Top 30 Plastic Gear Manufacturers You Should Know

Are you struggling to find the right plastic gear manufacturer for your project? It can be a daunting task with so many options out there! Choosing the wrong supplier can lead to delays, subpar quality, and inflated costs. Imagine working with a top-tier factory that delivers precision-engineered gears, exceptional service, and timely delivery. The right partner can elevate your project and streamline your production process.

In this article, we’ve compiled a list of the top 30 plastic gear manufacturers, making it easier for you to find the perfect match for your needs. Dive in to discover which factories stand out and why they could be your next go-to supplier!

Top 30 Gears Plastic Manufacturers

McMaster-Carr – Plastic Gears and Components

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: McMaster-Carr offers a variety of plastic gears, including gears, gear racks, and pawls, made from materials such as laminate and plastic.

SDP/SI – Custom Precision Gear Solutions

Domain: sdp-si.com

Registered: 1995 ( 30 years )

Introduction: SDP/SI is a precision gear manufacturer offering custom plastic gears, bevel gears, spur gears, and a large inventory of off-the-shelf plastic gears for immediate shipment worldwide.

KHK Gears – Engineering Plastic Gear Solutions

Domain: khkgears.net

Registered: 2015 ( 10 years )

Introduction: KHK offers a range of plastic gears made from engineering plastics such as polyacetal (POM) and MC Nylon, designed for various applications across multiple industries.

Igus – Wear-Resistant Plastic Gears

Domain: igus.com

Registered: 1995 ( 30 years )

Introduction: Wear-resistant plastic gears from iglide® designed for various applications.

Gear Plastic – Specialized Plastic Materials for Gears

Domain: gear-plastic.com

Registered: 2022 ( 3 years )

Introduction: The company offers various types of plastic materials specifically designed for manufacturing gears.

Welleshaft – Innovative Plastic Gears Solutions

Domain: welleshaft.com

Registered: 2018 ( 7 years )

Introduction: Plastic gears designed for various applications, offering advantages over traditional metal gears.

Delrin – Engineering Thermoplastics for Gears

Domain: delrin.com

Registered: 1998 ( 27 years )

Introduction: Delrin® is a widely used engineering thermoplastic for gears, known for its low-friction, high-wear resistance, high-strength, and stiffness, suitable for replacing metals in various applications.

Miller Plastics – Custom Plastic Gears Manufacturer

Domain: millerplastics.com

Registered: 1999 ( 26 years )

Introduction: Miller Plastic Products is a plastic gear manufacturer offering custom-made replacement plastic gears in diameters ranging from .5″ to 72″. They specialize in machining and fabricating components for machinery.

Iqsdirectory – Advanced Plastic Gears Manufacturing

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

Introduction: Plastic gears made from advanced engineering plastics such as nylon and polyacetal, manufactured through methods like hobbing, injection molding, and CNC machining.

Robu – Plastic Gears for Robotics Solutions

Domain: robu.in

Registered: 2012 ( 13 years )

Introduction: Robu.in offers a variety of plastic gears at competitive prices, focusing on mechanical parts and tools for robotics and related applications.

Performance Gear – Precision Plastic Gears & Actuators

Domain: performance-gear.com

Registered: 1999 ( 26 years )

Introduction: Performance Gear Systems specializes in the design, engineering, and manufacturing of high precision plastic gears and electro-mechanical actuators.

Winzelergear – Precision Molded Plastic Gears

Domain: winzelergear.com

Registered: 1998 ( 27 years )

Introduction: Precision molded plastic gears for automotive, off-road, lawn & garden, and office automation.

Gleason – Precision Plastic Gears Solutions

Domain: gleason.com

Registered: 1991 ( 34 years )

Introduction: Gleason Corporation offers a range of plastic gears designed for various applications, focusing on precision and durability.

Plastic Cogs – Noise-Reducing Plastic Gears

Plastic Machining Company – Custom Plastic Gears and Racks

Domain: plasticmachiningcompany.com

Registered: 2008 ( 17 years )

Introduction: The company specializes in manufacturing plastic gears and gear racks, offering custom solutions tailored to various applications.

V1Prototype – Durable Plastic Gears Solutions

Domain: v1prototype.com

Registered: 2022 ( 3 years )

Introduction: The company offers a range of plastic gears designed for various applications, focusing on durability, lightweight construction, and cost-effectiveness.

Gearsolutions – Precision Plastic Gears for Power Applications

Domain: gearsolutions.com

Registered: 2008 ( 17 years )

Introduction: Plastic gears designed for higher power and precision applications, offering reduced drive cost, noise, and weight.

Link – Precision Plastic Gear Manufacturing Solutions

Geartechnology – Plastic Gear Solutions

Domain: geartechnology.com

Registered: 1995 ( 30 years )

Introduction: Plastic gears are serious alternatives to traditional metal gears in a wide variety of applications, expanding from low-power, precision motion transmission into more demanding power transmission applications.

Plasticgear – Lightweight Plastic Gearboxes Solutions

Domain: plasticgear.net

Registered: 2020 ( 5 years )

Introduction: Plastic gearboxes designed for various applications, offering lightweight and corrosion-resistant solutions.

Sofeast – Custom Plastic Gears Solutions

Domain: sofeast.com

Registered: 2006 ( 19 years )

Introduction: Sofeast offers plastic gears made from various materials suitable for different mechanical applications.

Quandaplastic – Custom Plastic Gears and Materials

Domain: quandaplastic.com

Registered: 2009 ( 16 years )

Introduction: QUANDA Plastic specializes in the production of various plastic gears and materials, including sheets and rods made from different types of plastics such as ABS, acrylic, PTFE, and nylon.

Metro Sprocket – Custom Gears and Machining Solutions

Domain: metrosprocket.com

Registered: 2008 ( 17 years )

Introduction: Metro Sprocket & Gear specializes in manufacturing custom gears, helical gears, plastic gears, splines, worms, and worm gears. They also provide services such as CNC machining, hobbing, and internal spline broaching.

GearsMade – Custom Gear Manufacturing Solutions

Domain: gearsmade.com

Registered: 2009 ( 16 years )

Introduction: GearsMade.com specializes in manufacturing high-quality gears from various materials including brass, stainless steel, plastic, and more. They offer custom gear production based on samples provided by customers, with sizes ranging from very small up to 15 inches in diameter.

Motion Control Tips – Plastic Gears for Motion Systems

Domain: motioncontroltips.com

Registered: 2007 ( 18 years )

Introduction: The company offers a range of plastic gears designed for various applications in motion control systems.

Celanese – Engineered Materials and Specialty Chemicals

Domain: globalspec.com

Registered: 1998 ( 27 years )

Introduction: Celanese offers a range of engineered materials and solutions, including thermoplastics, polymers, and specialty chemicals.

Enplas – Precision Plastic Gears and Gear Trains

Domain: en.enplas.com

Registered: 1996 ( 29 years )

Introduction: Enplas offers a variety of plastic gears and gear trains designed for various applications across multiple industries, including medical, automotive, and consumer electronics.

Leobot – Robotics & Electronics Solutions

Domain: leobot.net

Registered: 2018 ( 7 years )

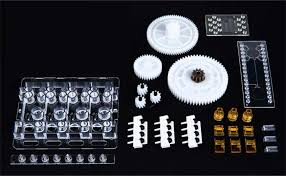

Introduction: Plastic Gears Set (106 pcs kit) – South Africa Arduino, Robotics & Electronics Supplier South Africa: R140.00

Machinedesign – Plastic Gears for Mechanical Applications

Domain: machinedesign.com

Registered: 1995 ( 30 years )

Introduction: Plastic gears for various mechanical applications.

Kore Industries – Custom Plastic Gears Manufacturer

Domain: koreindustries.com

Registered: 2010 ( 15 years )

Introduction: Kore Industries manufactures a variety of plastic gears including spur gears, helical gears, bevel gears, and worm gears, catering to custom requirements and high-demand needs.

Category Information

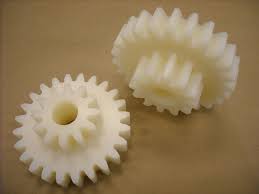

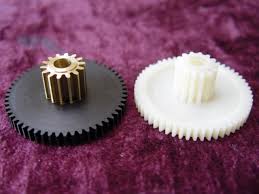

The category of “plastic gears” encompasses a range of mechanical components made from various types of plastic materials, designed to transmit motion and torque in machines and devices. These gears are essential in numerous applications, from small consumer electronics to larger industrial machinery. Their lightweight nature, resistance to corrosion, and ability to operate quietly make them a popular choice in many engineering designs. The significance of plastic gears lies in their versatility and cost-effectiveness.

They can be molded into complex shapes, allowing for intricate designs that metal gears may not achieve easily. Additionally, plastic gears reduce the overall weight of products, which is crucial in applications where weight savings are paramount, such as in automotive and aerospace industries. Their ability to withstand specific environmental conditions further enhances their applicability, making them integral components in modern mechanical systems.

Application Information

Plastic gears are widely utilized across various industries due to their lightweight, corrosion resistance, and cost-effectiveness. One prominent application area is the automotive industry, where plastic gears are used in window regulators, seat adjusters, and other mechanisms, reducing weight and improving fuel efficiency. Another key area is consumer electronics, where plastic gears facilitate the movement of components in devices like printers, cameras, and toys.

Their low noise operation and ability to be produced in intricate shapes make them ideal for these applications. Additionally, the medical field employs plastic gears in devices such as infusion pumps and surgical robots, where precision and hygiene are crucial. Lastly, industrial machinery often incorporates plastic gears in conveyor systems and automated equipment, benefiting from their durability and low maintenance requirements. Overall, plastic gears are essential components in many sectors, enhancing performance and efficiency.

Production Process Information

The production of plastic gears involves several key stages that transform raw materials into functional components. First, the process begins with design and engineering, where the specifications for the gear, including size, shape, and performance requirements, are created using computer-aided design (CAD) software. This step ensures that the gear will meet the necessary standards for its intended application. Next, the chosen plastic material, often a type of nylon or acetal, is prepared for manufacturing.

This can involve melting the plastic pellets and injecting them into a mold through a process called injection molding. Once the gear cools and solidifies, it is removed from the mold. Finally, the gears undergo quality control checks to ensure they meet the design specifications and are free of defects. After passing inspection, they are packaged and shipped to customers for use in various applications, such as machinery or automotive parts.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a plastic gear manufacturer?

When choosing a plastic gear manufacturer, consider their experience in the industry, production capabilities, quality control processes, and material options. It’s also important to check their certifications and customer reviews to ensure reliability and quality.

How can I evaluate the quality of a plastic gear supplier?

To evaluate a supplier’s quality, request samples of their products and examine them for precision and durability. Additionally, inquire about their manufacturing processes, quality assurance measures, and any relevant certifications like ISO standards.

What materials are commonly used for plastic gears?

Common materials for plastic gears include nylon, acetal (POM), and polycarbonate. Each material has its unique properties, such as strength, wear resistance, and temperature tolerance, so choose one that best fits your application’s requirements.

How do I ensure my design is compatible with the manufacturer’s capabilities?

Provide your manufacturer with detailed specifications, including dimensions, tolerances, and intended use. Collaborate closely during the design phase and ask for their input on manufacturability to avoid potential issues later on.

What is the typical lead time for plastic gear production?

Lead times can vary based on factors like order size, complexity, and the manufacturer’s workload. Generally, expect anywhere from a few weeks to several months. Always confirm lead times upfront to plan your project accordingly.