Master Bungee Cord Elasticity for Enhanced B2B Sourcing

Introduction: Navigating the Global Market for bungee cord elasticity

In the dynamic landscape of global trade, bungee cord elasticity has emerged as a critical component for various industries, from transportation and logistics to recreational activities and military applications. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of bungee cord elasticity is essential for ensuring product reliability and safety. The elasticity of bungee cords affects their performance in load-bearing scenarios, making it imperative for buyers to source high-quality materials that meet their specific needs.

This comprehensive guide delves into the multifaceted world of bungee cord elasticity, covering essential topics such as the types of bungee cords available, the materials used in their production, and the intricacies of the manufacturing and quality control processes. Additionally, we will explore various suppliers, cost considerations, and the overall market landscape to provide buyers with a well-rounded perspective.

By equipping yourself with this knowledge, you can make informed sourcing decisions that enhance operational efficiency and mitigate risks. Whether you are looking to secure cargo, support outdoor activities, or meet military specifications, this guide is designed to empower you with actionable insights tailored to your regional context. Together, let’s navigate the global market for bungee cord elasticity and unlock the potential for successful procurement strategies.

Understanding bungee cord elasticity Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Rubber Bungee | High resilience and tensile strength; excellent elasticity | Recreational activities, bungee jumping, securing loads | Pros: Superior elasticity; Cons: UV sensitive |

| Synthetic Rubber Bungee | Better UV and weather resistance; lower resilience than natural | Outdoor equipment, cargo securing, military uses | Pros: Durable in harsh environments; Cons: Less elastic |

| Heavy-Duty Bungee | Thicker diameter (up to 20mm); designed for extreme loads | Industrial applications, heavy cargo transport | Pros: High load capacity; Cons: Bulkier and heavier |

| Light-Duty Bungee | Smaller diameter (3-6mm); suitable for lightweight tasks | Household use, light cargo securing | Pros: Lightweight and flexible; Cons: Limited load capacity |

| Custom Bungee Cords | Tailored specifications for specific applications | Specialized industries, custom equipment needs | Pros: Meets unique requirements; Cons: Higher cost and longer lead time |

Natural Rubber Bungee

Natural rubber bungee cords are renowned for their high resilience and tensile strength, making them ideal for applications requiring significant elasticity. Commonly used in recreational activities, such as bungee jumping and securing loads during transport, these cords can stretch significantly without losing their original shape. However, they are sensitive to UV exposure, which may lead to degradation over time. B2B buyers should consider their specific use cases and whether they can provide adequate protection from sunlight or other environmental factors.

Synthetic Rubber Bungee

Synthetic rubber bungee cords offer superior resistance to UV and weather conditions, making them suitable for outdoor applications. Although they may lack the elasticity of natural rubber, they are often preferred for cargo securing in environments where exposure to the elements is a concern. Military applications also favor synthetic options due to their durability. Buyers should weigh the benefits of longevity and weather resistance against potential sacrifices in elasticity.

Heavy-Duty Bungee

Heavy-duty bungee cords, with diameters ranging from 6 to 20mm, are specifically designed to handle extreme loads. Their robust construction makes them ideal for industrial applications, including heavy cargo transport and securing equipment in demanding environments. While their strength is a significant advantage, the increased bulk and weight may be a consideration for buyers. Ensuring compatibility with existing equipment and understanding specific load requirements is crucial when purchasing these cords.

Light-Duty Bungee

Light-duty bungee cords are characterized by their smaller diameters (3-6mm) and are perfect for lightweight tasks. They are commonly used in household applications and for securing light cargo. While they are flexible and easy to handle, their load capacity is limited compared to heavier-duty options. B2B buyers should assess the weight of the items being secured to ensure that light-duty cords will suffice, as overloading can lead to failure.

Custom Bungee Cords

For specialized applications, custom bungee cords can be tailored to meet specific requirements, including size, elasticity, and material composition. These cords are invaluable for industries with unique needs, such as specialized equipment or unique load characteristics. While they offer the advantage of meeting precise specifications, buyers should be aware that custom solutions often come with higher costs and longer lead times. Thoroughly defining requirements before engaging with manufacturers can help streamline the purchasing process and ensure satisfaction with the final product.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of bungee cord elasticity

| Industry/Sector | Specific Application of bungee cord elasticity | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Securing cargo on trucks and trailers | Reduces damage to goods and improves safety | Durability, UV resistance, and tensile strength |

| Military and Defense | Shock absorption for parachute drops | Enhances safety and reliability in critical operations | Compliance with military specifications and standards |

| Recreational Activities | Bungee cords for extreme sports (e.g., bungee jumping) | Provides thrill while ensuring safety | Customization options and material quality |

| Construction and Events | Tensioning tarpaulins and banners | Ensures stability and visibility in outdoor settings | Weather resistance and load capacity |

| Marine Applications | Securing boat covers and equipment | Protects assets from environmental damage | Resistance to saltwater and UV exposure |

Transportation

In the transportation sector, bungee cords are extensively used to secure cargo on trucks and trailers. Their elasticity allows for the safe transportation of goods, preventing them from shifting during transit, which can lead to damage. B2B buyers in this sector should prioritize sourcing bungee cords with high durability and UV resistance, as these factors directly impact the longevity and effectiveness of the cords in varying weather conditions.

Military and Defense

The military utilizes bungee cord elasticity for shock absorption when dropping heavy loads by parachute. This application is critical for ensuring the safe delivery of supplies and equipment in combat zones. Buyers in this sector must focus on sourcing bungee cords that meet military specifications and standards, emphasizing tensile strength and reliability under extreme conditions to enhance operational safety.

Recreational Activities

In the realm of recreational activities, bungee cords are integral for extreme sports like bungee jumping. Their elasticity provides the necessary rebound effect while ensuring user safety. International buyers should look for customizable options that cater to specific weight limits and environmental conditions, as well as high-quality materials to guarantee performance and safety for participants.

Construction and Events

Bungee cords are also employed in construction and event management to tension tarpaulins and banners. This application ensures stability and visibility in outdoor settings, particularly during adverse weather. Buyers should consider the weather resistance and load capacity of the bungee cords to ensure they can withstand the rigors of outdoor environments, which is crucial for maintaining safety and aesthetic appeal.

Marine Applications

In marine applications, bungee cords are used for securing boat covers and equipment. Their elasticity allows for a snug fit that protects assets from environmental damage, including rain and wind. B2B buyers in this sector should prioritize sourcing bungee cords with resistance to saltwater and UV exposure, as these qualities significantly enhance the durability and effectiveness of the cords in marine environments.

Related Video: GCSE Physics – Elasticity, spring constant, and Hooke’s Law

Strategic Material Selection Guide for bungee cord elasticity

When selecting materials for bungee cord elasticity, international B2B buyers must consider various factors that impact performance, durability, and compliance with regional standards. Here’s an analysis of common materials used in the manufacturing of bungee cords, focusing on their properties, advantages, disadvantages, and implications for different markets.

Natural Rubber (Latex Rubber)

Key Properties:

Natural rubber is known for its excellent elasticity, resilience, and tensile strength. It can withstand a wide range of temperatures and has good resistance to wear and tear, making it suitable for dynamic applications.

Pros & Cons:

The primary advantage of natural rubber is its superior elasticity, allowing it to stretch significantly without permanent deformation. However, it is less resistant to UV radiation and environmental degradation compared to synthetic alternatives, which can limit its lifespan in outdoor applications.

Impact on Application:

Natural rubber is often used in recreational bungee cords, including those for bungee jumping, due to its high elasticity and performance under load. However, it may not be suitable for applications exposed to harsh weather conditions without additional protective measures.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local environmental regulations regarding natural rubber sourcing. Additionally, understanding the ASTM standards for rubber products can aid in selecting high-quality materials.

Synthetic Rubber (e.g., EPDM, Neoprene)

Key Properties:

Synthetic rubber offers enhanced resistance to UV rays, ozone, and temperature fluctuations. It maintains its elasticity over a broader range of conditions compared to natural rubber.

Pros & Cons:

The main advantage of synthetic rubber is its durability and resistance to environmental factors, making it ideal for outdoor use. However, it may not achieve the same level of elasticity as natural rubber, which can affect performance in specific applications.

Impact on Application:

Synthetic rubber is widely used in industrial bungee cords, particularly in applications requiring exposure to the elements, such as securing loads during transport. Its compatibility with various media makes it versatile for different industries.

Considerations for International Buyers:

Buyers in Europe and the Middle East should consider compliance with EU REACH regulations and other local standards. Understanding the differences in performance metrics, such as those outlined in DIN and JIS standards, is crucial for ensuring product suitability.

Polyester

Key Properties:

Polyester is known for its strength and resistance to stretching and shrinking. It also exhibits good resistance to UV light and moisture, making it suitable for outdoor applications.

Pros & Cons:

The primary advantage of polyester is its durability and low maintenance requirements. However, it does not provide the same level of elasticity as rubber materials, which may limit its use in applications requiring significant stretch.

Impact on Application:

Polyester is often used as an outer cover for bungee cords, providing protection to the elastic core while enhancing the overall strength of the cord. Its moisture resistance makes it suitable for marine and outdoor applications.

Considerations for International Buyers:

Buyers in regions with high humidity, such as parts of South America, should prioritize polyester for its moisture resistance. Compliance with international textile standards can also be a factor in selecting polyester-based products.

Nylon

Key Properties:

Nylon is a strong, durable synthetic material with good elasticity and abrasion resistance. It performs well under tension and has a high melting point, making it suitable for various applications.

Pros & Cons:

The advantage of nylon is its high tensile strength and resistance to wear, which makes it ideal for heavy-duty applications. However, it can absorb moisture, which may affect its performance in certain environments.

Impact on Application:

Nylon is commonly used in bungee cords designed for heavy-duty applications, such as cargo securing and industrial uses. Its strength allows for safe handling of significant loads.

Considerations for International Buyers:

B2B buyers in the Middle East and Europe should be aware of the specific nylon grades that meet regional standards. Additionally, understanding the implications of moisture absorption in humid climates is essential for ensuring product longevity.

Summary Table

| Material | Typical Use Case for bungee cord elasticity | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Recreational bungee jumping | Superior elasticity | Poor UV and environmental resistance | Medium |

| Synthetic Rubber | Industrial applications | High durability and UV resistance | Lower elasticity compared to natural rubber | Medium |

| Polyester | Outdoor and marine applications | Moisture and UV resistance | Limited elasticity | Low |

| Nylon | Heavy-duty cargo securing | High tensile strength | Moisture absorption can affect performance | Medium |

This guide provides a comprehensive overview of material options for bungee cord elasticity, enabling international B2B buyers to make informed decisions based on application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bungee cord elasticity

Manufacturing Processes for Bungee Cord Elasticity

The manufacturing of bungee cords, particularly those designed for elasticity, involves several critical stages that ensure the final product meets the required performance standards. Below are the main stages of the manufacturing process, along with key techniques utilized to enhance the elasticity and overall quality of the bungee cords.

1. Material Preparation

The quality of raw materials is fundamental to the elasticity of bungee cords. The inner core is typically made from either natural rubber or synthetic rubber, each offering distinct advantages. Natural rubber provides excellent resilience and tensile strength, while synthetic rubber offers superior UV and atmospheric resistance.

- Selection of Materials: Manufacturers must source high-quality rubber, ensuring it is free from impurities. The outer cover is usually made from synthetic yarns like nylon or polyester, which provide durability and protection against wear.

- Pre-Treatment: Before processing, raw rubber is often treated to enhance its elasticity. This may include the addition of certain chemical compounds that improve its extensibility and durability.

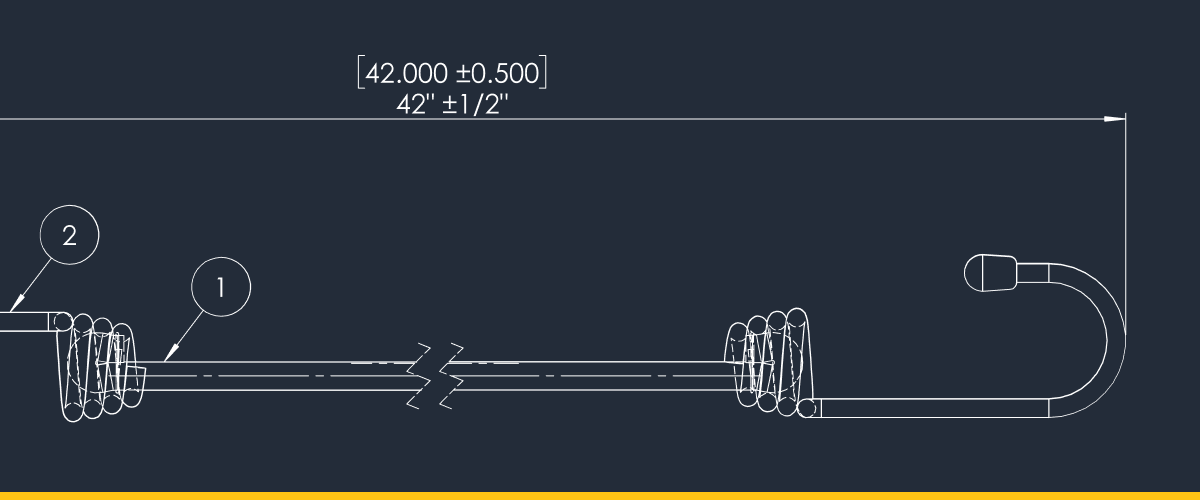

2. Forming

The forming stage involves transforming raw materials into the desired bungee cord shape. This is achieved through several methods, primarily extrusion and braiding.

- Rubber Ribbon Extrusion: The rubber is heated and forced through a die to create long ribbons. This process is crucial as it determines the cross-sectional shape of the cord, which directly affects its elasticity.

- Braiding: Multiple rubber ribbons are braided together to form the core. The braiding machine adjusts the tension on the rubber strands to ensure a tight bundle, enhancing the cord’s overall strength and elasticity.

3. Assembly

Once the core is formed, the next step is assembly, where the outer cover is added to the bungee cord.

- Cover Application: The outer cover is applied using a braiding technique that ensures a snug fit over the rubber core. This is vital for protecting the core from environmental factors while maintaining the elasticity.

- Customization: For specialized applications, manufacturers can customize the cords by varying the number of strands or using different outer materials. This flexibility allows buyers to specify the exact requirements for their applications.

4. Finishing

The finishing stage includes final quality checks and preparation for packaging.

- Curing Process: The assembled bungee cords may undergo a curing process to set the rubber and enhance its elasticity. This involves heating the cords to a specific temperature for a defined period.

- Cutting and Packaging: Finally, the cords are cut to the desired length and packaged for shipment. Proper packaging is essential to avoid damage during transportation.

Quality Assurance in Bungee Cord Manufacturing

Quality assurance (QA) is crucial in ensuring that bungee cords meet international safety and performance standards. B2B buyers must be aware of the various QA processes and certifications that suppliers should adhere to.

International Standards

- ISO 9001: This standard outlines the criteria for a quality management system. It ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, products must meet certain safety and environmental standards. CE marking indicates compliance with these regulations.

Industry-Specific Certifications

- API Standards: For military and industrial applications, adherence to API (American Petroleum Institute) standards may be necessary, particularly for heavy-duty bungee cords.

- ASTM Standards: The American Society for Testing and Materials provides specifications for the performance of bungee cords, especially those used in safety-critical applications like bungee jumping.

Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality before they enter the production line. This includes checking for material specifications and certifications.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, samples are taken to ensure that the production methods are adhering to the established quality standards. This can involve monitoring the extrusion and braiding processes.

- Final Quality Control (FQC): Before packaging, the finished bungee cords are tested for elasticity, tensile strength, and any defects. This is the last line of defense in ensuring product quality.

Common Testing Methods

- Tensile Testing: Measures the strength and elasticity of the bungee cord under load. This test is essential for ensuring that the cord can perform as expected in real-world applications.

- UV Resistance Testing: Assesses how well the material withstands UV radiation, which is crucial for products intended for outdoor use.

- Dynamic Load Testing: Simulates the conditions under which the bungee cord will be used, ensuring it can handle repeated stretching and loading.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical. Here are some actionable steps:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and quality assurance practices. This can include on-site visits to review their facilities and equipment.

- Request Quality Reports: Ask suppliers for quality assurance reports that detail their testing methods, results, and certifications. This documentation provides transparency and insight into their quality practices.

- Third-Party Inspections: Engage independent third-party inspectors to evaluate the quality of products before shipment. This is especially important for bulk orders to ensure compliance with international standards.

Navigating Quality Control Nuances for International Buyers

When sourcing bungee cords from different regions, international buyers must navigate various regulatory and quality control nuances:

- Local Regulations: Understand the local safety regulations in the purchasing country. For instance, products imported into the EU must comply with CE marking requirements.

- Cultural Considerations: Be aware of cultural differences in business practices and negotiation styles, which can affect quality assurance processes.

- Logistics and Supply Chain: Consider the logistics of shipping products internationally, including potential delays that could affect product quality during transit.

By understanding the manufacturing processes and quality assurance practices in bungee cord production, international B2B buyers can make informed decisions, ensuring they source high-quality, reliable products tailored to their specific needs.

Related Video: How Things Are Made | An Animated Introduction to Manufacturing Processes

Comprehensive Cost and Pricing Analysis for bungee cord elasticity Sourcing

Understanding the cost structure and pricing dynamics for bungee cord elasticity sourcing is essential for international B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. The key components and influencers of pricing must be navigated strategically to achieve optimal procurement outcomes.

Cost Components

-

Materials: The primary cost driver in bungee cord manufacturing is the raw materials used. The inner core typically consists of either natural rubber or synthetic rubber, with natural rubber often being more expensive due to its superior elasticity and resilience. The outer cover, made from synthetic yarns such as nylon or polyester, also contributes to the overall material costs.

-

Labor: Labor costs vary significantly across regions. In regions with a lower cost of living, such as parts of Africa and South America, labor costs may be lower, potentially leading to reduced overall manufacturing costs. However, skilled labor for quality control and specialized processes may require higher wages.

-

Manufacturing Overhead: This includes expenses related to the factory’s operational costs, such as utilities, maintenance, and administrative costs. Efficient production facilities can help minimize overhead, impacting the final price.

-

Tooling: Custom tooling for specialized bungee cords can add to the initial costs. Buyers should consider whether the required specifications necessitate unique molds or machinery.

-

Quality Control (QC): Stringent QC processes are essential to ensure product reliability, particularly for applications in extreme sports or military uses. The costs associated with QC can vary based on the complexity of the testing required.

-

Logistics: Shipping costs can fluctuate based on distance, weight, and the chosen Incoterms. International buyers must account for both freight and insurance when calculating total logistics costs.

-

Margin: Supplier margins can vary widely based on market competition, demand, and product uniqueness. Understanding the typical margins in the supplier’s region can assist buyers in assessing the fairness of quotes.

Price Influencers

-

Volume/MOQ: Bulk purchases typically lead to better pricing. Suppliers are often willing to negotiate discounts for larger orders or long-term contracts.

-

Specifications/Customization: Unique specifications or custom designs can significantly affect pricing. Buyers should be clear about their requirements to avoid unexpected costs.

-

Materials: The choice between natural and synthetic rubber impacts pricing. Buyers should evaluate the trade-offs between cost and performance.

-

Quality/Certifications: Products that meet specific international standards or certifications may carry a premium. Buyers should assess the necessity of these certifications based on their target markets.

-

Supplier Factors: Relationship history, reliability, and the supplier’s production capacity can influence pricing. Established relationships may yield better pricing and terms.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) affect the distribution of costs and risks. Understanding these terms can help buyers negotiate better deals.

Buyer Tips

-

Negotiation: Prepare to negotiate on multiple fronts, including price, delivery terms, and payment schedules. Leverage data on competitors to strengthen your position.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the purchase price. Consider factors like durability, maintenance, and potential failure rates.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and local economic conditions that might impact pricing. Secure fixed-rate agreements when possible to hedge against price volatility.

-

Market Research: Conduct thorough market research to identify reliable suppliers and understand regional pricing norms. This can help in benchmarking quotes received.

Disclaimer

Prices for bungee cords can vary significantly based on the aforementioned factors, and this analysis serves as a general guideline. Buyers should seek personalized quotes based on their specific requirements and local market conditions.

Spotlight on Potential bungee cord elasticity Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘bungee cord elasticity’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bungee cord elasticity

Key Technical Properties of Bungee Cord Elasticity

Understanding the technical properties of bungee cords is essential for international B2B buyers looking to source high-quality elastic materials. Here are the critical specifications that define bungee cord elasticity:

-

Material Composition

– Natural Rubber vs. Synthetic Rubber: Bungee cords are typically made from either natural rubber or synthetic rubber. Natural rubber offers superior resilience and tensile strength, making it ideal for high-stress applications like bungee jumping. Synthetic rubber, while more resistant to UV and atmospheric conditions, may not provide the same level of elasticity. Buyers must choose based on their specific use cases. -

Tensile Strength

– Definition: This measures the maximum load a bungee cord can withstand while being stretched. It is usually expressed in pounds (lbs) or newtons (N).

– Importance: For applications such as cargo securing or extreme sports, selecting a cord with appropriate tensile strength is crucial to prevent failures and ensure safety during use. -

Elongation at Break

– Definition: This property indicates how much a bungee cord can be stretched before it breaks, usually expressed as a percentage.

– Importance: A higher elongation percentage allows for greater flexibility and shock absorption, which is vital in applications involving dynamic loads, such as during bungee jumping or while securing loads on vehicles. -

Diameter

– Definition: The diameter of a bungee cord typically ranges from 3mm to 20mm, with thicker cords generally offering higher strength and elasticity.

– Importance: The diameter affects both the load capacity and the application suitability. Buyers should consider the environment and load requirements to select the appropriate size. -

Environmental Resistance

– Definition: This refers to a bungee cord’s ability to withstand elements such as UV exposure, moisture, and temperature variations.

– Importance: For international buyers operating in diverse climates, choosing cords with high environmental resistance ensures longevity and performance, reducing the need for frequent replacements. -

Packaging and Storage

– Definition: Proper packaging and storage conditions are vital for maintaining the integrity of bungee cords.

– Importance: Cords that are packaged inadequately may degrade over time, impacting their elasticity and performance. Buyers should ensure that suppliers adhere to appropriate storage practices.

Common Trade Terminology

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are essential terms related to bungee cord procurement:

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers identify quality sources for bungee cords that meet specific application requirements. -

MOQ (Minimum Order Quantity)

– This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for buyers to manage inventory costs and ensure they meet their purchasing needs without overcommitting. -

RFQ (Request for Quotation)

– A document sent to suppliers requesting a price quote for specific products. Including detailed specifications in an RFQ can streamline the procurement process and ensure accurate pricing and delivery timelines. -

Incoterms

– Short for International Commercial Terms, these are a set of rules that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms helps buyers understand shipping logistics, cost responsibilities, and risk management. -

Lead Time

– The time it takes from placing an order to receiving the product. Understanding lead times is vital for planning and ensuring that products arrive when needed, especially in industries where timing is critical. -

Custom Specifications

– Refers to tailored requirements that a buyer may have for a product, such as specific dimensions or material properties. Communicating custom specifications clearly can lead to better product alignment with business needs.

By understanding these properties and terms, international B2B buyers can make informed decisions, ensuring they select the right bungee cords for their applications while effectively navigating the procurement process.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bungee cord elasticity Sector

Market Overview & Key Trends

The bungee cord elasticity sector is experiencing significant growth driven by diverse applications across various industries, including automotive, outdoor recreation, and logistics. As international B2B buyers from Africa, South America, the Middle East, and Europe seek reliable solutions for load securing and shock absorption, understanding the dynamics of this market is crucial. Key trends include the increasing demand for customized bungee solutions tailored to specific industrial needs, particularly in construction and transportation sectors.

Additionally, technological advancements in manufacturing processes are enhancing product quality and reducing lead times. Automation and the use of advanced materials are becoming common, allowing manufacturers to produce bungee cords that offer improved durability and elasticity. Buyers should also be aware of the rising preference for lightweight yet strong materials, driven by the need for efficiency in shipping and handling.

Moreover, the global push towards sustainability is prompting manufacturers to innovate with eco-friendly materials. This shift not only appeals to environmentally conscious consumers but also aligns with regulatory requirements in various regions. For B2B buyers, this means sourcing from suppliers who prioritize sustainable practices can provide a competitive edge in the marketplace.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of procurement strategies in the bungee cord elasticity sector. The environmental impact of traditional manufacturing processes, particularly those relying on non-renewable resources, has raised concerns among stakeholders. As a result, ethical sourcing and the adoption of ‘green’ certifications are gaining traction. B2B buyers should prioritize suppliers who utilize sustainable materials, such as natural rubber or recycled synthetic fibers, in their bungee cord production.

Furthermore, buyers should look for manufacturers that comply with international environmental standards, such as ISO 14001, which ensures that organizations minimize their environmental footprint. Transparency in the supply chain is critical; partnering with suppliers who provide detailed information about their sourcing practices can mitigate risks associated with unethical labor practices and environmental degradation. Implementing these sustainability measures not only enhances brand reputation but also attracts a growing segment of eco-conscious consumers.

Brief Evolution/History

The bungee cord’s evolution can be traced back to the early 20th century, initially utilized in industrial applications. Its modern-day popularity surged in the 1980s with the advent of recreational activities like bungee jumping, which showcased the cord’s elasticity and strength. Over the years, advancements in materials and manufacturing have expanded its applications, leading to specialized designs for sectors ranging from military to outdoor sports. Understanding this history helps B2B buyers appreciate the cord’s versatility and the innovation driving its continued relevance in various markets today.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of bungee cord elasticity

-

What should I consider when vetting suppliers of bungee cords?

When vetting suppliers, assess their production capacity, quality control processes, and compliance with international standards. Look for certifications such as ISO 9001 or specific industry standards relevant to your region. Request references from previous clients, particularly those in your industry, to gauge reliability. Additionally, evaluate their responsiveness and willingness to engage in communication, as this can indicate their commitment to customer service. -

Can I customize bungee cords to meet my specific needs?

Yes, many manufacturers offer customization options, including variations in elasticity, length, diameter, and materials used. Be clear about your requirements and ensure that the supplier has the capability to meet them. Discuss the feasibility of custom designs and any additional costs involved. Additionally, request samples to evaluate the product’s performance before placing larger orders. -

What are the typical minimum order quantities (MOQ) and lead times for bungee cords?

MOQs can vary significantly based on the supplier and the complexity of the order. Generally, expect MOQs to range from 500 to 1,000 units for standard products, while custom orders may require larger quantities. Lead times typically range from 2 to 8 weeks, depending on production schedules and the supplier’s location. Always confirm these details in advance to ensure they align with your project timelines. -

What payment terms should I expect when sourcing bungee cords internationally?

Payment terms can vary, but common practices include a 30% deposit upon order confirmation and the balance before shipment. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Discuss payment terms clearly with your supplier and ensure they align with your financial capabilities and risk management strategies. -

How do I ensure quality assurance and certification for bungee cords?

Request documentation of quality assurance processes from your supplier, including any relevant certifications like CE marking or ASTM standards. Conduct inspections during production and before shipment, either through third-party services or through your own quality control team. Establish clear quality expectations in your contract, including specifications for elasticity, durability, and tensile strength. -

What logistics considerations should I keep in mind when importing bungee cords?

When importing, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner familiar with international shipping to ensure timely delivery. Factor in lead times for customs clearance and be prepared for potential delays. Additionally, ensure that your supplier provides all necessary shipping documents, including invoices and packing lists. -

How can I resolve disputes with suppliers over bungee cord orders?

Establish clear communication channels and maintain documentation of all agreements and correspondence. If a dispute arises, attempt to resolve it amicably through direct negotiation. If necessary, refer to the terms specified in your contract regarding dispute resolution mechanisms, which may include mediation or arbitration. Having a clear process in place can help minimize conflicts and protect your interests. -

What are the best practices for maintaining bungee cord performance over time?

To ensure longevity, store bungee cords in a cool, dry place away from direct sunlight and extreme temperatures, which can degrade elasticity. Regularly inspect cords for signs of wear, such as fraying or discoloration. Avoid overextending the cords beyond their rated capacity, as this can compromise their elasticity and tensile strength. Providing training for staff on proper usage can also enhance performance and safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bungee cord elasticity

In conclusion, the strategic sourcing of bungee cord elasticity presents significant opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the various materials, manufacturing processes, and applications of bungee cords is essential for making informed purchasing decisions. Buyers should prioritize suppliers who adhere to rigorous quality standards and offer customizable solutions to meet specific industry needs.

Illustrative Image (Source: Google Search)

Key Takeaways:

- Material Matters: Different types of rubber (natural vs. synthetic) impact elasticity and durability. Assess your requirements based on end-use applications.

- Supplier Selection: Choose manufacturers with a proven track record and certifications to ensure product reliability.

- Customization: Seek suppliers that can provide tailored solutions to fit unique operational demands, especially for specialized applications.

As the demand for robust, high-performance bungee cords continues to grow across diverse industries, now is the time to optimize your sourcing strategies. By focusing on quality, customization, and reliable partnerships, you can ensure that your supply chain remains competitive and resilient. Take action today to enhance your procurement process and secure the best value in the global market for bungee cords.