Top 30 Gear Drive Manufacturers You Should Know

Are you tired of sifting through countless gear drive manufacturers, only to be left more confused than when you started? Finding the right supplier can feel like searching for a needle in a haystack. With so many options out there, it’s crucial to identify a factory that meets your specific needs. Imagine the peace of mind that comes from partnering with a top-tier manufacturer known for quality, reliability, and exceptional service.

The right choice can elevate your projects and enhance your overall productivity. Ready to take the guesswork out of your search? Dive into our comprehensive comparison of the top 30 gear drive factories and discover the perfect fit for your business. Your next successful project starts here!

Top 30 Gear Drive Manufacturers

Iqsdirectory – Gear Drives & Mechanical Solutions

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

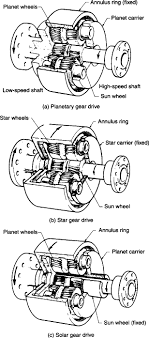

Introduction: Gear drives, also known as gear trains or gearboxes, are mechanical systems designed to transfer power from a driving source to a machine, allowing for speed reduction and torque amplification.

Electrical Workbook – Gear Drive Solutions

Domain: electricalworkbook.com

Registered: 2018 ( 7 years )

Introduction: Gear drive is used when the centre to centre distance between driver and driven shafts is very small. It consists of two wheels: a smaller wheel called the pinion and a larger wheel called the gear.

Theengineerspost – Precision Gear Solutions

Domain: theengineerspost.com

Registered: 2018 ( 7 years )

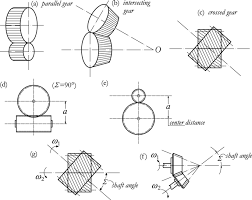

Introduction: The company offers a variety of gears including spur gears, helical gears, double helical gears, bevel gears, spiral bevel gears, and screw gears, among others.

Cedengineering – Online PDH Courses for Engineers

Domain: cedengineering.com

Registered: 2006 ( 19 years )

Introduction: Online continuing education courses for professional engineers to earn PDH credits.

Rexnord – Gear Drives and Components Solutions

Domain: rexnord.com

Registered: 1996 ( 29 years )

Introduction: Rexnord offers a range of gear drives including Concentric Inline, Parallel, Right Angle, and Shaft Mount gear drives, along with gear components.

Sciencedirect – Gear Drive Solutions

Domain: sciencedirect.com

Registered: 1997 ( 28 years )

Introduction: Gear drives are mechanical devices used to transmit power and motion between shafts, utilizing gears to achieve desired speed and torque characteristics.

Itstillruns – Automotive Gear Drive Solutions

Domain: itstillruns.com

Registered: 2017 ( 8 years )

Introduction: Gear drives are mechanical systems that use two spur-cut gears to transfer power from a drive gear to a driven gear, commonly used in automotive applications.

Control – Gear Drives and Control Systems

Domain: control.com

Registered: 1990 ( 35 years )

Introduction: The company offers a range of gear drives and related control systems, focusing on mechanical aspects of control in various industries.

Rskr – Precision Gear Solutions

Domain: rskr.irimee.in

Registered: 2017 ( 8 years )

Introduction: The company offers a range of gear types including spur gears, helical gears, bevel gears, mitter gears, worm gears, and hypoid gears, which are used for power transmission and motion control.

Engineeringenotes – Gear Drives for Power Transmission

Domain: engineeringenotes.com

Registered: 2017 ( 8 years )

Introduction: Gear drives for power transmission in mechanical engineering.

Mcmaster – Gear Boxes and Speed Reducers

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: The company offers a variety of gear boxes and speed reducers, including flexible-mount right-angle speed reducers, sanitary speed reducers, and various types of gear boxes designed for different applications.

Learnmech – Mechanical Drives and Components Solutions

Domain: learnmech.com

Registered: 2017 ( 8 years )

Introduction: The company offers mechanical drives including belts, chains, and gears for various applications.

Onlinelibrary – Mechanical Drive Solutions

Domain: onlinelibrary.wiley.com

Registered: 1994 ( 31 years )

Introduction: Information not available.

Clubtechnical – Mechanical Power Transmission Gears

Domain: clubtechnical.com

Registered: 2018 ( 7 years )

Introduction: The company offers a variety of gears used for mechanical power transmission, including spur gears, helical gears, bevel gears, worm gears, and hypoid gears.

Taylor & Francis – Gear Drive Systems Solutions

Domain: taylorfrancis.com

Registered: 2001 ( 24 years )

Introduction: Gear drive systems designed for various mechanical applications.

Gear Drive – Mechanical Power Transmission Solutions

Milodon – Gear Drive Service Parts

Domain: milodon.com

Registered: 2000 ( 25 years )

Introduction: Gear drive service parts including replacement gears, seals, bearings, and other components necessary for maintaining optimal gear drive operation.

Regal Rexnord – Industrial Gear Solutions

Domain: regalrexnord.com

Registered: 2021 ( 4 years )

Introduction: Regal Rexnord offers a variety of gears including spur gears, helical gears, bevel gears, and worm gears, designed for various industrial applications.

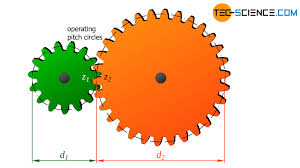

Tec Science – Gearbox Solutions

Domain: tec-science.com

Registered: 2017 ( 8 years )

Introduction: The company offers gearboxes that facilitate the conversion of speed and torque through various arrangements of gears or pulleys.

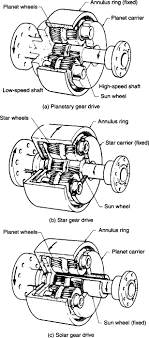

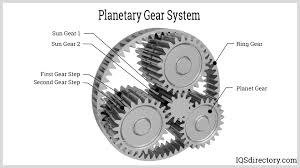

Yddrive – Precision Planetary Drives Solutions

Domain: yddrive.com

Registered: 2021 ( 4 years )

Introduction: Planetary drives designed for high torque and precision applications.

Wmberg – Worm Gear Drive Solutions

Domain: wmberg.com

Registered: 1996 ( 29 years )

Introduction: Worm gear drives are shaft gear assemblies that transmit power between non-intersecting drive and driven shafts, typically at 90° angles. They consist of a worm and a worm gear (wheel) that mesh together to reduce speed and increase torque.

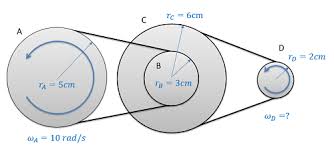

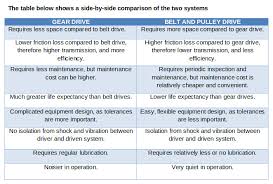

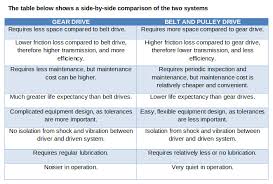

Eng – Motion Transfer Systems

Domain: eng.libretexts.org

Registered: 2016 ( 9 years )

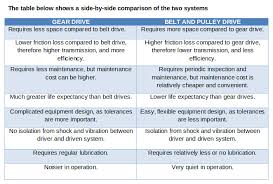

Introduction: Belt-and-pulley systems and gear-driven systems for transferring rotational motion and torque between shafts.

Mechteaching – Gear Drive Solutions

Domain: mechteaching.com

Registered: 2021 ( 4 years )

Introduction: Gear drives, also known as gear transmissions, are mechanisms used to transmit rotational motion between two or more shafts.

Insights – Gear Transmission Solutions

Domain: insights.globalspec.com

Registered: 1998 ( 27 years )

Introduction: Gears are toothed, compact, positive-engagement mechanical transmission devices used for the transfer of motion and power within machine components.

Idc Online – Gear Drives and Motors Solutions

Domain: idc-online.com

Registered: 1996 ( 29 years )

Introduction: The company offers gear drives and gear motors, which are mechanical systems that transmit motion and torque through toothed wheels and gear assemblies.

Engineers Guidebook – Precision Gear Solutions

Domain: engineersguidebook.com

Registered: 2024 ( 1 years )

Introduction: The company offers various types of gears including spur gears, helical gears, bevel gears, skew bevel gears, and spiral gears, classified based on the axes of the shafts, velocity, and type of gearing.

Sumitomo – Cycloidal Gearboxes and Precision Solutions

Domain: us.sumitomodrive.com

Registered: 2003 ( 22 years )

Introduction: Sumitomo offers a range of cycloidal gearboxes, including the Fine Cyclo® series, which features high precision, low backlash, and high torque capacities. The product lineup includes single-stage and multi-stage options designed for various industrial applications.

Mechlearning – Efficient Gear Drive Systems

Domain: mechlearning.com

Registered: 2021 ( 4 years )

Introduction: Gear drive systems designed for efficient power transmission in mechanical applications.

Link – Gear Units and Drives Solutions

SDP/SI – Precision Mechanical Components

Domain: sdp-si.com

Registered: 1995 ( 30 years )

Introduction: Small Mechanical Components: Precision Gears, Timing Belts, Gear Assemblies, Timing Belt Pulleys, Couplings, Bearings and much more from SDP/SI.

Category Information

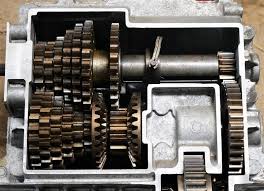

A gear drive is a mechanical system that transmits power and motion between shafts using gears. This category broadly encompasses various types of gear mechanisms, including spur gears, bevel gears, helical gears, and worm gears. Gear drives are fundamental in machinery and are widely used in applications ranging from automotive transmissions to industrial equipment and robotics. Their primary function is to alter torque and speed, allowing machines to operate efficiently under different load conditions.

The significance of gear drives lies in their ability to provide precise control over motion and force. By selecting appropriate gear ratios, engineers can optimize performance, enhance durability, and improve energy efficiency. Additionally, gear drives are essential for converting rotational motion into linear motion or vice versa, making them critical components in many mechanical systems. Overall, they play a vital role in modern engineering and technology, contributing to the effectiveness of countless devices and machines.

Application Information

Gear drives are fundamental components in various industries, facilitating the transfer of motion and power in mechanical systems. One primary application area is in manufacturing machinery, where gear drives are used to control the speed and torque of equipment such as conveyors, lathes, and milling machines, ensuring precision in production processes. Another significant application is in the automotive industry, where gear drives are integral to the operation of transmissions, differentials, and power steering systems.

They help optimize engine performance and enhance vehicle efficiency. Additionally, gear drives are crucial in aerospace applications, powering systems like landing gear mechanisms and control surfaces, where reliability and strength are paramount. Other notable areas include robotics, where gear drives enable precise movement and control, and renewable energy, particularly in wind turbines, where they convert rotational energy to electrical energy effectively.

Production Process Information

The production of gear drive products involves several key steps to ensure high-quality performance. First, the design phase is crucial, where engineers create detailed specifications for the gear system based on its intended use, including factors like load capacity and speed requirements. This stage often involves computer simulations to optimize performance. Next is the material selection and preparation. Manufacturers choose suitable metals or plastics, followed by processes like cutting and shaping to form the gear components.

Once the parts are ready, they undergo assembly, where gears, shafts, and bearings are fitted together to create the complete gear drive system. Finally, rigorous testing is performed to ensure durability and efficiency. This includes running the gear drive under simulated conditions to check for any potential failures. Proper quality control throughout these stages helps ensure that the final product meets industry standards and customer expectations.

Related Video

Frequently Asked Questions (FAQs)

What should I look for when choosing a gear drive manufacturer?

When selecting a gear drive manufacturer, consider their experience, reputation, and specialization in the type of gear drives you need. Check for certifications, quality control processes, and customer reviews. It’s also beneficial to assess their production capacity and lead times to ensure they can meet your demands.

How can I verify the quality of a gear drive factory?

To verify a factory’s quality, request samples of their gear drives and review their quality assurance processes. Look for certifications like ISO 9001, and ask about their testing methods. Visiting the factory in person or checking third-party audits can also provide insights into their quality standards.

What are the typical lead times for gear drive manufacturing?

Lead times can vary based on the complexity of the gear drive and the manufacturer’s workload. Generally, expect anywhere from a few weeks to several months. Always communicate your timeline upfront and confirm the manufacturer can meet your deadlines before placing an order.

Are there minimum order quantities (MOQs) for gear drives?

Many manufacturers have minimum order quantities, which can range from a few units to hundreds, depending on the product and factory. It’s important to discuss MOQs during your initial conversations to ensure they align with your needs and budget.

How can I ensure good communication with my gear drive supplier?

Establish clear communication channels from the start, such as email, phone, or messaging apps. Set expectations for response times and regular updates on production status. Building a good relationship with your supplier can lead to better collaboration and problem-solving down the line.

![12 Different Types of Gears and Their Applications [PDF] - gear drive](https://www.fobindustry.info/wp-content/uploads/2025/06/theengineerspostcom-gear-drive-image.jpg)