Master Efficient Sourcing of Heater Electrical Solutions

Introduction: Navigating the Global Market for heater electrical

In an increasingly interconnected world, the demand for reliable and efficient heating solutions has never been more critical. Heater electrical systems play a vital role across various industries, from manufacturing and construction to laboratories and food processing. These systems not only provide essential temperature control but also enhance operational efficiency, safety, and product quality. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of heater electrical technology is key to making informed purchasing decisions.

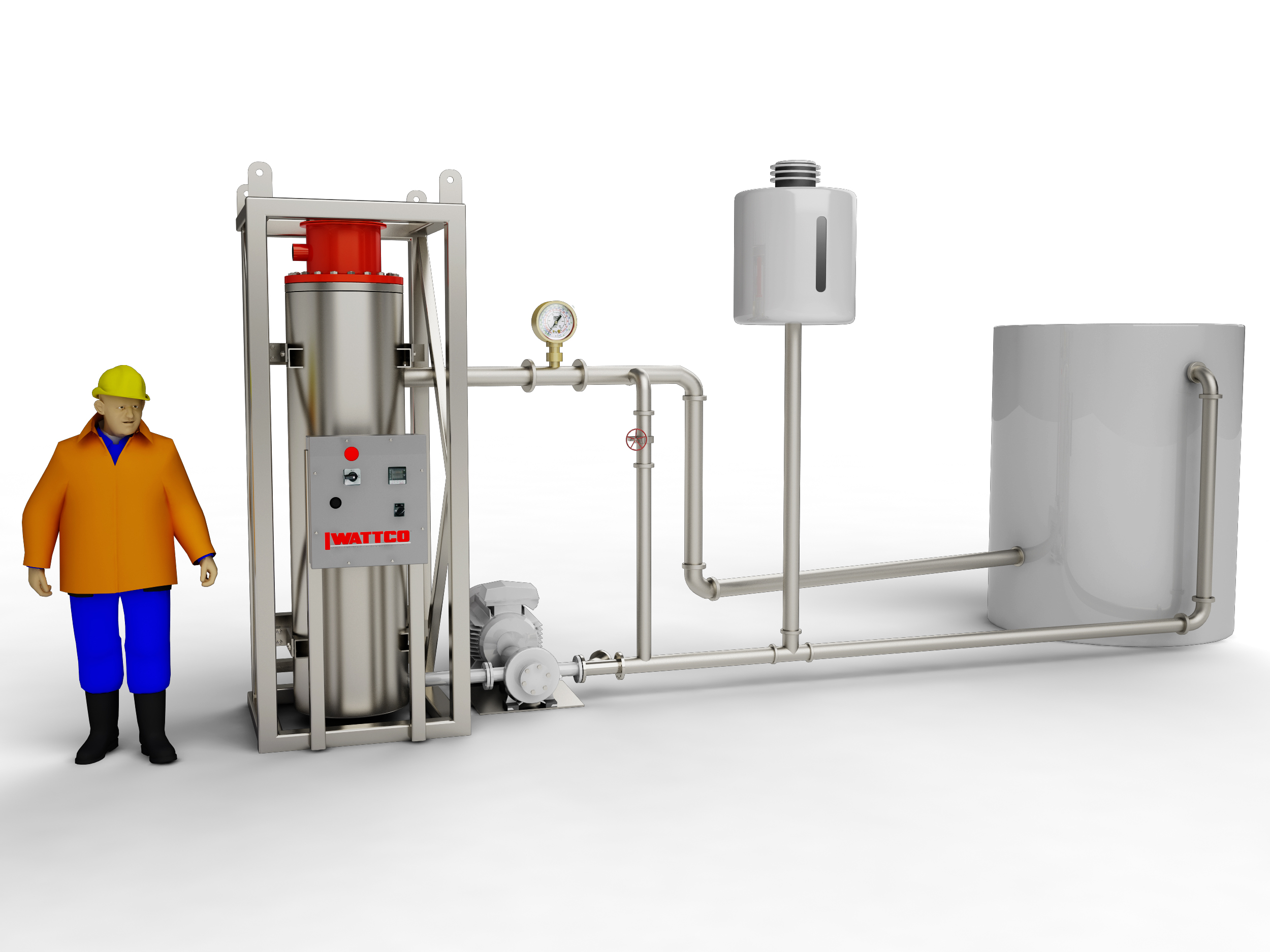

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the diverse types of electric heaters available, ranging from tubular and strip heaters to radiant and convection systems. It explores the materials used in their construction, ensuring buyers are equipped with knowledge on durability and efficiency. Additionally, the guide addresses critical manufacturing and quality control processes, helping buyers evaluate supplier reliability and product integrity.

Furthermore, a thorough analysis of cost factors, market trends, and leading suppliers in the heater electrical industry provides essential insights. Buyers will also find a dedicated FAQ section, clarifying common queries and empowering them with the information needed to assess their unique operational requirements.

By leveraging the insights presented in this guide, B2B buyers can navigate the global market with confidence, ensuring their investments in heater electrical solutions yield maximum returns and meet the rigorous demands of their industries.

Understanding heater electrical Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tubular Heaters | Long, cylindrical shape; versatile design | Oil & gas, food processing, plastics | Pros: High efficiency, customizable lengths. Cons: Installation complexity. |

| Strip Heaters | Flat, linear design; surface-mounted | Packaging, textile, and automotive | Pros: Space-saving, quick heating. Cons: Limited to flat surfaces. |

| Radiant Heaters | Uses infrared radiation; heats objects directly | Warehouses, outdoor spaces, workshops | Pros: Instant heat, energy-efficient. Cons: Limited range; requires direct line of sight. |

| Immersion Heaters | Submerged in liquid; rapid heat transfer | Chemical processing, water heating | Pros: Effective for large volumes, quick heating. Cons: Requires careful sizing and placement. |

| Convection Heaters | Circulates air for heating; fan-assisted | Warehouses, offices, and homes | Pros: Efficient air distribution, suitable for larger spaces. Cons: Slower to heat up compared to other types. |

Tubular Heaters

Tubular heaters are versatile heating elements that come in a long, cylindrical shape, allowing for various applications across industries such as oil and gas, food processing, and plastics manufacturing. Their customizable lengths and watt densities make them suitable for specific heating requirements. When purchasing, buyers should consider installation complexity and ensure compatibility with existing systems to maximize efficiency and minimize downtime.

Strip Heaters

Characterized by their flat, linear design, strip heaters are typically surface-mounted and ideal for applications in packaging, textiles, and automotive industries. Their space-saving nature allows for efficient heating in confined areas. Buyers should evaluate the specific heating requirements of their application, as strip heaters are limited to flat surfaces and may not be suitable for all heating scenarios.

Radiant Heaters

Radiant heaters utilize infrared radiation to heat objects directly, making them effective for warehouses, outdoor spaces, and workshops. They provide instant heat and are energy-efficient, as they do not require heating the surrounding air. However, buyers should note that radiant heaters have a limited range and require a direct line of sight for optimal performance, which may influence placement decisions.

Immersion Heaters

Immersion heaters are designed to be submerged in liquids, offering rapid heat transfer for applications such as chemical processing and water heating. Their effectiveness in heating large volumes quickly is a significant advantage. Buyers must carefully consider the sizing and placement of immersion heaters to ensure efficient operation and avoid overheating or damage to the heating element.

Convection Heaters

Convection heaters work by circulating air to distribute heat throughout a space, making them suitable for larger areas such as warehouses and offices. While they offer efficient air distribution, these heaters may take longer to reach the desired temperature compared to other heating types. Buyers should assess the heating needs of their environment and consider the potential energy costs associated with extended heating times.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of heater electrical

| Industry/Sector | Specific Application of heater electrical | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Process heating in production lines | Enhances efficiency and product quality | Energy efficiency, temperature control, safety standards |

| Food & Beverage | Heating in food processing and packaging | Ensures product safety and compliance with regulations | Hygiene standards, temperature accuracy, energy costs |

| Pharmaceuticals | Sterilization and temperature control in labs | Maintains integrity of sensitive processes | Precision, reliability, and compliance with health regulations |

| Chemical Processing | Heating of reaction vessels and storage tanks | Facilitates chemical reactions and prevents freezing | Material compatibility, safety certifications, energy efficiency |

| Construction | Concrete curing and temperature maintenance | Improves quality and accelerates project timelines | Climate considerations, heater capacity, portability |

Manufacturing

In the manufacturing sector, electrical heaters are essential for process heating in production lines. They provide consistent and controlled heating for various applications, such as melting, drying, and curing materials. This ensures that products meet quality standards and reduces waste due to temperature fluctuations. International buyers should prioritize energy efficiency and compliance with local safety standards, particularly in regions with stringent regulations.

Food & Beverage

Within the food and beverage industry, electrical heaters play a crucial role in heating processes, such as pasteurization and cooking. They help ensure product safety by maintaining the necessary temperatures to eliminate harmful bacteria. Buyers must consider hygiene standards and the heaters’ ability to deliver precise temperature control, as well as energy costs, to optimize operational efficiency and compliance with health regulations.

Pharmaceuticals

In pharmaceutical applications, electrical heaters are vital for processes such as sterilization and temperature control in laboratories. They maintain the integrity of sensitive compounds and ensure that experiments yield reliable results. Buyers in this sector need to focus on precision, reliability, and compliance with health regulations, as any deviation in temperature can compromise product efficacy and safety.

Chemical Processing

Electrical heaters are used extensively in chemical processing for heating reaction vessels and storage tanks. They facilitate chemical reactions by providing the necessary heat and preventing the freezing of materials in colder climates. When sourcing heaters for this application, businesses should ensure material compatibility with chemicals, obtain necessary safety certifications, and consider energy efficiency to minimize operational costs.

Construction

In construction, electrical heaters are utilized for curing concrete and maintaining temperature during colder months. Proper curing is essential for achieving desired strength and durability in concrete structures. Buyers must assess climate considerations, heater capacity, and portability to ensure that heating solutions can be effectively deployed on-site, particularly in regions with extreme weather conditions.

Related Video: Plate Heat Exchanger Applications and working principle hvac heat transfer

Strategic Material Selection Guide for heater electrical

When selecting materials for electric heaters, international B2B buyers must consider several factors that affect performance, durability, and overall cost-effectiveness. Below is an analysis of four common materials used in electric heater manufacturing, focusing on their properties, advantages, disadvantages, and implications for specific applications.

1. Stainless Steel

Key Properties: Stainless steel is known for its high corrosion resistance, good mechanical properties, and ability to withstand high temperatures (up to 1,500°F or 815°C). It also has a relatively high tensile strength, making it suitable for various heating applications.

Pros & Cons: The durability of stainless steel makes it a preferred choice for environments where moisture or corrosive substances are present. However, it is more expensive than other materials like carbon steel, which can increase manufacturing costs. Additionally, welding and fabrication can be complex, requiring skilled labor.

Impact on Application: Stainless steel is ideal for applications involving liquids or gases that may cause corrosion, such as in chemical processing or food production. Its compatibility with various media ensures longevity and reliability in performance.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 and DIN 1.4301. The higher initial cost may be justified by lower maintenance needs over time.

2. Copper

Key Properties: Copper boasts excellent thermal conductivity, making it highly efficient for heat transfer. It can typically withstand temperatures up to 1,000°F (538°C) but has lower corrosion resistance compared to stainless steel.

Pros & Cons: The primary advantage of copper is its superior thermal efficiency, which can lead to reduced energy costs. However, its susceptibility to corrosion, especially in humid environments, can limit its application lifespan. Additionally, copper is relatively expensive, which may not be feasible for all budgets.

Impact on Application: Copper is often used in heating elements where rapid heat transfer is critical, such as in immersion heaters or heat exchangers. However, its corrosion issues may necessitate protective coatings or treatments, particularly in humid climates.

Considerations for International Buyers: Buyers should be aware of the varying copper standards across regions, such as JIS H 3250 in Japan and ASTM B75 in the U.S. The cost implications of using copper should be carefully evaluated against its performance benefits.

3. Aluminum

Key Properties: Aluminum is lightweight, has good thermal conductivity, and can withstand temperatures up to about 1,200°F (650°C). It is also resistant to corrosion, especially when anodized.

Pros & Cons: The lightweight nature of aluminum makes it easy to handle and install, reducing labor costs. However, it has lower strength compared to stainless steel and copper, which can limit its use in high-pressure applications. Additionally, while it is generally less expensive, the need for protective coatings can add to costs.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable heaters or in automotive industries. Its thermal efficiency is beneficial for quick heating applications, but buyers should consider its limitations in high-stress environments.

Considerations for International Buyers: Compliance with standards like ASTM B221 is essential for aluminum products. Buyers in Africa and South America may find aluminum more accessible due to lower shipping costs compared to heavier materials.

4. Nickel-Chromium Alloy (NiCr)

Key Properties: Nickel-chromium alloys are known for their high-temperature resistance (up to 2,400°F or 1,315°C) and excellent oxidation resistance. They maintain strength and stability at elevated temperatures, making them ideal for heating elements.

Pros & Cons: The high-temperature capability of NiCr alloys makes them suitable for high-performance applications, such as industrial furnaces. However, they are more expensive than other materials and can be challenging to work with due to their hardness, which may require specialized manufacturing processes.

Impact on Application: NiCr is commonly used in high-temperature applications, such as industrial heaters and furnaces. Its ability to withstand extreme conditions ensures reliability and longevity in demanding environments.

Considerations for International Buyers: Buyers should verify compliance with specific standards such as ASTM B168 for nickel-chromium alloys. The higher cost may be offset by the durability and efficiency gained in high-performance applications.

Summary Table

| Material | Typical Use Case for heater electrical | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, food production | High corrosion resistance | Higher initial cost | High |

| Copper | Immersion heaters, heat exchangers | Superior thermal conductivity | Susceptible to corrosion | High |

| Aluminum | Portable heaters, automotive applications | Lightweight and easy to install | Lower strength in high-pressure | Medium |

| Nickel-Chromium Alloy | Industrial furnaces, high-performance heaters | High-temperature resistance | More expensive and harder to work with | High |

This guide provides a comprehensive overview of material selection for electric heaters, equipping international B2B buyers with the necessary insights to make informed decisions tailored to their specific operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for heater electrical

The manufacturing processes and quality assurance protocols for electrical heaters are critical components that international B2B buyers must understand. This knowledge enables buyers to evaluate potential suppliers effectively, ensuring that they receive products that meet their operational needs and compliance requirements. Below is a comprehensive overview of the typical manufacturing stages, key techniques, relevant quality control standards, and actionable insights for buyers from regions such as Africa, South America, the Middle East, and Europe.

Manufacturing Processes for Electrical Heaters

The manufacturing of electrical heaters generally follows several key stages, each essential for ensuring the final product’s performance and reliability.

1. Material Preparation

The first step in the manufacturing process involves the selection and preparation of materials. Common materials used in electrical heaters include:

- Metal Enclosures: Typically steel or aluminum, these materials provide structural integrity and durability.

- Insulation Materials: These are crucial for preventing heat loss and ensuring safety. Options include ceramic, fiberglass, and mineral wool.

- Heating Elements: Often made from nickel-chromium or copper alloys, these elements are responsible for generating heat.

During this stage, materials are sourced from certified suppliers who comply with international standards. Buyers should inquire about the origin and specifications of these materials to ensure they meet their local regulations.

2. Forming

Once materials are prepared, the next stage involves forming them into the desired shapes. This can include:

- Cutting: Metal sheets are cut into specified dimensions for enclosures and components.

- Stamping: This technique is used to create precise shapes for various parts, such as brackets and mounting components.

- Bending: Metal parts are bent to form enclosures and other structural elements.

Advanced techniques like laser cutting and CNC machining are often employed to enhance precision and reduce waste, which is particularly important for cost-sensitive buyers.

3. Assembly

The assembly process is where various components are brought together to create the final product. Key activities include:

- Wiring: Electrical connections are established, ensuring that heating elements are properly integrated with control systems.

- Mounting: Components such as thermostats and sensors are mounted securely.

- Sealing: Enclosures are sealed to protect internal components from dust and moisture.

Quality at this stage is paramount, as improper assembly can lead to malfunctions or safety hazards. Buyers should verify that suppliers employ skilled labor and adhere to standardized assembly procedures.

4. Finishing

The final stage involves applying finishes that enhance the heater’s appearance and functionality. Common finishing processes include:

- Painting: Protective coatings are applied to prevent corrosion and improve aesthetics.

- Testing: Each heater undergoes functional tests to ensure it meets performance specifications.

- Labeling: Proper labeling includes safety warnings and operational instructions, which are crucial for user compliance.

Buyers should ensure that the finishing processes do not compromise the heater’s thermal efficiency and safety standards.

Quality Assurance in Manufacturing

Quality assurance (QA) is integral to the manufacturing process, ensuring that every product meets established standards. Several international and industry-specific standards govern the QA process:

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries. Compliance indicates a supplier’s commitment to quality and continuous improvement.

- CE Marking: Required for products sold within the European Economic Area, CE marking ensures that heaters meet safety, health, and environmental protection standards.

Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process to identify and rectify issues early. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect defects as they occur.

- Final Quality Control (FQC): A thorough examination of the completed heaters before they are shipped, focusing on functionality, safety, and compliance with standards.

Common Testing Methods

Testing methods are essential for validating the performance of electrical heaters. Some common methods include:

- Electrical Safety Tests: These tests assess insulation resistance and ground continuity to ensure user safety.

- Thermal Performance Tests: Evaluating heating efficiency and response times under various conditions.

- Durability Tests: Simulating long-term use to identify potential failures.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Consider the following strategies:

- Supplier Audits: Conducting on-site audits allows buyers to observe manufacturing practices, inspect equipment, and review documentation.

- Requesting Quality Reports: Buyers should ask for detailed QC reports, including results from testing and inspections.

- Engaging Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of the supplier’s quality assurance processes.

Quality Control Nuances for International Buyers

Buyers from diverse regions must navigate specific nuances in quality control:

- Regulatory Compliance: Ensure that the supplier’s products comply with local regulations, which may vary significantly between regions such as Africa and Europe.

- Cultural Considerations: Understanding cultural differences in business practices can enhance communication and expectations regarding quality.

- Logistical Challenges: Consideration of shipping regulations and import duties may impact the overall cost and delivery timelines of heaters.

In summary, a thorough understanding of the manufacturing processes and quality assurance protocols for electrical heaters is essential for international B2B buyers. By focusing on material selection, assembly techniques, quality control standards, and verification strategies, buyers can make informed decisions that align with their operational requirements and regulatory standards.

Related Video: The Most Sophisticated Manufacturing Process In The World Inside The Fab | Intel

Comprehensive Cost and Pricing Analysis for heater electrical Sourcing

In the context of international B2B sourcing for heater electrical systems, understanding the comprehensive cost structure and pricing dynamics is crucial for making informed purchasing decisions. Below is a detailed analysis of the cost components, price influencers, and strategic buyer tips tailored for B2B buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The cost of raw materials significantly impacts the overall price of electric heaters. Common materials include steel, copper, and specialized alloys, which can fluctuate based on market conditions. Buyers should consider sourcing materials locally to reduce costs.

-

Labor: Labor costs vary by region and can influence manufacturing prices. Countries with lower labor costs may offer competitive pricing, but it’s essential to ensure that labor quality meets the necessary standards.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can help minimize overhead, allowing suppliers to offer better prices.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom solutions. Buyers should be aware that higher tooling costs may be reflected in the final price, especially for specialized heaters.

-

Quality Control (QC): Implementing stringent QC processes ensures that products meet quality standards, which can add to costs. However, the long-term benefits of reduced failures and increased reliability often justify these expenses.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can significantly affect the total price. Understanding Incoterms and optimizing shipping routes can help mitigate these costs.

-

Margin: Suppliers typically include a margin to cover their business expenses and profit. This margin can vary widely among suppliers based on their market positioning and the level of service they provide.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often leads to reduced per-unit costs. Buyers should negotiate MOQs to optimize pricing, especially when establishing long-term supplier relationships.

-

Specifications/Customization: Custom features or specific performance requirements can increase costs. Clearly defining specifications upfront can help suppliers provide accurate quotes and avoid unexpected charges later.

-

Materials: The choice of materials not only affects durability but also pricing. Higher-grade materials typically come at a premium, so buyers should balance performance needs with budget constraints.

-

Quality/Certifications: Products that meet international quality standards and certifications can command higher prices. Buyers should assess whether these certifications are necessary for their applications to avoid overpaying.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge more, but their reliability can reduce long-term costs associated with failures or delays.

-

Incoterms: Understanding shipping terms is vital for calculating total costs. Different Incoterms can affect who bears the cost of shipping, insurance, and customs, impacting the overall pricing structure.

Buyer Tips

-

Negotiation: Develop strong negotiation strategies based on volume commitments and long-term partnerships. Leverage competitive quotes from multiple suppliers to enhance negotiating power.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), not just the initial purchase price. Consider factors such as energy efficiency, maintenance costs, and expected lifespan when evaluating products.

-

Pricing Nuances: Be aware that international pricing can be influenced by currency fluctuations and economic conditions in both the buyer’s and supplier’s countries. Consider hedging strategies for large purchases.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into future pricing trends or innovations.

-

Market Research: Regularly conduct market research to stay informed about pricing trends, emerging suppliers, and new technologies that can impact costs.

Disclaimer

Prices can vary widely based on numerous factors, including market conditions and specific buyer requirements. The information provided is indicative and should be verified with suppliers for accurate pricing in specific contexts.

By understanding these components and strategies, international B2B buyers can navigate the complexities of sourcing heater electrical systems more effectively, ensuring they achieve optimal value for their investments.

Spotlight on Potential heater electrical Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘heater electrical’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for heater electrical

When sourcing industrial electric heaters, understanding the technical properties and trade terminology is crucial for making informed purchasing decisions. Here are the essential specifications and terms that international B2B buyers should be familiar with.

Key Technical Properties

-

Material Grade

The material grade of an electric heater influences its durability and performance. Common materials include stainless steel for corrosion resistance and aluminum for lightweight applications. Selecting the right material is vital to ensure longevity, especially in demanding environments such as manufacturing plants or laboratories. -

Power Rating (Wattage)

The power rating, typically measured in watts (W), indicates the heater’s capacity to generate heat. Higher wattage means more heat output, which is essential for large spaces or specific industrial processes. Buyers must assess their heating requirements to match the wattage to their operational needs effectively. -

Temperature Range

This specification defines the minimum and maximum temperatures the heater can achieve. Understanding the temperature range is crucial for applications like curing, drying, or heating liquids. Buyers should ensure that the selected heater meets the specific temperature requirements of their processes to avoid inefficiencies. -

Heating Method

Electric heaters can utilize different heating methods such as conduction, convection, or radiation. Each method has its own advantages and is suited for various applications. For instance, convection heaters are ideal for heating air in closed spaces, while radiant heaters are better for direct surface heating. Knowing the heating method helps buyers select the most efficient heater for their needs. -

Control Systems

Advanced heaters may come with integrated control systems for precise temperature regulation. Features like programmable thermostats, timers, and remote monitoring can enhance operational efficiency and energy savings. Buyers should consider these features, especially for environments requiring strict temperature control. -

Safety Standards

Compliance with safety standards such as UL, CE, or ISO ensures that the heaters meet specific safety and performance criteria. Buyers should verify that the heaters they are considering are certified to avoid risks associated with electrical faults or overheating, particularly in industrial settings.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM relationship is important for buyers looking to source heaters that meet specific quality and compatibility standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is critical for budgeting and inventory management, as it can impact overall costs and the feasibility of placing an order. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process allows buyers to compare offers from different manufacturers and negotiate better terms, making it a key step in the purchasing process. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms is essential for buyers to understand shipping costs, insurance, and the transfer of risk during transportation. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is important for planning and scheduling, as longer lead times can affect project timelines and operational efficiency. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and durability of the heater. Understanding the warranty terms is essential for buyers to ensure they are protected against defects and can plan for potential repairs or replacements.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing industrial electric heaters, ensuring they select the best equipment for their specific operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the heater electrical Sector

Market Overview & Key Trends

The global heater electrical market is witnessing significant transformation driven by a blend of technological advancements, sustainability concerns, and evolving customer demands. One of the primary drivers is the increasing need for energy-efficient heating solutions across various industries, including manufacturing, pharmaceuticals, and food processing. This trend is particularly relevant for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, where energy costs are a critical consideration.

Emerging technologies such as smart heating systems and IoT-enabled devices are gaining traction, allowing for improved control and monitoring of heating processes. Buyers are increasingly looking for suppliers that offer advanced features like predictive maintenance and remote management capabilities, which can lead to significant operational efficiencies. Furthermore, the shift towards renewable energy sources is prompting manufacturers to develop electric heaters that can integrate with solar and wind energy systems, appealing to environmentally conscious companies.

Market dynamics also indicate a growing preference for modular and customizable heating solutions. This flexibility allows businesses to scale their heating capabilities according to their specific needs without incurring excessive costs. For international buyers, particularly in emerging markets, understanding local regulations and standards is essential to ensure compliance and optimize sourcing strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of purchasing decisions in the heater electrical sector. The environmental impact of heating solutions is under increasing scrutiny, compelling manufacturers and buyers alike to prioritize eco-friendly options. Key considerations include the energy consumption of heaters, the materials used in their production, and the lifecycle management of these products.

Buyers should actively seek suppliers who adhere to ethical sourcing practices and offer products certified by recognized environmental standards, such as Energy Star or ISO 14001. These certifications not only demonstrate a commitment to reducing carbon footprints but also enhance a company’s reputation in the marketplace.

In addition, the adoption of sustainable materials—such as recycled metals and non-toxic insulation—can significantly reduce the environmental impact of heating systems. International B2B buyers, particularly from regions with stringent environmental regulations, must ensure that their suppliers align with these sustainability goals to foster responsible supply chains that contribute positively to both business and the planet.

Brief Evolution/History

The heater electrical sector has evolved dramatically over the past century, transitioning from basic resistive heating elements to sophisticated systems that integrate advanced technology and energy efficiency. Initially, industrial heating relied heavily on fossil fuels, but the oil crises of the 1970s spurred innovation in electric heating solutions as industries sought alternatives to reduce dependence on volatile fuel sources.

The introduction of programmable thermostats and automatic temperature controls in the late 20th century marked a significant leap forward, enabling more precise temperature management and energy savings. In recent years, the focus has shifted toward sustainable practices, with manufacturers now prioritizing the development of eco-friendly products and solutions that meet the growing demand for energy efficiency and lower environmental impact. This evolution reflects a broader trend within the B2B landscape, where sustainability and technology are increasingly intertwined, shaping the future of industrial heating solutions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of heater electrical

-

What key factors should I consider when vetting suppliers for electric heaters?

When vetting suppliers for electric heaters, prioritize their experience and reputation in the industry. Check for certifications such as ISO 9001, which indicates a commitment to quality management. Request references or case studies from similar industries and regions to assess their capability. Additionally, evaluate their manufacturing processes and technology used, as this can impact product reliability and performance. Lastly, consider their after-sales support and responsiveness to queries, which are crucial for long-term partnerships. -

Can I customize electric heaters to meet specific operational requirements?

Yes, many suppliers offer customization options for electric heaters to cater to specific operational needs. This can include adjustments in size, heating capacity, and control mechanisms. When discussing customization, clearly outline your requirements and ask for a detailed proposal. Ensure the supplier has experience with similar customizations and can provide examples of past projects. Note that customized solutions may come with longer lead times and potentially higher costs, so factor this into your budgeting. -

What are typical minimum order quantities (MOQ) and lead times for electric heaters?

Minimum order quantities (MOQ) for electric heaters can vary significantly depending on the supplier and the specific product. Some suppliers may have a low MOQ for standard models, while custom designs might require larger quantities. Lead times can range from a few weeks to several months, influenced by production schedules, customization requests, and shipping logistics. It’s essential to communicate your needs clearly and confirm these details upfront to avoid delays in your procurement process. -

How can I ensure the quality of electric heaters from international suppliers?

To ensure quality when sourcing electric heaters internationally, request comprehensive quality assurance (QA) documentation from suppliers, including inspection reports and test results. Verify that the products meet international standards and certifications relevant to your industry. Conduct factory audits if possible, or consider third-party inspections to evaluate manufacturing practices. Establish clear quality expectations in your contract, including provisions for handling defective products or non-compliance with specifications.

Illustrative Image (Source: Google Search)

-

What payment terms are common when sourcing electric heaters globally?

Payment terms for sourcing electric heaters can vary based on supplier policies, order size, and buyer-supplier relationships. Common options include advance payment, letter of credit, or payment upon delivery. For first-time transactions, suppliers may require partial payment upfront to mitigate risks. It’s advisable to negotiate terms that provide a balance between security for the supplier and flexibility for your cash flow. Always ensure that payment terms are clearly documented in the purchase agreement to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing electric heaters?

When importing electric heaters, consider the logistics of shipping, including transportation modes, customs regulations, and potential tariffs. Evaluate the reliability of the shipping partners and confirm that they have experience with similar products. Ensure that all necessary documentation, such as commercial invoices and certificates of origin, is prepared to facilitate smooth customs clearance. Additionally, factor in lead times for shipping and any potential delays that may arise from international regulations or local customs inspections. -

How can disputes with suppliers over electric heater orders be effectively managed?

To effectively manage disputes with suppliers, establish clear communication channels and maintain detailed records of all transactions, agreements, and correspondence. Include dispute resolution clauses in contracts, outlining procedures for mediation or arbitration, which can provide a structured approach to resolving conflicts. Engage in open dialogue to address issues as they arise, and aim for collaborative solutions that prioritize long-term relationships. If disputes escalate, consider involving legal counsel familiar with international trade regulations. -

What certifications should I look for when sourcing electric heaters?

When sourcing electric heaters, look for certifications that indicate compliance with international safety and performance standards. Key certifications include CE marking for compliance with European regulations, UL certification for safety in the U.S., and ISO standards for quality management. Depending on your industry, additional certifications may be required, such as ATEX for hazardous environments. Always verify the authenticity of certifications and ensure they align with the regulations applicable in your region to avoid compliance issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for heater electrical

In conclusion, the strategic sourcing of electrical heaters is crucial for international B2B buyers looking to enhance operational efficiency and reduce costs. Understanding the various types of industrial electric heaters, such as tubular, strip, and radiant heaters, empowers businesses to select equipment that aligns with their specific heating needs. Key considerations include energy efficiency, maintenance requirements, and the adaptability of the heating solutions to diverse environments across Africa, South America, the Middle East, and Europe.

The value of strategic sourcing cannot be overstated; it not only minimizes operational risks but also maximizes return on investment through informed purchasing decisions. As global markets evolve, staying abreast of technological advancements and supplier capabilities is essential for maintaining a competitive edge.

For buyers in regions like the UAE and Spain, leveraging local supplier networks while considering global innovations will position your operations for future success. Embrace the opportunity to engage with reliable manufacturers and explore innovative solutions that meet the demands of your industry. Start your sourcing journey today, and ensure your business is equipped for the challenges and opportunities of tomorrow.