precise tolerances ensure proper fitment and optimal performance. For example, a tolerance of ±0.5 mm in pipe diameter can significantly affect exhaust flow and engine efficiency. Buyers should pay attention to these specifications to avoid installation issues, especially in custom applications. -

Emissions Compliance:

Dynaflex products are designed to meet various emissions standards, such as EPA and Euro 6 regulations. Compliance with these standards is critical for businesses operating in regulated markets, as non-compliance can lead to hefty fines and operational shutdowns. Buyers should verify that the products they purchase adhere to local regulations to ensure legal compliance and environmental responsibility. -

Noise Reduction:

Many Dynaflex exhaust systems are equipped with noise-reducing features, such as mufflers and resonators. The ability to minimize noise is particularly important for businesses in urban areas or those operating in noise-sensitive environments. Buyers should assess the decibel levels and noise reduction capabilities to align with local noise regulations and customer expectations. -

Heat Resistance:

Exhaust systems must withstand high temperatures generated by engine operation. Dynaflex products often feature heat-resistant coatings or materials that enhance their performance under extreme conditions. Buyers should consider the heat resistance properties, especially in applications involving heavy machinery or performance vehicles.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some key terms:

-

OEM (Original Equipment Manufacturer):

Refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of Dynaflex exhaust systems, understanding OEM parts is crucial for buyers looking for replacements that maintain the original performance and quality standards. -

MOQ (Minimum Order Quantity):

The smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ can help in planning inventory and budget allocation. Smaller companies may find it challenging to meet high MOQs, leading to increased costs. -

RFQ (Request for Quotation):

A document that a buyer sends to suppliers requesting pricing and other details for specific products. An RFQ helps buyers compare offers from different suppliers, ensuring they make informed purchasing decisions. It is a critical step in the procurement process for large-scale purchases. -

Incoterms:

International Commercial Terms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms (such as FOB, CIF, DDP) is vital for B2B buyers to clarify shipping responsibilities, costs, and risks associated with the transport of goods. -

Lead Time:

The amount of time from placing an order to receiving the product. For international buyers, lead time can affect project timelines significantly. It is important to discuss lead times with suppliers to ensure that products arrive when needed. -

Warranty:

A guarantee provided by the manufacturer regarding the condition of the product and the terms under which it can be repaired or replaced. For B2B buyers, understanding warranty terms is essential for managing risk and ensuring product reliability over time.

By grasping these technical properties and trade terms, international B2B buyers can make informed purchasing decisions, ensuring the longevity and performance of Dynaflex exhaust systems in their applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dynaflex exhaust systems Sector

Market Overview & Key Trends

The global market for Dynaflex exhaust systems is driven by several key factors, including increasing regulatory pressures for emissions reduction, advancements in automotive technology, and the growing demand for high-performance vehicles. Particularly in regions like Africa, South America, the Middle East, and Europe, there is a notable shift towards sustainable and efficient exhaust solutions. International B2B buyers should be aware that local regulations often dictate the specifications of exhaust systems, making it crucial to stay informed about compliance standards in their respective markets.

Emerging technologies are reshaping sourcing trends within the industry. The adoption of digital platforms for procurement and supply chain management is on the rise, enabling buyers to make more informed decisions based on real-time data. Additionally, the integration of automation and artificial intelligence in manufacturing processes is enhancing productivity and reducing lead times, which is beneficial for B2B buyers looking for timely deliveries and cost-effective solutions.

As the market evolves, collaboration among manufacturers, suppliers, and buyers is becoming increasingly important. Establishing long-term partnerships can lead to better pricing, improved quality, and innovation in product development. Buyers should actively seek suppliers who demonstrate a commitment to research and development, as this can be a significant differentiator in the competitive landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of the Dynaflex exhaust systems sector, reflecting a broader global shift towards environmental responsibility. The production and disposal of exhaust systems have considerable environmental impacts, including resource depletion and pollution. Therefore, B2B buyers should prioritize suppliers that engage in sustainable practices, such as using recycled materials and implementing energy-efficient manufacturing processes.

Ethical sourcing is equally important. Buyers must assess their supply chains for compliance with environmental regulations and ethical labor practices. This includes ensuring that suppliers adhere to international labor standards and do not engage in practices such as child labor or unsafe working conditions. Certifications like ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to ethical practices.

Moreover, using ‘green’ materials—such as low-emission metals and biodegradable components—can enhance the sustainability profile of exhaust systems. Buyers should inquire about the availability of these materials and the supplier’s efforts in reducing their carbon footprint. By aligning purchasing decisions with sustainability goals, B2B buyers can not only comply with regulations but also enhance their brand reputation in a market increasingly focused on corporate responsibility.

Brief Evolution/History

The Dynaflex exhaust systems sector has undergone significant transformation since its inception. Initially focused on basic exhaust functionality, the industry has evolved to prioritize performance, emissions control, and sustainability. In the early days, exhaust systems were primarily made from standard metals, but advancements in materials science have led to the adoption of high-performance alloys that enhance durability and efficiency.

As environmental regulations became more stringent, manufacturers were compelled to innovate, leading to the development of technologies such as catalytic converters and advanced noise reduction systems. The integration of digital technologies in design and manufacturing has further propelled the industry forward, allowing for greater customization and efficiency in production. This historical context highlights the importance of staying informed about technological advancements and regulatory changes, as they directly impact sourcing strategies and market dynamics for international B2B buyers.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of dynaflex exhaust systems

-

What should I consider when vetting a supplier for Dynaflex exhaust systems?

When vetting suppliers, focus on their experience in the exhaust systems industry, especially in the international market. Check their references and past client reviews. Ensure they have certifications that comply with your region’s regulations, such as ISO or specific emissions standards. Additionally, evaluate their production capabilities, quality control processes, and customer support. A supplier with a robust track record in international trade will be more adept at handling logistics and customs, which is crucial for smooth transactions. -

Can Dynaflex exhaust systems be customized for specific applications?

Yes, Dynaflex offers customization options for exhaust systems to meet various application needs. Buyers can request specific dimensions, materials, and performance characteristics. It’s advisable to communicate your requirements clearly and discuss potential modifications during the initial stages of engagement with the supplier. Custom solutions often enhance system performance and compliance with regional regulations, making them a valuable option for specialized applications in different markets. -

What are the minimum order quantities (MOQ) and lead times for Dynaflex products?

MOQs for Dynaflex exhaust systems can vary based on product type and customization levels. Generally, expect an MOQ that aligns with production efficiency, often ranging from 50 to 100 units. Lead times also depend on order complexity; standard products may ship within 2-4 weeks, while customized solutions might take longer. Always confirm these details upfront to align your procurement timeline with your project needs and avoid delays. -

What payment options are typically available for international orders?

Payment options for international orders may include bank transfers, letters of credit, and payment platforms like PayPal. Discuss terms with the supplier to understand their policies regarding deposits and balance payments. A common practice is to pay a deposit upon order confirmation, with the remaining balance due before shipment. Ensure to clarify any currency conversion implications and transaction fees when dealing with international payments. -

How can I ensure quality assurance and certifications for Dynaflex exhaust systems?

To ensure quality, request documentation of certifications from the supplier, such as ISO 9001 or compliance with environmental standards relevant to your region. A reputable supplier should provide quality assurance processes, including testing methods and inspection protocols. Additionally, consider requesting samples or third-party inspections before placing large orders to verify that the products meet your specifications and quality expectations. -

What logistics considerations should I keep in mind when importing Dynaflex products?

Logistics play a crucial role in the import process. Understand the shipping methods available—air freight is faster but more expensive than sea freight. Factor in customs duties, taxes, and any potential tariffs specific to your country. Collaborate with a logistics partner familiar with international trade to navigate these complexities effectively. Ensure that the supplier provides all necessary shipping documentation to facilitate smooth customs clearance. -

How can disputes be effectively resolved in international transactions?

To mitigate potential disputes, establish clear terms in your contract regarding product specifications, payment schedules, and delivery timelines. Include a dispute resolution clause that outlines the process, such as mediation or arbitration, and specify the governing law. Maintaining open lines of communication with your supplier can also help address issues before they escalate. If disputes arise, document all communications and evidence to support your case during resolution discussions.

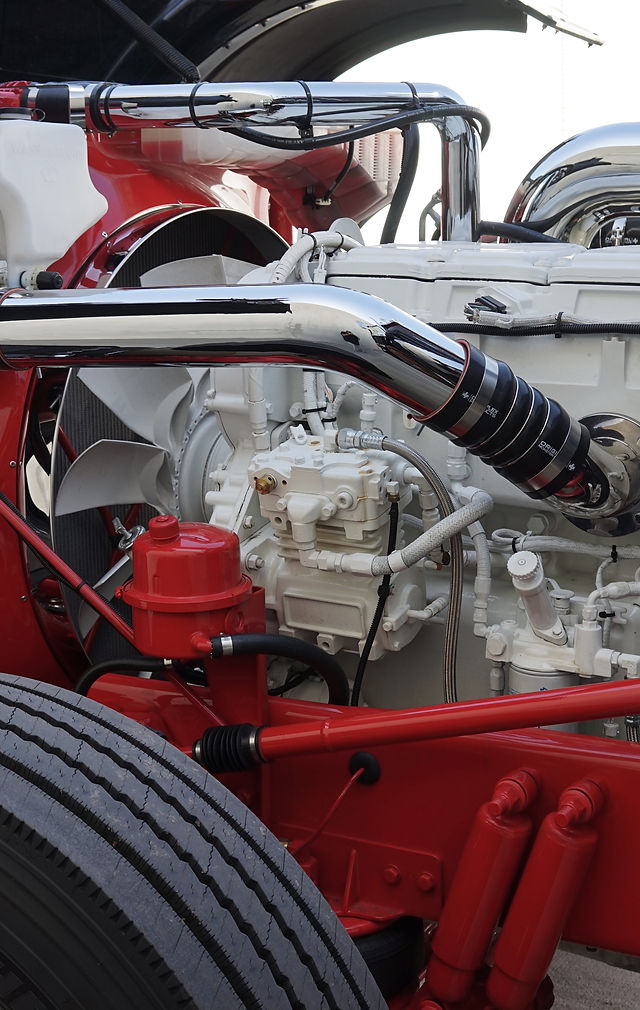

Illustrative Image (Source: Google Search)

- What are the best practices for maintaining a long-term relationship with Dynaflex suppliers?

Building a long-term relationship requires consistent communication and transparency. Regularly provide feedback on product performance and service quality. Engage in discussions about future needs and potential product improvements. Consider establishing a partnership approach, where both parties collaborate on product development or marketing strategies. Recognizing your supplier’s efforts and achievements can foster loyalty and encourage them to prioritize your business in future engagements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dynaflex exhaust systems

As international B2B buyers increasingly seek quality and reliability, strategic sourcing of Dynaflex exhaust systems stands out as a crucial factor in enhancing operational efficiency. By prioritizing partnerships with reputable manufacturers, businesses can leverage Dynaflex’s commitment to innovation and performance. Buyers from Africa, South America, the Middle East, and Europe should consider the advantages of sourcing high-performance exhaust systems that comply with local emissions regulations, ensuring both sustainability and compliance.

Moreover, the diverse product range offered by Dynaflex, including OEM replacement parts and universal solutions, allows for tailored sourcing strategies that meet specific market needs. Establishing strong supplier relationships not only fosters trust but also enables access to the latest technologies and innovations in exhaust system design.

Looking ahead, the demand for efficient, high-quality exhaust systems will continue to grow globally. International buyers are encouraged to explore Dynaflex products as a viable solution to enhance their supply chains. By taking decisive action now, businesses can position themselves favorably in an evolving market landscape, ultimately driving growth and success in their respective industries.