Discover the Top 30 Helix Gear Manufacturers

Are you struggling to find a reliable supplier for high-quality helix gears? You’re not alone! Many engineers and manufacturers face the daunting task of sourcing precision components that meet their exacting standards. Choosing the right helix gear manufacturer can make or break your project. The right supplier not only ensures quality but can also save you time and money, allowing you to focus on what you do best.

Imagine having a trusted partner that delivers exceptional products consistently, enhancing your operations and boosting your reputation. Ready to discover the top 30 helix gear factories that can meet your needs? Dive into our comprehensive guide and unlock the potential of partnering with the best in the business!

Top 30 Helix Gear Manufacturers

Boston Gear – Helical Gears for Industrial Applications

Domain: bostongear.com

Registered: 1997 ( 28 years )

Introduction: Boston Gear offers a range of helical gears designed for various industrial applications, focusing on durability and performance.

Mcmaster – High-Power Metal Gears Solutions

Domain: mcmaster.com

Registered: 1994 ( 31 years )

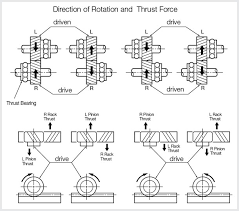

Introduction: The company offers a variety of high-power metal gears, including crossed right-hand and left-hand gears, parallel gears on gear racks, and gears with keyed bores and set screws. These gears are designed for high load transmission and speed.

KHK Gears – Helical Gears for Quiet Operation

Domain: khkgears.net

Registered: 2015 ( 10 years )

Introduction: KHK offers helical gears, which are cylindrical gears with slanted tooth traces, designed for quiet operation and capable of transmitting large forces.

Motion Control Tips – Helical Gear Solutions

Domain: motioncontroltips.com

Registered: 2007 ( 18 years )

Introduction: Helical gears are a type of gear with teeth that are cut at an angle to the axis of rotation, allowing for smoother and quieter operation compared to other gear types.

Drivetrainhub – Helical Gear Solutions

Testbook – Helical Gears Solutions

Domain: testbook.com

Registered: 2004 ( 21 years )

Introduction: Helical gears are essential mechanical components used for transmitting motion and power between parallel shafts, characterized by their helically-shaped teeth.

Gearsolutions – Helical Gear Solutions

Domain: gearsolutions.com

Registered: 2008 ( 17 years )

Introduction: Helical gears, which are a type of gear with teeth that are cut at an angle to the axis of rotation, providing smoother and quieter operation compared to other gear types.

Iqsdirectory – Helical Gears for High-Speed Applications

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

Introduction: Helical gears designed for high-speed applications, significant power transmission, and noise reduction, suitable for various industrial gearboxes and automotive transmissions.

Tec Science – Helical Gear Solutions

Domain: tec-science.com

Registered: 2017 ( 8 years )

Introduction: Helical gears are a type of gear characterized by their angled teeth, which provide smoother and quieter operation compared to other gear types.

Roymech – Helical Gear Solutions

Domain: roymech.org

Registered: 2019 ( 6 years )

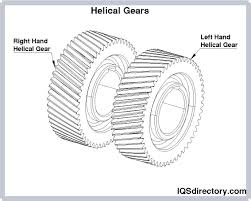

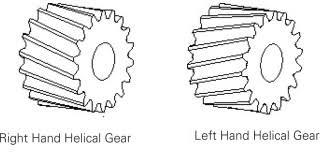

Introduction: Helical gears designed for smoother operation and higher speed capabilities compared to spur gears, with options for right-handed and left-handed configurations.

ZHY Gear – Helical Gear Manufacturing Solutions

Domain: zhygear.com

Registered: 2018 ( 7 years )

Introduction: ZHY Gear specializes in the design and manufacturing of helical gears, which are known for their efficiency and smooth operation in various mechanical applications.

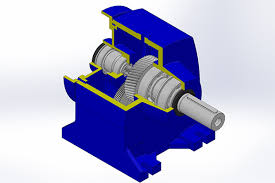

Speedogears – Helical Gearbox Solutions

Domain: speedogears.com

Registered: 2021 ( 4 years )

Introduction: Helical Gearbox is a type of industrial gearbox used for power transmission, designed to reduce speed and increase force between turning shafts. It features helical gears with slanted teeth for improved performance.

Us – Helical Gears for Power Transmission

Domain: us.misumi-ec.com

Registered: 2007 ( 18 years )

Introduction: Helical gears designed for efficient power transmission and motion control.

Learnmech – Helical Gear Solutions

Domain: learnmech.com

Registered: 2017 ( 8 years )

Introduction: Helical gears are a type of gear used in various mechanical applications, known for their angled teeth that provide smooth and efficient power transmission.

Qtcgears – High-Speed Helical Gears Solutions

Domain: qtcgears.com

Registered: 1996 ( 29 years )

Introduction: KHK stock helical gears are quiet, compact and economical, suitable for high-speed rotation in machine tools, speed reducers, and other industrial machinery.

Cnclathing – Precision CNC Machining Services

Domain: cnclathing.com

Registered: 2018 ( 7 years )

Introduction: CNC machining services including 5-axis machining, CNC turning, CNC milling, Swiss machining, and more. The company also offers rapid prototyping, precision machining, and various material fabrications.

Link – Helical Gear Solutions

Domain: link.springer.com

Registered: 1997 ( 28 years )

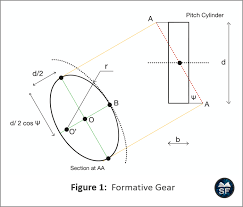

Introduction: Helical gears are cylindrical gears with teeth that follow a helix on the pitch cylinder, available in external and internal configurations.

KHK Gears – Premium Metric Helical Gears

Domain: khkgears.us

Registered: 2015 ( 10 years )

Introduction: KHK USA offers premium metric helical gears made from alloy steel and carbon steel, available in various configurations of modules and numbers of teeth. Their helical gears are designed for high-speed rotation applications and allow for secondary operations.

WM Berg – Precision Helical Gears and Gearboxes

Domain: wmberg.com

Registered: 1996 ( 29 years )

Introduction: WM Berg specializes in precision helical gears and offers a wide range of related products including custom gears, gearboxes, and various mechanical components.

Santram Engineers – Helical Gears Solutions

Domain: santramengineers.com

Registered: 2008 ( 17 years )

Introduction: The company offers single and double helical gears for helical gearboxes, focusing on performance, efficiency, and durability.

Engineers Edge – Gear Design Calculations and Formulas

Domain: engineersedge.com

Registered: 2000 ( 25 years )

Introduction: The company offers gear design formulas and calculations for various types of gears, including spur gears, bevel gears, and worm gears.

Sanfoundry – Helical Gears for Efficient Power Transmission

Domain: sanfoundry.com

Registered: 2010 ( 15 years )

Introduction: Helical gears designed for various applications, providing efficient power transmission with reduced noise and vibration.

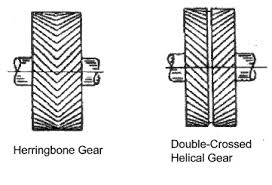

Geartechnology – Helical and Herringbone Gears

Domain: geartechnology.com

Registered: 1995 ( 30 years )

Introduction: Helical gears with varying helix angles, including herringbone gears.

Sciencedirect – Helical Gears for Mechanical Applications

Domain: sciencedirect.com

Registered: 1997 ( 28 years )

Introduction: Helical gears designed for high efficiency and smooth operation in various mechanical applications.

The Engineers Post – Precision Gear Solutions

Domain: theengineerspost.com

Registered: 2018 ( 7 years )

Introduction: The company offers a variety of gears including spur gears, helical gears, double helical gears, bevel gears, spiral bevel gears, and screw gears, which are used for transmitting energy and motion in mechanical devices.

KHK Gears – Precision Gear Solutions

Domain: khkgears2.net

Registered: 2018 ( 7 years )

Introduction: KHK offers a variety of gears including helical gears, spur gears, gear racks, worm gears, bevel gears, miter gears, internal gears, and screw gears.

Linquip – Helical Gearbox Solutions

Domain: linquip.com

Registered: 2019 ( 6 years )

Introduction: Helical gearboxes are power transmission instruments primarily utilized to reduce speed and increase torque between turning shafts. They are one of the most widely used gearboxes and are more effective than other types.

Bdgears – Double Helical Gears Solutions

Domain: bdgears.com

Registered: 2023 ( 2 years )

Introduction: Double helical gears designed for high load capacity and smooth operation.

Ocw – Helical Gear Solutions

Domain: ocw.mit.edu

Registered: 1985 ( 40 years )

Introduction: Helical gears designed for gear drive systems, focusing on their geometry and load capacity.

Reference – Helical Gear Solutions

Domain: reference.com

Registered: 1995 ( 30 years )

Introduction: Helical gears, which are mechanical components known for their efficiency and smooth operation, characterized by their helix angle.

Category Information

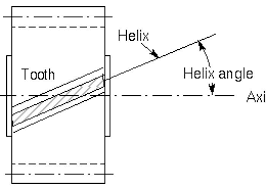

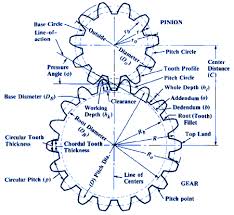

Helix gears, also known as helical gears, are a type of gear that features teeth that are cut at an angle to the axis of rotation. This design allows for smoother and quieter operation compared to traditional spur gears, as the teeth engage gradually rather than simultaneously. Helix gears are commonly used in various mechanical applications, including automotive transmissions, industrial machinery, and robotics, where high torque and efficiency are essential.

The significance of helix gears lies in their ability to transmit power effectively while minimizing wear and noise. Their angled teeth provide better contact over a larger surface area, resulting in reduced stress and increased load capacity. This makes them an ideal choice for high-performance applications, contributing to advancements in engineering and technology across multiple industries.

Application Information

Helix gears, characterized by their helical tooth design, are widely utilized in various industries due to their efficiency in transmitting power and reducing noise. One significant application area is in the automotive industry, where they are employed in gearboxes and differentials, providing smooth operation and improved torque transfer. Their ability to handle higher loads makes them ideal for vehicle drivetrain systems. Another key area is in industrial machinery, where helix gears are used in conveyors, mixers, and pumps.

Their design allows for continuous engagement, which enhances performance and durability in heavy-duty applications. Additionally, they find use in robotics and automation systems, where precision and reliability are crucial. By minimizing backlash and ensuring consistent motion, helix gears play a vital role in the efficiency of these technologies. Overall, their versatility makes them essential in many mechanical systems across diverse sectors.

Production Process Information

Manufacturing helix gears involves several key stages to ensure precision and functionality. First, the design phase is crucial, where engineers create detailed specifications using computer-aided design (CAD) software. This step includes determining the gear’s dimensions, helix angle, and material, which can significantly impact performance. Next, the material selection comes into play. Helix gears are typically made from metals like steel or aluminum for durability, but plastics may be used for lighter applications.

Once materials are chosen, the production process begins, often involving machining techniques such as milling and grinding to shape the gears accurately. After machining, gears undergo quality control checks to ensure they meet the required specifications. Finally, the gears are assembled into their respective systems, like gearboxes or machinery, where they play a vital role in transmitting motion efficiently. Proper lubrication and testing of the assembled products ensure smooth operation and longevity.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a helix gear manufacturer?

When choosing a helix gear manufacturer, consider their experience in gear production, quality certifications (like ISO), production capabilities, and material options. Also, check their ability to meet your specific design requirements and lead times. Customer reviews and case studies can provide insight into their reliability and service quality.

How can I assess the quality of a helix gear factory?

To assess quality, request samples of their products and review their manufacturing processes. Look for certifications like ISO 9001, which indicates a commitment to quality management. Additionally, inquire about their quality control measures and any testing methods they use to ensure product durability and performance.

What is the typical lead time for helix gear production?

Lead times can vary based on complexity and order size, but they typically range from a few weeks to several months. It’s best to discuss your specific requirements with potential manufacturers to get a more accurate estimate. Always factor in additional time for any design revisions or adjustments.

Are there minimum order quantities (MOQs) for helix gears?

Yes, many manufacturers have minimum order quantities, which can vary widely. Some may require a minimum of a few pieces, while others may have higher thresholds. Always clarify MOQs upfront to ensure they align with your project needs and budget.

How can I ensure good communication with my chosen manufacturer?

Establish clear communication channels from the start. Use emails, video calls, or project management tools to stay in touch. Discuss your expectations regarding updates and feedback, and ensure the manufacturer is responsive and open to your questions. Building a good relationship fosters better collaboration throughout the project.

![12 Different Types of Gears and Their Applications [PDF] - helix gear](https://www.fobindustry.info/wp-content/uploads/2025/06/theengineerspostcom-helix-gear-image.jpg)