Master Gasket Specialties Sourcing for Operational

Introduction: Navigating the Global Market for gasket specialties

Navigating the global market for gasket specialties is a critical endeavor for B2B buyers seeking reliable sealing solutions across diverse industries. Gaskets play an essential role in ensuring system integrity, safety, and operational efficiency, serving as the vital link that prevents leaks and failures in applications ranging from energy production in the Middle East to food processing in South America. With the increasing complexity of industrial requirements, selecting the right gasket type and material is paramount for maintaining compliance with international standards and minimizing downtime.

This guide offers a comprehensive roadmap for international procurement professionals, detailing the various types of gaskets and their specific applications, materials, and manufacturing processes. Buyers will find in-depth analyses of quality control practices, supplier evaluation methods, and regional pricing benchmarks that are crucial for making informed sourcing decisions. Key market trends and regulatory compliance requirements are also addressed, providing a holistic view of the gasket landscape.

By equipping B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Italy and Saudi Arabia—with actionable insights, this guide empowers them to navigate the complexities of gasket sourcing confidently. Whether for large-scale infrastructure projects or specialized industrial applications, understanding these dynamics is essential for securing durable, compliant, and cost-effective sealing solutions that support long-term operational success.

Understanding gasket specialties Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Rubber (NR) | High elasticity, abrasion resistance, low cost | Water systems, automotive, general machinery | Pros: Affordable, flexible; Cons: Limited chemical resistance, not suitable for oils or high temperatures. |

| EPDM (Ethylene Propylene Diene) | Excellent weather, ozone, steam, and chemical resistance | Water treatment, HVAC, outdoor piping | Pros: Durable in outdoor environments, low maintenance; Cons: Not compatible with oils or fuels. |

| Neoprene (CR) | Good chemical/oil resistance, flame retardant | Oil & gas, refrigeration, marine, HVAC | Pros: Versatile and durable; Cons: Not optimal for extreme temperatures. |

| Silicone Rubber | Wide temperature tolerance, chemically inert | Food & beverage, pharmaceuticals, electronics | Pros: High purity and safety, extreme temperature performance; Cons: Higher cost, less tear resistant. |

| Ring-Type Joint (RTJ, Metal) | Precision-machined metal, withstands extreme pressure/heat | Oil & gas pipelines, petrochemical, power plants | Pros: Exceptional seal in high-pressure environments; Cons: Single-use, higher lifecycle cost. |

Natural Rubber (NR) Washers & Gaskets

Natural rubber is a cost-effective choice for industrial applications, particularly in environments where flexibility and abrasion resistance are critical. Commonly used in water systems and automotive applications, NR is suitable for general machinery seals. However, buyers must consider its limitations regarding chemical exposure and temperature extremes; it is not suitable for applications involving oils or high heat. For projects that prioritize budget and operate under mild conditions, NR remains a practical option.

EPDM (Ethylene Propylene Diene) Gaskets

EPDM gaskets excel in environments exposed to UV, ozone, and steam, making them ideal for water treatment facilities and HVAC systems. Their robust chemical resistance allows them to perform well in outdoor settings, reducing maintenance costs and extending service life. However, they are incompatible with oils and fuels, which can limit their application in certain industrial sectors. Buyers looking for long-term durability in variable weather conditions will find EPDM a reliable choice.

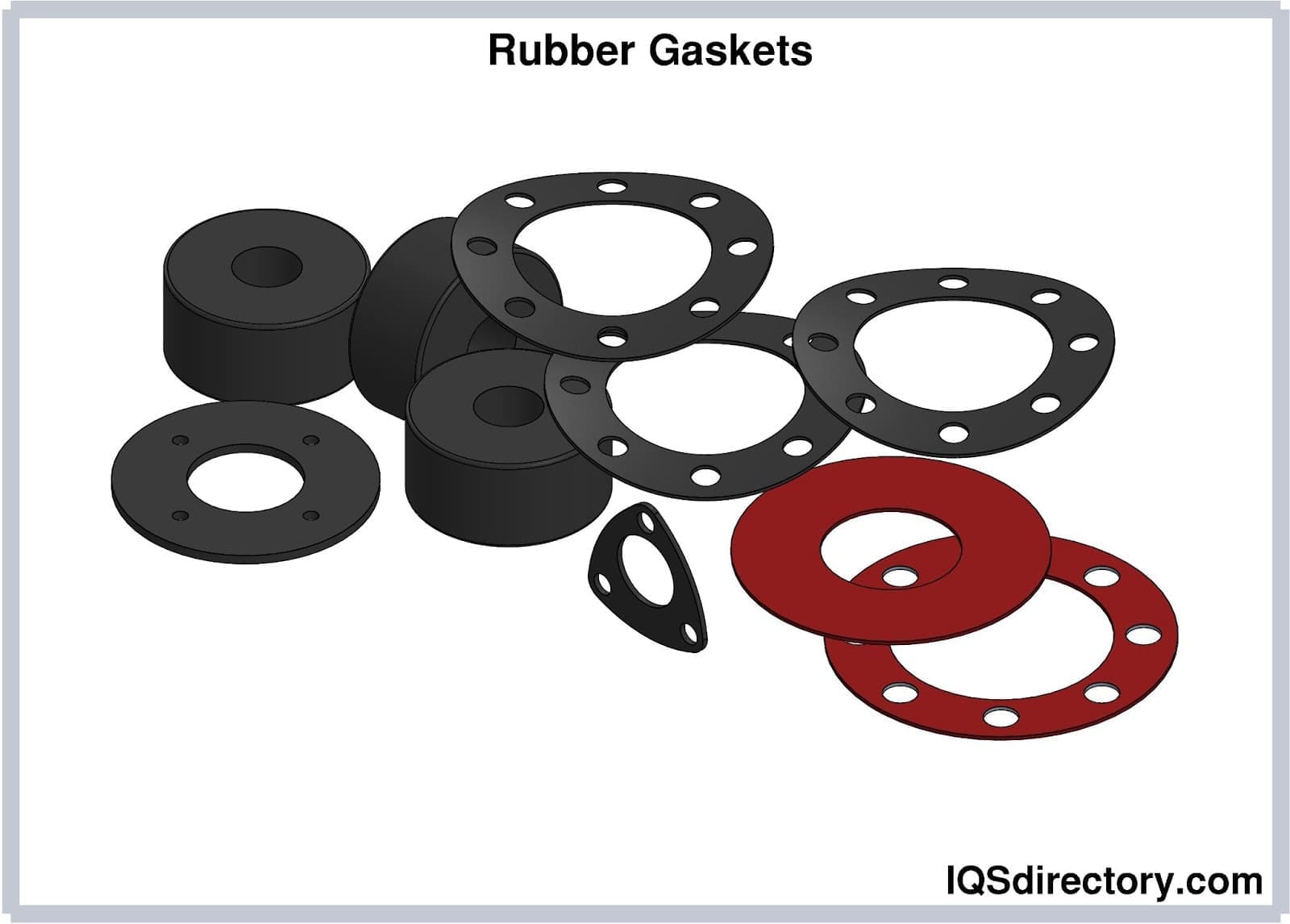

Illustrative Image (Source: Google Search)

Neoprene (CR) Washers & Gaskets

Neoprene gaskets are recognized for their versatility, providing good resistance to oils, chemicals, and flames. They are commonly used in the oil & gas sector, refrigeration, and marine applications due to their stable performance across a broad temperature range. While neoprene is a durable option, it may not perform optimally in extreme conditions. B2B buyers should weigh its benefits in safety and chemical resistance against the specific needs of their applications.

Silicone Rubber Gaskets

Silicone rubber gaskets are favored for their exceptional temperature tolerance and chemical inertness, making them ideal for regulated industries such as food processing and pharmaceuticals. Their ability to perform under extreme temperatures enhances their application range. However, the higher cost and lower tear resistance may deter some buyers. For B2B procurement professionals in sectors with strict health and safety standards, silicone gaskets represent a premium investment in quality and compliance.

Ring-Type Joint (RTJ, Metal)

Ring-Type Joint gaskets are engineered for high-pressure and high-temperature applications, particularly in the oil and gas sector. Their precision-machined design ensures exceptional sealing performance, critical for safety and regulatory compliance. However, these gaskets are typically single-use, which can increase lifecycle costs. B2B buyers must evaluate the trade-off between initial cost and long-term operational safety, especially in hazardous environments where reliability is paramount.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of gasket specialties

| Industry/Sector | Specific Application of gasket specialties | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Sealing in pipelines and drilling equipment | Ensures safety and efficiency, minimizing leaks and downtime | Material compatibility with hydrocarbons and extreme conditions |

| Water Management | Gaskets for water treatment and distribution systems | Prevents leaks, ensuring clean water supply and regulatory compliance | Durability against corrosion and environmental factors |

| Manufacturing | Seals in machinery and equipment | Increases operational efficiency and reduces maintenance costs | Precision in dimensions and resistance to wear |

| Food & Beverage | Gaskets for processing equipment | Ensures product safety and compliance with health regulations | FDA-approved materials and temperature resistance |

| Automotive | Engine gaskets and seals | Enhances engine performance and longevity | Tolerance to temperature fluctuations and chemical exposure |

Oil & Gas

In the oil and gas industry, gasket specialties are critical for sealing applications in pipelines and drilling equipment. These gaskets prevent leaks that can lead to environmental hazards and costly downtime. Buyers in this sector must prioritize materials that can withstand extreme temperatures and pressures, as well as compatibility with hydrocarbons. International B2B buyers should also consider local regulations and standards to ensure compliance and safety.

Water Management

Gaskets play a vital role in water treatment and distribution systems, where they help maintain the integrity of pipes and prevent leaks. This is particularly important for municipal water systems in regions like Africa and South America, where clean water supply is crucial. Buyers should focus on materials that resist corrosion and environmental degradation, ensuring long-lasting performance. Additionally, compliance with local and international water quality standards is essential for successful sourcing.

Manufacturing

In manufacturing, gasket specialties are essential for sealing machinery and equipment, contributing to overall operational efficiency. High-quality seals minimize the risk of leaks and equipment failure, which can lead to significant downtime and maintenance costs. Buyers should seek gaskets that offer precision in dimensions and resistance to wear, particularly in high-demand environments. Understanding the specific operational conditions and requirements of machinery will guide effective sourcing decisions.

Food & Beverage

The food and beverage industry requires gaskets that meet stringent health and safety regulations. Gasket specialties are used in processing equipment to ensure product safety and prevent contamination. B2B buyers must prioritize FDA-approved materials that can withstand temperature fluctuations and maintain integrity during cleaning processes. Selecting the right gaskets not only ensures compliance but also enhances the overall quality of the final product.

Automotive

In the automotive sector, gaskets are crucial for engine performance and longevity. They provide essential sealing to prevent leaks of fluids and gases, thereby enhancing the efficiency of the engine. B2B buyers need to consider gaskets that can tolerate temperature variations and exposure to various chemicals. The choice of materials is critical, as it directly impacts the vehicle’s performance and durability, making informed sourcing decisions essential for automotive manufacturers.

Related Video: What are all the Laboratory Apparatus and their uses?

Strategic Material Selection Guide for gasket specialties

When selecting materials for gasket specialties, international B2B buyers must consider various factors including performance characteristics, application suitability, and regional compliance standards. Below, we analyze four common materials used in gasket manufacturing, providing insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Natural Rubber (NR)

Key Properties:

Natural rubber is known for its high elasticity and excellent abrasion resistance. It typically operates effectively at temperatures ranging from -20°C to 70°C and can withstand moderate pressures. However, it has limited resistance to oils, fuels, and extreme temperatures.

Pros & Cons:

Natural rubber is cost-effective and flexible, making it suitable for general sealing applications in non-aggressive environments. However, its limitations in chemical and heat resistance may lead to early failure in more demanding applications, potentially increasing long-term costs due to frequent replacements.

Impact on Application:

Best suited for water pipelines and automotive vibration dampers, NR is not recommended for applications involving hydrocarbons or extreme temperatures. Buyers should ensure that the operating environment aligns with the material’s limitations.

Considerations for International Buyers:

Buyers should verify compliance with local standards such as ASTM or DIN. In regions with varying climates, such as the Middle East, the suitability of NR should be carefully evaluated against local environmental conditions.

EPDM (Ethylene Propylene Diene Monomer)

Key Properties:

EPDM boasts exceptional resistance to weathering, ozone, and steam, with a temperature range of -40°C to 120°C. It is particularly effective in aqueous environments and can handle moderate pressure.

Pros & Cons:

The material’s durability and low maintenance requirements make it ideal for outdoor applications like water treatment and HVAC systems. However, EPDM is not compatible with oils or fuels, which limits its use in certain industries.

Impact on Application:

EPDM is particularly valuable in applications exposed to UV light and harsh weather conditions, making it a preferred choice for outdoor piping systems. Its chemical resistance enhances system integrity, reducing the need for frequent replacements.

Considerations for International Buyers:

B2B buyers in regions like Africa and South America should assess local regulations regarding material specifications and environmental compliance. Understanding regional preferences for durable materials can also guide purchasing decisions.

Neoprene (CR)

Key Properties:

Neoprene offers good chemical and oil resistance, with a temperature tolerance between -40°C and 120°C. It is flame-retardant and provides stable performance under varying conditions.

Pros & Cons:

This material is versatile and suitable for a range of applications, including oil & gas and refrigeration. However, while it performs well in moderate environments, it may not withstand extreme chemical exposure or high temperatures.

Impact on Application:

Neoprene is effective in marine and industrial settings where exposure to lubricants and coolants is common. Its flame-retardant properties also make it a safe choice in applications where fire safety is a concern.

Considerations for International Buyers:

Buyers should ensure that Neoprene gaskets meet specific industry standards for safety and performance. Regions like Saudi Arabia may have stringent regulations for materials used in oil and gas applications.

Silicone Rubber

Key Properties:

Silicone rubber excels in extreme temperature conditions, with a range from -60°C to 230°C. It is chemically inert and offers excellent resistance to moisture and UV exposure.

Pros & Cons:

Silicone is ideal for applications requiring high purity, such as food and pharmaceuticals. However, it tends to be more expensive than other materials and may have lower tear resistance.

Impact on Application:

Silicone is particularly suitable for food processing and medical applications where contamination risks must be minimized. Its ability to withstand extreme temperatures makes it a reliable choice for diverse industrial settings.

Considerations for International Buyers:

International buyers should prioritize suppliers who can provide compliance documentation for food-grade and medical applications. Understanding local regulations in Europe and the Middle East regarding silicone usage is crucial for successful procurement.

Summary Table

| Material | Typical Use Case for gasket specialties | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber (NR) | Water pipelines, automotive seals | Cost-effective and flexible | Limited chemical and heat resistance | Low |

| EPDM | Outdoor piping, HVAC systems | Excellent weather and ozone resistance | Not compatible with oils and fuels | Medium |

| Neoprene (CR) | Oil & gas, refrigeration | Good chemical and oil resistance | Less effective in extreme conditions | Medium |

| Silicone Rubber | Food processing, medical applications | High purity and extreme temperature tolerance | Higher cost, lower tear resistance | High |

This strategic material selection guide equips international B2B buyers with the necessary insights to make informed decisions regarding gasket specialties, ensuring optimal performance and compliance across various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for gasket specialties

Manufacturing Processes for Gasket Specialties

The manufacturing of gasket specialties involves a systematic approach that ensures the production of high-quality sealing solutions. Understanding the main stages of the manufacturing process is crucial for B2B buyers, especially those operating in diverse and demanding environments like Africa, South America, the Middle East, and Europe.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: The choice of material—be it rubber, silicone, or metallic components—depends on the specific application requirements. Common materials include Natural Rubber (NR), Ethylene Propylene Diene Monomer (EPDM), Neoprene, and various metals for composite gaskets.

– Mixing and Compounding: For rubber-based gaskets, the raw materials are mixed with additives (such as curing agents and fillers) to enhance properties like durability, resistance to chemicals, and temperature stability. This step is crucial for achieving the desired performance characteristics. -

Forming

– Molding Techniques: Various molding techniques, including compression, transfer, and injection molding, are employed. Each technique has its advantages; for instance, injection molding offers precision and is ideal for large production runs.

– Cutting and Shaping: Gasket sheets are cut into specified shapes using die cutting or waterjet cutting. Precision in this stage is essential to ensure that the gaskets fit perfectly into their intended applications. -

Assembly

– Layering and Bonding: For composite gaskets, different materials may be layered and bonded together using adhesives or heat. This is particularly relevant for applications requiring enhanced durability or chemical resistance.

– Final Assembly: This stage may involve attaching additional components, such as metal rings for improved sealing in high-pressure applications. -

Finishing

– Surface Treatment: Gaskets may undergo surface treatments to enhance their properties, such as increasing abrasion resistance or improving adhesion qualities.

– Quality Checks: Before the gaskets are packaged, they go through a final inspection process to ensure they meet the required specifications.

Quality Assurance in Gasket Manufacturing

Quality assurance is a critical aspect of the gasket manufacturing process. B2B buyers must be aware of the standards and practices that ensure the reliability and safety of the products they are sourcing.

Relevant International Standards

- ISO 9001: This is the most recognized quality management standard, ensuring that manufacturers meet customer and regulatory requirements consistently. Compliance with ISO 9001 indicates a commitment to quality and continuous improvement.

- Industry-Specific Certifications: Depending on the application, additional certifications may apply:

- CE Marking: Required for products sold within the European Economic Area, ensuring they meet safety and environmental standards.

- API (American Petroleum Institute) Standards: Particularly relevant for gaskets used in the oil and gas sector, ensuring they can withstand extreme conditions.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. Techniques such as visual inspections and measurements are standard practices.

- Final Quality Control (FQC): Before gaskets are shipped, they undergo rigorous testing to verify that they meet all specifications and standards. This may include pressure tests, thermal cycling tests, and chemical resistance tests.

Common Testing Methods

- Pressure Testing: Ensures that the gasket can withstand the pressures it will encounter in service.

- Thermal Cycling: Tests how well the gasket performs under varying temperature conditions.

- Chemical Resistance Testing: Determines how the gasket material reacts with various chemicals it may encounter during its lifecycle.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of potential suppliers is essential to mitigate risks associated with product failures. Here are effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s quality control systems, production capabilities, and adherence to industry standards. This firsthand observation can provide invaluable insights into the supplier’s operational practices.

-

Requesting Quality Reports: Buyers should ask for documentation of quality control processes and results from previous batches. This includes test reports, compliance certificates, and records of any non-conformance incidents.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality assurance practices. This is particularly useful for large orders or when working with new suppliers.

Quality Control and Certification Nuances for International Buyers

International B2B buyers should be aware of specific nuances when it comes to quality control and certification processes:

-

Regional Standards Compliance: Depending on the region, different standards may apply. For instance, gaskets used in the European market must comply with CE marking, while those in the Middle East may require adherence to local regulatory frameworks.

-

Documentation and Traceability: Ensure that suppliers provide complete documentation for traceability, including material certifications and batch records. This is particularly important for industries with stringent regulatory requirements, such as pharmaceuticals and food processing.

-

Language and Cultural Barriers: When sourcing from different regions, be prepared to navigate potential language barriers that may affect the clarity of quality documentation and communication about standards.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions that align with their operational needs, ensuring they procure reliable and compliant gasket solutions tailored to their specific applications.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for gasket specialties Sourcing

When sourcing gasket specialties, understanding the comprehensive cost structure and pricing landscape is essential for making informed purchasing decisions. The costs associated with gaskets can be broken down into several key components, and various factors influence the final pricing. This analysis provides actionable insights for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, including countries like Italy and Saudi Arabia.

Cost Components

-

Materials: The choice of raw materials significantly impacts costs. Common materials such as natural rubber, EPDM, neoprene, and silicone vary in price based on market demand, quality, and availability. Specialty materials like metal gaskets will command higher prices due to their durability and application in high-stress environments.

-

Labor: Labor costs can fluctuate depending on the region of production. Skilled labor in Europe may increase manufacturing costs compared to lower-cost labor markets in Africa or South America. Understanding local labor dynamics is crucial for estimating total expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, maintenance, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead, which can be a point of negotiation with suppliers.

-

Tooling: Custom gaskets often require specialized tooling, which can lead to significant upfront costs. For buyers needing unique specifications, it is essential to factor in these costs when evaluating total expenditure.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Buyers should assess the quality assurance practices of potential suppliers to understand how these costs are reflected in their pricing.

-

Logistics: Shipping costs vary based on distance, mode of transport, and trade regulations. Buyers should consider the implications of Incoterms on logistics costs, as this can affect pricing structures significantly.

-

Margin: Supplier margins can vary widely based on market competition, brand reputation, and the complexity of the product. Understanding typical margins in the region can help buyers gauge whether they are receiving a fair price.

Price Influencers

Several factors can influence pricing beyond the basic cost components:

-

Volume/MOQ: Larger orders typically lead to reduced per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs without overcommitting.

-

Specifications/Customization: Customized gaskets will generally incur higher costs due to specialized manufacturing processes. Clear communication of requirements can help suppliers provide accurate quotes.

-

Quality/Certifications: Gaskets that meet specific industry certifications may be priced higher. Buyers should weigh the importance of these certifications against their budget and application requirements.

-

Supplier Factors: The supplier’s experience, reputation, and reliability can impact pricing. Established suppliers may charge a premium but often offer higher quality and consistency.

Buyer Tips

-

Negotiation: Always approach negotiations with a clear understanding of market prices and supplier costs. Presenting competitive quotes from other suppliers can be effective in securing better deals.

-

Cost Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors like maintenance, longevity, and potential downtime when assessing cost efficiency.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and regional economic conditions that may affect pricing. Establishing relationships with local suppliers can mitigate some of these risks.

In conclusion, while indicative prices can provide a baseline, the actual costs associated with sourcing gasket specialties can vary significantly based on multiple factors. B2B buyers must conduct thorough market research and maintain open lines of communication with suppliers to navigate this complex landscape effectively.

Spotlight on Potential gasket specialties Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘gasket specialties’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gasket specialties

Understanding the technical specifications and trade terminology relevant to gasket specialties is crucial for B2B buyers aiming to make informed purchasing decisions. Here, we outline key properties and terms that will enhance your sourcing strategy and help you navigate the complexities of the gasket market effectively.

Key Technical Properties

-

Material Grade

– Definition: This refers to the quality and composition of the gasket material, which can include rubber types such as NR, EPDM, Neoprene, and Silicone.

– Importance: Different grades determine the gasket’s resistance to temperature, pressure, and chemicals. Selecting the appropriate material grade ensures the gasket performs optimally in its intended application, thereby reducing maintenance costs and downtime. -

Tolerance

– Definition: Tolerance is the permissible limit of variation in a physical dimension of the gasket. It indicates how closely the actual dimensions match the specified dimensions.

– Importance: Accurate tolerances are critical for ensuring a proper fit in assembly and preventing leaks. In industries where precision is paramount, such as aerospace or pharmaceuticals, strict adherence to tolerance specifications can significantly affect product integrity and safety. -

Durometer Hardness

– Definition: This measures the hardness of rubber materials, quantified using a durometer scale (typically Shore A).

– Importance: The hardness of a gasket influences its sealing capability and compression set. Softer materials tend to conform better to surfaces but may wear out faster, while harder materials provide better durability but may not seal as effectively. Understanding durometer ratings helps buyers choose gaskets that meet their specific application requirements. -

Compression Set

– Definition: Compression set is a measure of a material’s ability to return to its original thickness after being compressed over time.

– Importance: A low compression set indicates that a gasket can maintain its sealing properties after prolonged use, which is essential for long-term reliability in applications subjected to varying pressures and temperatures. -

Chemical Resistance

– Definition: This property denotes a gasket’s ability to withstand exposure to various chemicals without degrading or losing functionality.

– Importance: Buyers must assess the chemical exposure in their applications to ensure the selected gasket material won’t deteriorate. Proper chemical resistance can prevent costly failures in sectors like petrochemicals or food processing.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM requirements is vital for buyers looking to source replacement parts that meet original specifications, ensuring compatibility and quality in their equipment. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchases, manage inventory levels, and negotiate better terms with suppliers. It can also impact cash flow, especially for smaller companies. -

RFQ (Request for Quotation)

– Definition: A formal document sent to suppliers requesting pricing and terms for specific products or services.

– Importance: An RFQ is essential for securing competitive pricing and understanding supplier capabilities. It enables buyers to compare offers and make data-driven procurement decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Importance: Familiarity with Incoterms helps buyers navigate international trade logistics, ensuring clarity on cost responsibilities and risk management during shipping processes. -

Lead Time

– Definition: The amount of time that passes from the start of a process until its completion.

– Importance: Understanding lead times is crucial for project planning and inventory management. Buyers must account for lead times in their procurement strategies to avoid delays in production or project execution.

By grasping these essential properties and terminology, B2B buyers can enhance their sourcing strategies and ensure they select the most suitable gasket solutions for their operational needs. This understanding not only aids in reducing costs but also in ensuring compliance with industry standards and regulations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gasket specialties Sector

Market Overview & Key Trends

The gasket specialties sector is currently witnessing significant transformation driven by several global factors. The increasing demand for reliable sealing solutions in energy, automotive, and manufacturing industries is a primary driver, particularly in regions like Africa and South America, where infrastructure projects are expanding. Technological advancements are also reshaping the procurement landscape, with digital tools facilitating more efficient sourcing processes. B2B buyers can leverage platforms that offer real-time data analytics, supplier performance insights, and automated procurement workflows to enhance decision-making.

Emerging trends include a growing preference for advanced materials such as silicone and EPDM due to their superior performance in extreme conditions. This shift is particularly relevant for buyers in the Middle East and Europe, where operational environments often involve high temperatures or exposure to harsh chemicals. Additionally, the market is moving towards customization, with suppliers increasingly offering tailored solutions that meet specific industry needs, enhancing operational efficiency and reliability.

Furthermore, international buyers are focusing on cost-effective sourcing strategies that take into account not only the price but also the total cost of ownership, including maintenance and compliance. Understanding regional market dynamics, such as import tariffs and trade agreements, is crucial for buyers in Europe and Africa to navigate the complexities of global sourcing effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming an integral part of the sourcing strategy in the gasket specialties sector. B2B buyers are increasingly aware of the environmental impact of their procurement choices. The use of eco-friendly materials and sustainable manufacturing processes is gaining traction, driven by both regulatory pressures and consumer demand for greener products. Buyers should prioritize suppliers who adopt sustainable practices, such as waste reduction, energy-efficient production, and the use of recycled materials.

Ethical sourcing is equally vital in establishing a responsible supply chain. Buyers should seek partners that adhere to recognized standards and certifications, such as ISO 14001 for environmental management and certifications for fair labor practices. These measures not only mitigate risks associated with supply chain disruptions but also enhance brand reputation in a market that increasingly values corporate responsibility.

The adoption of ‘green’ certifications for gasket materials, such as those made from bio-based or recycled components, can significantly impact purchasing decisions. For buyers in regions like Europe, where regulatory frameworks are stringent, ensuring compliance with environmental standards is essential to avoid penalties and enhance market competitiveness. By integrating sustainability into procurement practices, companies can drive innovation while contributing to broader environmental goals.

Brief Evolution/History

The gasket specialties sector has evolved significantly over the past century. Initially, gaskets were made from basic materials like cloth and rubber, primarily designed for steam engines and early machinery. As industries grew and technology advanced, the demand for more durable and efficient sealing solutions emerged. This led to the development of synthetic materials such as neoprene and EPDM, which offered superior performance and resilience in diverse environments.

In recent years, the focus has shifted toward innovation and sustainability, with an emphasis on creating products that not only meet performance standards but also minimize environmental impact. This evolution reflects the broader trends within the manufacturing sector, where efficiency, durability, and sustainability are now paramount considerations for B2B buyers globally.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of gasket specialties

-

How can I effectively vet suppliers for gasket specialties?

Vetting suppliers is crucial to ensure reliability and quality. Start by evaluating their industry experience and market reputation. Request references from previous clients, particularly those in your region or industry. Verify their certifications, such as ISO or industry-specific standards. Additionally, assess their production capabilities and whether they have the technology to meet your specific requirements. Conduct on-site visits if feasible, or utilize virtual tours to gain insights into their operations. Engaging third-party inspection services can further assure compliance with quality standards. -

What customization options should I consider when sourcing gaskets?

Customization can significantly enhance the performance of gaskets in your applications. Discuss material specifications, dimensions, and design features with potential suppliers to ensure they can meet your needs. Consider options like thickness, shape (e.g., O-rings, flat gaskets), and the addition of specific chemical or temperature resistance properties. Request samples to test fit and functionality before placing large orders. Ensure that suppliers have the capacity to handle small batch customizations efficiently, particularly if you are working on unique or specialized projects. -

What are typical minimum order quantities (MOQs) and lead times for gasket products?

MOQs can vary widely among suppliers, often depending on the complexity of the gasket and the materials used. For standard products, MOQs might range from 100 to 1,000 units, while custom gaskets may require larger orders due to setup costs. Lead times typically range from 2 to 8 weeks, influenced by the supplier’s production capacity and your order size. Always clarify these details upfront and factor them into your project timelines to avoid disruptions. Building a relationship with suppliers may also lead to more flexible terms. -

What payment terms are common when purchasing gaskets internationally?

Payment terms can significantly impact cash flow. Most suppliers require a deposit (often 30-50%) upfront, with the balance due before shipment or upon delivery. For larger orders or established relationships, negotiate for more favorable terms, such as net 30 or net 60 days. Consider using secure payment methods like letters of credit or escrow services for larger transactions to mitigate risks. Understand the currency exchange implications and any fees associated with international payments to ensure accurate budgeting. -

How can I ensure quality assurance and certifications for gasket products?

Quality assurance is paramount in gasket sourcing. Request documentation of the supplier’s quality management system, including relevant certifications (e.g., ISO 9001). Inquire about their testing procedures for materials and finished products. Suppliers should provide a Certificate of Compliance or Material Safety Data Sheets (MSDS) for the materials used. Consider incorporating quality checks at various stages of production, including pre-shipment inspections, to ensure that the gaskets meet your specifications before they leave the factory.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I keep in mind for gasket shipments?

Logistics play a critical role in international sourcing. Discuss shipping options with your supplier, including air, sea, or land freight, and the associated costs and transit times. Ensure that the supplier can accommodate your preferred method and provide tracking information. Understand customs regulations in your country to avoid delays and additional fees. Work with logistics partners experienced in your region to facilitate smooth transportation and delivery. Factor in lead times for shipping when planning your procurement strategy. -

How should I handle disputes with gasket suppliers?

Disputes can arise over quality, delivery, or contractual terms. To mitigate potential issues, establish clear contracts outlining specifications, timelines, and penalties for non-compliance. In case of a dispute, maintain open communication with the supplier to resolve issues amicably. If necessary, refer to the contract for dispute resolution clauses, which may include arbitration or mediation. Document all communications and agreements to support your position. Building a strong relationship with suppliers can often help prevent disputes from escalating. -

What role does sustainability play in sourcing gasket products?

Sustainability is increasingly important in B2B sourcing. Inquire about suppliers’ environmental practices, including material sourcing, waste management, and energy usage. Look for certifications like ISO 14001 that demonstrate a commitment to environmental management. Consider suppliers who use eco-friendly materials or processes, as this can enhance your corporate responsibility profile. Being proactive about sustainability can also open opportunities for partnerships with clients who prioritize environmentally conscious practices in their supply chains.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gasket specialties

As we conclude this comprehensive guide on gasket specialties, it is essential to underscore the critical role of strategic sourcing in the procurement process. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must recognize that the choice of materials—be it natural rubber, EPDM, neoprene, or silicone—can significantly impact operational efficiency, cost control, and regulatory compliance.

Key takeaways include the importance of understanding regional market dynamics, the performance characteristics of various gasket materials, and the necessity of rigorous supplier evaluation. By leveraging these insights, procurement professionals can build resilient supply chains that not only meet immediate operational needs but also support long-term sustainability goals.

Looking ahead, the gasket industry is poised for growth, driven by increasing demands for energy efficiency and environmental compliance. Buyers are encouraged to stay informed about evolving material innovations and market trends. Act now by engaging with reputable suppliers, exploring diverse sourcing options, and investing in quality gasket solutions that align with your strategic objectives. The future of your operations depends on the decisions you make today in the gasket procurement landscape.