Master Compression Moulding: Essential Insights for B2B

Introduction: Navigating the Global Market for compression moulding

In today’s competitive landscape, compression molding stands out as a critical manufacturing process for B2B buyers seeking efficiency and cost-effectiveness. This versatile technique is utilized across various industries, enabling the production of both simple and complex parts, from automotive components to household items. As global markets continue to evolve, understanding the nuances of compression molding can provide strategic advantages for businesses looking to optimize their supply chains and product offerings.

This comprehensive guide delves into the essential aspects of compression molding, covering a wide array of topics including types of molding processes, suitable materials, manufacturing and quality control practices, and cost considerations. It also highlights key suppliers and market trends, ensuring that buyers are well-informed and equipped to make strategic sourcing decisions.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe (including countries like Mexico and the UK), this guide serves as an indispensable resource. It empowers businesses to navigate the complexities of the global market, enabling them to identify reliable partners and make informed decisions that enhance their competitive edge. By leveraging the insights provided, companies can harness the full potential of compression molding, ultimately driving innovation and growth in their respective industries.

Understanding compression moulding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Compression Molding | Utilizes preheated materials in open molds; ideal for simple shapes | Automotive parts, gaskets, seals | Pros: Cost-effective for large parts; Cons: Limited to simpler geometries. |

| Transfer Molding | Material preheated in a separate chamber and transferred to mold; better for complex shapes | Electrical components, intricate parts | Pros: Handles complex designs; Cons: Higher setup costs. |

| Injection Compression Molding | Combines injection and compression; reduces internal stresses | Thin-walled products, complex geometries | Pros: Improved accuracy; Cons: More expensive machinery. |

| Vacuum Compression Molding | Uses vacuum to remove air pockets before molding | Aerospace components, high-quality finishes | Pros: Denser products; Cons: Slower cycle times. |

| Cold Compression Molding | Molds materials at room temperature; suitable for certain plastics | Medical devices, consumer goods | Pros: Energy-efficient; Cons: Limited material compatibility. |

Standard Compression Molding

Standard compression molding is the most widely used variation, characterized by placing a preheated charge into an open mold cavity. Once the mold is closed, heat and pressure are applied to shape the material. This method is particularly effective for manufacturing large, simple parts such as automotive components, gaskets, and seals. Buyers should consider the limitations of this process, as it is not suitable for highly intricate designs; however, it remains a cost-effective choice for straightforward applications.

Transfer Molding

Transfer molding involves heating the material in a separate chamber before transferring it into the mold cavity through a runner system. This process allows for more complex shapes and precise control over temperature and pressure, making it ideal for electrical components and intricate parts. B2B buyers should weigh the advantages of versatility and design capability against the potentially higher setup costs associated with this method.

Injection Compression Molding

This hybrid method merges injection molding and compression molding techniques. It involves injecting molten material into an open mold, which is then closed to apply compression. This process is particularly beneficial for producing thin-walled products and complex geometries, resulting in improved dimensional accuracy. Buyers looking for high-quality components with intricate designs should consider this option, although the machinery can be more expensive.

Vacuum Compression Molding

Vacuum compression molding enhances the standard process by applying a vacuum before closing the mold, which helps eliminate air pockets and ensures denser products. This method is particularly effective for aerospace components and products requiring high-quality finishes. While it provides superior results, buyers must consider the trade-off of slower cycle times, which may impact production schedules.

Cold Compression Molding

Cold compression molding operates at room temperature, making it suitable for certain types of plastics. This method is energy-efficient and often used for medical devices and consumer goods. However, its material compatibility is limited compared to other methods, so buyers should evaluate their specific material requirements. Overall, this method offers a unique approach for specific applications where energy conservation is a priority.

Related Video: Compression Moulding Process – A Detailed explanation.

Key Industrial Applications of compression moulding

| Industry/Sector | Specific Application of Compression Moulding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of gaskets and seals | Enhances durability and performance of automotive components | Quality of materials, compliance with automotive standards |

| Consumer Goods | Manufacturing of kitchenware and utensils | Cost-effective production of durable, lightweight products | Material safety certifications, design flexibility |

| Aerospace | Creation of lightweight structural components | Reduces weight, improving fuel efficiency and performance | Supplier reliability, material specifications |

| Electrical & Electronics | Production of insulators and housings | Ensures electrical safety and reliability | Precision in mold design, compliance with safety standards |

| Medical Devices | Fabrication of components like syringe bodies | Meets stringent regulations for safety and sterility | Quality control processes, material biocompatibility |

Automotive Industry

In the automotive sector, compression moulding is extensively used to produce gaskets and seals, which are critical for ensuring the integrity of vehicle systems. This method allows manufacturers to create durable components that withstand extreme conditions, enhancing the overall performance of vehicles. For international buyers, especially in regions like Africa and South America, sourcing high-quality materials that comply with automotive standards is crucial to ensure product reliability and safety.

Consumer Goods

Compression moulding is widely applied in the production of kitchenware and utensils, enabling manufacturers to create lightweight and durable products efficiently. This method provides a cost-effective solution for producing high volumes of items like bowls, plates, and cooking tools. Buyers from Europe and the Middle East should prioritize suppliers that offer materials with safety certifications, ensuring that the final products are safe for food contact and meet local regulations.

Aerospace Sector

In aerospace applications, compression moulding is utilized to create lightweight structural components, essential for enhancing fuel efficiency and performance. The process allows for the production of complex shapes while maintaining the structural integrity of the materials. For buyers in the aerospace industry, particularly in Europe, it is vital to work with suppliers that demonstrate reliability and can meet specific material specifications to ensure compliance with rigorous industry standards.

Electrical & Electronics

Compression moulding plays a significant role in producing insulators and housings for electrical components. This manufacturing technique allows for the creation of parts that ensure electrical safety and reliability. Buyers in the electrical sector, especially those from Africa and the Middle East, should focus on suppliers that offer precision in mold design and adherence to safety standards, as these factors are critical in preventing electrical failures.

Medical Devices

In the medical field, compression moulding is employed to fabricate components such as syringe bodies, which require adherence to stringent safety and sterility regulations. This process ensures that the materials used are biocompatible and safe for patient use. For international B2B buyers in this sector, it is essential to evaluate the quality control processes of suppliers and confirm that the materials meet necessary regulatory requirements to avoid any compliance issues.

Related Video: JETLINE low-pressure metering machines for Wet Compression Moulding (WCM) applications

Strategic Material Selection Guide for compression moulding

Compression molding is a widely adopted manufacturing process that allows for the efficient production of various parts using different materials. The choice of material significantly impacts the performance, cost, and suitability of the final product. Below, we analyze four common materials used in compression molding, focusing on their key properties, advantages and disadvantages, application impacts, and specific considerations for international B2B buyers.

1. Thermosetting Plastics (e.g., Phenolic, Epoxy)

Key Properties:

Thermosetting plastics are known for their excellent thermal stability, chemical resistance, and mechanical strength. They can withstand high temperatures (up to 200°C) and pressures during the molding process, making them ideal for applications that require durability.

Pros & Cons:

These materials offer high durability and resistance to deformation under heat, but they are more expensive compared to thermoplastics. Manufacturing complexity is moderate, as they require precise temperature control to ensure proper curing. They are well-suited for automotive parts, electrical components, and industrial applications.

Impact on Application:

Thermosetting plastics are compatible with a wide range of media, including oils and solvents, which makes them suitable for automotive and aerospace applications.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM D638 for tensile strength and ASTM D648 for heat deflection. In regions like Europe and the Middle East, certifications may be required for specific applications.

2. Rubber Compounds (e.g., Natural Rubber, Silicone)

Key Properties:

Rubber compounds exhibit excellent elasticity, flexibility, and resilience. They can withstand a wide range of temperatures (from -50°C to 150°C) and are often used in applications requiring vibration damping and sealing.

Pros & Cons:

While rubber compounds are cost-effective and provide good performance in dynamic applications, they may not have the same level of chemical resistance as thermosetting plastics. Manufacturing complexity can vary based on the specific rubber compound used.

Impact on Application:

These materials are particularly effective in applications that involve contact with water, oils, and other chemicals, making them ideal for seals, gaskets, and automotive parts.

Considerations for International Buyers:

Buyers should be aware of compliance with standards such as ASTM D2000 for rubber materials. In regions like Africa and South America, sourcing reliable suppliers who adhere to these standards is crucial.

3. Composite Materials (e.g., Fiber-Reinforced Plastics)

Key Properties:

Composite materials combine polymers with reinforcing fibers, providing exceptional strength-to-weight ratios and resistance to environmental degradation. They can withstand high temperatures and pressures, making them suitable for demanding applications.

Pros & Cons:

While composites offer high performance and durability, they can be more expensive and complex to manufacture. The molding process requires careful handling to avoid defects, and they may not be suitable for high-volume production.

Impact on Application:

Composites are ideal for applications in aerospace, automotive, and marine industries, where lightweight and strong materials are essential.

Considerations for International Buyers:

Buyers must consider compliance with international standards like ASTM D3039 for tensile properties. In Europe, the REACH regulation may also impact the choice of materials used in composites.

4. Thermoplastics (e.g., Polypropylene, Polyethylene)

Key Properties:

Thermoplastics are characterized by their ability to be remolded and recycled. They have good chemical resistance and can withstand moderate temperatures (up to 100°C).

Pros & Cons:

These materials are generally less expensive and easier to process than thermosetting plastics. However, they may not provide the same level of heat resistance or mechanical strength. They are suitable for a wide range of applications, including consumer goods and packaging.

Impact on Application:

Thermoplastics are compatible with various media, making them versatile for applications in automotive, consumer electronics, and household products.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM D638 for tensile properties and consider local regulations regarding recycling and material safety, especially in Europe.

Summary Table

| Material | Typical Use Case for Compression Moulding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermosetting Plastics | Automotive parts, electrical components | High durability and thermal stability | Higher cost and manufacturing complexity | High |

| Rubber Compounds | Seals, gaskets, automotive parts | Cost-effective and good elasticity | Limited chemical resistance | Medium |

| Composite Materials | Aerospace, automotive, marine applications | Exceptional strength-to-weight ratio | Higher cost and complex manufacturing | High |

| Thermoplastics | Consumer goods, packaging | Easy processing and lower cost | Moderate heat resistance | Low |

This guide provides a strategic overview for international B2B buyers in selecting the appropriate materials for compression molding, taking into account performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for compression moulding

Compression molding is a widely adopted manufacturing process, especially for creating durable and complex parts from materials such as thermosetting plastics and rubber. This section provides an in-depth examination of the key manufacturing processes involved in compression molding, as well as the quality assurance measures essential for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

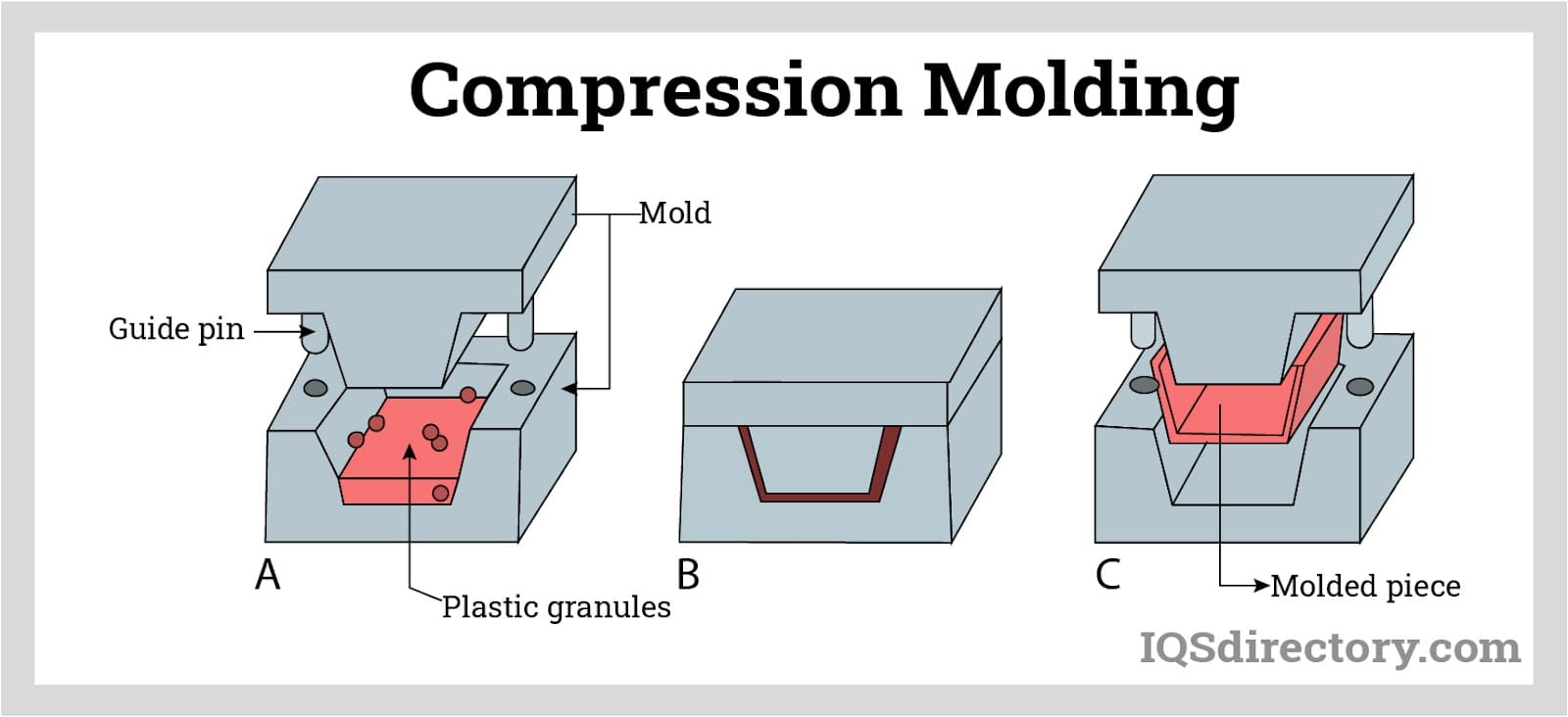

Manufacturing Process of Compression Molding

The manufacturing process for compression molding can be broken down into several critical stages:

1. Material Preparation

The first step involves selecting and preparing the raw materials. This typically includes:

- Mixing Materials: The primary material, often a thermosetting plastic or rubber, is blended with additives such as fillers, curing agents, and pigments. This mixture is crucial for achieving the desired properties in the final product.

- Preheating: The mixed materials are then preheated to a specific temperature to enhance their flow characteristics. This step ensures that the material can easily fill the mold cavity during the forming stage.

2. Forming

The forming stage is where the actual molding occurs, consisting of:

- Loading the Mold: A pre-measured charge of the prepared material is placed into the heated cavity of the lower mold half. Precision in this step is vital; an excessive charge can lead to flash, requiring additional trimming.

- Applying Heat and Pressure: The mold is closed, and heat and pressure are applied. This process compresses the material, allowing it to flow and fill the mold contours. The controlled application of heat and pressure is essential for uniformity and minimizing defects in the final product.

- Curing: During this phase, the heat initiates chemical reactions that transform the material from a pliable state into a solid form, retaining the mold’s configuration.

3. Assembly

Once the parts are formed, they may require assembly. This can involve:

- Joining Components: If the product consists of multiple parts, assembly may be necessary. Techniques such as adhesive bonding, mechanical fastening, or welding might be used, depending on the application.

- Integration with Other Systems: For components used in larger systems (e.g., automotive parts), ensuring compatibility and fit with other parts is crucial.

4. Finishing

The finishing stage ensures that the final product meets the required specifications:

- Trimming and Cleaning: Any excess material or flash must be removed, and the parts are cleaned to eliminate debris.

- Surface Treatment: Depending on the end-use application, additional surface treatments may be applied, such as coating or polishing, to enhance durability or aesthetic appeal.

Quality Assurance in Compression Molding

Quality assurance (QA) is critical in ensuring that the final products meet international standards and customer expectations. The QA process involves several stages and standards.

International Standards

B2B buyers should be familiar with the following quality standards:

- ISO 9001: This international standard outlines requirements for a quality management system (QMS). Compliance ensures consistent quality and continuous improvement in processes.

- CE Marking: For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: For components used in the oil and gas industry, API standards ensure that products meet specific technical and safety requirements.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified quality standards before use.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor critical parameters such as temperature, pressure, and material consistency.

- Final Quality Control (FQC): Once the parts are completed, they undergo final inspections to verify that they meet design specifications and quality standards.

Common Testing Methods

To ensure product integrity, various testing methods are employed, including:

- Dimensional Inspection: Using tools like calipers and micrometers to measure the physical dimensions of the parts.

- Mechanical Testing: Assessing properties such as tensile strength, impact resistance, and hardness to ensure they meet specifications.

- Visual Inspection: Checking for surface defects, color consistency, and overall appearance.

Verifying Supplier Quality Control

For B2B buyers, especially those operating internationally, verifying a supplier’s quality control processes is essential. Here are actionable strategies:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and compliance with international standards.

- Quality Reports: Request detailed quality reports from suppliers, including inspection records, testing outcomes, and certifications. These documents provide insights into their QC practices.

- Third-Party Inspections: Engage third-party inspection services to evaluate the quality of products before shipment. This provides an unbiased assessment of the supplier’s quality control measures.

Quality Control Nuances for International Buyers

International B2B buyers must also consider regional nuances in quality control:

- Cultural Differences: Understand that different regions may have varying approaches to quality control and manufacturing standards. Building relationships with suppliers can help bridge these gaps.

- Regulatory Compliance: Ensure that suppliers are compliant with local regulations and international standards that may apply to specific industries.

- Logistics and Transport: Consider how transportation can affect product quality. For instance, sensitive components may require special handling and climate-controlled environments during shipping.

In summary, understanding the manufacturing processes and quality assurance measures in compression molding is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, along with implementing robust quality control measures, buyers can ensure they are sourcing high-quality products that meet their specifications and standards.

Related Video: Compression Moulding Process

Comprehensive Cost and Pricing Analysis for compression moulding Sourcing

When sourcing compression molding services, international B2B buyers must navigate a multifaceted cost structure that includes several key components. Understanding these components and the factors that influence pricing is critical for making informed procurement decisions.

Cost Components

-

Materials: The choice of raw materials significantly impacts overall costs. Common materials used in compression molding include thermosetting plastics and rubber. Prices vary based on market availability, quality, and material type. Specialty materials may incur higher costs but can provide superior performance and durability.

-

Labor: Labor costs encompass the wages of skilled workers who operate molding machines, manage production, and perform quality control. Labor rates can differ based on the region; for instance, skilled labor may be more expensive in Europe compared to Africa or South America.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, maintenance of equipment, and factory space. Buyers should inquire about overhead percentages applied by suppliers to better understand total costs.

-

Tooling: Tooling costs cover the creation of molds, which can be a significant upfront expense. The complexity and size of the mold, as well as the material used, can dramatically affect tooling prices. Buyers should consider the longevity and reuse potential of molds to assess their cost-effectiveness.

-

Quality Control (QC): Implementing quality control measures is essential to ensure product consistency and compliance with specifications. QC costs can vary based on the level of inspection and testing required, including certifications for specific industries.

-

Logistics: Transportation and shipping costs should not be overlooked. These costs can fluctuate based on distance, mode of transport, and international duties or tariffs, particularly for buyers in Africa, South America, and the Middle East.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the compression molding industry can help buyers negotiate better deals.

Price Influencers

Several factors influence the pricing of compression molding services:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs. Suppliers may offer discounts for larger orders, making it beneficial for buyers to consolidate their purchases.

-

Specifications/Customization: Customized products can incur additional costs due to the need for unique tooling or processes. Clear specifications can help avoid unexpected costs.

-

Materials: The choice of materials affects not only the base price but also the overall quality and performance of the final product. Buyers should weigh material costs against desired product characteristics.

-

Quality/Certifications: Parts that require specific quality certifications may come at a premium. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation, location, and capabilities of the supplier can all impact pricing. Established suppliers may charge more due to their experience and reliability.

-

Incoterms: Understanding international commercial terms is crucial for cost management. Incoterms dictate responsibilities for shipping, insurance, and tariffs, which can significantly affect the total landed cost.

Buyer Tips

To optimize sourcing strategies, buyers should consider the following tips:

-

Negotiation: Engage suppliers in discussions about pricing and terms. Leverage volume commitments or long-term contracts to secure better rates.

-

Cost-Efficiency: Evaluate the total cost of ownership, including not just the purchase price but also logistics, maintenance, and potential waste.

-

Pricing Nuances: For international buyers, currency fluctuations can affect pricing. It’s advisable to agree on fixed pricing or terms that account for currency changes.

-

Market Research: Conduct thorough market research to understand typical pricing structures in different regions. This knowledge can empower buyers during negotiations.

Disclaimer

Prices for compression molding services can vary widely based on numerous factors and are subject to change based on market conditions. This analysis serves as a guide and should not be interpreted as definitive pricing. Always request detailed quotes from multiple suppliers to gain a comprehensive understanding of potential costs.

Spotlight on Potential compression moulding Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘compression moulding’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for compression moulding

Compression molding is a critical manufacturing process widely utilized across various industries, from automotive to consumer goods. Understanding the essential technical properties and trade terminology is crucial for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Key Technical Properties

-

Material Grade

– Definition: This refers to the specific classification of the raw material used, such as thermosetting plastics or rubber.

– B2B Importance: Different applications require different material grades to ensure durability, flexibility, and temperature resistance. Choosing the correct material grade can affect the performance and longevity of the final product. -

Tolerance

– Definition: Tolerance defines the permissible limit of variation in a physical dimension of the molded part.

– B2B Importance: Accurate tolerances are essential for ensuring parts fit and function correctly. In industries like automotive and aerospace, precise tolerances can be critical for safety and performance. -

Cure Time

– Definition: This is the duration required for the material to fully cure and reach its final hardness and shape after being molded.

– B2B Importance: Understanding cure times can help buyers plan production schedules effectively. Shorter cure times can lead to faster turnaround and increased productivity. -

Mold Temperature

– Definition: The temperature of the mold during the compression process, which affects the flow and curing of the material.

– B2B Importance: Proper mold temperature is vital for achieving uniformity in the molded parts. It influences cycle time, production efficiency, and the quality of the final product. -

Flash Tolerance

– Definition: This refers to the acceptable amount of excess material that may seep out of the mold during the compression process.

– B2B Importance: Managing flash is important to reduce waste and the need for post-production trimming, thereby minimizing costs and improving efficiency.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is crucial for B2B buyers, as they often rely on OEMs for quality components that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers manage budgets and inventory effectively. It can also affect pricing, as larger orders often lead to discounts.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific quantities of a product.

– Importance: Issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring they get the best value for their procurement needs. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce that defines the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risk management, particularly for international buyers. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the product.

– Importance: Knowing lead times is crucial for planning production schedules and inventory management, especially for businesses operating in fast-paced industries.

By understanding these critical technical properties and industry terminology, international B2B buyers can make more informed decisions, ultimately leading to better procurement strategies and successful partnerships in the compression molding market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the compression moulding Sector

Market Overview & Key Trends

The compression molding sector is experiencing significant growth driven by the increasing demand for lightweight and high-performance materials across various industries, including automotive, aerospace, and consumer goods. Globalization and advances in technology are enabling international B2B buyers from regions such as Africa, South America, the Middle East, and Europe to access diverse suppliers and innovative solutions. Key trends include the integration of automation and digital technologies, such as Industry 4.0, which enhance operational efficiency and reduce production costs.

Furthermore, the rise of additive manufacturing is reshaping sourcing strategies, allowing for the rapid prototyping of molds and parts, thereby shortening lead times and minimizing waste. Buyers should focus on suppliers who adopt these technologies to gain a competitive edge. The shift towards more sustainable practices is also noteworthy, as companies are increasingly prioritizing eco-friendly materials and processes, responding to consumer demand for greener products.

As the market evolves, understanding regional differences in supply chain dynamics is essential. For instance, buyers in Africa may encounter varying levels of infrastructure development, impacting logistics and lead times. Conversely, European buyers may benefit from stringent regulations that ensure quality and sustainability, which can influence sourcing decisions. Overall, staying abreast of these trends will empower B2B buyers to make informed decisions in a rapidly changing market landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of modern manufacturing, and the compression molding sector is no exception. The environmental impact of material sourcing, production processes, and waste management is under scrutiny, prompting companies to adopt more sustainable practices. For B2B buyers, understanding the ecological footprint of their suppliers is crucial in making ethical sourcing decisions. This includes evaluating the use of renewable materials, energy-efficient processes, and waste reduction strategies.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should prioritize suppliers who demonstrate a commitment to fair labor practices, transparency, and community engagement. Certifications such as ISO 14001 (Environmental Management) and other green certifications can serve as indicators of a supplier’s dedication to sustainability.

In the context of compression molding, the use of bio-based or recycled materials is gaining traction. These materials not only reduce reliance on fossil fuels but also contribute to a circular economy. Buyers should actively seek out suppliers who offer green alternatives and can provide documentation of their sustainability claims. This focus on sustainability will not only enhance brand reputation but also align with global trends towards corporate responsibility.

Brief Evolution/History

The compression molding process has its roots in the early 19th century, evolving significantly alongside advancements in material science and manufacturing technology. Initially used for creating simple rubber parts, the method gained prominence with the advent of thermosetting plastics in the mid-20th century, allowing for more complex shapes and applications.

As industries expanded, so did the capabilities of compression molding, adapting to meet the demands of various sectors, including automotive and aerospace. Recent developments, such as the incorporation of automation and digital technologies, have further transformed the landscape, making it more efficient and responsive to market needs. For B2B buyers, understanding this historical context can provide valuable insights into the reliability and adaptability of compression molding as a manufacturing solution.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of compression moulding

-

What should I consider when vetting suppliers for compression molding?

When vetting suppliers for compression molding, prioritize their experience in the industry and expertise in the specific materials and products you require. Request references and case studies to evaluate their past performance. Verify their quality assurance processes, certifications, and compliance with international standards. It’s also wise to assess their production capabilities and technological advancements, as these factors can significantly affect quality and lead times. Finally, consider their geographical location to understand logistics and potential tariffs. -

Can I customize my compression molded parts?

Yes, customization is a key advantage of compression molding. Most suppliers offer tailored solutions based on your specific design requirements, including materials, sizes, and geometries. When discussing customization, provide detailed specifications and, if possible, prototypes or drawings. This ensures that the supplier fully understands your needs. Keep in mind that complex designs may increase costs and lead times, so clarify these aspects upfront. -

What are the typical minimum order quantities (MOQs) and lead times?

Minimum order quantities (MOQs) for compression molded parts can vary significantly based on the supplier and the complexity of the parts. Generally, MOQs can range from 100 to several thousand units. Lead times also depend on the order size, material availability, and production capacity, typically ranging from a few weeks to several months. Discuss these factors during negotiations to align expectations and plan your inventory accordingly. -

What payment terms are commonly used in international B2B transactions for compression molding?

Payment terms in international B2B transactions for compression molding often include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for custom molds. It’s crucial to negotiate clear payment terms that protect both parties and ensure timely delivery of goods. Additionally, consider currency fluctuations and any international banking fees that could affect the final cost. -

How can I ensure quality assurance and certifications for my products?

To ensure quality assurance, request documentation of the supplier’s quality management system, such as ISO 9001 certification. This indicates adherence to international quality standards. Regular audits and inspections during production can help maintain quality. Discuss the supplier’s quality control processes, including testing methods and acceptance criteria for the finished products. Establish a clear agreement on how defects will be handled, including return policies and warranty terms. -

What logistics considerations should I be aware of when sourcing compression molded parts?

Logistics play a vital role in sourcing compression molded parts. Consider factors such as shipping methods, import/export regulations, and potential tariffs. Evaluate the supplier’s ability to manage logistics effectively, including their experience with international shipping and customs clearance. Establish clear communication about delivery schedules, and consider using a freight forwarder to streamline the process and reduce delays. -

What steps should I take if a dispute arises with my supplier?

In the event of a dispute with your supplier, start by reviewing your contract and any agreements made regarding quality, delivery, and payment. Attempt to resolve the issue through direct communication, as many disputes can be settled amicably. If necessary, escalate the matter through formal mediation or arbitration, as specified in your contract. Maintaining clear documentation of all communications and transactions will support your case should legal action be required. -

How do I assess the long-term viability of a compression molding supplier?

To assess the long-term viability of a compression molding supplier, consider their financial stability, production capacity, and investment in technology. Review their track record for meeting deadlines and maintaining quality standards. Engage in regular communication to gauge their responsiveness and willingness to adapt to your evolving needs. Additionally, evaluate their reputation in the industry through feedback from other customers and third-party reviews to ensure a reliable partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for compression moulding

In conclusion, strategic sourcing in compression molding presents a significant opportunity for international B2B buyers across Africa, South America, the Middle East, and Europe. By leveraging this versatile manufacturing process, companies can achieve cost efficiency and high-quality production for a diverse range of applications, from automotive components to consumer goods. Key takeaways include the importance of selecting appropriate materials, understanding the nuances of different molding techniques, and optimizing production cycles to enhance overall profitability.

Illustrative Image (Source: Google Search)

Value of Strategic Sourcing:

– Cost-Effectiveness: Compression molding often results in lower tooling costs and reduced material waste, particularly advantageous for low to medium production volumes.

– Quality Assurance: This method yields parts with superior structural integrity and fewer defects, ensuring reliability in end products.

– Flexibility in Design: The process accommodates various materials and shapes, making it suitable for innovative applications.

As the global market evolves, staying informed about advancements in compression molding technology will be crucial. B2B buyers are encouraged to explore partnerships with manufacturers who prioritize sustainable practices and innovation. By doing so, they can position themselves advantageously in an increasingly competitive landscape.