Your Ultimate Guide to Sourcing Door Spring Hinge

Introduction: Navigating the Global Market for door spring hinge

In the ever-evolving landscape of global commerce, the door spring hinge stands out as a crucial component in a multitude of applications—from residential doors to industrial machinery. These small yet mighty mechanisms are essential for ensuring functionality, safety, and durability, making them a focal point for international B2B buyers. As the global hinge market is projected to reach $27.3 billion by 2033, understanding the dynamics of door spring hinges becomes imperative for businesses looking to optimize their supply chains and enhance product offerings.

This comprehensive guide delves into the intricacies of door spring hinges, exploring various types—including concealed, continuous, and adjustable models—as well as the materials used in their production, such as stainless steel and brass. We will also cover manufacturing practices and quality control standards that ensure reliability and performance in demanding environments. Additionally, an overview of reputable suppliers across regions—including Africa, South America, the Middle East, and Europe (notably Turkey and Poland)—will empower buyers to make informed sourcing decisions.

By addressing key factors such as cost considerations, market trends, and frequently asked questions, this guide serves as a vital resource for B2B buyers aiming to navigate the complexities of the global market. Equip yourself with the knowledge to make strategic decisions that enhance your business operations and foster successful partnerships in the door spring hinge industry.

Understanding door spring hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Continuous Spring Hinge | Long, continuous design; provides uniform support | Heavy doors, industrial applications | Pros: High strength, durability; Cons: More expensive than standard hinges. |

| Piano Hinge | Long, narrow hinge; allows for full rotation | Pianos, cabinets, and doors | Pros: Even weight distribution; Cons: Requires precise installation. |

| Self-Closing Hinge | Automatically closes the door after use | Commercial entry doors, cabinets | Pros: Convenience, enhances security; Cons: Can wear out over time. |

| Spring Loaded Hinge | Integrated spring mechanism for smooth operation | Heavy-duty doors, gates | Pros: Reduces slamming; Cons: Potential for mechanical failure. |

| Double Action Hinge | Allows doors to swing both ways | Restaurant and café doors | Pros: Easy access from both sides; Cons: Limited to lighter doors. |

Continuous Spring Hinge

Continuous spring hinges feature a long, continuous design that spans the entire height of the door. This design provides uniform support and is particularly suitable for heavy doors in industrial applications. When considering this hinge type, buyers should evaluate the door weight and frequency of use, as these factors directly influence durability and performance. While they offer exceptional strength and longevity, the cost can be higher compared to standard hinges, making them a significant investment for businesses.

Piano Hinge

Piano hinges, also known as continuous hinges, are long and narrow, allowing for full rotation. This type is commonly used in pianos, cabinets, and various door applications. Their even weight distribution makes them ideal for heavier doors, but they require precise installation to function correctly. B2B buyers should assess installation capabilities and the specific application needs, as the investment in piano hinges can lead to enhanced durability and performance in high-use environments.

Self-Closing Hinge

Self-closing hinges automatically close a door after it has been opened, making them ideal for commercial entry doors and cabinets. Their convenience enhances security and energy efficiency by ensuring that doors remain closed when not in use. Buyers should consider the frequency of door usage and the potential for wear over time, as these hinges may require replacement or maintenance. While they offer significant advantages, the longevity and effectiveness depend on the quality of the hinge and the conditions in which it operates.

Spring Loaded Hinge

Spring loaded hinges come equipped with an integrated spring mechanism that allows for smooth operation and helps prevent slamming. They are particularly suitable for heavy-duty doors and gates, where a gentle closing action is desired. When purchasing spring loaded hinges, buyers should evaluate the potential for mechanical failure, especially in high-traffic areas. Although they provide a level of convenience and safety, understanding the maintenance needs and load capacities is crucial for ensuring long-term functionality.

Double Action Hinge

Double action hinges allow doors to swing both ways, providing easy access from either side. This feature is particularly beneficial in high-traffic environments such as restaurants and cafes. While they facilitate quick movement, they are generally limited to lighter doors due to structural constraints. B2B buyers should consider the specific application and door weight when selecting this hinge type, as the benefits of convenience and accessibility must be balanced against the limitations in door design and material.

Related Video: Justor Double Action Spring Hinge Installation

Key Industrial Applications of door spring hinge

| Industry/Sector | Specific Application of door spring hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Commercial and residential door installations | Ensures smooth operation and durability of doors, enhancing security and accessibility. | Look for high-quality materials (e.g., stainless steel), and consider local regulations for safety. |

| Manufacturing | Machinery access panels | Facilitates easy access for maintenance, reducing downtime and improving operational efficiency. | Assess load capacity and corrosion resistance based on the environment. |

| Transportation | Vehicle doors (e.g., buses, trucks) | Enhances user safety and ease of use, contributing to a better customer experience. | Evaluate compliance with safety standards and durability under varying conditions. |

| Retail | Storefront glass doors | Provides a seamless entry and exit experience, attracting customers and improving foot traffic. | Consider aesthetic appeal alongside functionality, and ensure compatibility with existing door designs. |

| Healthcare | Hospital room doors | Ensures quick access for medical staff while maintaining patient privacy and safety. | Prioritize hinges that allow for easy cleaning and are resistant to wear from frequent use. |

Detailed Applications of Door Spring Hinges

Construction

In the construction industry, door spring hinges are critical for both commercial and residential door installations. These hinges provide smooth operation and durability, ensuring that doors can withstand daily use while enhancing security and accessibility. For international buyers, especially from Africa and South America, sourcing hinges that comply with local building codes and regulations is essential. Additionally, selecting high-quality materials, such as stainless steel, can prevent rust and extend the lifespan of the hinges in varying climates.

Manufacturing

In manufacturing settings, door spring hinges are often used on access panels of machinery. These hinges facilitate easy access for maintenance, which is vital for reducing downtime and improving operational efficiency. Buyers should assess the load capacity and corrosion resistance of the hinges, particularly in environments where exposure to harsh chemicals is common. International buyers should also consider suppliers that offer customization to meet specific machinery requirements.

Transportation

The transportation sector utilizes door spring hinges in vehicle doors, including buses and trucks. These hinges enhance user safety and ease of use, contributing to a better overall customer experience. When sourcing hinges for transportation applications, it’s crucial to evaluate compliance with safety standards specific to different regions, including the Middle East and Europe. Additionally, durability under varying weather conditions should be a top consideration to ensure long-term performance.

Retail

In the retail sector, door spring hinges are commonly applied to storefront glass doors. These hinges provide a seamless entry and exit experience, which is essential for attracting customers and improving foot traffic. Buyers should consider the aesthetic appeal of the hinges alongside their functionality, ensuring that they complement the overall design of the storefront. Compatibility with existing door designs is also crucial for international buyers looking to upgrade or replace existing systems.

Healthcare

Healthcare facilities rely on door spring hinges for hospital room doors, which must balance quick access for medical staff with patient privacy and safety. These hinges ensure that doors can be opened easily while maintaining a secure environment. When sourcing hinges for healthcare applications, it’s important to prioritize those that allow for easy cleaning and are resistant to wear from frequent use. Buyers from Europe and the Middle East should also consider regulatory compliance for healthcare settings.

Strategic Material Selection Guide for door spring hinge

When selecting materials for door spring hinges, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in door spring hinges, highlighting their properties, advantages, disadvantages, and implications for specific markets.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high tensile strength, and the ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°F (427°C) and performs well under high-pressure conditions.

Pros & Cons:

Stainless steel is highly durable and suitable for both indoor and outdoor applications. However, it can be more expensive than other materials, and its manufacturing process may require specialized equipment, increasing production complexity.

Impact on Application:

Due to its corrosion resistance, stainless steel is ideal for environments exposed to moisture, such as coastal areas or regions with high humidity. It is compatible with a variety of media, including chemicals and cleaning agents.

Considerations for International Buyers:

Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with standards like ASTM A240 for stainless steel products. It is also essential to consider local sourcing options to mitigate costs associated with import tariffs.

Brass

Key Properties:

Brass is known for its excellent machinability and resistance to corrosion, particularly in humid environments. It has a moderate temperature rating, generally up to 300°F (149°C).

Pros & Cons:

Brass hinges are aesthetically pleasing and often used in decorative applications. However, they may not be as durable as stainless steel and can tarnish over time, requiring maintenance. The cost of brass is generally moderate, but its availability can vary by region.

Impact on Application:

Brass is well-suited for applications where appearance is important, such as residential doors. However, it may not be the best choice for heavy-duty industrial applications due to its lower strength compared to stainless steel.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of brass, especially in regions with strict environmental standards. Compliance with standards such as ASTM B36 for brass products is crucial.

Plastic (Polymer)

Key Properties:

Plastic hinges are lightweight, resistant to corrosion, and can operate effectively in a wide range of temperatures, typically from -40°F to 200°F (-40°C to 93°C).

Pros & Cons:

Plastic hinges are cost-effective and easy to manufacture, making them suitable for high-volume applications. However, they may not offer the same strength and durability as metal options, limiting their use in heavy-duty applications.

Impact on Application:

Plastic hinges are ideal for environments where moisture is prevalent, such as bathrooms or outdoor settings. They are also compatible with a variety of media, including water and some chemicals.

Considerations for International Buyers:

Buyers should check for compliance with specific plastic material standards, such as ASTM D638 for tensile properties. Additionally, they should consider the environmental impact of plastic and look for suppliers that offer recyclable options.

Aluminum

Key Properties:

Aluminum is lightweight, resistant to corrosion, and has a temperature rating of up to 400°F (204°C). It is also known for its good strength-to-weight ratio.

Pros & Cons:

Aluminum hinges are durable and suitable for various applications, including both residential and commercial. However, they can be more expensive than plastic and may require protective coatings to enhance corrosion resistance.

Impact on Application:

Aluminum is often used in applications where weight is a concern, such as in aircraft or automotive doors. It is compatible with many media but may not be suitable for highly corrosive environments without additional treatment.

Considerations for International Buyers:

Compliance with standards such as ASTM B221 for aluminum extrusions is vital. Buyers should also consider the availability of aluminum in their region, as supply chains can vary significantly.

Summary Table

| Material | Typical Use Case for door spring hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor and industrial applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Decorative residential doors | Aesthetic appeal | Tarnishes and less durable | Medium |

| Plastic (Polymer) | Moisture-prone environments | Lightweight and cost-effective | Lower strength | Low |

| Aluminum | Lightweight commercial applications | Good strength-to-weight ratio | Requires protective coatings | Medium |

This guide provides a comprehensive overview of material options for door spring hinges, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for door spring hinge

The manufacturing of door spring hinges involves a series of well-defined processes that ensure both functionality and durability. Understanding these processes is critical for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. This section provides insights into the typical manufacturing stages, quality assurance measures, and how buyers can effectively assess supplier capabilities.

Manufacturing Processes

1. Material Preparation

The manufacturing process begins with the selection of raw materials, which typically include high-strength metals like stainless steel, brass, or carbon steel. These materials are chosen based on their mechanical properties and corrosion resistance.

- Material Sourcing: Buyers should prioritize suppliers that source materials from reputable mills with certifications.

- Preparation Techniques: Sheets or bars of metal are cut to size using methods such as laser cutting or shearing. This precision ensures that the components fit together correctly during assembly.

2. Forming

Once the materials are prepared, the next stage is forming, which shapes the components into their final design.

- Techniques Used:

- Stamping: A common method where metal sheets are stamped into specific shapes, creating the hinge’s leaves.

- Bending: This process shapes the metal into the desired angles, crucial for the hinge’s operation.

- Machining: Additional machining processes may be employed to create holes for the pin or to refine dimensions.

3. Assembly

After forming, the components are assembled. This stage includes the following steps:

- Component Alignment: Ensuring that all parts fit together accurately.

- Pin Insertion: The hinge pin, which allows rotation, is inserted. This step is vital for ensuring smooth operation.

- Welding or Riveting: Depending on the design, components may be welded or riveted for strength.

4. Finishing

The final stage involves surface treatment and finishing processes to enhance durability and appearance.

- Surface Treatments:

- Plating: Zinc or chrome plating is often applied for corrosion resistance.

- Powder Coating: This provides a durable finish that can be customized in various colors.

- Inspection: Each hinge undergoes a visual and dimensional inspection to ensure it meets specifications.

Quality Assurance

Quality assurance is crucial in ensuring that door spring hinges meet international standards and customer expectations. The following outlines key quality control measures.

1. International Standards Compliance

Suppliers should adhere to internationally recognized quality standards:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health and safety standards.

- API Standards: For hinges used in specific industries like oil and gas, compliance with API standards may be required.

2. Quality Control Checkpoints

Quality control is implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help catch defects early.

- Final Quality Control (FQC): Finished products undergo comprehensive testing, including functionality tests and dimensional checks.

3. Common Testing Methods

Testing methods are essential to verify the durability and performance of the hinges:

- Load Testing: Ensures the hinge can withstand specified weight and stress.

- Corrosion Testing: Assesses the hinge’s resistance to environmental factors.

- Cycle Testing: Evaluates the hinge’s performance over repeated use to ensure longevity.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control measures is paramount. Here are some actionable steps:

- Conduct Audits: Regular audits of suppliers can reveal their adherence to quality standards and manufacturing processes.

- Request Quality Reports: Buyers should ask for detailed quality reports that document the results of inspections and tests performed on the hinges.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality processes and products.

Quality Certification Nuances for International Buyers

When sourcing door spring hinges internationally, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should consider the following nuances:

- Regional Standards: Different countries may have specific standards. Familiarize yourself with local regulations that may affect product compliance.

- Language Barriers: Ensure that all quality documentation is available in a language you understand to avoid misinterpretation of quality standards.

- Cultural Differences: Be aware of cultural differences in business practices that may impact negotiations and supplier relationships.

Conclusion

Understanding the manufacturing processes and quality assurance measures for door spring hinges is essential for international B2B buyers. By focusing on the manufacturing stages, compliance with international standards, and effective verification methods, buyers can ensure they partner with reliable suppliers capable of delivering high-quality products that meet their specific needs. This knowledge empowers buyers to make informed decisions, ultimately enhancing their supply chain and operational efficiency.

Related Video: How Millions of Door Hinges are Produced in a Chinese Stainless Steel Factory

Comprehensive Cost and Pricing Analysis for door spring hinge Sourcing

Understanding Cost Structure for Door Spring Hinges

When sourcing door spring hinges, it’s essential to understand the various cost components that contribute to the final price. The main cost components include:

- Materials: The choice of materials significantly affects the overall cost. Common materials for door spring hinges include stainless steel, brass, and plastic. Stainless steel tends to be more expensive due to its durability and resistance to corrosion.

- Labor: Labor costs can vary based on the region and the complexity of the manufacturing process. Skilled labor is often required for high-quality hinges, which can increase costs.

- Manufacturing Overhead: This includes expenses related to factory utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can help reduce overhead costs.

- Tooling: Initial tooling costs for custom hinges can be substantial. Buyers should consider these costs when evaluating quotes, especially for low-volume orders.

- Quality Control (QC): Rigorous quality checks are essential for ensuring product reliability. Implementing a robust QC process incurs additional costs but is crucial for maintaining standards.

- Logistics: Shipping costs can vary widely based on distance, weight, and shipping method. International buyers should factor in customs duties and taxes, which can add to overall expenses.

- Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers negotiate better.

Key Price Influencers

Several factors can influence the pricing of door spring hinges:

- Volume/MOQ: Suppliers often have minimum order quantities (MOQs). Higher order volumes can lead to lower per-unit costs due to economies of scale.

- Specifications/Customization: Custom designs or specific functionalities can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

- Materials Quality/Certifications: Premium materials and certifications (like ISO or CE) can enhance product reliability but may also increase the price.

- Supplier Factors: The reputation and location of suppliers can affect pricing. Established suppliers with strong quality records might charge more but offer better reliability.

- Incoterms: The chosen Incoterms (International Commercial Terms) will dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting total costs.

Buyer Tips for Cost Efficiency

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can benefit from several strategies:

- Negotiation: Always negotiate pricing, especially for large orders. Suppliers may offer discounts for bulk purchases or long-term contracts.

- Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. Consider factors like maintenance, replacement, and logistics to understand the true cost.

- Pricing Nuances: Be aware that prices can vary significantly based on regional economic conditions, exchange rates, and local demand. Conduct market research to understand typical price ranges in your region.

- Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, improved service, and priority during high-demand periods. Regular communication can also help in negotiating favorable terms.

- Review Multiple Quotes: Always obtain multiple quotes to compare pricing and terms. This practice not only helps in finding the best deal but also provides leverage during negotiations.

Disclaimer

Prices for door spring hinges can vary widely based on the factors mentioned above. This analysis provides indicative information and should be supplemented with current market research to obtain accurate pricing.

Spotlight on Potential door spring hinge Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘door spring hinge’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for door spring hinge

Key Technical Properties of Door Spring Hinges

When sourcing door spring hinges, understanding their technical specifications is crucial for ensuring optimal performance and durability. Here are some essential properties to consider:

-

Material Grade

The material used in door spring hinges typically includes stainless steel, brass, or zinc-plated steel. Stainless steel is favored for its corrosion resistance, making it suitable for humid environments. Brass offers aesthetic appeal and is often used in decorative applications. Selecting the appropriate material ensures longevity and performance, particularly in outdoor or industrial settings. -

Load Capacity

This specification indicates the maximum weight the hinge can support without failure. Load capacity is critical for applications involving heavy doors or gates, as inadequate support can lead to malfunction or safety hazards. B2B buyers should assess the weight of the door and select hinges that exceed this requirement. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions. For door spring hinges, tight tolerances are important to ensure proper alignment and function. Poor tolerance can result in uneven wear or failure, affecting the door’s operation. Understanding tolerance levels helps buyers select hinges that fit precisely within their applications. -

Spring Force

This property measures the strength of the spring mechanism within the hinge. It is essential for doors that need to close automatically. The right spring force ensures that the door operates smoothly and returns to a closed position without excessive noise or effort. B2B buyers must consider the application requirements to choose the correct force rating. -

Finish Type

The finish of a door spring hinge can influence both aesthetics and functionality. Common finishes include polished, brushed, or powder-coated options. The finish not only impacts the visual appeal but also offers additional protection against wear and corrosion, making it a key consideration in B2B purchasing decisions.

Common Trade Terminology

Familiarity with industry jargon can streamline communication and negotiations in the B2B space. Here are several key terms relevant to door spring hinges:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the hinge industry, buyers often engage with OEMs to procure hinges that meet specific design or performance criteria, ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively. Suppliers may impose MOQs based on production costs, so negotiating favorable terms can benefit both parties. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to request pricing and availability from suppliers. It is a critical step in the procurement process, allowing buyers to compare options and negotiate terms. A well-structured RFQ can expedite sourcing and enhance decision-making.

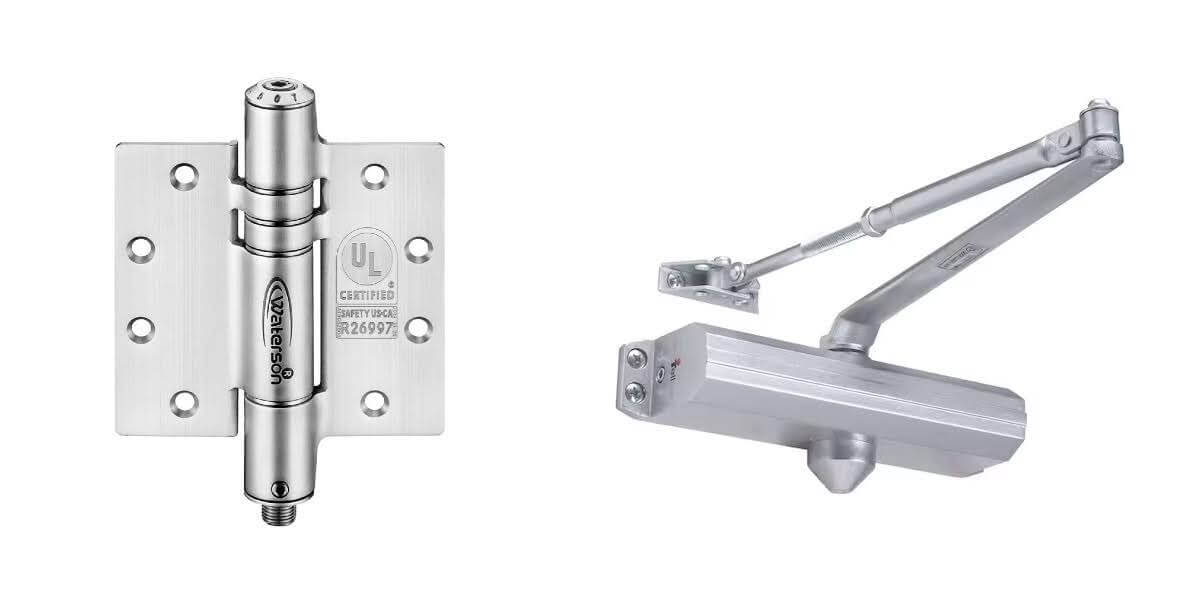

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

Incoterms are a set of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping, insurance, and delivery obligations, minimizing misunderstandings. -

Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. In the context of door spring hinges, it is vital for project planning and inventory management. Buyers should assess lead times when sourcing to ensure timely project completion. -

Certification Standards

These are quality assurance benchmarks that products must meet to ensure safety and reliability. Common certifications for door spring hinges include ISO 9001 and ANSI standards. Understanding certification requirements helps buyers ensure compliance and quality assurance in their procurement process.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing door spring hinges, ultimately enhancing their procurement strategies and operational efficiencies.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the door spring hinge Sector

Market Overview & Key Trends

The global door spring hinge market is poised for substantial growth, with projections indicating an increase from $12.5 billion in 2024 to $27.3 billion by 2033, reflecting a robust CAGR of 9.2%. This growth is primarily driven by increasing demand for automation and enhanced functionalities in construction and manufacturing sectors. In regions such as Africa, South America, the Middle East, and Europe (notably Turkey and Poland), the trend toward smart buildings and energy-efficient designs is influencing sourcing strategies. Buyers should be aware of the rising emphasis on high-performance, heavy-duty hinges that can withstand varying environmental conditions and mechanical stress.

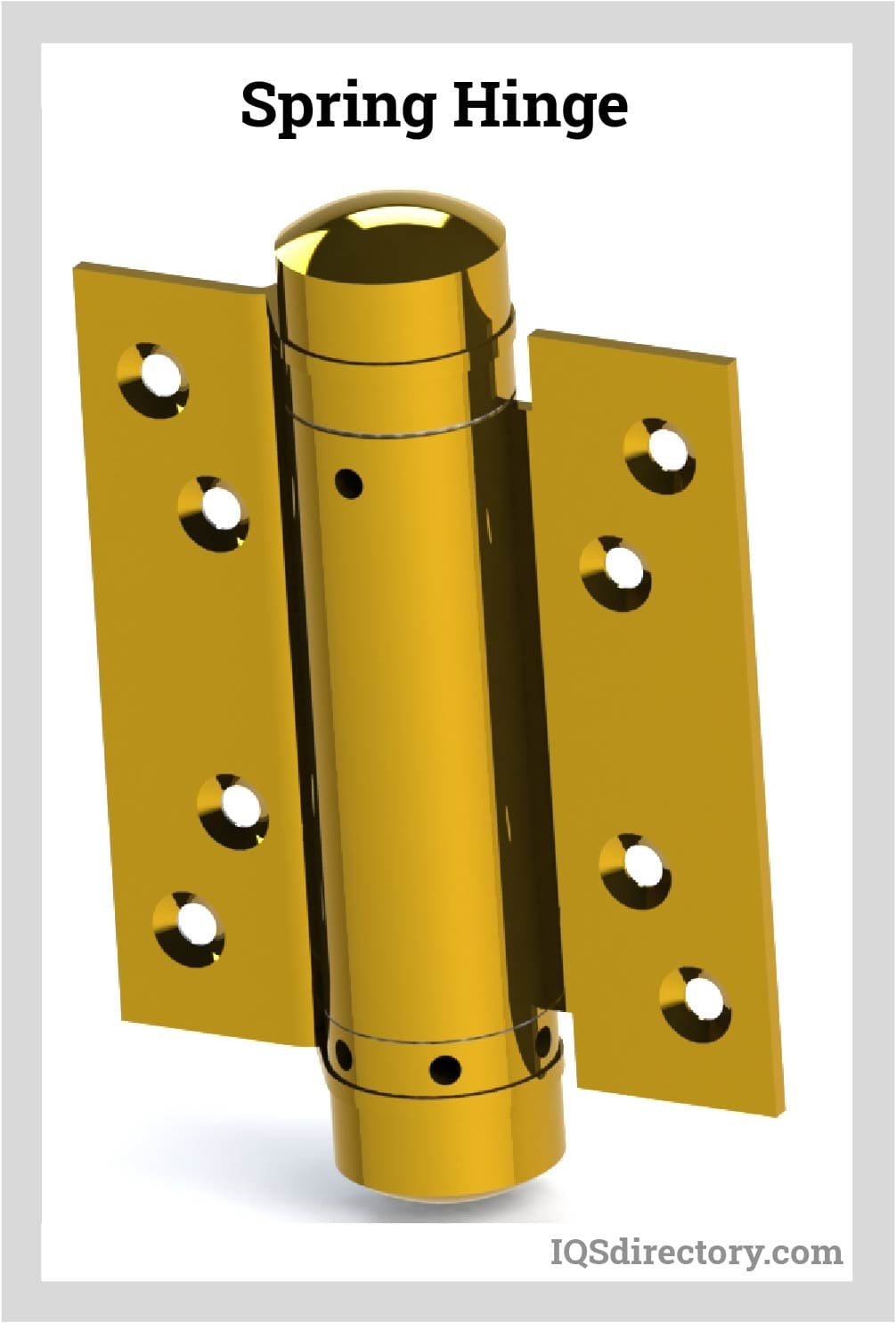

Illustrative Image (Source: Google Search)

Emerging technologies such as IoT and AI are shaping the sourcing landscape, allowing for better inventory management and predictive analytics. B2B buyers are encouraged to leverage platforms that provide real-time data on hinge performance and supplier capabilities. Additionally, the trend of customization is gaining traction, with manufacturers offering tailored solutions that meet specific client requirements, thereby enhancing operational efficiency. Understanding these dynamics will enable buyers to make informed sourcing decisions that align with their operational goals and market needs.

Sustainability & Ethical Sourcing in B2B

As global awareness of environmental issues grows, sustainability has become a crucial factor in the sourcing of door spring hinges. The production of these components can have significant environmental impacts, including resource depletion and waste generation. B2B buyers must prioritize suppliers who implement sustainable practices, such as using recycled materials and minimizing waste throughout their manufacturing processes.

Ethical sourcing is equally important. Suppliers should demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices meet international standards. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable wood products can provide buyers with assurance of a supplier’s commitment to sustainability. Additionally, opting for hinges made from eco-friendly materials, like biodegradable plastics or sustainably sourced metals, can significantly reduce a company’s carbon footprint and contribute positively to its corporate social responsibility (CSR) initiatives.

Brief Evolution/History

The door spring hinge has evolved significantly since its inception, adapting to technological advancements and changing market demands. Initially used in basic mechanical applications, these hinges have transformed into sophisticated components integral to modern architecture and design. The introduction of materials such as stainless steel and advanced polymers has enhanced their durability and functionality, allowing for smoother operation and greater load-bearing capacities. Today, the emphasis on automation and smart technology integration continues to drive innovations in hinge design, making them essential components in various industries, from construction to automotive.

By understanding these trends and historical contexts, international B2B buyers can navigate the complexities of the door spring hinge market more effectively, ensuring that their sourcing decisions align with both current demands and future innovations.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of door spring hinge

-

What factors should I consider when vetting suppliers of door spring hinges?

When vetting suppliers, assess their experience and reputation in the industry. Look for certifications like ISO 9001, which indicate adherence to quality standards. Client testimonials and case studies can provide insights into their reliability and customer service. Additionally, consider their production capacity and delivery timelines to ensure they can meet your demands. Engaging in a preliminary conversation can also help gauge their responsiveness and willingness to meet your specific needs. -

Can I customize door spring hinges to fit my specific requirements?

Many suppliers offer customization options for door spring hinges, including dimensions, materials, and finishes. When discussing customization, clearly outline your specifications and desired applications. Request samples to ensure the product meets your expectations before placing a larger order. Be aware that customized products may have longer lead times and could affect pricing, so it’s essential to discuss these details upfront. -

What are the typical minimum order quantities (MOQs) and lead times for door spring hinges?

MOQs can vary significantly based on the supplier and the complexity of the product. Generally, standard products may have lower MOQs, while customized hinges may require larger orders. Lead times are influenced by factors such as production schedules, material availability, and shipping logistics. It’s advisable to confirm these details early in the negotiation process to align your purchasing strategy with the supplier’s capabilities. -

What payment terms should I expect when sourcing door spring hinges internationally?

Payment terms can vary widely depending on the supplier’s policies and the nature of the transaction. Common terms include advance payment, net 30, or letter of credit for larger orders. Always clarify payment methods accepted, as some suppliers may only deal in specific currencies. Consider using escrow services for added security, especially when working with new suppliers, to mitigate risks associated with international transactions. -

How can I ensure the quality of door spring hinges before finalizing my purchase?

To ensure quality, request certifications and test reports from suppliers that demonstrate compliance with relevant standards. Conducting a factory audit or utilizing third-party inspection services can also provide assurance. Establish a quality assurance (QA) process that includes specific acceptance criteria for the hinges. Additionally, consider negotiating for a trial order to evaluate the hinges’ performance before committing to larger quantities. -

What logistics considerations should I keep in mind when importing door spring hinges?

Logistics play a crucial role in the import process. Factor in shipping methods, which can affect costs and delivery times, and consider using freight forwarders to navigate customs regulations. Be aware of any import duties and tariffs that may apply to your order. Establish clear communication with your supplier regarding shipping schedules and documentation to avoid delays and ensure a smooth import process. -

How should I handle disputes with suppliers of door spring hinges?

Dispute resolution should start with clear communication. Document all agreements and interactions to have a record if issues arise. If a dispute occurs, attempt to resolve it amicably through negotiation. Should this fail, refer to the contractual agreements regarding dispute resolution, which may include mediation or arbitration. Maintaining a professional relationship can often lead to better outcomes, so approach conflicts with a collaborative mindset. -

Are there specific certifications I should look for when sourcing door spring hinges?

Yes, certifications are essential indicators of product quality and compliance. Look for ISO 9001 for general quality management and ISO 14001 for environmental management. If the hinges are intended for specific applications, such as food or pharmaceuticals, additional certifications like FDA approval or CE marking may be required. Understanding the certifications relevant to your industry can help you select suppliers that align with your quality and compliance needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for door spring hinge

In conclusion, the strategic sourcing of door spring hinges is pivotal for international B2B buyers looking to enhance operational efficiency and product quality. The growing global hinge market, projected to reach $27.3 billion by 2033, underscores the importance of selecting high-performance and durable solutions tailored to diverse applications. Buyers should prioritize suppliers that demonstrate robust quality certifications and the ability to customize products to meet specific needs, especially in demanding environments.

Moreover, leveraging platforms like Thomasnet can facilitate easier access to a wide range of suppliers, helping businesses in Africa, South America, the Middle East, and Europe identify reliable partners. As the market evolves, staying informed about emerging trends and innovations in hinge design and manufacturing will be crucial for maintaining a competitive edge.

As you navigate your sourcing strategy, consider the long-term benefits of establishing strong supplier relationships. Invest in partnerships that align with your operational goals and sustainability practices. The future of door spring hinges holds exciting possibilities; take proactive steps today to secure your position in this dynamic market. Engage with suppliers and explore new technologies to ensure your offerings remain at the forefront of industry standards.