Top 30 Helical Gear Manufacturers You Should Know

Are you tired of sifting through countless suppliers for helical gears, only to find subpar quality and service? You’re not alone! Choosing the right manufacturer can be a daunting challenge, especially when precision and reliability are critical to your projects. Imagine having access to a curated list of the top 30 helical gear factories that stand out for their excellence, innovation, and customer satisfaction.

These leading manufacturers not only deliver high-quality products but also ensure timely support and partnership throughout your journey. Ready to streamline your search and elevate your projects? Dive into our article to discover the best helical gear manufacturers and make your next sourcing decision a breeze!

Top 30 Helical Gear Manufacturers

Motion Control Tips – Helical Gear Solutions

Domain: motioncontroltips.com

Registered: 2007 ( 18 years )

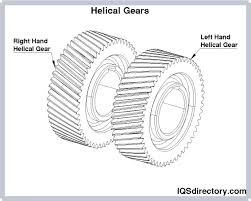

Introduction: Helical gears are a type of gear with teeth that are cut at an angle to the face of the gear, allowing for smoother and quieter operation compared to other gear types.

Iqsdirectory – Helical Gears for High-Speed Applications

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

Introduction: Helical gears designed for high-speed applications, significant power transmission, and noise reduction, suitable for various industrial gearboxes and automotive transmissions.

KHK Gears – Helical Gears for Quiet Operation

Domain: khkgears.net

Registered: 2015 ( 10 years )

Introduction: KHK offers helical gears, which are cylindrical gears with slanted tooth traces, designed for quiet operation and high force transmission.

Drivetrainhub – Helical Gear Learning Resources

Boston Gear – Helical Gears Solutions

Domain: bostongear.com

Registered: 1997 ( 28 years )

Introduction: Boston Gear offers a range of helical gears designed for various applications, focusing on durability and efficiency.

Gearsolutions – Helical Gear Solutions

Domain: gearsolutions.com

Registered: 2008 ( 17 years )

Introduction: Helical gears are a type of gear characterized by their angled teeth, which provide smoother and quieter operation compared to other gear types.

Globalspec – Precision Helical Gears Solutions

Domain: globalspec.com

Registered: 1998 ( 27 years )

Introduction: Helical gears are a type of gear with teeth that are cut at an angle to the axis of rotation, allowing for smoother and quieter operation compared to other gear types.

Testbook – Helical Gears Solutions

Domain: testbook.com

Registered: 2004 ( 21 years )

Introduction: Helical gears are essential mechanical components used for transmitting motion and power between parallel shafts, characterized by their helically-shaped teeth.

Tec Science – Helical Gear Solutions

Domain: tec-science.com

Registered: 2017 ( 8 years )

Introduction: Helical gears are a type of gear characterized by their angled teeth, which allow for smoother and quieter operation compared to other gear types.

ZHY Gear – Helical Gear Manufacturing Solutions

Domain: zhygear.com

Registered: 2018 ( 7 years )

Introduction: ZHY Gear specializes in the design and manufacturing of helical gears, which are known for their efficiency and smooth operation in various mechanical applications.

Speedogears – Helical Gearbox Solutions

Domain: speedogears.com

Registered: 2021 ( 4 years )

Introduction: Helical Gearbox, a type of cylindrical gear with slanted teeth designed for power transmission, reducing speed and increasing force between shafts.

Roymech – Helical Gears for Smooth Operation

Domain: roymech.org

Registered: 2019 ( 6 years )

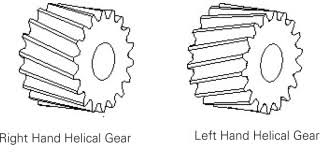

Introduction: Helical gears designed for smoother operation and higher speeds compared to spur gears, available in right-handed and left-handed configurations.

McMaster – High-Power Metal Gears

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: High-Power Metal Gears including crossed right-hand and left-hand gears, parallel gears, and gears with keyed bore and set screw.

The Engineers Post – Precision Gear Solutions

Domain: theengineerspost.com

Registered: 2018 ( 7 years )

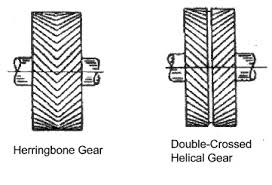

Introduction: The company offers a variety of gears including spur gears, helical gears, double helical gears, bevel gears, spiral bevel gears, and screw gears, among others.

Sciencedirect – Helical Gear Solutions

Domain: sciencedirect.com

Registered: 1997 ( 28 years )

Introduction: Helical gears are designed to connect non-parallel and parallel shafts, providing superior load-carrying capacity, quietness, and smoothness of operation compared to spur gears.

Cnclathing – Precision CNC Machining Services

Domain: cnclathing.com

Registered: 2018 ( 7 years )

Introduction: CNC machining services including 5-axis machining, CNC turning, CNC milling, Swiss machining, 3D printing, rapid prototyping, precision machining, and sheet metal fabrication.

Us – Helical Gears and Configurations

Domain: us.misumi-ec.com

Registered: 2007 ( 18 years )

Introduction: Helical gears with a module of 3.0, available in various configurations including straight bore, tapped holes, and keyways.

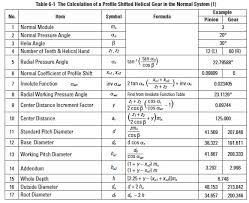

Helical Gear – Precision Gear Geometry Solutions

Bdgears – Precision Gear Solutions

Domain: bdgears.com

Registered: 2023 ( 2 years )

Introduction: Double Helical Gear and various types of gears including Spiral Bevel Gear, Hypoid Bevel Gear, Zerol Bevel Gear, Straight Bevel Gear, Spur Gear, Helical Gear, Internal Gear, and Shafts.

Ocw – Helical Gear Solutions

Domain: ocw.mit.edu

Registered: 1985 ( 40 years )

Introduction: Helical gears designed for gear drive systems, focusing on their geometry and load capacity.

KHK Gears – Premium Metric Helical Gears

Domain: khkgears.us

Registered: 2015 ( 10 years )

Introduction: KHK USA offers premium metric helical gears made from alloy steel and carbon steel, with various configurations of modules and numbers of teeth. Their helical gears are designed for high-speed rotation applications and allow for secondary operations.

Learnmech – Helical Gears for Efficient Power Transmission

Domain: learnmech.com

Registered: 2017 ( 8 years )

Introduction: Helical gears are a type of gear used in various mechanical applications, known for their angled teeth that provide smooth and efficient power transmission.

Themechanicalengineering – Precision Gear Solutions

Domain: themechanicalengineering.com

Registered: 2019 ( 6 years )

Introduction: The company offers various types of gears including Spur Gear, Helical Gear, Double Helical and Herring Bone Gear, Crossed Helical Gears, and Worm Gear.

Machinedesign – Precision Gear Solutions

Domain: machinedesign.com

Registered: 1995 ( 30 years )

Introduction: The company offers various types of gears including spur gears, helical gears, bevel gears, and worm gears.

Calculator Ultra – Helical Gear Pitch Diameter Calculator

Domain: calculatorultra.com

Registered: 2024 ( 1 years )

Introduction: Helical gear pitch diameter calculator for accurate gear design and functionality.

Linquip – Helical Gearbox Solutions

Domain: linquip.com

Registered: 2019 ( 6 years )

Introduction: Helical gearboxes are power transmission instruments primarily utilized to reduce speed and increase torque between turning shafts. They are one of the most widely used gearboxes and are more effective than any other gearbox.

Link – Helical Gear Design and Analysis Solutions

Domain: link.springer.com

Registered: 1997 ( 28 years )

Introduction: Helical gear designed using Structural Steel (S45C), focusing on design, simulation, and analysis.

Gear Motions – Precision Helical Gear Manufacturing

Domain: gearmotions.com

Registered: 1997 ( 28 years )

Introduction: Precision Helical Gear Manufacturing at Gear Motions.

Santram Engineers – Helical Gearbox Solutions

Domain: santramengineers.com

Registered: 2008 ( 17 years )

Introduction: Santram Engineers offers a variety of helical gearboxes including single helical gear, double helical gear, and herringbone gear configurations. They provide specific models such as Helical H1 125 3.05:1 and Helical H1 125 3.38:1, as well as parallel helical gearboxes.

WM Berg – Precision Gears and Mechanical Components

Domain: wmberg.com

Registered: 1996 ( 29 years )

Introduction: WM Berg specializes in precision helical gears and various other mechanical components including assemblies, belts, chains, sprockets, pulleys, shafting, bearings, couplings, and custom precision parts.

Category Information

Helical gears are a type of gear mechanism characterized by their teeth, which are cut at an angle to the axis of rotation. This design allows for smoother and quieter operation compared to other gear types, such as spur gears. Helical gears are commonly used in various applications, including automotive transmissions, industrial machinery, and robotics, where efficient power transmission and reduced noise are essential.

The significance of helical gears lies in their ability to handle higher loads and provide greater torque than their spur counterparts, thanks to the gradual engagement of their teeth. This feature makes them ideal for high-speed and high-performance applications. Additionally, the angled teeth help to distribute the load more evenly across the gear, enhancing durability and reducing wear over time. Overall, helical gears play a crucial role in modern engineering and mechanical systems.

Application Information

Helical gears are widely utilized in various industries due to their efficiency in transmitting motion and power between shafts at different angles. One prominent application area is in the automotive industry, where they are used in gearboxes to provide smooth and quiet operation, enhancing vehicle performance and fuel efficiency. Another key area is in manufacturing equipment, particularly in conveyor systems and machine tools, where helical gears facilitate precise motion control and improve load handling.

Additionally, they are integral to the aerospace sector, where reliability and durability are critical for gear systems in aircraft engines and landing gear mechanisms. Other applications include robotics, where helical gears contribute to accurate positioning and movement, and power generation systems, enhancing the performance of turbines and generators. Overall, helical gears play a crucial role in numerous mechanical systems across various sectors.

Production Process Information

The production of helical gears involves several key steps that ensure precision and quality. First, the process begins with design and engineering, where specifications such as size, material, and tooth configuration are determined using computer-aided design (CAD) software. This stage is crucial, as it lays the foundation for how the gear will perform in its intended application. Next comes material selection and preparation. Helical gears are typically made from metals like steel or aluminum, chosen for their strength and durability.

The selected material is then machined, which involves cutting and shaping it to form the gear’s teeth and overall structure. This can include processes like hobbing or grinding to achieve the desired finish. Finally, quality control is essential. Each helical gear undergoes inspection to ensure it meets the required specifications and tolerances. This may involve testing for strength and precision before the gears are packaged and shipped for use in various machinery and applications.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a helical gear manufacturer?

When choosing a helical gear manufacturer, consider their experience in the industry, production capabilities, quality certifications, and customer reviews. It’s also important to assess their ability to provide custom solutions and their responsiveness to inquiries. A good manufacturer should demonstrate expertise in gear design and have a solid track record of delivering reliable products.

How can I verify the quality of a helical gear factory?

To verify a factory’s quality, request samples of their products and review their quality control processes. Look for certifications like ISO 9001, which indicates a commitment to quality management. Additionally, check customer testimonials and case studies to see how they handle quality issues and their overall reputation in the industry.

What is the typical lead time for helical gears?

Lead times can vary based on the manufacturer’s production capacity and the complexity of your order. Generally, you can expect lead times to range from a few weeks to a couple of months. It’s best to discuss your specific requirements with the manufacturer to get a more accurate estimate.

Are custom helical gears more expensive than standard ones?

Yes, custom helical gears typically cost more than standard options due to the additional design and manufacturing processes involved. However, the investment can be worthwhile if you need gears that meet specific performance requirements. Always request quotes from multiple manufacturers to compare prices and find the best value.

How do I ensure good communication with my helical gear supplier?

To ensure effective communication, establish clear expectations from the start and maintain regular updates throughout the project. Use multiple communication channels like email, phone calls, and video meetings. Building a good relationship with your supplier can also foster open dialogue, making it easier to address any concerns as they arise.

![12 Different Types of Gears and Their Applications [PDF] - helical gear](https://www.fobindustry.info/wp-content/uploads/2025/06/theengineerspostcom-helical-gear-image.jpg)

![Types of Gear: Spur, Helical, Herring Bone, Worm Gear [Notes & PDF] - helical gear](https://www.fobindustry.info/wp-content/uploads/2025/06/themechanicalengineeringcom-helical-gear-image.jpg)