Master Membrane Keys Sourcing: Essential Insights for B2B

Introduction: Navigating the Global Market for membrane keys

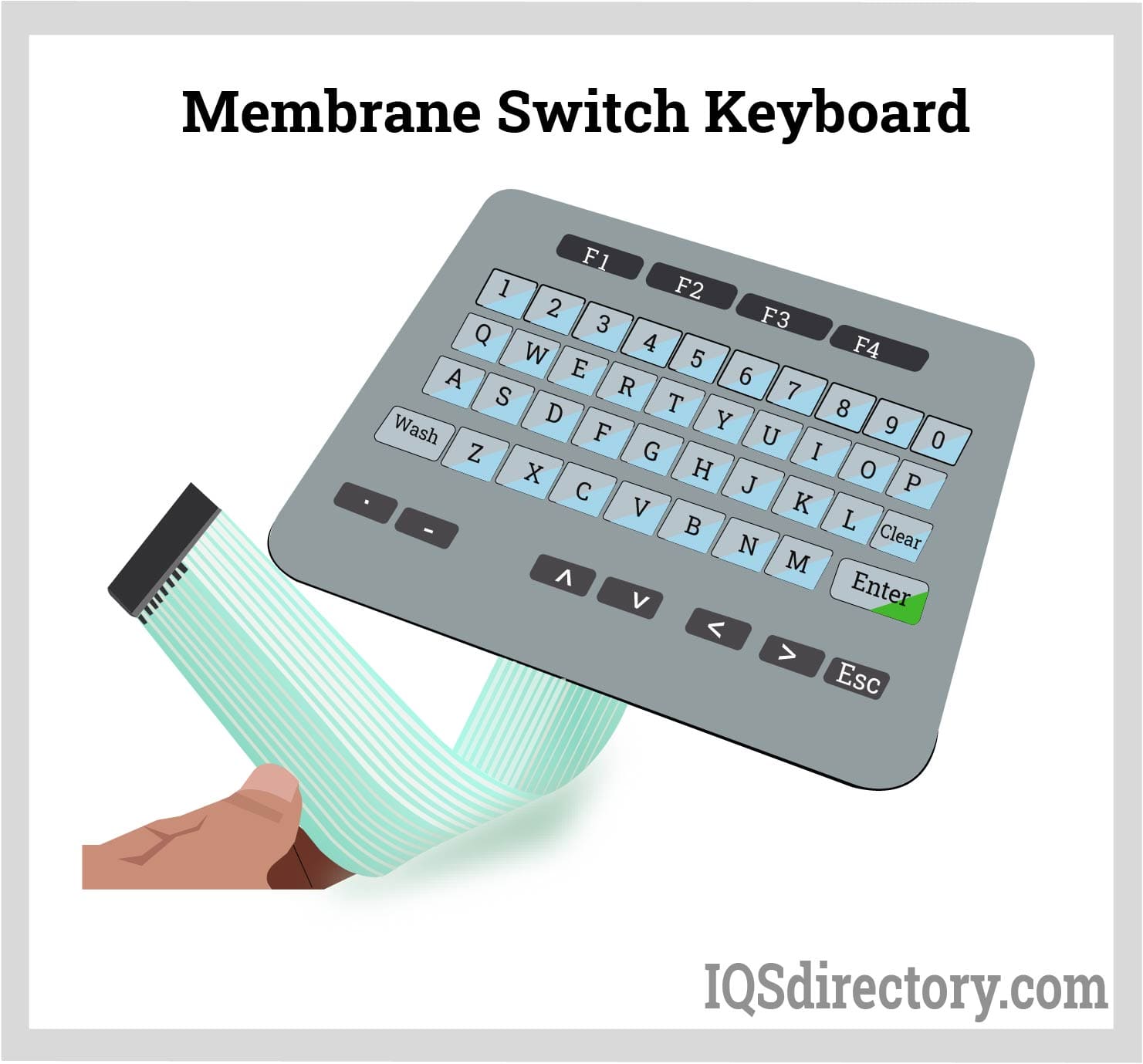

Membrane keys are revolutionizing the way industries interact with technology, serving as a crucial interface in applications ranging from medical devices to industrial automation. Their design offers not only durability and resistance to environmental factors but also the customization that modern manufacturers demand. For international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe, understanding the nuances of membrane keys is essential for enhancing product performance and user experience.

This comprehensive guide delves into the multifaceted world of membrane keys, covering a variety of critical topics. Buyers will discover different types of membrane switches, including tactile, non-tactile, and waterproof options, each tailored to specific industry needs. Insights into materials—like PET and polycarbonate—will illuminate choices that drive both functionality and longevity. Additionally, the guide addresses manufacturing and quality control essentials, enabling buyers to ensure that their products meet the highest standards.

Furthermore, it provides strategic advice on supplier selection and cost structures, equipping buyers with the knowledge to navigate global trade channels effectively. With an emphasis on regional compliance and end-user expectations, this guide empowers B2B buyers to make informed sourcing decisions, turning procurement into a strategic advantage in today’s competitive landscape. Whether you are in the UK, Saudi Arabia, or elsewhere, mastering the membrane key market is vital for achieving operational excellence and innovation.

Understanding membrane keys Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tactile Membrane Key | Provides physical feedback through a dome structure | Medical devices, industrial controls | Clear feedback enhances user experience; may wear out faster in harsh conditions. |

| Non-Tactile Membrane Key | Silent operation without mechanical feedback | Consumer electronics, appliances | Sleek design; lacks tactile confirmation which may lead to user errors. |

| Capacitive Touch Key | Responds to touch via electrical capacitance | High-end electronics, automotive | Modern aesthetics; sensitive to moisture and interference. |

| Waterproof Membrane Key | Additional sealing against water, dust, and chemicals | Outdoor equipment, food processing | Enhanced durability; typically higher cost and limited tactile feedback. |

| Backlit Membrane Key | Integrated illumination for visibility in low-light conditions | Medical, aerospace, low-light areas | Improves usability in dark environments; adds complexity and cost. |

Tactile Membrane Key

Tactile membrane keys feature a dome structure, often made from metal or polyester, providing a physical “click” when pressed. This feedback is crucial in applications where user assurance is necessary, such as in medical devices or industrial controls. When considering procurement, B2B buyers should evaluate the material of the dome, required actuation force, and expected lifecycle, ensuring compatibility with local environmental conditions to optimize performance.

Non-Tactile Membrane Key

Non-tactile membrane keys operate silently and maintain a flat surface, making them ideal for consumer electronics and appliances that prioritize aesthetics and ease of cleaning. While they can incorporate visual indicators like LEDs for feedback, they lack physical confirmation, which may lead to user errors. Buyers should weigh the benefits of a streamlined design against the potential for accidental activation, especially in high-usage environments.

Capacitive Touch Key

Capacitive touch keys utilize electrical capacitance to detect user input, enabling modern interface features such as sliders and multi-touch gestures. Commonly found in high-end electronics and automotive applications, these keys provide a sleek and modern user experience. However, B2B buyers must consider environmental factors, as moisture or contaminants can interfere with functionality, potentially necessitating additional protective measures.

Waterproof Membrane Key

Waterproof membrane keys are designed with enhanced sealing to resist water, dust, and chemicals, making them suitable for outdoor equipment and food processing applications. Their durability in harsh environments is a significant advantage, though they often come at a higher cost and may provide less tactile feedback. Buyers should assess the balance between durability and user experience, particularly in demanding settings.

Backlit Membrane Key

Backlit membrane keys feature integrated lighting, usually LEDs, allowing for visibility in low-light conditions. This type is commonly used in medical, aerospace, and other applications where visibility is critical. While backlighting enhances usability, it can complicate manufacturing and increase costs. B2B buyers should consider the added value of improved visibility against potential increases in overall project costs.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of membrane keys

| Industry/Sector | Specific Application of Membrane Keys | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Technology | Control panels for diagnostic equipment | Enhanced user interaction with tactile feedback; improves accuracy in critical settings | Compliance with medical standards; durability against sterilization processes |

| Industrial Automation | Operator interfaces on machinery | Streamlined operations with customizable layouts; reduces error rates in high-stakes environments | Robustness against dust and moisture; ease of installation and maintenance |

| Consumer Electronics | Keypads for home appliances | Aesthetic design with backlighting options; user-friendly interfaces enhance customer satisfaction | Compatibility with various electronics; cost-effectiveness for mass production |

| Aerospace | Control interfaces for avionics | High reliability and performance in extreme conditions; essential for safety-critical applications | Compliance with aviation standards; resistance to temperature fluctuations |

| Food Processing | Control systems for processing equipment | Hygiene and ease of cleaning; operational efficiency ensures minimal downtime | IP-rated designs for water and dust resistance; materials suitable for food safety regulations |

Medical Technology

In the medical technology sector, membrane keys are integral to control panels of diagnostic equipment, such as ultrasound machines and patient monitoring systems. These keys provide tactile feedback, ensuring that healthcare professionals can operate devices accurately, which is crucial in high-stakes environments. International B2B buyers must consider compliance with stringent medical standards and the durability of materials against frequent sterilization processes, especially in regions with varying regulatory requirements.

Industrial Automation

Membrane keys are commonly used in operator interfaces for machinery in industrial automation. They allow for customizable layouts that streamline operations and reduce error rates, which is vital in environments where precision is paramount. Buyers should focus on sourcing robust designs that can withstand harsh conditions, such as dust and moisture, particularly in manufacturing hubs across Africa and the Middle East. Additionally, ease of installation and maintenance can significantly affect operational efficiency.

Consumer Electronics

In the consumer electronics industry, membrane keys are utilized in keypads for home appliances, such as microwaves and washing machines. The ability to incorporate aesthetic features, like backlighting, enhances user interaction and satisfaction. B2B buyers in this sector should ensure that the membrane keys are compatible with a range of electronics and consider cost-effectiveness for mass production. This is particularly important in competitive markets in South America and Europe, where consumer preferences vary.

Aerospace

Aerospace applications often require membrane keys for control interfaces in avionics systems, where high reliability and performance are non-negotiable. These keys must function effectively in extreme conditions, contributing to safety-critical operations. Buyers should prioritize compliance with aviation standards, ensuring that the membrane keys can withstand temperature fluctuations and other environmental challenges. This is especially critical for suppliers from Europe, where stringent regulations are common.

Food Processing

In food processing, membrane keys are essential for control systems in processing equipment, allowing for easy operation while ensuring hygiene and cleanliness. The seamless design of membrane keys facilitates effective cleaning, minimizing downtime and maintaining operational efficiency. B2B buyers should look for IP-rated designs that offer protection against water and dust, as well as materials that comply with food safety regulations. This is particularly relevant for businesses operating in regions with strict health standards, such as the Middle East.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

Strategic Material Selection Guide for membrane keys

Membrane keys are integral components in various applications, and the choice of material significantly influences their performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the production of membrane keys, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Polyester (PET)

Key Properties:

Polyester is known for its excellent chemical resistance, flexibility, and durability. It can withstand temperatures up to 120°C and is resistant to moisture and UV light, making it suitable for outdoor applications.

Pros & Cons:

Polyester offers a balance of durability and cost, making it an economical choice for many applications. However, while it is robust, it can be prone to scratching and may not be the best choice for high-wear environments.

Impact on Application:

PET is compatible with various media, including water and oils, but may not withstand harsh chemicals. This makes it ideal for consumer electronics and moderate industrial use.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with local environmental regulations regarding material safety and recycling. Certifications such as RoHS and REACH are crucial for market entry.

2. Polycarbonate

Key Properties:

Polycarbonate is a high-performance plastic known for its impact resistance and optical clarity. It can handle temperatures up to 130°C and is often used in applications requiring transparency.

Pros & Cons:

This material is highly durable and resistant to breakage, making it suitable for demanding environments. However, polycarbonate can be more expensive than polyester and may yellow over time when exposed to UV light.

Impact on Application:

Polycarbonate is ideal for applications requiring clear graphics and high durability, such as medical devices and automotive dashboards. Its resistance to impact makes it a preferred choice in safety-critical environments.

Considerations for International Buyers:

B2B buyers should consider the material’s compliance with international standards such as ASTM and ISO for safety and performance. In regions with high UV exposure, additional coatings may be necessary to enhance longevity.

3. Conductive Inks (Silver, Carbon)

Key Properties:

Conductive inks, primarily silver or carbon-based, are critical for the functionality of membrane keys. Silver offers superior conductivity but is more expensive, while carbon is a cost-effective alternative with lower conductivity.

Pros & Cons:

Silver inks provide excellent performance in terms of conductivity and durability, but their higher cost can be a limiting factor for budget-sensitive projects. Carbon inks are more affordable but may not perform as well in high-frequency applications.

Impact on Application:

The choice of conductive ink impacts the responsiveness of the membrane key. Silver is often used in high-end applications, while carbon may suffice for less demanding uses.

Considerations for International Buyers:

Buyers should assess the availability of conductive inks in their region and consider the implications of sourcing materials from different suppliers. Compliance with electrical safety standards is also essential.

4. Adhesives (Acrylic, Silicone)

Key Properties:

Adhesives used in membrane keys can vary widely, with acrylic and silicone being popular choices. Acrylic adhesives offer good temperature resistance and adhesion strength, while silicone adhesives provide flexibility and high-temperature resistance.

Pros & Cons:

Acrylic adhesives are generally more cost-effective and provide strong bonds, but they may not perform well in extreme temperatures. Silicone adhesives excel in flexibility and temperature extremes but can be more expensive.

Impact on Application:

The choice of adhesive affects the overall durability and usability of the membrane key. Applications in extreme environments, such as outdoor equipment, may benefit from silicone adhesives.

Considerations for International Buyers:

It is crucial for buyers to understand the adhesive properties and ensure compatibility with local environmental regulations. Certifications for chemical resistance may also be required in certain markets.

Summary Table

| Material | Typical Use Case for membrane keys | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester (PET) | Consumer electronics, moderate industrial use | Good chemical resistance, economical | Prone to scratching | Low |

| Polycarbonate | Medical devices, automotive dashboards | High impact resistance, clarity | More expensive, potential UV yellowing | Medium |

| Conductive Inks | High-end applications, consumer electronics | Superior conductivity (silver) | Higher cost (silver), lower performance (carbon) | Medium/High |

| Adhesives (Acrylic, Silicone) | Outdoor equipment, flexible applications | Strong bonds, temperature resistance | Cost (silicone), performance limits (acrylic) | Medium/High |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions about membrane keys, ensuring compliance and performance across diverse applications.

In-depth Look: Manufacturing Processes and Quality Assurance for membrane keys

The manufacturing of membrane keys involves a series of well-defined stages, ensuring that the final product is durable, reliable, and tailored to specific applications. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures is crucial for making informed procurement decisions.

Manufacturing Processes for Membrane Keys

-

Material Preparation

– Selection of Materials: The manufacturing process begins with the careful selection of materials such as PET (polyethylene terephthalate), polycarbonate, and specialized conductive inks (silver, carbon, or copper). The choice of material significantly impacts the durability and functionality of the membrane keys.

– Pre-treatment Processes: Materials undergo pre-treatment processes to enhance adhesion and surface properties. This may include cleaning, chemical treatments, or applying primers to ensure optimal bonding during the printing and assembly stages. -

Forming

– Printing Layers: The production of membrane keys involves printing the various layers, including the graphic overlay and circuit layers. High-resolution printing techniques such as screen printing or digital printing are commonly used, allowing for intricate designs and branding elements to be incorporated.

– Layer Assembly: The printed layers are assembled, with the spacer layer placed between the upper and lower circuit layers. This assembly must be precise to prevent accidental activation of the keys. Techniques such as heat sealing or adhesive bonding are employed to ensure that the layers adhere correctly. -

Assembly

– Integration of Components: After layering, additional components such as tactile feedback mechanisms (e.g., metal domes) and backlighting elements (LEDs) are integrated. This step is crucial for enhancing user experience, especially in applications where tactile feedback is essential.

– Final Assembly: The assembled membrane key is then affixed to a backing material, which provides structural support. This backing can be made from materials like stainless steel or aluminum, depending on the application’s durability requirements.

Illustrative Image (Source: Google Search)

- Finishing

– Surface Treatment: Final surface treatments may include coatings for additional protection against wear, chemicals, and moisture. This is particularly important for applications in harsh environments, such as outdoor or industrial use.

– Quality Checks: Before the product is packaged, it undergoes a series of quality checks to ensure that it meets specified performance criteria and industry standards.

Quality Assurance in Membrane Key Manufacturing

Quality assurance (QA) is a critical aspect of membrane key manufacturing, ensuring that products meet both international standards and specific industry requirements. For B2B buyers, understanding these QA processes is essential for ensuring product reliability and performance.

-

International Standards

– ISO 9001 Certification: This globally recognized standard outlines the criteria for a quality management system. Manufacturers with ISO 9001 certification demonstrate their commitment to consistent quality and customer satisfaction.

– CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly relevant for medical devices and consumer electronics. -

Industry-Specific Standards

– API Standards: In industries such as oil and gas, adherence to American Petroleum Institute (API) standards is crucial for ensuring that products can withstand demanding operational environments.

– IEC Standards: The International Electrotechnical Commission (IEC) provides guidelines for electrical components, ensuring that membrane keys used in electrical applications meet safety and performance benchmarks. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to verify that they meet specified standards. Buyers should inquire about the supplier’s IQC processes to ensure material integrity.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, IPQC checks are performed at various stages to monitor production quality. This may include monitoring printing accuracy, layer alignment, and component integration.

– Final Quality Control (FQC): Once the membrane keys are fully assembled, they undergo FQC to assess functionality, durability, and compliance with design specifications. This final check is crucial for ensuring that all products are defect-free before shipment. -

Common Testing Methods

– Functional Testing: This involves simulating user interaction to ensure that the keys respond accurately and consistently. Testing for tactile feedback, responsiveness, and durability under various conditions is critical.

– Environmental Testing: Membrane keys are often subjected to environmental tests such as temperature cycling, humidity exposure, and chemical resistance to ensure they can withstand the conditions they will face in real-world applications.

– Electrical Testing: Conductive paths are checked for continuity and resistance to ensure proper functionality.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential for mitigating risks associated with procurement.

-

Supplier Audits

– Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality control systems. Buyers should request access to audit reports and certifications to confirm compliance with industry standards. -

Quality Reports

– Requesting comprehensive quality reports that detail testing results, defect rates, and corrective actions taken can help buyers assess a supplier’s commitment to quality. These reports should be updated regularly to reflect the current state of quality assurance. -

Third-Party Inspections

– Engaging third-party inspection services can provide an independent assessment of a supplier’s quality control processes. This is particularly beneficial for buyers unfamiliar with local manufacturing practices or standards. -

Understanding QC Nuances

– B2B buyers should be aware of regional differences in quality standards and practices. For example, some markets may have stricter regulations regarding environmental compliance or product safety. Familiarizing oneself with these nuances can help buyers make more informed decisions.

In summary, the manufacturing processes and quality assurance measures for membrane keys are critical factors that B2B buyers must consider. By understanding these processes, buyers can ensure that they source high-quality products that meet their specific needs and industry requirements, ultimately enhancing their competitive edge in the global marketplace.

Related Video: Water Quality Testing Methods

Comprehensive Cost and Pricing Analysis for membrane keys Sourcing

When sourcing membrane keys, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will break down the cost components, identify key price influencers, and provide actionable tips for negotiation and procurement.

Cost Components

-

Materials: The primary materials for membrane keys include graphic overlays (often polyester or polycarbonate), conductive inks (commonly silver or carbon), and spacer layers. The choice of materials significantly impacts the overall cost, with high-quality or specialized materials leading to higher prices.

-

Labor: Labor costs encompass the workforce involved in the design, assembly, and quality control of membrane keys. Regions with higher labor costs, such as Europe, may see increased pricing compared to regions in Africa or South America where labor may be more cost-effective.

-

Manufacturing Overhead: This includes costs associated with facility operations, utilities, and administrative expenses. Manufacturers with advanced technologies and stringent quality control processes may incur higher overhead costs, which can reflect in the pricing.

-

Tooling: Tooling costs arise from the need for specialized equipment and molds to produce membrane keys. These costs can be amortized over large production runs, making them less significant per unit for high-volume orders.

-

Quality Control (QC): Ensuring product reliability and compliance with standards incurs costs related to inspection and testing processes. Buyers should prioritize suppliers with robust QC measures, even if it means a slight increase in costs, to avoid issues in the field.

-

Logistics: Shipping and handling costs depend on the origin of the products and the destination market. Variability in logistics costs can stem from distance, transport mode, and local tariffs or duties, which can significantly affect the total cost of ownership.

-

Margin: Supplier margins can vary widely based on market positioning, brand reputation, and exclusivity of the product. Understanding the supplier’s pricing strategy can help buyers gauge fair pricing.

Price Influencers

-

Volume/MOQ: Bulk orders generally attract lower prices per unit due to economies of scale. Suppliers often have minimum order quantities (MOQs) that buyers must meet to benefit from volume pricing.

-

Specifications/Customization: Customized designs, such as unique overlays or specific tactile feedback features, can drive costs up. Buyers should clearly outline their needs to avoid unexpected charges.

-

Materials: The choice of materials influences not only the upfront cost but also durability and performance. Premium materials may increase initial costs but can lead to lower maintenance and replacement expenses.

-

Quality/Certifications: Products meeting industry standards or certifications (e.g., ISO, UL) may carry a higher price tag. However, these certifications can enhance product reliability and marketability.

-

Supplier Factors: The supplier’s reputation, location, and production capacity play a role in pricing. Established suppliers with proven track records may charge more but offer reliability and better service.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects the risk and cost-sharing between buyer and seller. Buyers should understand these terms to optimize shipping costs and responsibilities.

Buyer Tips

-

Negotiation: Engage suppliers early in the process to negotiate terms, especially for bulk orders. Leverage your purchasing power and explore potential discounts for long-term partnerships.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the purchase price. Evaluate long-term durability, maintenance, and potential replacements when assessing overall value.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and shipping costs that can affect pricing. Always request detailed quotes that include all potential fees.

-

Supplier Assessment: Conduct thorough assessments of potential suppliers, looking at their manufacturing capabilities, quality control processes, and previous client feedback to ensure they align with your standards.

Disclaimer

Pricing for membrane keys can vary significantly based on the factors outlined above. The figures mentioned are indicative and should be validated through direct engagement with suppliers for accurate and current pricing information.

Spotlight on Potential membrane keys Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘membrane keys’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for membrane keys

Membrane keys are integral components in various industries, offering a unique blend of functionality and design flexibility. Understanding their essential technical properties and common trade terminology is crucial for B2B buyers looking to make informed procurement decisions.

Key Technical Properties of Membrane Keys

-

Material Grade

– Membrane keys are typically constructed from materials like polyester, polycarbonate, or specialized conductive inks. The material choice affects durability, flexibility, and resistance to environmental factors. For instance, polyester is known for its strength and resistance to chemicals, making it suitable for industrial applications. Buyers should assess material grades based on their specific operational environments to ensure longevity and performance. -

Tolerance

– Tolerance refers to the permissible limits of variation in the dimensions of the membrane keys. A tight tolerance is critical in applications where precise alignment and functionality are essential, such as in medical devices. Inaccurate tolerances can lead to malfunction or reduced user experience. B2B buyers must ensure that suppliers can meet the required tolerances to avoid costly rework or product failures. -

Environmental Resistance

– This property indicates how well the membrane keys can withstand various environmental conditions, such as moisture, dust, and extreme temperatures. Membrane keys designed with IP ratings (Ingress Protection) can provide assurance against these elements. For manufacturers in outdoor or industrial sectors, environmental resistance is a key consideration to ensure operational reliability. -

Actuation Force

– Actuation force is the amount of pressure required to activate the membrane key. This specification is particularly important in applications requiring tactile feedback, such as industrial controls or medical devices. Buyers should evaluate the actuation force to ensure it aligns with user expectations and ergonomics, enhancing the overall user experience. -

Backlighting Options

– Many membrane keys can be equipped with backlighting features, which improve visibility in low-light environments. This is essential for applications in medical or automotive sectors where clear visibility is critical. Buyers should consider the types of backlighting available and how they can enhance product usability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of membrane keys, understanding OEM relationships can help buyers identify reliable suppliers who can provide customized solutions to meet specific application needs. -

MOQ (Minimum Order Quantity)

– MOQ denotes the smallest order size that a supplier is willing to accept. This term is crucial for B2B buyers to consider, as it can impact inventory management and cash flow. Knowing the MOQ helps buyers plan their procurement strategy effectively. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price proposals from suppliers for specific products or services. For membrane keys, an RFQ allows buyers to compare costs, lead times, and specifications from multiple suppliers, ensuring they make cost-effective decisions. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers involved in cross-border procurement, as it clarifies shipping responsibilities, risk management, and cost distribution. -

Lead Time

– Lead time is the duration from the placement of an order until the product is delivered. Understanding lead times for membrane keys helps buyers manage project timelines effectively and ensures that products arrive when needed to avoid delays in production.

By mastering these technical specifications and trade terms, international B2B buyers can optimize their procurement processes, ensuring that they select the best membrane keys for their specific applications while navigating the complexities of global sourcing.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the membrane keys Sector

Market Overview & Key Trends

The membrane keys market is experiencing robust growth driven by several global factors. One significant driver is the increasing demand for user-friendly interfaces in diverse sectors such as industrial automation, healthcare, and consumer electronics. As companies strive to enhance user experiences, membrane keys offer an attractive solution due to their flexibility, durability, and cost-effectiveness. Emerging trends include the adoption of touch-sensitive and backlit membrane keys, which cater to modern aesthetic preferences and functional requirements.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe must pay attention to the growing customization capabilities of membrane keys. As industries look for unique solutions tailored to specific applications, suppliers are investing in advanced manufacturing technologies that enable high levels of personalization. Furthermore, environmental resistance is becoming a priority, with membrane keys increasingly designed to withstand harsh conditions, which is particularly crucial for buyers in regions with extreme climates.

Another trend is the shift towards digital transformation, with many organizations adopting smart technologies that integrate membrane keys into IoT devices. This trend opens up new opportunities for B2B buyers to source innovative solutions that enhance connectivity and operational efficiency. Buyers should also be aware of the competitive landscape, as emerging markets are seeing an influx of local suppliers that can offer cost-effective alternatives without compromising quality.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial factor in the sourcing of membrane keys. The environmental impact of production processes and materials used in membrane key manufacturing has prompted buyers to seek suppliers committed to sustainable practices. Ethical sourcing is essential, as it not only enhances a company’s reputation but also aligns with the growing consumer demand for environmentally friendly products.

B2B buyers should prioritize suppliers that utilize green certifications and sustainable materials, such as recyclable substrates and non-toxic inks. Additionally, the adoption of life cycle assessments can help buyers understand the environmental footprint of membrane keys, guiding them toward more responsible purchasing decisions. Implementing eco-friendly manufacturing processes is also a key consideration, as it minimizes waste and energy consumption.

In regions like Europe, where regulatory frameworks are increasingly stringent regarding environmental standards, B2B buyers must ensure their supply chains comply with these regulations. By fostering partnerships with suppliers who prioritize sustainability, companies can not only reduce their environmental impact but also enhance their market positioning as leaders in responsible sourcing.

Brief Evolution/History

The evolution of membrane keys has been marked by significant technological advancements since their inception in the late 20th century. Initially developed for basic applications, membrane keys have transformed into sophisticated user interface components that meet the demands of modern electronics. The introduction of tactile feedback mechanisms and customizable overlays in the 1990s revolutionized their usability, making them essential in sectors requiring precision and reliability.

Over the past two decades, advances in materials science and manufacturing techniques have further enhanced the durability and functionality of membrane keys. This evolution has been driven by the need for interfaces that can withstand harsh environments while providing an aesthetically pleasing user experience. Today, membrane keys are integral to various applications, from industrial control systems to high-end consumer electronics, reflecting their adaptability and continuous innovation in response to market needs.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of membrane keys

-

What should I consider when vetting suppliers of membrane keys?

When vetting suppliers, assess their experience in the membrane key industry, particularly in your specific application area. Check for certifications such as ISO 9001, which indicate quality management practices. Request references and samples to evaluate product quality. Additionally, consider their manufacturing capabilities, lead times, and the flexibility to accommodate customization requests. It’s also wise to ensure the supplier has a robust logistics network to facilitate timely deliveries, especially for international trade. -

How customizable are membrane keys, and what factors influence customization?

Membrane keys are highly customizable in terms of design, materials, and functionality. You can tailor aspects like graphic overlays, tactile feedback, and environmental sealing based on your specific needs. Factors influencing customization include your industry requirements, user preferences, and branding elements. Discuss your needs with suppliers early in the process to ensure they can meet your specifications and timelines. Be aware that extensive customization may affect lead times and pricing. -

What are the typical minimum order quantities (MOQs) and lead times for membrane keys?

Minimum order quantities (MOQs) for membrane keys can vary significantly by supplier, often ranging from 100 to 1,000 units, depending on the complexity and customization level of the product. Lead times typically range from 2 to 8 weeks, contingent on the supplier’s production capacity and your order’s complexity. To ensure timely procurement, it is essential to communicate your requirements clearly and confirm lead times during the negotiation phase. -

What payment terms should I expect when sourcing membrane keys internationally?

Payment terms can vary, but common practices include partial upfront payments (30-50%) followed by the balance upon delivery or after receipt of goods. Some suppliers may offer letters of credit or escrow services for larger orders to mitigate risk. Always clarify payment methods, currencies, and any potential transaction fees associated with international payments. Establishing clear payment terms upfront helps prevent misunderstandings and builds trust with your supplier.

Illustrative Image (Source: Google Search)

-

What quality assurance measures should I look for in membrane key suppliers?

Look for suppliers that implement rigorous quality assurance (QA) protocols throughout the manufacturing process. This includes material inspection, in-process testing, and final product evaluations. Request documentation of QA practices, such as inspection reports and compliance certificates, to ensure products meet industry standards. Additionally, consider suppliers that offer warranties or guarantees on their products, as this can be an indicator of confidence in their quality. -

How can I navigate logistics challenges when sourcing membrane keys internationally?

To navigate logistics challenges, work with suppliers who have experience in international shipping and can provide support in customs clearance and documentation. Discuss shipping options and costs upfront to avoid unexpected fees. Consider using freight forwarders who specialize in international trade to streamline the shipping process. Additionally, be aware of potential delays due to customs or regulatory compliance, and factor these into your planning. -

What should I do if there is a dispute with a supplier over membrane keys?

If a dispute arises, start by addressing the issue directly with the supplier, ensuring clear communication about your concerns. Refer to the contract terms to support your position, and maintain a professional tone throughout the discussion. If a resolution cannot be reached, consider mediation or arbitration as alternatives to litigation. It’s beneficial to have a clear dispute resolution clause in your contracts to guide this process and minimize potential conflicts. -

What certifications are important for membrane keys, and how do they impact sourcing?

Important certifications for membrane keys include ISO 9001 for quality management, RoHS for hazardous substances, and UL or CE for safety compliance. These certifications assure buyers that the products meet specific quality and safety standards, which is crucial for industries like healthcare and automotive. When sourcing, verify that suppliers can provide documentation for these certifications, as they can significantly impact your product’s acceptance in regulated markets and enhance your credibility with customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for membrane keys

In conclusion, the strategic sourcing of membrane keys presents a significant opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Understanding the intricacies of membrane switch technology—from tactile feedback to environmental sealing—enables buyers to select solutions that enhance user experience while ensuring durability and performance in demanding applications.

Key takeaways include the importance of customization in design, the selection of appropriate materials for specific environments, and the need for robust supplier partnerships to guarantee quality and reliability. By prioritizing strategic sourcing, businesses can not only optimize operational efficiency but also gain a competitive edge in their respective markets.

Looking ahead, the market for membrane keys is poised for growth, driven by advancements in technology and increasing demand for user-friendly interfaces. International B2B buyers are encouraged to leverage this momentum by actively engaging with suppliers and exploring innovative solutions that meet their unique requirements. By making informed sourcing decisions now, companies can position themselves for long-term success in an evolving global landscape.