Master Electrical Coil Sourcing: A Comprehensive B2B

Introduction: Navigating the Global Market for electrical coil

In the ever-evolving landscape of global commerce, electrical coils are fundamental components that drive efficiency and reliability across numerous industries. From manufacturing to renewable energy, these coils facilitate the control and distribution of electrical power, making them indispensable for operational success. For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of electrical coils is crucial for optimizing sourcing strategies and enhancing overall performance.

This guide provides a comprehensive exploration of electrical coils, covering essential topics such as types and variations, materials used, manufacturing processes, quality control measures, and supplier networks. It also delves into cost considerations and current market trends, enabling buyers to navigate the complexities of sourcing with confidence.

By equipping buyers with actionable insights and expert analysis, this guide empowers them to make informed decisions that align with their operational needs. Understanding the nuances of electrical coils not only facilitates better negotiations with suppliers but also enhances product reliability and compliance with safety standards. As you engage with this resource, you will gain the clarity needed to harness the full potential of electrical coils, driving your business towards greater success in the global marketplace.

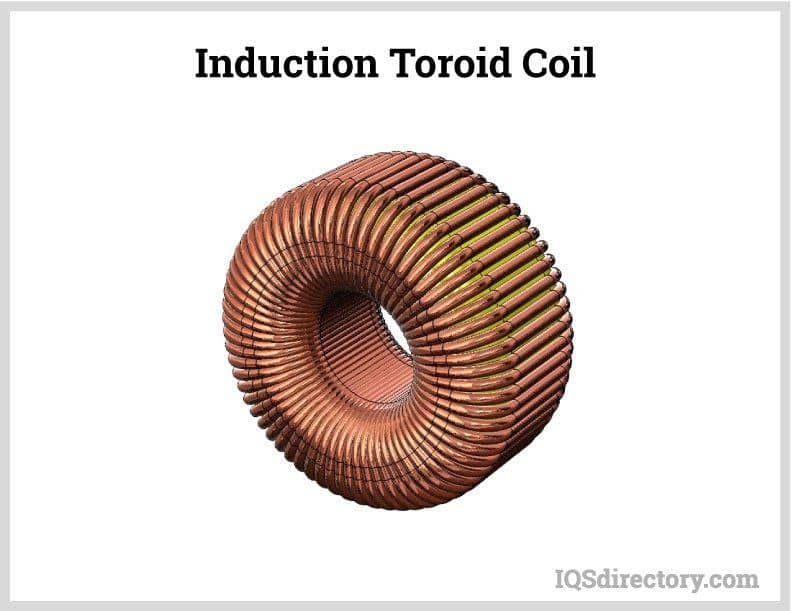

Understanding electrical coil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Contactor Coil | Operates on alternating current; compact design | Industrial machinery, HVAC systems | Efficient but may require additional control components. |

| DC Contactor Coil | Designed for direct current; typically larger | Renewable energy systems, electric vehicles | Robust performance but often more expensive than AC coils. |

| Latching Contactor Coil | Maintains position without continuous power | Automation systems, lighting control | Energy-efficient but higher initial cost. |

| Relay Contactor Coil | Combines relay and contactor functions | Control panels, low-voltage applications | Versatile but may have slower response times. |

| Soft Start Contactor Coil | Gradual power ramp-up to reduce inrush current | Motor control, industrial applications | Protects equipment but can be complex to install. |

AC Contactor Coil

AC contactor coils are essential in applications that utilize alternating current. Their compact design allows for straightforward integration into industrial machinery and HVAC systems. B2B buyers should prioritize compatibility with existing electrical systems and consider any auxiliary components needed for proper operation, such as timers or relays. While AC coils are efficient, their requirement for additional control elements can increase overall system complexity.

Illustrative Image (Source: Google Search)

DC Contactor Coil

DC contactor coils are specifically tailored for direct current applications, making them ideal for sectors like renewable energy and electric vehicles. These coils are typically larger and designed to handle higher currents, providing robust performance. Buyers must evaluate the cost-effectiveness of these coils compared to AC options, as they tend to be pricier. Additionally, compatibility with the specific application is crucial for ensuring optimal performance.

Latching Contactor Coil

Latching contactor coils stand out due to their ability to maintain their position without a continuous power supply, which enhances energy efficiency. They are particularly useful in automation systems and lighting controls, where energy conservation is a priority. However, the initial investment for latching coils can be higher, and buyers should assess their operational needs to determine if the energy savings justify the upfront costs.

Relay Contactor Coil

Relay contactor coils integrate the functionalities of both relays and contactors, making them versatile for various applications, particularly in control panels and low-voltage systems. This type of coil is beneficial for managing multiple circuits simultaneously. However, buyers should be aware of potential slower response times compared to dedicated contactors, which may affect performance in high-speed applications. Evaluating the specific requirements of the application is essential.

Soft Start Contactor Coil

Soft start contactor coils are designed to gradually increase power to connected motors, significantly reducing inrush currents that can cause equipment damage. This feature is particularly advantageous in industrial applications where motor control is critical. While soft start coils offer excellent protection, their installation can be complex, and buyers should prepare for potential additional costs related to integration into existing systems. Careful planning and consultation with suppliers can help mitigate these challenges.

Key Industrial Applications of electrical coil

| Industry/Sector | Specific Application of electrical coil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automation Systems | Increases production efficiency and reduces costs | Voltage ratings, compatibility with machinery, lead times |

| Renewable Energy | Wind Turbine Control Systems | Enhances energy reliability and system longevity | Environmental certifications, temperature and humidity ratings |

| Automotive | Electric Vehicle (EV) Battery Management Systems | Improves performance and safety of EVs | Compliance with automotive standards, durability under stress |

| HVAC | Climate Control Systems | Optimizes energy consumption and enhances comfort | Energy efficiency ratings, compatibility with existing systems |

| Oil & Gas | Pump Control Systems | Ensures operational reliability in harsh environments | Certification for explosion-proof design, temperature ratings |

Manufacturing: Automation Systems

In the manufacturing sector, electrical coils are integral to automation systems, controlling motors and actuators that drive production lines. They enhance operational efficiency by enabling precise control over machinery, which ultimately reduces downtime and operational costs. Buyers in this sector must consider the voltage ratings and compatibility of coils with existing machinery to ensure seamless integration. Sourcing suppliers with a strong track record in quality control and timely delivery is also crucial for maintaining production schedules.

Renewable Energy: Wind Turbine Control Systems

In renewable energy, particularly in wind turbine technology, electrical coils are used in control systems that manage turbine operations. These coils ensure reliable energy production by adjusting the angle of blades and controlling the generator. For B2B buyers, it’s essential to focus on suppliers that offer environmentally certified products, as well as those that can meet specific temperature and humidity ratings required for outdoor installations. Understanding the lifecycle and maintenance needs of these coils can also enhance system longevity and reliability.

Automotive: Electric Vehicle (EV) Battery Management Systems

Electrical coils play a vital role in the battery management systems of electric vehicles (EVs), where they regulate charge and discharge cycles to optimize battery performance. This application is critical for ensuring the safety and efficiency of EVs. Buyers should prioritize suppliers that comply with automotive standards and provide durable coils capable of withstanding the stresses of automotive environments. Additionally, understanding the technological advancements in coil design can lead to better performance outcomes in EV applications.

HVAC: Climate Control Systems

In HVAC systems, electrical coils are essential for controlling various components, including fans, compressors, and heating elements. They contribute to optimizing energy consumption and enhancing indoor comfort levels. Buyers should look for coils that are rated for energy efficiency and compatibility with existing HVAC infrastructure. Sourcing suppliers that offer reliable after-sales support and technical expertise can significantly aid in the successful implementation of these systems.

Oil & Gas: Pump Control Systems

Electrical coils are critical in the oil and gas industry for controlling pumps that transport fluids. Their reliable operation in harsh environments is vital for maintaining production levels and preventing costly downtimes. When sourcing coils for this application, buyers must ensure that the products are certified for explosion-proof designs and meet stringent temperature ratings. Establishing relationships with suppliers who understand the unique challenges of the oil and gas sector can lead to more effective procurement strategies and improved operational reliability.

Strategic Material Selection Guide for electrical coil

When selecting materials for electrical coils, international B2B buyers must consider various factors that influence performance, cost, and application suitability. Here’s an analysis of four common materials used in electrical coils, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Copper

Key Properties:

Copper is known for its excellent electrical conductivity, thermal conductivity, and malleability. It typically operates effectively at high temperatures (up to 200°C) and has good corrosion resistance, especially when coated.

Pros & Cons:

Copper coils are durable and provide superior performance in electrical applications, making them a preferred choice for high-efficiency systems. However, they are more expensive than alternatives like aluminum, and their manufacturing process can be complex due to the need for precise handling to avoid damage.

Impact on Application:

Copper is highly compatible with various media, making it suitable for diverse applications, including industrial machinery and power distribution systems.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM B170 for copper wire. Additionally, they should consider the impact of local environmental conditions on corrosion resistance and the availability of copper in their region.

Aluminum

Key Properties:

Aluminum is lightweight, has good electrical conductivity (about 60% that of copper), and offers excellent corrosion resistance due to its natural oxide layer. It can withstand temperatures up to 150°C.

Pros & Cons:

Aluminum coils are less expensive than copper, making them attractive for cost-sensitive projects. However, they are less durable and may require larger cross-sectional areas to achieve the same conductivity as copper, which can complicate design and installation.

Impact on Application:

Aluminum is suitable for applications where weight is a concern, such as in automotive or aerospace industries, but it may not perform as well in high-temperature environments.

Considerations for International Buyers:

Buyers should be aware of the relevant standards, such as ASTM B231 for aluminum wire. Additionally, they should assess the local supply chain for aluminum, as availability can vary significantly across regions.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high tensile strength, and can withstand temperatures up to 800°C. It is less conductive than copper and aluminum but provides durability in harsh environments.

Pros & Cons:

The main advantage of stainless steel coils is their longevity and resistance to environmental factors, making them ideal for applications in corrosive environments. However, they are more expensive and can be challenging to work with due to their rigidity.

Impact on Application:

Stainless steel is particularly useful in applications involving exposure to chemicals or extreme temperatures, such as in the oil and gas industry.

Considerations for International Buyers:

Buyers should look for compliance with standards like ASTM A313 for stainless steel wire. Understanding local regulations regarding corrosion resistance and environmental impact is also crucial for successful procurement.

Ferrite

Key Properties:

Ferrite materials are magnetic ceramics that exhibit good electrical insulation and can operate effectively at high frequencies. They have a low temperature coefficient and can withstand moderate pressures.

Pros & Cons:

Ferrite coils are lightweight and cost-effective, making them suitable for a variety of electronic applications. However, they are less durable than metals and can be brittle, which may lead to breakage during handling.

Impact on Application:

Ferrite is commonly used in inductors and transformers, especially in high-frequency applications such as RF circuits and power supplies.

Considerations for International Buyers:

Buyers should ensure compliance with international standards for electronic components, such as IEC 60068 for environmental testing. Additionally, understanding local market preferences for ferrite materials can influence sourcing decisions.

Summary Table

| Material | Typical Use Case for electrical coil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Power distribution, industrial machinery | Superior electrical conductivity and durability | Higher cost and complex manufacturing process | High |

| Aluminum | Automotive, aerospace applications | Lightweight and cost-effective | Lower conductivity and durability | Medium |

| Stainless Steel | Oil and gas, harsh environments | Excellent corrosion resistance and strength | More expensive and challenging to work with | High |

| Ferrite | RF circuits, inductors, transformers | Lightweight and cost-effective for electronics | Brittle and less durable than metals | Low |

This analysis provides a comprehensive overview of material options for electrical coils, enabling international B2B buyers to make informed decisions that align with their operational needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical coil

In the global marketplace, the manufacturing processes and quality assurance of electrical coils are critical for ensuring reliability and efficiency in various applications. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can enhance procurement decisions and ensure compliance with local and international standards.

Manufacturing Processes for Electrical Coils

1. Material Preparation

The manufacturing of electrical coils begins with the selection of appropriate materials, which typically include copper or aluminum wire, insulation materials, and magnetic cores. The wire is often coated with an insulating layer to prevent short circuits. Key considerations during this stage include:

- Material Quality: Buyers should ensure that suppliers use high-purity metals and appropriate insulation materials that meet the required electrical and thermal properties.

- Sourcing: Buyers should verify the origin of materials, especially if sourcing from regions with varying quality standards.

2. Forming

Once materials are prepared, the next step is forming the coils. This involves winding the wire around a core to create the desired shape and specifications. The techniques employed may vary based on the type of coil being manufactured:

- Manual Winding: Often used for small production runs or custom coils.

- Automated Winding Machines: These machines enhance efficiency and precision, especially for large-scale production.

During this phase, it’s crucial for buyers to assess the machinery and technology used by suppliers, as this can impact the consistency and quality of the coils produced.

3. Assembly

After winding, the coils undergo assembly, where additional components, such as terminals and connectors, are attached. This stage may also include integrating the coil into a larger electrical system or device. Key aspects include:

- Component Compatibility: Ensure that all components meet the specifications required for the intended application.

- Workmanship Standards: Buyers should be aware of the assembly techniques employed, as skilled labor and proper practices can significantly affect the final product’s quality.

4. Finishing

The finishing process involves applying protective coatings, conducting final inspections, and packaging the coils for shipping. This stage is essential for ensuring durability and functionality. Important considerations include:

- Coating Materials: The choice of coatings can affect the coil’s resistance to environmental factors, such as moisture and corrosion.

- Packaging: Proper packaging is vital to prevent damage during transport, especially for international shipments.

Quality Assurance in Electrical Coil Manufacturing

Quality assurance (QA) is a systematic process that ensures the manufactured coils meet specified standards and customer expectations. International B2B buyers should be particularly vigilant regarding quality assurance practices, as they can significantly impact operational efficiency and safety.

Relevant International Standards

Several international standards govern the quality of electrical coils, including:

- ISO 9001: This quality management standard ensures that organizations consistently provide products that meet customer and regulatory requirements.

- CE Marking: Essential for products sold within the European Economic Area (EEA), CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For coils used in oil and gas applications, adherence to American Petroleum Institute (API) standards is crucial.

Quality Control Checkpoints

Quality control (QC) checkpoints are integral to the manufacturing process. They typically include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, reducing waste and ensuring consistent quality.

- Final Quality Control (FQC): A comprehensive assessment of the finished product before shipment ensures that all specifications and standards are met.

Common Testing Methods

B2B buyers should be familiar with common testing methods to verify product quality:

- Electrical Testing: Includes insulation resistance tests, dielectric strength tests, and continuity tests.

- Mechanical Testing: Assessing the physical properties of the coils, such as tensile strength and flexibility.

- Environmental Testing: Evaluating the performance of coils under various environmental conditions, such as temperature and humidity.

Verifying Supplier Quality Control

For international buyers, verifying a supplier’s quality control processes is essential. Here are actionable strategies:

- Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and QA practices.

- Requesting Quality Reports: Buyers should ask for detailed QC reports, including the results of IQC, IPQC, and FQC.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased assessment of the supplier’s quality assurance measures.

Quality Control and Certification Nuances for International Buyers

When sourcing electrical coils internationally, buyers must navigate various certification and compliance requirements specific to their regions. For instance:

- Local Regulations: Each country may have unique regulations regarding electrical products. Buyers should ensure compliance with local laws to avoid penalties and ensure product safety.

- Cultural Considerations: Understanding local business practices can facilitate smoother negotiations and foster better relationships with suppliers.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for electrical coils is crucial for B2B buyers. By focusing on material quality, production techniques, and stringent quality control measures, buyers can ensure they source reliable and compliant products that meet their operational needs.

Related Video: Inside the World’s Most Advanced Cable Manufacturing Plant – ZMS Cable

Comprehensive Cost and Pricing Analysis for electrical coil Sourcing

Understanding the cost structure and pricing dynamics of electrical coil sourcing is essential for international B2B buyers. This analysis covers key cost components, price influencers, and actionable tips for optimizing procurement, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost of electrical coils. Common materials include copper, aluminum, and various insulating materials. Prices for these raw materials fluctuate based on global supply and demand, making it crucial for buyers to monitor market trends.

-

Labor: Labor costs vary by region, influenced by local wage rates and labor laws. Countries with higher labor costs may produce coils with enhanced craftsmanship and quality assurance, while lower-cost regions may offer more budget-friendly options. Understanding the labor market of the supplier’s location can help buyers gauge the potential quality and pricing of the coils.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and administrative costs. Suppliers in regions with higher operational costs will generally pass these expenses onto buyers, affecting pricing.

-

Tooling: The initial investment in tooling can be substantial, especially for customized coils. Buyers should inquire about tooling costs when requesting quotes, as these costs can be amortized over larger order volumes, reducing the per-unit price.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with industry standards. However, enhanced QC measures may increase manufacturing costs. Buyers should consider the balance between quality assurance and cost when selecting suppliers.

-

Logistics: Shipping and handling costs are critical in the total cost structure. Factors such as distance, mode of transport, and packaging requirements can influence logistics costs. Buyers should evaluate the total logistics expenses, especially when sourcing from distant suppliers.

-

Margin: Supplier profit margins vary widely based on market positioning and competitive landscape. Understanding the typical margins for electrical coils can help buyers negotiate effectively.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Larger volumes often lead to discounts, while small orders may incur higher per-unit costs. Buyers should assess their needs to negotiate favorable terms.

-

Specifications/Customization: Customized coils that meet specific operational requirements typically command higher prices. Buyers must weigh the benefits of customization against the additional costs.

-

Materials Quality/Certifications: Higher quality materials and certifications (e.g., ISO, RoHS) can elevate costs but may enhance performance and reliability. Buyers should determine the necessary quality standards for their applications.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can influence pricing. Established suppliers may offer premium pricing due to their reliability and service level.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining responsibility for shipping costs, insurance, and risk. Buyers should clarify these terms to avoid unexpected expenses.

Buyer Tips

-

Negotiation: Leverage insights from your cost analysis to negotiate better prices. Use volume commitments or long-term contracts to secure discounts.

-

Cost-Efficiency: Consider total cost of ownership (TCO) rather than just upfront costs. Evaluate maintenance, operational efficiency, and lifecycle costs when making sourcing decisions.

-

Pricing Nuances for International Buyers: Buyers in regions like Africa and South America may face unique challenges such as currency fluctuations and import tariffs. It’s essential to factor these elements into pricing discussions.

-

Market Research: Stay informed about market trends, material costs, and supplier capabilities. This knowledge enables buyers to make informed decisions and adapt their strategies as market conditions change.

-

Disclaimer for Indicative Prices: Pricing for electrical coils can fluctuate due to various factors, including market conditions and supplier negotiations. Buyers should request updated quotes and consider potential variations in pricing over time.

By understanding these elements, international B2B buyers can navigate the complexities of electrical coil sourcing and optimize their procurement strategies for better cost management and operational efficiency.

Spotlight on Potential electrical coil Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘electrical coil’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for electrical coil

Understanding the essential technical properties and trade terminology related to electrical coils is crucial for international B2B buyers. This knowledge not only enhances sourcing strategies but also ensures compliance with industry standards and operational efficiency. Below are some key specifications and common terms that buyers should familiarize themselves with.

Key Technical Properties

-

Material Grade

– Definition: The specific alloy or metal used in the coil’s construction, typically copper or aluminum for electrical applications.

– B2B Importance: Material grade affects conductivity, durability, and resistance to corrosion. Selecting the right material is vital for optimizing performance and extending the lifespan of electrical systems. -

Winding Type

– Definition: Refers to the arrangement of wire coils, which can be either concentric or layered.

– B2B Importance: The winding type influences the coil’s inductance and efficiency. Buyers must consider the application requirements, as different winding types can impact energy consumption and overall system reliability. -

Inductance Value

– Definition: A measure of the coil’s ability to store electrical energy in a magnetic field, typically expressed in henries (H).

– B2B Importance: Inductance value is critical for applications involving electromagnetic fields. It helps in determining the coil’s suitability for specific tasks, such as motor control or power switching, ensuring optimal performance. -

Tolerance

– Definition: The permissible limit of variation in the coil’s dimensions or electrical characteristics.

– B2B Importance: Tolerance affects the reliability and compatibility of the coil with other components. Strict tolerances are often required in high-precision applications to avoid malfunction and ensure safety. -

Rated Voltage

– Definition: The maximum voltage that a coil can handle without risk of failure.

– B2B Importance: Understanding the rated voltage is crucial for preventing overload conditions that can lead to equipment damage or failures. Buyers must match the rated voltage with their operational requirements to ensure safe and efficient usage.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: OEMs often provide high-quality components that meet specific standards, making them essential partners for businesses looking for reliable electrical coils. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers gauge supplier flexibility and plan their purchasing strategy to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for a specific quantity of goods.

– Importance: RFQs are crucial for comparing prices and terms from multiple suppliers, enabling buyers to make informed decisions based on cost and quality. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, cost allocation, and risk management, ensuring smoother transactions and logistics. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Importance: Knowing the lead time is essential for effective inventory management and production planning. It helps buyers align their supply chain activities with production schedules.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions, enhancing their sourcing strategies and ensuring compliance with industry standards. This foundational knowledge is vital for navigating the complexities of the electrical coil market and optimizing operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the electrical coil Sector

In the current landscape of the electrical coil sector, international B2B buyers are witnessing a series of dynamic changes driven by technological advancements, market demands, and evolving regulations. The global market for electrical coils is expanding, fueled by the rise of automation across industries, increasing demand for renewable energy solutions, and the ongoing digital transformation that emphasizes smart technologies. In regions such as Africa and South America, there is a growing emphasis on infrastructure development, which requires reliable electrical components, while Europe and the Middle East are focusing on energy efficiency and sustainable practices.

Illustrative Image (Source: Google Search)

Key trends influencing sourcing decisions include the adoption of Industry 4.0 technologies that enhance operational efficiency and transparency. Buyers are increasingly looking for suppliers that leverage advanced manufacturing processes, such as 3D printing and IoT-enabled devices, which can optimize production and reduce lead times. Additionally, the shift towards just-in-time (JIT) sourcing is enabling companies to minimize inventory costs and enhance flexibility, catering to rapid market changes. As a result, buyers must evaluate suppliers not just on price but on their technological capabilities and adaptability to market demands.

The competitive landscape is also marked by the emergence of local suppliers who offer cost-effective solutions while ensuring shorter supply chains. This trend is particularly significant for buyers in Africa and South America, where local production can mitigate import challenges. Furthermore, the focus on supply chain resilience post-pandemic has led buyers to prioritize suppliers with robust risk management strategies.

Sustainability & Ethical Sourcing in B2B

The importance of sustainability in the electrical coil sector cannot be overstated. As global concerns about climate change intensify, companies are increasingly held accountable for their environmental impact. Buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as reducing waste, minimizing energy consumption, and using eco-friendly materials in their production processes.

Ethical sourcing is also becoming a critical consideration. Buyers are encouraged to engage with suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainable and ethical practices. Moreover, sourcing materials that are recyclable or derived from renewable resources can significantly reduce the carbon footprint associated with electrical coils.

Incorporating sustainability into procurement strategies not only enhances brand reputation but also aligns with the growing consumer preference for environmentally responsible products. This trend is especially relevant for buyers in Europe, where regulatory frameworks increasingly mandate sustainable sourcing practices.

Brief Evolution/History

The electrical coil sector has evolved significantly over the decades, transitioning from simple electromechanical devices to complex, electronically controlled systems. Early developments in the 19th century laid the groundwork for today’s advanced coils used in various applications, from industrial machinery to renewable energy systems. The introduction of automation and smart technology in the late 20th century further transformed the industry, enabling more precise control and efficiency. As we move forward, the integration of artificial intelligence and machine learning into coil design and manufacturing processes is expected to drive further innovation, enhancing performance and sustainability in the sector.

International B2B buyers must remain vigilant about these trends and historical shifts, ensuring that their sourcing strategies align with both current market demands and future developments in the electrical coil industry.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of electrical coil

-

How can I effectively vet suppliers of electrical coils?

When sourcing electrical coils, it’s crucial to conduct thorough supplier vetting. Start by checking certifications such as ISO 9001 for quality management and relevant industry-specific certifications. Look for suppliers with a proven track record in your target market, considering factors like years in business and client testimonials. Engaging in direct communication can also reveal their responsiveness and willingness to customize products. Additionally, utilize platforms such as Alibaba or Global Sources to read reviews and ratings from previous buyers, which can provide insights into reliability and product quality. -

What customization options are typically available for electrical coils?

Many suppliers offer customization for electrical coils to meet specific application needs. Customization can include variations in coil size, voltage ratings, and material types. Discuss your requirements in detail with potential suppliers to explore options, including the possibility of prototype development. Ensure that the supplier has experience with custom orders and can provide examples of previous work. This approach not only enhances product compatibility with your systems but also ensures better performance in your specific industrial applications. -

What are the common minimum order quantities (MOQs) and lead times for electrical coils?

Minimum order quantities (MOQs) for electrical coils can vary significantly depending on the supplier and the type of coil. Generally, MOQs can range from 50 to several hundred units. Lead times typically span from 2 to 12 weeks, influenced by factors such as the complexity of customization and the supplier’s production capacity. It’s advisable to discuss your needs upfront to negotiate favorable terms and plan your procurement schedule accordingly. Understanding these parameters helps in managing inventory effectively and avoiding production delays. -

What payment terms should I expect when sourcing electrical coils internationally?

Payment terms can vary widely among suppliers, especially in international trade. Common options include advance payment, letters of credit, and payment upon delivery. Many suppliers require a deposit (usually 30-50%) before production starts, with the balance due before shipment. Ensure you clarify payment conditions and explore options like PayPal or escrow services for added security. It’s also advisable to consider currency fluctuations and potential transaction fees, particularly when dealing with suppliers in different regions. -

How important is quality assurance and certification for electrical coils?

Quality assurance (QA) and certification are critical when sourcing electrical coils, as they ensure product reliability and compliance with safety standards. Look for suppliers that implement rigorous QA processes, including material inspections and performance testing. Certifications such as CE for European markets or UL for North America can indicate adherence to industry standards. Request documentation of these certifications and ask about the supplier’s QA protocols to assure that the coils will perform effectively in your applications, minimizing risk and potential failures. -

What logistics considerations should I keep in mind when importing electrical coils?

Logistics play a vital role in the sourcing process. Assess shipping options, including air freight for urgent needs or sea freight for larger orders. Understand the associated costs, customs duties, and taxes that may apply when importing into your region. Working with a logistics provider experienced in international trade can streamline the process, ensuring compliance with local regulations and timely delivery. Additionally, consider the supplier’s ability to handle packaging and documentation to avoid delays at customs. -

How can I resolve disputes with suppliers effectively?

Disputes may arise during the sourcing process, so having a clear resolution strategy is essential. Start by maintaining open communication with your supplier to address any issues promptly. Document all agreements, including specifications, delivery timelines, and payment terms, to reference during disputes. If direct communication fails, consider mediation or arbitration as a resolution method, which can be less costly than legal action. Familiarize yourself with the supplier’s terms and conditions, especially those related to dispute resolution, to ensure you are prepared. -

What market trends should I be aware of when sourcing electrical coils?

Understanding current market trends can provide a competitive edge when sourcing electrical coils. Key trends include the increasing demand for energy-efficient solutions and the growing integration of smart technologies in industrial applications. Suppliers are also focusing on sustainable materials and production methods to meet environmental regulations. Staying informed about technological advancements and shifting buyer preferences can guide your purchasing decisions, helping you select suppliers that align with these trends and ensuring that your operations remain relevant in a rapidly changing marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electrical coil

In navigating the complexities of sourcing electrical coils, international B2B buyers must prioritize strategic sourcing to ensure quality, reliability, and cost-effectiveness. Understanding the various types of coils—such as AC, DC, and latching—enables buyers to select products that align with specific operational needs, enhancing efficiency and performance across applications. Moreover, recognizing the importance of supplier networks and regional market dynamics, particularly in Africa, South America, the Middle East, and Europe, can lead to better negotiation outcomes and stronger partnerships.

As the demand for advanced electrical components continues to grow, staying informed about market trends, pricing fluctuations, and technological advancements will empower buyers to make proactive decisions. By implementing best practices in sourcing, companies can not only optimize their supply chains but also mitigate risks associated with quality and compliance.

Looking ahead, it is crucial for international buyers to engage with trusted suppliers and leverage data-driven insights to navigate future challenges. Embrace the opportunity to refine your sourcing strategies and invest in relationships that foster innovation and sustainability in your operations. The time to act is now—position your business for success in the evolving global market for electrical coils.