Master AC Motors Sourcing: Essential Guide for B2B Buyers

Introduction: Navigating the Global Market for ac motors

Electric motors are the unsung heroes of modern industry, playing a pivotal role in enhancing productivity across various sectors—from agriculture and manufacturing to logistics and infrastructure. As global demand for energy-efficient solutions rises, AC motors have emerged as a preferred choice due to their reliability, versatility, and cost-effectiveness. For B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, the selection of the right AC motor is not just a technical decision but a strategic one that can significantly impact operational efficiency and bottom-line performance.

This comprehensive guide serves as a crucial resource for international buyers navigating the complexities of the AC motor market. It covers a broad spectrum of topics, including:

- Types of AC Motors: Detailed insights into induction, synchronous, and servo motors tailored to specific industrial applications.

- Materials and Manufacturing Quality: Evaluating durability and compliance with regional standards to ensure long-lasting performance.

- Supplier Selection: Frameworks for identifying and qualifying suppliers, negotiating contracts, and managing risks.

- Cost Considerations: Strategies to optimize procurement expenses while maximizing value.

- Market Insights: Up-to-date intelligence on trends and challenges affecting AC motor sourcing.

By leveraging the insights offered in this guide, B2B buyers can make informed decisions that not only enhance operational capabilities but also foster a competitive edge in an increasingly interconnected global market.

Understanding ac motors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Induction Motor | Simple design, robust, operates on AC power | Pumps, compressors, conveyors, fans | Reliable, widely available; less efficient at variable speeds |

| Synchronous Motor | Rotor speed synchronized with supply frequency | Process plants, mills, power factor correction | High efficiency, precise speed; complex start-up, higher cost |

| Brushless DC (BLDC) Motor | Electronic commutation, high efficiency, minimal maintenance | Electric vehicles, HVAC, medical equipment | Long lifespan, compact; higher upfront cost, requires electronic control |

| Servo Motor | Precise position/speed control, closed-loop feedback | Robotics, CNC, high-precision automation | Exceptional accuracy; more expensive, complex commissioning |

| Gear Motor | Integrated gearbox for torque and speed adaptation | Packaging, materials handling, agitators | Simplifies system design; gearbox wear, modest efficiency loss |

AC Induction Motor

AC induction motors are characterized by their robustness and simplicity, making them a staple in various industrial applications. They operate efficiently on alternating current and are particularly suitable for environments with fluctuating voltages, common in regions like Africa and South America. When purchasing, buyers should ensure compatibility with local electrical standards and consider the availability of spare parts and maintenance services. The primary downside is their reduced efficiency when operating at variable speeds, which may impact applications requiring precise speed control.

Synchronous Motor

Synchronous motors are known for their ability to maintain a constant speed synchronized with the electrical supply frequency. This feature makes them ideal for applications where precise speed control is essential, such as in process plants and power factor correction systems. While they offer high efficiency and performance, buyers should be aware of the complexities involved in their installation and maintenance, which may require specialized skills. Additionally, the initial costs can be higher than those of induction motors, making it essential to evaluate the long-term operational benefits against upfront investments.

Brushless DC (BLDC) Motor

BLDC motors provide high efficiency and low maintenance due to their electronic commutation, eliminating the need for brushes. This makes them particularly appealing for applications in electric vehicles, HVAC systems, and medical equipment where space and energy efficiency are critical. B2B buyers should consider the higher initial costs and ensure that local technicians are trained to handle the necessary electronic controls. The long lifespan and compact design of BLDC motors can lead to lower total lifecycle costs, making them a strategic investment for forward-thinking organizations.

Servo Motor

Servo motors excel in applications requiring precise control over position and speed, making them indispensable in robotics and CNC machinery. Their closed-loop feedback systems ensure exceptional accuracy, which is crucial in high-precision automation tasks. However, the complexity of commissioning and the higher price point can be barriers for some buyers. Organizations looking to enhance automation capabilities should weigh these factors against the potential productivity gains and consider the availability of skilled personnel for installation and maintenance.

Gear Motor

Gear motors combine an electric motor with a gearbox, allowing for torque and speed adaptation tailored to specific applications. They are commonly used in packaging, materials handling, and agitators, where space and design simplicity are priorities. While they simplify system design, buyers should consider the potential for gearbox wear and modest efficiency losses. It’s essential to evaluate the specific torque requirements and installation constraints of the application to ensure optimal performance and longevity of the gear motor system.

Related Video: Types of AC Motor – Different Types of Motors – Electric Motor Types

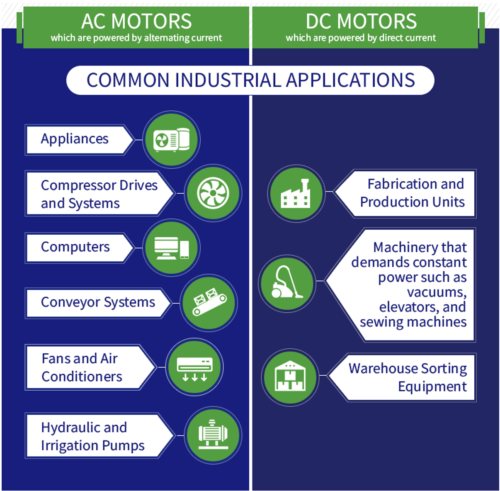

Key Industrial Applications of ac motors

| Industry/Sector | Specific Application of AC Motors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Increased efficiency and reduced labor costs | Ensure compatibility with local voltage and frequency standards; assess availability of spare parts. |

| Agriculture | Irrigation Pumps | Enhanced water management and crop yield improvement | Evaluate energy efficiency ratings; confirm local service support for maintenance. |

| Water Treatment | Filtration and Pumping Systems | Improved water quality and compliance with regulations | Verify compliance with local environmental standards; assess the durability of motors in harsh conditions. |

| HVAC | Air Conditioning Units | Better climate control and energy savings | Check for energy efficiency ratings; ensure compatibility with existing systems and local regulations. |

| Transportation | Electric Vehicle Charging Stations | Support for sustainable transport solutions | Assess the infrastructure for local electrical compatibility; consider the availability of technical support and installation services. |

Manufacturing: Conveyor Systems

In manufacturing environments, AC motors are integral to conveyor systems, facilitating the movement of materials and products through production lines. They enhance operational efficiency, reduce labor costs, and minimize manual handling. For international buyers, particularly in regions like Africa and South America, it’s crucial to ensure that the selected motors are compatible with local voltage and frequency standards. Additionally, assessing the availability of spare parts and service providers can prevent costly downtimes, ensuring seamless operations.

Agriculture: Irrigation Pumps

AC motors power irrigation pumps, which are essential for effective water management in agriculture. They enable farmers to optimize water usage, leading to improved crop yields and resource efficiency. Buyers in emerging markets should prioritize energy-efficient models to reduce operational costs. Furthermore, confirming that local technicians are skilled in servicing these motors can enhance long-term reliability and performance, making it a vital consideration during procurement.

Water Treatment: Filtration and Pumping Systems

In the water treatment sector, AC motors drive filtration and pumping systems that are critical for ensuring clean and safe water supply. These motors help improve water quality while ensuring compliance with environmental regulations. For B2B buyers, especially in the Middle East, it is essential to verify that the motors meet local environmental standards and can withstand harsh operating conditions. Evaluating the durability and reliability of the motors can mitigate risks associated with system failures.

HVAC: Air Conditioning Units

AC motors are fundamental in HVAC systems, particularly in air conditioning units, where they control fans and compressors. They contribute to better climate control and energy savings, which are increasingly important in both commercial and residential settings. Buyers from Europe and other regions must check for energy efficiency ratings and ensure that the motors are compatible with existing HVAC systems. Understanding local regulations regarding energy use can also guide purchasing decisions.

Transportation: Electric Vehicle Charging Stations

In the transportation sector, AC motors are critical for electric vehicle (EV) charging stations, facilitating the conversion of electrical energy for vehicle charging. This application supports sustainable transport solutions and contributes to the growing demand for electric mobility. International buyers should assess the infrastructure for local electrical compatibility to ensure efficient operations. Additionally, considering the availability of technical support and installation services can enhance the overall procurement strategy.

Related Video: Working principle of AC motors

Strategic Material Selection Guide for ac motors

When selecting materials for AC motors, international B2B buyers must consider several key factors, including the properties of the materials, their suitability for specific applications, and the implications for cost and manufacturing complexity. Here, we analyze four common materials used in AC motors: aluminum, copper, steel, and composite materials.

Aluminum

Key Properties:

Aluminum is lightweight and exhibits excellent corrosion resistance, making it ideal for applications in humid or corrosive environments. It has a moderate temperature rating and is capable of withstanding typical operational pressures found in industrial settings.

Pros & Cons:

Aluminum’s lightweight nature allows for easier handling and installation, reducing overall labor costs. However, it is less durable than steel and can be more prone to deformation under heavy loads. The cost of aluminum is generally moderate, though prices can fluctuate based on market conditions.

Impact on Application:

Aluminum is particularly suitable for applications where weight savings are critical, such as in mobile equipment or where space is limited. However, buyers should be cautious of its lower tensile strength in high-torque applications.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure that aluminum components comply with local standards, such as ASTM or ISO certifications, to guarantee performance and safety.

Copper

Key Properties:

Copper is known for its excellent electrical conductivity and thermal properties. It also offers good corrosion resistance and can handle high temperatures, making it suitable for demanding applications.

Pros & Cons:

The primary advantage of copper is its superior conductivity, which enhances motor efficiency and reduces energy losses. However, copper is relatively expensive compared to alternatives, and its weight can be a drawback in applications where weight is a concern.

Impact on Application:

Copper is ideal for windings and connections in AC motors, especially in high-performance applications requiring efficient heat dissipation. Its compatibility with various media makes it versatile across different sectors.

Considerations for International Buyers:

B2B buyers should verify that copper components meet relevant international standards, as variations in quality can impact performance. Buyers should also consider the implications of copper pricing volatility in their procurement strategies.

Steel

Key Properties:

Steel is known for its high strength and durability, with excellent resistance to wear and deformation. It can handle high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons:

The robust nature of steel ensures long-lasting performance, particularly in high-load environments. However, its weight can increase installation and transportation costs. Steel is generally more affordable than aluminum and copper, offering a good balance between cost and performance.

Impact on Application:

Steel is commonly used for motor housings, shafts, and rotors, where strength and durability are paramount. It is well-suited for industrial applications such as manufacturing and heavy machinery.

Considerations for International Buyers:

Buyers should ensure that steel components comply with local and international standards, such as DIN or JIS, to ensure compatibility with existing systems and regulatory requirements.

Composite Materials

Key Properties:

Composite materials, often made from a combination of plastics and fibers, offer unique properties such as lightweight construction and good resistance to corrosion and environmental factors.

Pros & Cons:

The lightweight nature of composites can lead to reduced energy consumption in applications where weight is critical. However, they may not provide the same level of strength or thermal conductivity as metals, which can limit their use in high-load or high-temperature environments. Composite materials can vary significantly in cost, often falling into the medium to high range depending on the specific formulation.

Impact on Application:

Composites are suitable for applications requiring corrosion resistance and lightweight components, such as in marine or chemical processing environments. However, their performance under mechanical stress should be carefully evaluated.

Considerations for International Buyers:

Buyers should assess the certification and testing standards for composite materials to ensure they meet the specific requirements of their applications. Understanding local preferences for material types can also influence procurement decisions.

Summary Table

| Material | Typical Use Case for AC Motors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications, mobile equipment | Excellent corrosion resistance | Less durable than steel | Medium |

| Copper | Windings and connections | Superior electrical conductivity | Higher cost and weight | High |

| Steel | Motor housings, shafts, and rotors | High strength and durability | Increased weight | Low |

| Composite Materials | Corrosion-resistant applications | Lightweight and corrosion-resistant | Limited strength and conductivity | Medium to High |

This strategic analysis of materials provides B2B buyers with essential insights to make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ac motors

Manufacturing Processes for AC Motors

Understanding the manufacturing processes behind AC motors is crucial for international B2B buyers who seek reliable and efficient solutions for their operations. The production of AC motors typically involves several key stages, including material preparation, forming, assembly, and finishing. Each stage employs specific techniques that ensure the motors meet performance and quality standards.

Material Preparation

The manufacturing process begins with the careful selection and preparation of materials. Commonly used materials include:

- Copper: For windings due to its excellent electrical conductivity.

- Silicon Steel: Used for the stator and rotor cores to minimize energy losses.

- Insulation Materials: Such as varnishes and resins, which are essential for electrical insulation.

Material quality is crucial, as it directly affects the motor’s efficiency and longevity. Suppliers should provide certification for the materials used, ensuring they meet relevant international standards.

Forming

The next stage involves forming the components of the AC motor. Key techniques include:

- Stamping: For creating the laminations of the stator and rotor cores, which reduces eddy current losses.

- Winding: The process of winding the copper wire around the stator and rotor. This can be done manually or through automated machines, with precise control over winding patterns to optimize performance.

- Casting: Used for creating end shields and housings, often employing aluminum or other lightweight materials to reduce overall weight.

Precision in forming is essential to ensure that parts fit together correctly and function efficiently. Variations in dimensions can lead to operational inefficiencies or increased wear.

Assembly

Assembly is a critical phase where individual components are brought together to form the complete motor. This stage typically involves:

- Fitting the Rotor and Stator: Ensuring the rotor spins freely within the stator.

- Installation of Bearings: Critical for smooth operation and longevity.

- Connection of Electrical Components: Including terminal blocks and controllers, ensuring correct wiring to prevent short circuits or other electrical issues.

Quality control during assembly is vital. Any misalignment or improper installation can lead to performance issues or failures.

Finishing

The finishing stage encompasses several processes aimed at enhancing the motor’s durability and aesthetic appeal. Key activities include:

- Surface Treatment: Such as painting or powder coating to prevent corrosion and improve appearance.

- Balancing: Ensuring that the rotor is balanced to reduce vibrations during operation.

- Testing: Initial testing of motor functionality before packaging, which may include performance tests under various load conditions.

Quality Assurance for AC Motors

Quality assurance is critical in the manufacturing of AC motors, as it directly impacts reliability and operational efficiency. B2B buyers must be aware of international standards and industry-specific certifications that suppliers should adhere to.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers to ensure consistent quality in their processes and products.

- CE Marking: Required for products sold in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- API Standards: Important for motors used in oil and gas applications, ensuring that products meet industry-specific requirements.

Quality Control Checkpoints

Quality control should be integrated at multiple checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Evaluating materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring processes during production to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products before shipping, ensuring they meet performance and safety standards.

Common Testing Methods

B2B buyers should be familiar with the following testing methods to assess motor quality:

- Electrical Testing: Measures parameters such as resistance, inductance, and insulation resistance.

- Performance Testing: Evaluates efficiency, power factor, and thermal performance under load.

- Vibration Analysis: Identifies potential mechanical issues and ensures that the motor operates smoothly.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensure the reliability of AC motors. Here are some actionable steps:

- Conduct Audits: Regular audits of suppliers can help assess their manufacturing processes and quality control measures.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including records of tests performed and compliance with standards.

- Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of the motor’s quality before final acceptance.

Quality Control Nuances for International Buyers

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate additional nuances in quality control:

- Local Standards Compliance: Ensure that the supplier’s products comply with local regulations and standards, which may differ from international ones.

- Supply Chain Reliability: Evaluate the supplier’s ability to provide consistent quality amidst regional challenges such as infrastructure limitations or political instability.

- Cultural Considerations: Understand the cultural context of the supplier’s operations, which may affect communication and quality expectations.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance for AC motors is essential for B2B buyers. By focusing on material selection, production techniques, and robust quality control measures, buyers can ensure they procure reliable and efficient motors that meet their operational needs.

Related Video: BMW 5 Series (2024) PRODUCTION 🇩🇪 Car Manufacturing Process

Comprehensive Cost and Pricing Analysis for ac motors Sourcing

Navigating the cost structure and pricing landscape for AC motors is essential for international B2B buyers looking to optimize their procurement strategies. Understanding the components that contribute to the total cost, as well as the factors that influence pricing, can empower buyers to make informed decisions that align with their operational needs.

Cost Components of AC Motors

- Materials: The primary cost driver in AC motor manufacturing is the raw materials used, including copper, steel, and insulation materials. Fluctuations in the prices of these materials can significantly impact the final cost of motors. Buyers should be aware of global market trends, especially in regions like Africa and South America where local sourcing may influence material costs.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs vary widely depending on the manufacturing location. In regions with lower labor costs, such as parts of South America and Southeast Asia, buyers might find more competitive pricing. However, it’s essential to consider the skill level and labor laws of the region, as these factors can affect production quality.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can lower overhead costs, making it vital for buyers to assess the operational efficiency of potential suppliers.

-

Tooling: Initial tooling costs can be significant, particularly for custom motors. Buyers looking for specialized designs should factor in these costs, as they can be amortized over larger production runs, potentially lowering the unit price.

-

Quality Control (QC): Investing in quality assurance processes ensures that the motors meet performance and safety standards. While this adds to the cost, it can mitigate risks associated with downtime and maintenance in the long run.

-

Logistics: Transportation costs can vary based on the Incoterms agreed upon in the contract. For international shipments, consider freight costs, insurance, and potential tariffs that may apply, especially when sourcing from regions with different trade agreements.

-

Margin: Supplier margins can fluctuate based on market demand, competition, and the supplier’s positioning. Understanding the typical margins in your region can aid in negotiations.

Price Influencers

-

Volume/MOQ: Higher order volumes often lead to lower unit prices due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that suit their operational needs while maximizing cost efficiency.

-

Specifications/Customization: Custom specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses while still ensuring the motor meets application needs.

-

Quality/Certifications: Motors that comply with international quality standards or certifications (like ISO or CE) may command higher prices but offer assurance of reliability and performance. This is particularly important for critical applications in sectors like manufacturing and oil and gas.

-

Supplier Factors: Supplier reputation and reliability can influence pricing. Established suppliers may offer higher prices due to their proven track record, while emerging suppliers might provide competitive rates to enter the market.

-

Incoterms: Understanding the agreed-upon Incoterms can affect total landed costs. For example, DDP (Delivered Duty Paid) includes all costs up to delivery, while FOB (Free on Board) requires buyers to manage shipping and customs.

Buyer Tips

-

Negotiation: Leverage your knowledge of cost components and price influencers during negotiations. Building long-term relationships with suppliers can also lead to better pricing and terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes purchase price, installation, maintenance, and energy costs over the motor’s lifecycle. This holistic view helps identify the most economically viable options.

-

Pricing Nuances for International Buyers: International buyers should account for currency fluctuations, local market conditions, and geopolitical factors that may impact pricing. Engage local experts or procurement consultants to navigate these complexities.

In conclusion, a thorough understanding of the cost components, price influencers, and strategic negotiation tactics can significantly enhance the procurement process for AC motors. By being informed and proactive, B2B buyers can ensure they achieve the best value for their investments in this critical technology.

Disclaimer: Prices and cost structures can vary widely based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier assessments before making purchasing decisions.

Spotlight on Potential ac motors Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ac motors’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ac motors

Key Technical Properties of AC Motors

When procuring AC motors, understanding critical technical specifications is essential for ensuring optimal performance and compatibility with your applications. Here are some of the most important properties to consider:

-

Efficiency Rating

The efficiency rating indicates how effectively a motor converts electrical energy into mechanical energy. Higher efficiency translates to lower operational costs and reduced energy consumption, making it a vital consideration for businesses aiming to minimize expenses. Compliance with international efficiency standards also reflects a commitment to sustainability. -

Power Rating

Measured in horsepower (HP) or kilowatts (kW), the power rating defines the motor’s output capability. Selecting the appropriate power rating is crucial to ensure that the motor can handle the specific demands of your application, whether it be in manufacturing, HVAC, or transportation sectors. Underestimating power requirements can lead to performance issues and increased wear on the motor. -

Torque Characteristics

Torque is a measure of rotational force, with starting torque and full-load torque being critical metrics. Different applications require varying torque levels; therefore, understanding these characteristics helps ensure that the motor can perform effectively under load. For example, high starting torque is essential for applications like conveyors or lifts that require an initial push to start movement. -

Material Grade

The materials used in the construction of AC motors affect their durability, performance, and resistance to environmental factors. Common materials include cast iron for housings and copper for windings. Selecting motors with high-quality materials can enhance reliability and longevity, reducing the frequency and cost of maintenance. -

Cooling Mechanism

Effective cooling is vital, particularly in high-performance scenarios where excessive heat can lead to motor failure. Common cooling methods include air cooling and liquid cooling. Understanding the cooling requirements will help in selecting a motor suitable for the intended operating environment and ensure consistent performance. -

Voltage and Frequency Compatibility

AC motors are designed to operate at specific voltage and frequency levels. Buyers must verify that the motor matches the local electrical supply to avoid operational issues. In regions with unstable power supply, selecting motors that can tolerate voltage fluctuations is crucial.

Common Trade Terminology

Familiarity with industry jargon can facilitate smoother negotiations and procurement processes. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for ensuring compatibility and support for your motor systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively and avoid overstocking or stockouts, especially in markets with variable demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. Submitting an RFQ helps buyers compare costs and terms across multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for managing logistics and costs effectively. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Recognizing lead times is crucial for project planning and ensuring that production schedules are met without delays.

Illustrative Image (Source: Google Search)

- Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and reliability of the motor over a specified period. Reviewing warranty terms can protect buyers from unforeseen failures and associated costs.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and align with their organizational goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ac motors Sector

Market Overview & Key Trends

The global AC motors market is experiencing significant growth, driven by increasing demand for energy efficiency and automation across various sectors. Key drivers include the shift towards renewable energy sources, the need for industrial automation, and the growing emphasis on reducing operational costs. According to MarketsandMarkets, the market is projected to reach $21.74 billion by 2026, with a CAGR of 5.3%. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic procurement.

Emerging trends in sourcing include a heightened focus on digitalization and smart technologies. Manufacturers are increasingly integrating IoT capabilities into AC motors, enabling real-time monitoring and predictive maintenance. This trend not only enhances operational efficiency but also minimizes downtime—a critical factor for buyers in industries like manufacturing and logistics. Furthermore, buyers are leveraging data analytics to optimize their procurement strategies, identifying the best suppliers based on performance metrics and sustainability practices.

Another significant trend is the growing importance of local sourcing and supply chain resilience. Fluctuating global supply chains, exacerbated by recent geopolitical events, have prompted buyers to seek local suppliers or those with a robust regional presence. This shift not only reduces lead times but also mitigates risks associated with international logistics. B2B buyers should prioritize suppliers who demonstrate flexibility and responsiveness to changing market conditions, ensuring a seamless integration of AC motors into their operations.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable factor for B2B buyers in the AC motors sector. The environmental impact of electric motors, particularly regarding energy consumption, is significant, as they account for approximately 43% of global electricity usage. Buyers must prioritize sourcing AC motors that meet or exceed international efficiency standards, thereby reducing their carbon footprint and operational costs.

Ethical sourcing is equally important, with increasing scrutiny on supply chains. Buyers should consider suppliers that adhere to sustainability certifications such as ISO 14001 or those that employ recycled materials in their manufacturing processes. Transparency in sourcing practices not only enhances brand reputation but also aligns with the growing consumer demand for responsible business practices.

In addition, the adoption of “green” technologies in motor production—such as the use of environmentally friendly lubricants and eco-efficient cooling systems—can further bolster sustainability efforts. B2B buyers should engage with manufacturers committed to sustainable practices and consider the lifecycle impact of AC motors, from production through to end-of-life recycling.

Brief Evolution/History

The evolution of AC motors has been marked by significant technological advancements since their inception in the late 19th century. Initially, AC motors were primarily used in industrial applications due to their efficiency and robustness. Over the decades, innovations in materials, design, and control systems have transformed their capabilities, making them suitable for a wider range of applications, including HVAC systems and electric vehicles.

Today, the focus has shifted towards enhancing energy efficiency and integrating smart technologies. Modern AC motors are equipped with advanced features such as variable frequency drives (VFDs), allowing for precise control over speed and torque, which is essential for optimizing energy usage in diverse applications. This evolution reflects the industry’s response to global challenges, including the need for sustainable energy solutions and the push for greater automation in manufacturing and other sectors.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of ac motors

-

What should I consider when vetting suppliers for AC motors?

When vetting suppliers, prioritize their industry experience, certifications, and customer references. Investigate their production capacity and quality assurance processes to ensure they can meet your demands. Look for suppliers with a solid track record in your specific region, as they will better understand local regulations and market conditions. Additionally, assess their ability to provide after-sales support, spare parts availability, and warranty policies, which are critical for minimizing downtime and maintaining operational efficiency. -

Can I customize AC motors to meet specific application requirements?

Yes, many suppliers offer customization options for AC motors, allowing you to tailor specifications such as power ratings, dimensions, and features like cooling mechanisms or torque characteristics. When considering customization, communicate your requirements clearly to the supplier and ask for detailed documentation on the proposed modifications. Be aware that customizations may affect lead times and costs, so it’s essential to evaluate whether the benefits align with your operational needs and budget. -

What are typical minimum order quantities (MOQs) and lead times for AC motors?

Minimum order quantities can vary significantly between suppliers and are often influenced by production capabilities and the complexity of the motor. For standard AC motors, MOQs may range from 10 to 100 units, while customized motors could have higher MOQs. Lead times typically range from 4 to 12 weeks, depending on factors like order size, customization, and supplier location. Always confirm these details before placing an order to ensure they align with your project timelines. -

What payment terms are commonly offered by AC motor suppliers?

Payment terms can vary widely, but common practices include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer net payment terms (e.g., net 30 or net 60) for established customers. It’s advisable to discuss payment options upfront and consider using secure payment methods to protect your interests. Additionally, consider negotiating payment terms that offer flexibility, especially for larger orders or ongoing contracts. -

How do I ensure quality assurance and compliance with certifications when sourcing AC motors?

To ensure quality assurance, request documentation of relevant certifications (e.g., ISO 9001, CE marking, or UL certification) from your supplier. These certifications indicate adherence to international quality standards and safety regulations. Consider arranging for third-party inspections during production or before shipment to verify compliance with your specifications. Additionally, ask for test reports and performance data to assess the motor’s reliability and efficiency under expected operating conditions. -

What logistics considerations should I keep in mind when importing AC motors?

When importing AC motors, consider factors like shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling industrial equipment to minimize delays and ensure safe transport. Be proactive in preparing necessary documentation for customs clearance, including invoices, packing lists, and compliance certificates. Additionally, account for potential lead time variations due to customs processing and local transportation logistics in your project timelines. -

How can I resolve disputes with my AC motor supplier?

To resolve disputes effectively, maintain open communication with your supplier and document all interactions related to the issue. Start by discussing the problem directly with your supplier’s designated contact. If a resolution is not reached, refer to the contract for dispute resolution procedures, which may include mediation or arbitration. It’s also beneficial to involve legal counsel experienced in international trade to navigate complex issues and ensure that your rights are protected. -

What are the best practices for maintaining AC motors to ensure longevity and performance?

Regular maintenance is crucial for the longevity and performance of AC motors. Implement a routine inspection schedule that includes checking electrical connections, lubricating bearings, and cleaning ventilation systems to prevent overheating. Monitor operational parameters such as temperature, vibration, and noise levels for early detection of potential issues. Additionally, keep a log of maintenance activities and repairs to track performance trends and ensure compliance with warranty conditions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ac motors

As the demand for AC motors continues to surge across diverse industries, strategic sourcing has emerged as a critical factor for international B2B buyers. Key takeaways from this guide emphasize the importance of understanding motor types, efficiency ratings, and compatibility with regional standards. Buyers must prioritize suppliers who not only provide high-quality products but also offer robust after-sales support and spare parts availability.

The complexity of the global market necessitates a proactive approach to procurement, allowing businesses to mitigate risks associated with fluctuating costs and supply chain disruptions. By investing time in supplier qualification and leveraging market intelligence, organizations can enhance their operational efficiency and sustainability.

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe should remain vigilant in monitoring industry trends and technological advancements. As the landscape evolves, embracing innovative motor solutions will be paramount to maintaining competitive advantages. Engage with suppliers who align with your strategic goals and invest in partnerships that foster long-term success. The future of AC motor sourcing is bright for those who act decisively and intelligently.