Master Global Material Technologies: Your Essential B2B

Introduction: Navigating the Global Market for global material technologies

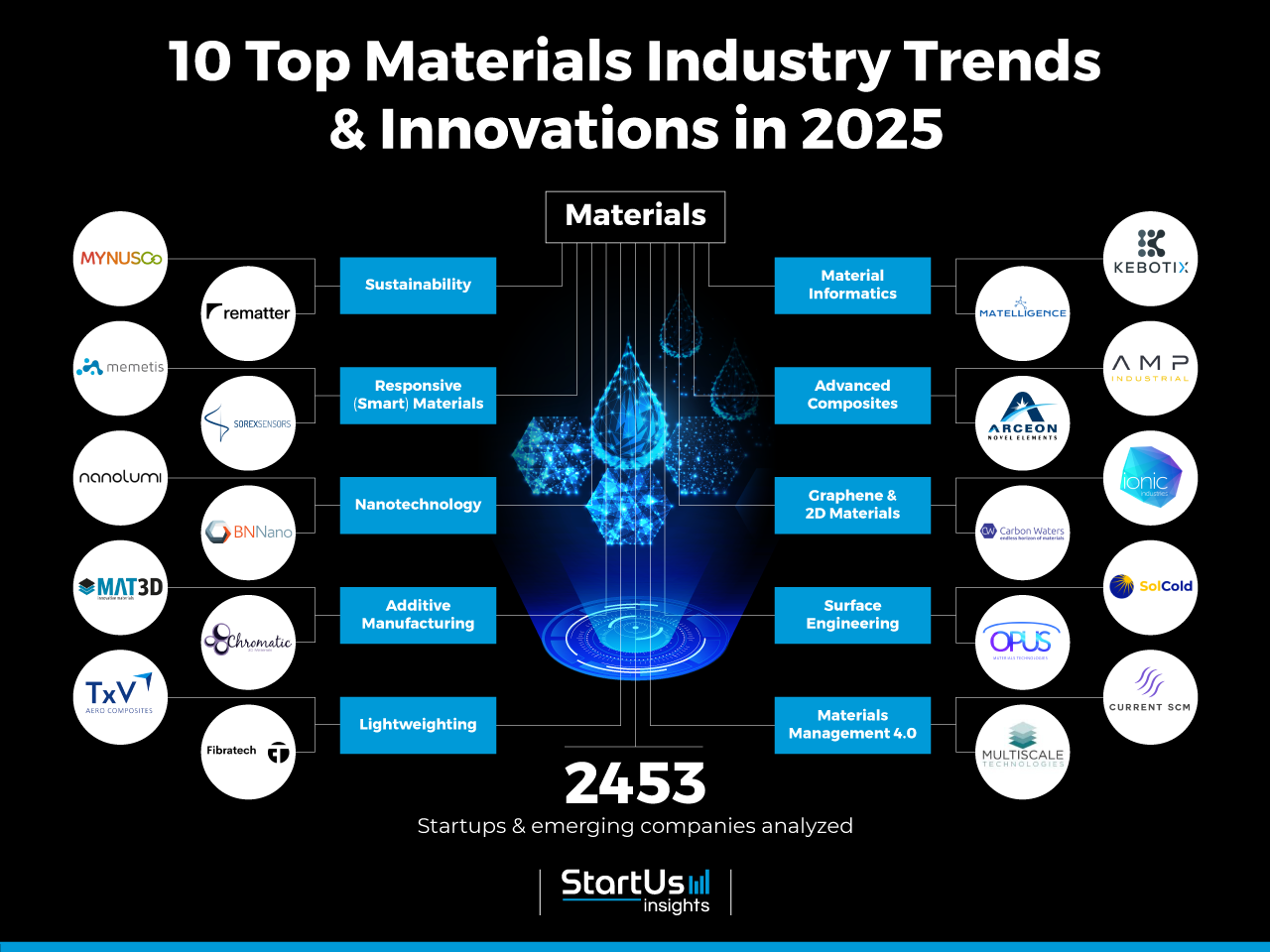

In today’s interconnected world, the significance of global material technologies cannot be overstated. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the dynamics of sourcing materials from diverse global markets is crucial for maintaining a competitive edge. Global material technologies encompass a range of innovative materials and manufacturing processes that enhance product quality, sustainability, and cost-effectiveness.

This guide aims to empower decision-makers by providing a comprehensive overview of the global material technologies landscape. It will cover various types of materials, including advanced composites, metals, and sustainable alternatives; manufacturing and quality control practices that ensure reliability; and strategies for identifying and engaging with suppliers across different regions. Additionally, the guide will delve into cost considerations, market trends, and frequently asked questions that arise in the sourcing process.

By leveraging the insights offered in this guide, B2B buyers can make informed sourcing decisions that not only optimize their supply chains but also mitigate risks associated with global sourcing. The diverse perspectives and actionable strategies presented here will equip businesses to navigate the complexities of the international market, ultimately driving innovation and growth in their respective industries.

Understanding global material technologies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Advanced Composite Materials | Lightweight, high strength-to-weight ratio | Aerospace, automotive, construction | Pros: Excellent performance; Cons: Higher costs, complex manufacturing processes. |

| Nanomaterials | Engineered at the nanoscale, unique properties | Electronics, healthcare, energy | Pros: Enhanced functionality; Cons: Regulatory challenges, potential toxicity. |

| Biodegradable Plastics | Made from renewable resources, environmentally friendly | Packaging, consumer goods | Pros: Sustainable; Cons: May lack durability compared to traditional plastics. |

| Smart Materials | Responsive to environmental changes (e.g., temperature) | Construction, electronics, textiles | Pros: Innovative applications; Cons: Higher initial costs, limited availability. |

| Metal Alloys | Mixtures of metals designed for specific properties | Manufacturing, construction, automotive | Pros: Improved strength and corrosion resistance; Cons: Potentially complex sourcing and standards. |

Advanced Composite Materials

Advanced composite materials, such as carbon fiber and fiberglass, are characterized by their high strength-to-weight ratios and durability. These materials are primarily used in industries where weight reduction is critical, such as aerospace and automotive. B2B buyers should consider their applications in high-performance products, understanding that while they offer superior performance, the costs may be higher due to complex manufacturing processes.

Nanomaterials

Nanomaterials, which exhibit unique physical and chemical properties due to their nanoscale dimensions, find applications across various sectors, including electronics, healthcare, and energy. Their ability to enhance product functionality—such as increased strength, lighter weight, and improved conductivity—makes them appealing for innovative applications. However, buyers must navigate regulatory challenges and potential safety concerns related to nanomaterials, making thorough supplier vetting essential.

Biodegradable Plastics

Biodegradable plastics are derived from renewable resources and are designed to break down more quickly than traditional plastics. They are increasingly used in packaging and consumer goods, appealing to environmentally conscious businesses. While they offer sustainability benefits, buyers should evaluate their performance characteristics, as they may not be as durable as conventional plastics, potentially affecting product lifespan.

Smart Materials

Smart materials are engineered to respond dynamically to external stimuli such as temperature, pressure, or light. Their applications span construction, electronics, and textiles, providing innovative solutions for responsive environments. B2B buyers should consider the potential for enhanced functionality and market differentiation; however, they may face challenges related to initial costs and sourcing, as these materials are not yet widely available.

Metal Alloys

Metal alloys are combinations of two or more metals designed to enhance specific properties like strength, corrosion resistance, and ductility. They are widely used in manufacturing, construction, and automotive applications. Buyers must consider the specific requirements of their projects, as sourcing can be complex due to varying standards and specifications. While metal alloys can provide significant performance advantages, they may also involve higher procurement costs and longer lead times.

Related Video: SE 12 : All SDLC Models Revision | Software Engineering Full Course

Key Industrial Applications of global material technologies

| Industry/Sector | Specific Application of global material technologies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Lightweight composite materials for vehicle design | Improved fuel efficiency and performance | Availability of advanced materials and local regulations |

| Construction | High-performance concrete and prefabricated elements | Enhanced durability and reduced construction time | Local sourcing options and compliance with safety standards |

| Electronics | Advanced semiconductor materials | Increased device performance and miniaturization | Supplier reliability and technology compatibility |

| Aerospace | Carbon fiber components for aircraft manufacturing | Weight reduction and fuel savings | Quality certifications and international shipping logistics |

| Renewable Energy | Advanced photovoltaic materials | Higher energy conversion efficiency | Material sourcing sustainability and regional regulations |

Automotive

In the automotive industry, lightweight composite materials are increasingly utilized to enhance vehicle design. These materials contribute to improved fuel efficiency and overall performance by reducing the vehicle’s weight. For international B2B buyers, sourcing these advanced composites involves ensuring compliance with local regulations and availability of materials. It’s crucial to consider suppliers that not only provide cost-effective solutions but also adhere to strict quality standards to ensure safety and performance.

Construction

The construction sector benefits significantly from high-performance concrete and prefabricated elements that leverage global material technologies. These innovations enhance durability and drastically reduce construction time, making projects more efficient and cost-effective. Buyers must focus on local sourcing options to mitigate logistics costs and ensure compliance with regional safety standards. Additionally, understanding the supply chain dynamics in different regions can help in selecting reliable suppliers that meet project timelines.

Electronics

In electronics, the use of advanced semiconductor materials is pivotal for enhancing device performance and enabling miniaturization. These materials are essential for the production of high-speed and energy-efficient devices. For B2B buyers, sourcing these materials requires a deep understanding of supplier reliability and technology compatibility. Buyers should prioritize suppliers who can demonstrate proven track records in quality and innovation, as well as those who can navigate the complexities of international trade.

Aerospace

The aerospace industry is leveraging carbon fiber components to achieve significant weight reductions in aircraft manufacturing. This not only leads to fuel savings but also enhances overall flight performance. For international buyers, key considerations include ensuring quality certifications from suppliers and navigating the intricacies of international shipping logistics. The aerospace sector demands high precision and reliability, making it essential for buyers to engage with reputable suppliers who can meet stringent industry standards.

Renewable Energy

In the renewable energy sector, advanced photovoltaic materials are critical for improving energy conversion efficiency in solar panels. This technology allows for more effective harnessing of solar energy, which is vital for sustainable energy solutions. Buyers must consider the sustainability of material sourcing and be aware of regional regulations that may affect procurement. Establishing partnerships with suppliers who prioritize innovation and environmental responsibility can significantly enhance the competitiveness of renewable energy projects.

Related Video: Types Of Flowmeters And Their Industrial Applications.

Strategic Material Selection Guide for global material technologies

When selecting materials for global material technologies, international B2B buyers must consider various factors, including the properties, advantages, disadvantages, and specific application impacts of each material. Below is an analysis of four common materials used in global material technologies, focusing on their relevance to B2B buyers from Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and durability. It typically performs well under a wide range of temperatures and pressures, making it suitable for various applications, including food processing and chemical manufacturing.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which extends the lifespan of products. However, it can be more expensive than other metals, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application:

Stainless steel is compatible with a variety of media, including water, steam, and many chemicals. Its non-reactive nature makes it ideal for industries that require stringent hygiene standards.

Considerations for International Buyers:

Buyers must ensure compliance with international standards such as ASTM and DIN, particularly for applications in food and pharmaceuticals. Additionally, understanding the local availability of stainless steel grades can impact procurement strategies.

2. Polypropylene (PP)

Key Properties:

Polypropylene is a thermoplastic polymer known for its chemical resistance, lightweight nature, and flexibility. It can withstand temperatures up to 100°C and is resistant to many acids and bases.

Pros & Cons:

The key advantage of polypropylene is its low cost and ease of manufacturing, which allows for quick production and customization. However, it has lower temperature resistance compared to metals and may not be suitable for high-stress applications.

Impact on Application:

Polypropylene is widely used in packaging, automotive parts, and consumer goods. Its chemical resistance makes it suitable for applications involving corrosive substances.

Considerations for International Buyers:

Buyers should be aware of the varying quality standards for polypropylene across regions. Compliance with local regulations regarding plastic materials is crucial, especially in markets with strict environmental laws.

3. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. Its strength-to-weight ratio makes it a preferred choice in aerospace and automotive applications.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which can significantly reduce transportation costs. However, it can be more expensive than some other materials, and its lower strength compared to steel may limit its use in certain applications.

Impact on Application:

Aluminum is ideal for applications requiring weight savings, such as in aircraft and automotive components. Its corrosion resistance makes it suitable for outdoor applications.

Considerations for International Buyers:

Buyers must consider the availability of specific aluminum alloys and their compliance with international standards. Understanding the local market dynamics regarding aluminum pricing can also influence procurement decisions.

4. Carbon Fiber Reinforced Polymer (CFRP)

Key Properties:

CFRP is known for its high strength-to-weight ratio and excellent fatigue resistance. It can withstand high temperatures and is often used in high-performance applications.

Pros & Cons:

The key advantage of CFRP is its lightweight and high tensile strength, making it ideal for applications in aerospace and sports equipment. However, it is relatively expensive and can be challenging to manufacture and repair.

Impact on Application:

CFRP is particularly suitable for applications requiring high performance and durability, such as in aerospace components and high-end automotive parts.

Considerations for International Buyers:

Buyers should be aware of the specific manufacturing processes and standards for CFRP, as these can vary significantly by region. Ensuring compliance with international certifications is essential for maintaining product integrity.

| Material | Typical Use Case for global material technologies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical manufacturing | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Polypropylene (PP) | Packaging, automotive parts | Low cost and easy to manufacture | Lower temperature resistance | Low |

| Aluminum | Aerospace, automotive components | Lightweight and corrosion-resistant | Higher cost compared to some metals | Med |

| Carbon Fiber Reinforced Polymer | Aerospace components, high-end automotive parts | High strength-to-weight ratio | Expensive and challenging to repair | High |

In-depth Look: Manufacturing Processes and Quality Assurance for global material technologies

Manufacturing Processes for Global Material Technologies

In the realm of global material technologies, understanding the manufacturing processes is crucial for international B2B buyers. The typical stages in the manufacturing process include material preparation, forming, assembly, and finishing. Each of these stages employs specific techniques and practices that impact the final product’s quality and compliance with international standards.

1. Material Preparation

The first stage of manufacturing involves the preparation of raw materials. This can include:

- Material Selection: Choosing the right materials based on properties such as strength, weight, and durability. Buyers must consider the specific requirements of their applications, including environmental and regulatory factors.

- Material Treatment: Processes such as annealing, hardening, or surface treatment are often employed to enhance material properties. Understanding the treatment processes used by suppliers can help buyers assess the suitability of materials for their products.

2. Forming

Forming is where the raw materials are shaped into the desired form. Key techniques include:

- Casting: Pouring liquid material into molds. This is common for metals and plastics and can produce complex shapes.

- Molding: Similar to casting but often used for thermoplastics and composites.

- Machining: Involves removing material to achieve desired dimensions and surface finishes. Techniques include turning, milling, and grinding.

- Additive Manufacturing: Also known as 3D printing, this technique is gaining traction for producing intricate designs with less waste.

Understanding these techniques is essential for buyers, as they can influence material properties and production lead times.

3. Assembly

The assembly stage involves putting together the various components that make up the final product. This can include:

- Manual Assembly: Skilled labor is often required for intricate assemblies, particularly in industries like aerospace and electronics.

- Automated Assembly: Utilizing robotics and automated systems to enhance efficiency and precision. Buyers should consider the level of automation as it can significantly impact production speed and consistency.

4. Finishing

Finishing processes enhance the product’s appearance and performance. Common techniques include:

- Coating: Applying a layer of material for protection or aesthetics, such as painting, plating, or anodizing.

- Polishing: Improving surface smoothness, which can be critical for optical or mechanical components.

- Quality Control Checks: Ensuring the final product meets specifications before shipping.

Buyers should inquire about the finishing processes used by suppliers to ensure product quality and compliance with industry standards.

Quality Assurance in Global Manufacturing

Quality assurance (QA) is vital for ensuring that products meet the required specifications and standards. For international B2B buyers, understanding QA processes and standards is essential in mitigating risks associated with global sourcing.

Illustrative Image (Source: Google Search)

Relevant International Standards

Several international quality standards are relevant to global material technologies, including:

- ISO 9001: This standard specifies requirements for a quality management system (QMS) and is essential for ensuring consistent quality.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Particularly relevant for oil and gas industries, these standards ensure quality in the production of equipment and materials.

By choosing suppliers that adhere to these standards, buyers can significantly reduce risks related to product quality.

Quality Control Checkpoints

Implementing a structured quality control system is critical. Key checkpoints include:

- Incoming Quality Control (IQC): Verifying the quality of raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process at various stages to detect defects early.

- Final Quality Control (FQC): Conducting comprehensive tests on the finished product to ensure it meets all specifications before shipment.

These checkpoints help maintain quality throughout the manufacturing process.

Common Testing Methods

To ensure product quality, various testing methods can be employed, including:

- Mechanical Testing: Assessing properties such as tensile strength, hardness, and fatigue resistance.

- Chemical Testing: Verifying material composition and resistance to corrosion or degradation.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, X-ray inspection, and magnetic particle testing are used to detect internal flaws without damaging the product.

B2B buyers should inquire about the specific testing methods used by suppliers to ensure they meet industry standards.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are some effective strategies:

- Conduct Audits: Regularly auditing suppliers can provide insights into their quality management systems and adherence to standards.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including results from testing and inspections.

- Utilize Third-Party Inspections: Engaging third-party inspection agencies can offer unbiased assessments of supplier quality and compliance with standards.

Quality Control Nuances for International Buyers

International buyers, particularly from Africa, South America, the Middle East, and Europe, face unique challenges when it comes to quality control:

- Cultural Differences: Different regions may have varying standards and practices. Understanding these cultural nuances is vital in establishing effective communication and collaboration.

- Regulatory Compliance: Buyers must be aware of the specific regulations in their home markets, as these can differ significantly from those in the supplier’s country.

- Logistical Considerations: The complexities of international shipping can impact product quality. Buyers should consider the entire supply chain, including transportation and storage conditions.

By addressing these factors, B2B buyers can navigate the complexities of international sourcing and ensure they partner with suppliers committed to quality and excellence.

Related Video: BMW Car Factory – ROBOTS Fast PRODUCTION Manufacturing

Comprehensive Cost and Pricing Analysis for global material technologies Sourcing

Understanding the cost structure and pricing dynamics in global material technologies sourcing is essential for international B2B buyers. This knowledge helps in making informed procurement decisions and optimizing supply chain efficiency. Below is a comprehensive analysis of cost components, price influencers, and actionable tips for buyers.

Cost Components

-

Materials: The cost of raw materials significantly affects the overall pricing. Variations in material availability and pricing in different regions can lead to substantial cost differences. Buyers should consider sourcing from regions where raw materials are abundant and cost-effective.

-

Labor: Labor costs vary by region, influenced by local wage rates, skill levels, and productivity. Countries in Africa and South America may offer lower labor costs compared to Europe, but it is crucial to assess the skill levels to ensure quality production.

-

Manufacturing Overhead: This includes expenses associated with the operation of manufacturing facilities, such as utilities, rent, and equipment depreciation. Understanding the overhead structure of potential suppliers can provide insights into their pricing strategies.

-

Tooling: Initial tooling costs can be significant, especially for customized products. Buyers should negotiate tooling costs upfront and consider sharing these costs with suppliers if ordering large volumes.

-

Quality Control (QC): Implementing quality control measures is essential to maintain product standards. The cost of QC can vary based on the supplier’s processes and certifications. Buyers should prioritize suppliers with robust QC systems to minimize defects and returns.

-

Logistics: Shipping costs, including freight, insurance, and tariffs, can significantly impact total costs. Understanding the logistics landscape, including Incoterms, is vital for accurate cost estimation.

-

Margin: Supplier margins can vary widely based on their operational efficiencies and market positioning. Buyers should evaluate supplier margins to ensure they are competitive without compromising quality.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQ) can affect pricing. Higher volumes typically lead to lower per-unit costs. Buyers should assess their purchasing power and negotiate better rates with suppliers based on anticipated order volumes.

-

Specifications/Customization: Custom products often come at a premium. Clearly defining specifications and exploring standard alternatives can help manage costs.

-

Materials: The choice of materials directly impacts price. Buyers should explore alternative materials that meet their quality standards but are more cost-effective.

-

Quality/Certifications: Suppliers with internationally recognized certifications may charge higher prices. However, these certifications often guarantee quality and reliability, which can reduce long-term costs associated with defects.

-

Supplier Factors: Supplier reputation, location, and relationship history can influence pricing. Building strong relationships can lead to better pricing and service.

-

Incoterms: Understanding Incoterms is crucial for accurately calculating total costs. Different Incoterms can shift responsibilities and costs between buyers and suppliers, affecting overall pricing.

Buyer Tips

-

Negotiation: Engage in open negotiations with suppliers. Leverage your purchasing power and consider long-term partnerships to secure better pricing.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes all costs associated with acquiring, using, and disposing of a product. This holistic approach can reveal hidden costs and help in making more informed decisions.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, geopolitical factors, and trade regulations that may affect pricing and supply chain stability.

-

Disclaimer for Indicative Prices: Pricing in global sourcing can fluctuate due to various factors, including market demand, geopolitical tensions, and economic changes. Always seek updated quotes and be prepared for potential changes in costs.

By understanding these components and dynamics, international B2B buyers can navigate the complexities of global material technologies sourcing more effectively, leading to enhanced procurement strategies and improved supply chain resilience.

Spotlight on Potential global material technologies Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘global material technologies’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for global material technologies

Key Technical Properties in Global Material Technologies

In the realm of global material technologies, understanding specific technical properties is crucial for making informed procurement decisions. Here are some critical specifications that B2B buyers should consider:

-

Material Grade

– Definition: Material grade refers to the classification of materials based on their chemical composition and mechanical properties.

– Importance: Selecting the appropriate material grade ensures that the products meet performance standards and regulatory requirements. This is particularly vital for industries such as aerospace and automotive, where safety and durability are paramount. -

Tolerance

– Definition: Tolerance is the permissible limit of variation in a physical dimension or measured value.

– Importance: Tighter tolerances can lead to higher production costs but are necessary for precision-engineered components. Understanding tolerance helps buyers assess the manufacturability of a product and its compatibility with existing systems. -

Yield Strength

– Definition: Yield strength is the stress at which a material begins to deform plastically. Beyond this point, the material will not return to its original shape.

– Importance: This property is critical for applications that involve heavy loads or stress, as it determines the material’s ability to withstand operational conditions without failure. -

Corrosion Resistance

– Definition: Corrosion resistance indicates a material’s ability to withstand deterioration due to chemical exposure or environmental conditions.

– Importance: For buyers operating in harsh environments, selecting materials with high corrosion resistance can extend product life and reduce maintenance costs. -

Thermal Conductivity

– Definition: Thermal conductivity measures a material’s ability to conduct heat.

– Importance: This property is essential for industries that require temperature control, such as electronics and HVAC systems. Understanding thermal conductivity helps buyers select materials that optimize energy efficiency.

Illustrative Image (Source: Google Search)

Common Trade Terms in Global Material Technologies

Familiarity with industry jargon is vital for effective communication in B2B transactions. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding the role of OEMs can help buyers identify reliable suppliers and assess product quality, particularly when sourcing components for assembly. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers evaluate whether they can meet purchasing requirements while managing inventory costs effectively. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Importance: Issuing an RFQ is a critical step in the procurement process, enabling buyers to compare pricing, terms, and conditions from multiple suppliers. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of predefined commercial terms that outline the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is essential for understanding shipping responsibilities, risk allocation, and cost management in global sourcing agreements. -

Lead Time

– Definition: Lead time is the amount of time that passes from the initiation of a process until its completion.

– Importance: Knowing lead times is crucial for supply chain management and inventory planning. It helps buyers anticipate product availability and manage production schedules effectively. -

Certification

– Definition: Certification refers to the verification process that a product meets specific standards set by regulatory bodies or industry organizations.

– Importance: Certifications can enhance product credibility and compliance, making it easier for buyers to trust suppliers and ensure that materials meet necessary quality and safety standards.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of global material technologies more effectively, leading to smarter sourcing decisions and enhanced supply chain resilience.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the global material technologies Sector

Market Overview & Key Trends

The global material technologies sector is undergoing significant transformation, driven by several key factors that international B2B buyers must navigate. Digitalization is at the forefront, with advancements in automation and data analytics enabling businesses to enhance their supply chain efficiency. Technologies such as AI and machine learning are being integrated to predict market trends, optimize inventory management, and improve supplier selection processes. Sourcing trends are also shifting towards greater diversification. Buyers are increasingly looking beyond traditional supply markets—such as China and Vietnam—to mitigate risks associated with geopolitical tensions and supply disruptions. This diversification enables companies to establish a more robust supply chain and adapt swiftly to changing market conditions.

Emerging sustainability demands are reshaping procurement practices. Buyers from regions like Africa, South America, and the Middle East are now prioritizing suppliers who adhere to sustainable practices, as consumers increasingly favor environmentally responsible products. Additionally, the push for circular economy initiatives is prompting businesses to seek out materials that can be reused or recycled, thereby reducing waste and enhancing resource efficiency. Regulatory frameworks across Europe and other regions are also evolving, with stricter compliance requirements for sustainable sourcing practices, influencing how companies approach their procurement strategies.

For B2B buyers, understanding these dynamics is crucial. Leveraging technology to gain insights into global sourcing options while aligning with sustainability goals can provide a competitive edge. Companies must remain agile, adapting their sourcing strategies to incorporate emerging technologies and sustainability initiatives effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a peripheral concern; it is central to the procurement strategies of international B2B buyers. The environmental impact of sourcing decisions is under scrutiny, with a growing emphasis on minimizing carbon footprints and reducing resource depletion. Buyers are increasingly required to evaluate the sustainability credentials of their suppliers, focusing on factors such as energy consumption, waste management, and the carbon emissions associated with production processes.

Ethical supply chains are gaining traction, as stakeholders demand transparency and accountability from businesses. This involves ensuring that suppliers adhere to fair labor practices and do not contribute to environmental degradation. Buyers should seek suppliers with recognized green certifications, such as ISO 14001 or certifications for sustainable materials, which can validate their commitment to environmental stewardship. Utilizing materials that are certified as sustainable not only enhances a company’s brand reputation but also meets the growing consumer demand for eco-friendly products.

Investing in sustainable sourcing practices can lead to significant long-term benefits, including enhanced customer loyalty, improved operational efficiencies, and compliance with increasingly stringent regulations. By prioritizing sustainability, B2B buyers can create a competitive advantage while contributing to a more sustainable future.

Brief Evolution/History

The evolution of global material technologies has been marked by a shift from cost-driven sourcing strategies to more strategic, value-based approaches. Initially, companies focused primarily on reducing costs through outsourcing to regions with cheaper labor. However, as global markets matured, the emphasis shifted towards quality, innovation, and risk management.

The rise of technology in procurement has further transformed the landscape. Enhanced data analytics and digital platforms now allow businesses to make more informed sourcing decisions, improving efficiency and responsiveness. As sustainability considerations have come to the forefront, the historical focus on cost reduction has evolved into a holistic approach that balances financial objectives with ethical and environmental responsibilities. This evolution reflects the changing dynamics of global trade and the increasing importance of responsible sourcing in building resilient supply chains.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of global material technologies

-

How should I vet international suppliers for material technologies?

When vetting suppliers, start by assessing their reputation and reliability through online reviews and industry references. Request documentation such as business licenses, ISO certifications, and quality assurance processes. Conduct site visits if feasible, or utilize third-party inspection services to verify operational capabilities. Additionally, consider their financial stability and past performance with similar clients. Establish communication protocols to gauge their responsiveness and willingness to collaborate, which can indicate their commitment to customer service. -

Can I customize materials sourced from global suppliers?

Yes, many global suppliers offer customization options for materials. Before initiating a partnership, clearly communicate your specific requirements, such as dimensions, material properties, and delivery timelines. Collaborate closely during the design phase to ensure that the supplier can meet your standards. Be aware that customization may affect lead times and minimum order quantities (MOQs), so it’s essential to discuss these factors upfront to align expectations and avoid delays. -

What are the typical minimum order quantities (MOQs) and lead times for international material sourcing?

MOQs and lead times can vary significantly by supplier and product type. Generally, international suppliers may have higher MOQs due to production costs and logistical considerations. Lead times can range from a few weeks to several months, depending on the complexity of the order and the supplier’s location. It’s crucial to negotiate these terms early in the relationship and consider factors like shipping time, customs clearance, and potential delays in your overall project timeline. -

What quality assurance certifications should I look for in suppliers?

Key certifications to look for include ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific industry-related standards such as ASTM or SAE. These certifications indicate a commitment to maintaining high-quality products and processes. Additionally, inquire about the supplier’s internal quality control measures and testing protocols. A reliable supplier should provide transparency regarding their QA processes and be willing to share test results and certifications upon request. -

How can I manage logistics effectively when sourcing materials internationally?

Effective logistics management begins with selecting a supplier with robust shipping capabilities and clear communication about shipping methods. Utilize freight forwarders to navigate customs and transportation logistics. Implement a tracking system to monitor shipments and anticipate potential delays. It’s also wise to establish contingency plans for disruptions, such as alternative suppliers or expedited shipping options, to maintain your supply chain’s resilience and minimize downtime. -

What should I do if a dispute arises with an international supplier?

In the event of a dispute, first attempt to resolve the issue amicably through direct communication with the supplier. Document all communications and agreements to provide a clear record of the situation. If direct negotiation fails, refer to the terms outlined in your contract, particularly concerning dispute resolution mechanisms. Consider mediation or arbitration as alternatives to litigation, as these methods can be less costly and time-consuming. Always consult legal counsel experienced in international trade law before proceeding with formal actions. -

How do payment terms typically work in international transactions?

Payment terms can vary based on the supplier’s policies and your negotiation. Common methods include letters of credit, advance payments, or payment upon delivery. It’s advisable to use secure payment methods that provide protection, such as escrow services or trade finance solutions. Ensure that all payment terms are clearly defined in the contract, including currency, payment milestones, and any penalties for late payments. This clarity helps mitigate risks and fosters trust between both parties. -

What are the risks associated with sourcing materials globally, and how can I mitigate them?

Risks include supply chain disruptions due to geopolitical tensions, natural disasters, and fluctuating costs. To mitigate these risks, diversify your supplier base across different regions to reduce dependence on a single source. Establish strong relationships with multiple suppliers, and continuously monitor global market trends and conditions. Implement robust contract terms that include force majeure clauses and insurance options to protect against unforeseen circumstances. Regularly review and update your risk management strategies to adapt to changing conditions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for global material technologies

In today’s interconnected marketplace, strategic sourcing has become a fundamental approach for international B2B buyers seeking to optimize their supply chains. By leveraging global sourcing strategies, businesses can achieve significant cost savings, enhance product quality, and build resilience against supply chain disruptions. The ability to access diverse suppliers across different geographical regions not only mitigates risks associated with geopolitical tensions but also fosters innovation through collaboration with specialized providers.

As we look to the future, it is imperative for buyers in Africa, South America, the Middle East, and Europe to remain agile and informed. Embracing technology-driven solutions can streamline procurement processes and enhance data management, enabling quicker decision-making in response to market fluctuations.

Call to Action: Engage actively with global suppliers and invest in tools that facilitate seamless communication and data exchange. By doing so, you can position your business to thrive in an ever-evolving landscape of global material technologies. The time to embrace strategic sourcing is now—unlock the potential of your supply chain and drive your business towards a sustainable and prosperous future.