Top 30 Anodized Aluminium Manufacturers You Should Know

Are you overwhelmed by the search for the perfect anodized aluminum supplier? With so many options out there, it’s easy to feel lost. The right manufacturer can make all the difference in quality, durability, and cost-effectiveness of your projects. Imagine having a reliable partner that consistently delivers top-notch products, ensuring your projects shine. Choosing a leading factory not only boosts your reputation but also enhances your bottom line.

In this article, we’ll explore the top 30 anodized aluminum manufacturers, giving you insights to make an informed choice. Ready to streamline your search and elevate your projects? Let’s dive in!

Top 30 Anodized Aluminium Manufacturers

Lorin – Anodized Aluminum Solutions

Domain: lorin.com

Registered: 1996 ( 29 years )

Introduction: Anodized aluminum products that enhance durability and aesthetic appeal.

Wikihow – Aluminum Anodizing Services

Domain: wikihow.com

Registered: 2004 ( 21 years )

Introduction: Anodizing services for aluminum products.

Sheffield Metals – Anodized Aluminum Solutions

Domain: sheffieldmetals.com

Registered: 1998 ( 27 years )

Introduction: Anodized aluminum, a durable and lightweight metal, enhanced through an electrochemical process that grows a protective oxide layer from the aluminum itself.

Vivaacp – Anodized Aluminium Solutions

Domain: vivaacp.com

Registered: 2020 ( 5 years )

Introduction: The company primarily offers a variety of anodized aluminium products, including Aluminium Composite Panels (ACP), Zinc Composite Panels, Copper Aluminium Panels, Solid Aluminium Sheets, Honey Comb Panels, Louvers, Rainscreen Systems, and Color Coated Aluminium Coils.

Valence Surface Tech – Aluminum Anodizing Services

Domain: valencesurfacetech.com

Registered: 2014 ( 11 years )

Introduction: The company offers anodizing services for aluminum components, enhancing their properties and appearance through the formation of a durable oxide layer.

Gabrian – Anodized Aluminum Solutions

Domain: gabrian.com

Registered: 2000 ( 25 years )

Introduction: Anodized aluminum products that provide corrosion protection and aesthetic finishes.

Xometry – Aluminum Anodizing Services

Domain: xometry.com

Registered: 2015 ( 10 years )

Introduction: Aluminum anodizing services for enhancing the durability and aesthetics of aluminum parts.

Runsom – Aluminum Anodizing Services

Domain: runsom.com

Registered: 2011 ( 14 years )

Introduction: The company offers anodizing services for aluminum, enhancing its properties for various applications.

Shop – Anodized Aluminum Solutions

Domain: shop.machinemfg.com

Registered: 2017 ( 8 years )

Introduction: Anodized aluminum, created through an electrochemical process that enhances its durability, corrosion resistance, and aesthetic appeal by thickening its natural oxide layer.

Anodizing – Aluminum Anodization Services

Domain: anodizing.eu

Registration year: Not available

Introduction: The company offers aluminum anodization services, which enhance the natural oxide layer on aluminum to improve its strength, corrosion resistance, and aesthetic appeal.

Madearia – Aluminum Anodising Solutions

Domain: madearia.com

Registered: 2017 ( 8 years )

Introduction: Aluminum anodising is an electrochemical process that enhances the natural oxide layer on aluminum surfaces, providing corrosion resistance, durability, and aesthetic versatility.

Scienceinfo – Aluminum Anodizing Services

Domain: scienceinfo.com

Registered: 2002 ( 23 years )

Introduction: Aluminum anodizing services for enhancing the durability and aesthetic appeal of aluminum products.

Rapiddirect – Aluminum Anodizing Solutions

Domain: rapiddirect.com

Registered: 2010 ( 15 years )

Introduction: Aluminum anodizing is an electrochemical process that coats aluminum parts with a layer of hard, corrosion-resistant, and wear-resistant aluminum oxide, enhancing durability, corrosion resistance, and aesthetics.

Diecastor – Anodized Aluminum Enhancements

Domain: diecastor.com

Registered: 2021 ( 4 years )

Introduction: Anodized aluminum products that enhance surface properties for durability, corrosion resistance, and aesthetic appeal.

Matweb – Aluminum Anodizing Solutions

Domain: matweb.com

Registered: 1997 ( 28 years )

Introduction: The company offers aluminum anodizing, hardcoat anodizing, and chemical conversion coatings for aluminum surfaces.

Wevolver – Aluminum Anodizing Services

Domain: wevolver.com

Registered: 2004 ( 21 years )

Introduction: Anodizing services for aluminum products.

Makeitfrommetal – Home Anodizing Guide

Domain: makeitfrommetal.com

Registered: 2018 ( 7 years )

Introduction: The company offers a guide on how to anodize aluminum at home, providing detailed instructions and necessary equipment for the process.

SendCutSend – In-House Anodizing Services for Aluminum

Domain: sendcutsend.com

Registered: 2015 ( 10 years )

Introduction: SendCutSend offers in-house anodizing services for aluminum parts, along with guidance for DIY anodizing.

Metalfixes – Black Anodizing Services for Aluminum

Domain: metalfixes.com

Registered: 2023 ( 2 years )

Introduction: Black anodizing services for aluminum products.

Easiahome – Anodizing and Aluminum Solutions

Domain: easiahome.com

Registered: 2021 ( 4 years )

Introduction: Easiahome specializes in anodizing aluminum products, offering a range of services including investment casting, CNC machining, and finishing manufacturing. Their products cater to various industries such as construction, automotive, marine, and medical devices.

Naview Aluminium – Anodized Aluminum Solutions

Domain: naviewaluminium.com

Registered: 2021 ( 4 years )

Introduction: Naview offers a range of anodized aluminum products including interior decoration materials, industrial aluminum profiles, aluminum windows, aluminum doors, and curtain walls.

Proleantech – Anodizing Solutions for Nonferrous Metals

Domain: proleantech.com

Registered: 2020 ( 5 years )

Introduction: Anodizing chemical treatment for nonferrous metals, enhancing aesthetic appeal, durability, and corrosion resistance.

Jp Murphy – Aluminum Anodizing Solutions

Domain: jp-murphy.com

Registered: 2022 ( 3 years )

Introduction: Anodizing aluminum is a post-process coating applied to machined and cast parts and prototypes, enhancing their durability and aesthetics.

Tfgusa – Aluminum Anodizing Solutions

Domain: tfgusa.com

Registered: 2008 ( 17 years )

Introduction: Anodizing aluminum parts to enhance mechanical properties and aesthetics.

Members – Anodizing Services for Metals

Domain: members.anodizing.org

Registered: 1998 ( 27 years )

Introduction: Anodizing services for aluminum and other metals, providing surface finishing solutions.

Rpproto – Anodized Aluminum Finishing Solutions

Domain: rpproto.com

Registered: 2021 ( 4 years )

Introduction: The company offers various types of anodized aluminum finishes including standard anodizing, hard anodizing, bright anodizing, clear anodizing, and color anodizing.

Diycraftsy – Aluminum Anodizing Guides

Domain: diycraftsy.com

Registered: 2016 ( 9 years )

Introduction: DIY aluminum anodizing guide for achieving a professional finish on aluminum parts.

Neway Precision – Anodized Aluminum Solutions

Domain: newayprecision.com

Registered: 2017 ( 8 years )

Introduction: Anodized aluminum parts that enhance corrosion resistance, durability, and surface finishing properties through various anodizing processes.

Zintilon – Anodized Aluminum Solutions

Domain: zintilon.com

Registered: 2023 ( 2 years )

Introduction: Anodized aluminum is aluminum alloy that has undergone an anodizing process to create a corrosion-resistant, durable, and aesthetically pleasing surface.

Fictiv – Aluminum Anodizing Services

Domain: fictiv.com

Registered: 2007 ( 18 years )

Introduction: Aluminum anodizing services for enhancing the durability and aesthetics of aluminum products.

Category Information

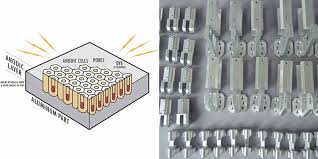

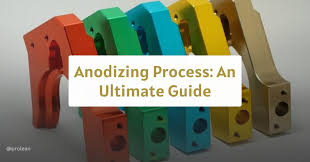

Anodized aluminum refers to aluminum that has undergone an electrochemical process to form a protective oxide layer on its surface. This process enhances the metal’s natural properties, increasing its corrosion resistance, durability, and aesthetic appeal. Anodization can also allow for the dyeing of aluminum, providing a variety of color options while maintaining the material’s strength. The significance of anodized aluminum spans various industries, including automotive, aerospace, construction, and consumer goods.

Its lightweight yet robust nature makes it an ideal choice for applications where both strength and weight reduction are critical. Additionally, the anodized surface is non-toxic, making it suitable for use in food and medical applications. Overall, anodized aluminum combines functionality with visual enhancement, making it a popular choice in modern manufacturing and design.

Application Information

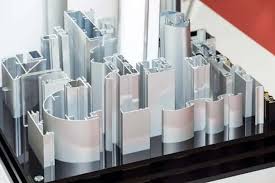

Anodized aluminum is widely utilized across various industries due to its enhanced durability, corrosion resistance, and aesthetic appeal. One significant application area is the construction industry, where anodized aluminum is used for window frames, doors, and curtain walls, providing both strength and an attractive finish. Its resistance to weathering makes it ideal for outdoor applications. Another key area is automotive manufacturing, where anodized aluminum components are used to reduce weight while increasing durability and corrosion resistance.

This is crucial for improving fuel efficiency and vehicle longevity. Additionally, consumer electronics frequently employ anodized aluminum for casings and components, as it offers a sleek appearance while protecting against scratches and oxidation. Other applications include aerospace, where the lightweight and robust nature of anodized aluminum is essential for aircraft parts, and furniture design, where it adds a modern touch to various products while ensuring longevity.

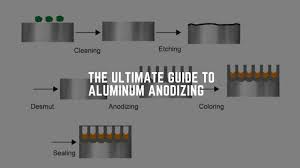

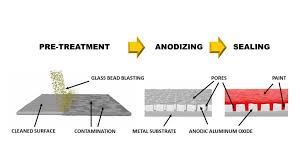

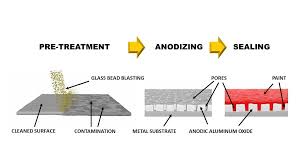

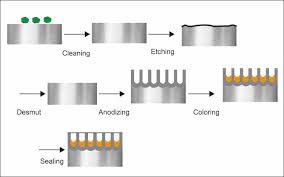

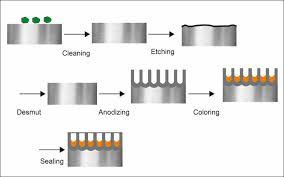

Production Process Information

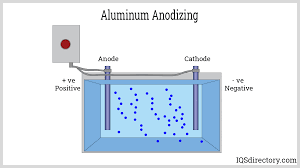

Anodized aluminum products are created through a process that enhances the metal’s durability and appearance. The first key step is preparation, where raw aluminum is cleaned to remove any dirt, grease, or oxidation. This ensures a smooth surface for the anodizing process. Next comes the anodizing stage, where the aluminum is submerged in an electrolytic solution. An electric current is passed through, forming a thick oxide layer on the surface.

This layer not only protects the aluminum from corrosion but can also be dyed in various colors for aesthetic purposes. Finally, the aluminum undergoes sealing, where the anodized surface is treated to close the pores of the oxide layer, enhancing its durability and resistance to wear. This process results in anodized aluminum products that are both functional and visually appealing, widely used in industries like construction, automotive, and consumer goods.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in an anodized aluminum manufacturer?

When choosing a manufacturer, consider their experience, production capacity, quality control processes, and certifications. Check if they have the capability to meet your specific anodizing requirements, such as color options and thickness. Reviews and testimonials from previous clients can also provide insight into their reliability and service quality.

How can I ensure the quality of anodized aluminum products?

Request samples to evaluate the finish, thickness, and overall quality. Inquire about their quality assurance processes and whether they perform tests for corrosion resistance and adhesion. Certifications like ISO 9001 can also indicate a commitment to quality standards.

What are the typical lead times for anodized aluminum orders?

Lead times can vary based on the manufacturer and the complexity of your order. Generally, expect anywhere from 2 to 6 weeks for standard orders. It’s best to discuss timelines upfront and consider factors like order size and current production schedules.

How do I compare pricing between different anodized aluminum suppliers?

When comparing prices, ensure you’re looking at similar specifications and quantities. Ask for detailed quotes that break down costs, including any additional fees for custom colors or finishes. Remember, the cheapest option isn’t always the best; consider quality and service as well.

What should I ask during the initial conversation with a potential supplier?

Start by asking about their experience with projects similar to yours and their production capabilities. Inquire about lead times, minimum order quantities, and their approach to quality control. It’s also helpful to ask about their communication style and customer support to ensure a smooth collaboration.