Top 30 Bevel Gear Manufacturers You Should Know

Are you struggling to find the right bevel gear manufacturer for your project? You’re not alone! With so many options out there, it can be overwhelming to choose a supplier that meets your quality, price, and delivery needs. Imagine having access to a carefully curated list of the top 30 bevel gear factories. By selecting a reputable manufacturer, you’ll ensure reliability, superior craftsmanship, and ultimately, the success of your machinery. Ready to streamline your search and boost your project’s performance?

Dive into our article to uncover the best bevel gear manufacturers and make an informed choice that will set you up for success!

Top 30 Bevel Gear Manufacturers

Iqsdirectory – Bevel Gears Solutions

Domain: iqsdirectory.com

Registration year: Not available

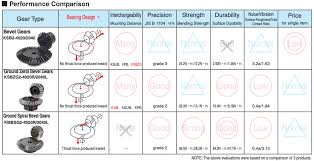

Introduction: Bevel gears are toothed, rotating devices designed to transmit mechanical energy or power between intersecting shafts, often at right angles. They include types such as straight bevel gears, spiral bevel gears, zerol bevel gears, and hypoid gears.

KHK Gears – Bevel Gear Solutions

Domain: khkgears.net

Registered: 2015 ( 10 years )

Introduction: KHK offers a range of bevel gears including straight bevel gears and spiral bevel gears, manufactured primarily using the Gleason method. Their products vary in materials, tooth finishes, and technical specifications.

Mechanic Times – Bevel Gears for Mechanical Applications

Domain: mechanictimes.com

Registered: 2022 ( 3 years )

Introduction: Bevel gears designed for various mechanical applications.

Industrial Gearbox Solutions – Bevel Gear Specialists

Domain: industrialgearboxsolutions.com

Registered: 2024 ( 1 years )

Introduction: Bevel gears are mechanical components used to transfer power between shafts that intersect at an angle, typically 90 degrees. They come in various types including straight, spiral, Zerol, and miter gears.

Engineers Guidebook – Bevel Gear Solutions

Domain: engineersguidebook.com

Registered: 2024 ( 1 years )

Introduction: Bevel gears are mechanical components designed for power transmission between intersecting shafts, primarily at 90 degrees. They come in various types including straight, spiral, hypoid, zerol, and miter gears.

Gear Solutions – Bevel Gear Power Transmission

Domain: gearsolutions.com

Registered: 2008 ( 17 years )

Introduction: Bevel gears are mechanical devices used to transmit power between shafts that are at an angle to each other, typically at 90 degrees.

Linquip – Precision Bevel Gears Solutions

Domain: linquip.com

Registered: 2019 ( 6 years )

Introduction: Bevel gears, including straight bevel gears, spiral bevel gears, Zerol bevel gears, hypoid bevel gears, and mitre gears, designed for various applications requiring angular motion transfer.

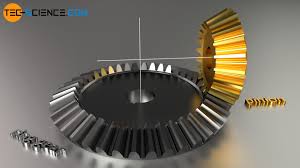

Tec Science – Bevel Gears and Gearboxes

Domain: tec-science.com

Registered: 2017 ( 8 years )

Introduction: Bevel gears and bevel gearboxes used to change the spatial direction of rotation, with options for straight cut and spiral tooth lines.

Aludiecasting – Precision Bevel Gears Manufacturer

Domain: aludiecasting.com

Registered: 2018 ( 7 years )

Introduction: Bevel gears are mechanical components used to transmit rotation between two axes that intersect at right angles. They come in various types including straight bevel gears, spiral bevel gears, zerol bevel gears, hypoid gears, and miter gears.

Link – Bevel Gear Solutions

Roymech – Bevel Gears for Mechanical Systems

Domain: roymech.org

Registered: 2019 ( 6 years )

Introduction: Bevel gears for various applications in mechanical systems.

Jlcmc – Bevel Gears for Efficient Power Transmission

Domain: jlcmc.com

Registered: 2023 ( 2 years )

Introduction: Bevel gears designed for various applications, providing efficient power transmission at different angles.

Us – Bevel Gears for Power Transmission

Domain: us.misumi-ec.com

Registered: 2007 ( 18 years )

Introduction: Bevel gears designed for rotary power transmission applications.

Sanfoundry – Engineering Education and MCQs

Domain: sanfoundry.com

Registered: 2010 ( 15 years )

Introduction: Sanfoundry offers educational resources and multiple-choice questions (MCQs) related to the design of bevel gears and various engineering disciplines.

Arrow Gear – Precision Bevel Gear Solutions

Domain: arrowgear.com

Registered: 1995 ( 30 years )

Introduction: Arrow Gear specializes in manufacturing bevel gears, including hypoid gears, spiral bevel gears, right angle gears, straight bevel gears, and Zerol bevel gears.

Gear Sprocket – Bevel Gears Solutions

Domain: gear-sprocket.com

Registered: 2018 ( 7 years )

Introduction: Bevel gears are mechanical devices with conical teeth used to change the direction of shaft rotation, typically at right angles.

Zhygear – Straight Bevel Gears Solutions

Domain: zhygear.com

Registered: 2018 ( 7 years )

Introduction: Straight bevel gears designed for efficient power transmission and mechanical applications.

Qtcgears – Bevel Gears and Gear Solutions

Domain: qtcgears.com

Registered: 1996 ( 29 years )

Introduction: KHK stock bevel gears are available in two types, spiral and straight tooth, with gear ratios of 1.5 through 5, and offered in a variety of modules, numbers of teeth, materials, and styles.

Meshingwithgears – Gear Design and Manufacturing Solutions

Domain: meshingwithgears.us

Registered: 2009 ( 16 years )

Introduction: The company offers a range of gear-related products and services, focusing on gear design, manufacturing, and meshing analysis.

Fg Machine – Bevel Gears for Mechanical Applications

Domain: fg-machine.com

Registered: 2021 ( 4 years )

Introduction: Bevel gears used for various mechanical applications.

Sciencedirect – Bevel Gear Solutions

Domain: sciencedirect.com

Registered: 1997 ( 28 years )

Introduction: Bevel gears are conical gears used to transmit motion between angular or intersecting shafts, commonly for 90° drives.

Bdgears – Precision Bevel Gears Solutions

Domain: bdgears.com

Registered: 2023 ( 2 years )

Introduction: Bevel gears designed for various applications, offering precision and durability.

KHK Gears – Premium Metric Bevel Gears

Domain: khkgears.us

Registered: 2015 ( 10 years )

Introduction: KHK USA is a supplier of premium metric bevel gears, including straight bevel gears, spiral bevel gears, miter gears, hypoid gears, and zerol gears. They offer a variety of gear ratios, modules, materials, and styles.

Designwithajay – Spiral Bevel Gears Solutions

Domain: designwithajay.com

Registered: 2022 ( 3 years )

Introduction: Spiral bevel gears are sophisticated mechanical components used for power transmission between intersecting shafts in various applications.

Extrudergearbox – Bevel Gears and Mechanical Solutions

Domain: extrudergearbox.net

Registered: 2022 ( 3 years )

Introduction: Bevel gears, including straight, spiral, zerol, and hypoid types, used in various mechanical systems.

Globalspec – Bevel and Miter Gears Solutions

Domain: globalspec.com

Registered: 1998 ( 27 years )

Introduction: Bevel and miter gears are mechanical components used for transmitting power between shafts that are at an angle to each other, typically 90 degrees.

Books – Bevel Gear Fundamentals and Applications

Domain: books.google.com

Registered: 1997 ( 28 years )

Introduction: Bevel Gear: Fundamentals and Applications is a comprehensive book that presents the fundamentals, geometrical features, and various gear cutting processes related to bevel gears.

Hanswerner – Bevel Gear Solutions

Domain: hanswerner.net

Registered: 2023 ( 2 years )

Introduction: Bevel gears are a special type of gear used to transmit power between intersecting shafts, typically at 90 degrees, with conical shapes and angled teeth.

Belongear – Precision OEM Gears and Shafts Solutions

Domain: belongear.com

Registered: 2020 ( 5 years )

Introduction: Shanghai Belon Machinery Co., Ltd. specializes in high precision OEM gears, shafts, and solutions for various industries including agriculture, automotive, mining, aviation, construction, robotics, automation, and motion control. Their product range includes straight bevel gears, spiral bevel gears, cylindrical gears, worm gears, and spline shafts, which can be designed or produced according to…

American Gear, Inc. – Precision Gear Manufacturing

Domain: americangearinc.com

Registered: 2000 ( 25 years )

Introduction: American Gear, Inc. manufactures precision gears including spur gears, helical gears, involute splines, miniature gears, worms/worm gears, straight bevel gears, and timing pulleys.

Category Information

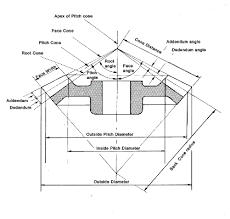

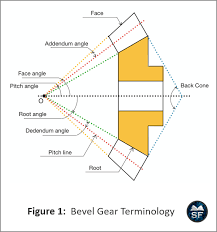

Bevel gears are mechanical components used to transmit power and motion between shafts that are typically oriented at right angles to each other. They are characterized by their conical shape, which allows for efficient angle changes in mechanical systems. Bevel gears can be classified into various types, including straight, spiral, and hypoid bevel gears, each offering different advantages in terms of load capacity, efficiency, and noise levels.

The significance of bevel gears lies in their widespread application across various industries, including automotive, aerospace, and manufacturing. They play a crucial role in the design of gearboxes, differentials, and other machinery that require the transfer of rotational motion with minimal energy loss. Their ability to facilitate smooth and effective power transmission makes them essential for improving the performance and reliability of mechanical systems.

Application Information

Bevel gears are crucial components in various industries, primarily used for transmitting power and motion between shafts that are at right angles to each other. One key application area is in automotive engineering, where bevel gears facilitate the transfer of power from the engine to the wheels, particularly in differential systems. This enables smooth turning and handling of vehicles. Another significant application is in industrial machinery, such as conveyor systems and manufacturing equipment.

Bevel gears help adjust the direction of rotation and improve efficiency in processes like material handling. Additionally, they are utilized in aerospace applications, where precise motion control is vital for flight systems and landing gear mechanisms. Overall, bevel gears play a pivotal role in enhancing performance and reliability across various mechanical systems.

Production Process Information

The production of bevel gears involves several key steps to ensure precision and functionality. First, the process begins with design and engineering, where specifications are created based on the intended application. This involves choosing materials and determining the gear’s dimensions and tooth profile. Next, the manufacturing stage takes place. This includes cutting the raw material into the rough shape of the gear, followed by machining processes like grinding and shaping to achieve the final dimensions.

Quality control is crucial here; each gear is inspected for accuracy and performance. Finally, the finished bevel gears are assembled, if necessary, and packaged for delivery. Throughout the entire process, considerations like material selection, machining precision, and quality testing play a vital role in producing reliable and effective bevel gears for various applications, from automotive to industrial machinery.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a bevel gear manufacturer?

When choosing a bevel gear manufacturer, consider their experience, production capabilities, and quality assurance processes. Look for certifications like ISO 9001, which indicate a commitment to quality. It’s also important to assess their ability to meet your specific design requirements and delivery timelines.

How can I verify the quality of a bevel gear factory?

To verify quality, request samples and review their production processes. Check for customer testimonials and case studies. Visiting the factory, if possible, allows you to see their equipment and quality control measures firsthand. Additionally, inquire about their testing procedures for finished products.

What is the typical lead time for bevel gear manufacturing?

Lead times can vary significantly based on the complexity of the gears, order size, and the manufacturer’s workload. Generally, expect anywhere from a few weeks to several months. Always ask for a specific timeline when you place your order to avoid surprises.

Are there minimum order quantities for bevel gears?

Many manufacturers have minimum order quantities (MOQs) due to setup costs and production efficiency. These can range from a few pieces to hundreds. It’s best to discuss your needs with potential suppliers to find one that can accommodate your order size.

How can I ensure good communication with my bevel gear supplier?

Establish clear communication channels from the start. Use email, phone calls, or project management tools to stay in touch. Make sure you have a dedicated contact person at the factory. Regular updates and feedback will help build a strong working relationship.