Master Helix Gear Sourcing: Strategies for Optimal Quality

Introduction: Navigating the Global Market for helix gear

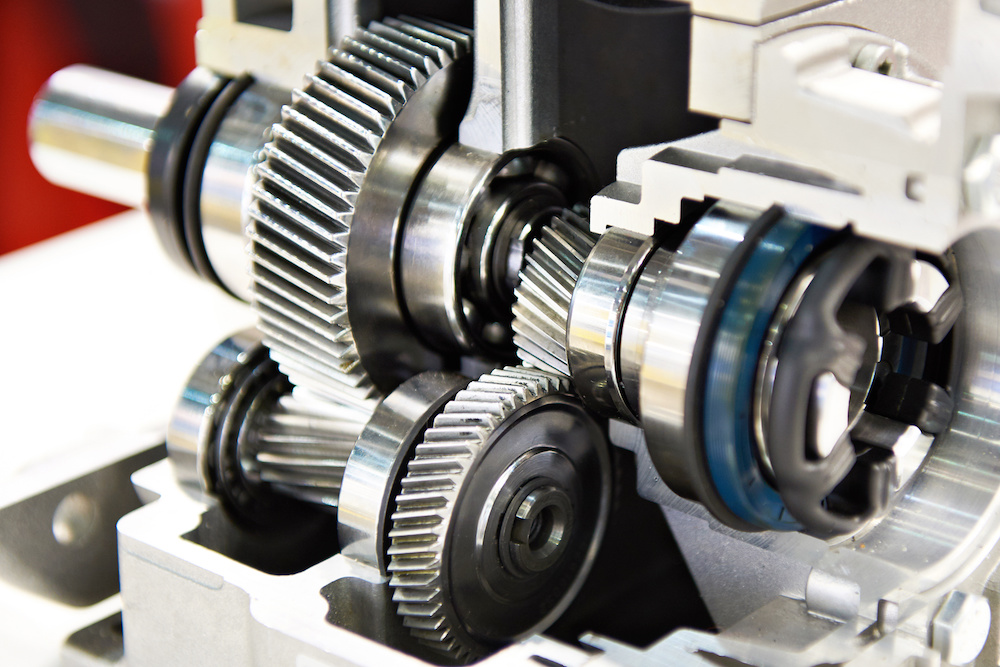

The global market for helix gear has become increasingly significant in various industries, including automotive, aerospace, and manufacturing, due to its critical role in enhancing efficiency and performance. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, seek to optimize their supply chains, understanding the nuances of helix gear sourcing is paramount. This guide provides a comprehensive exploration of this specialized product category, equipping buyers with the insights necessary to make informed decisions.

Key areas of focus include the diverse types of helix gear available, highlighting their specific applications and benefits. Buyers will gain a solid understanding of material specifications and quality control benchmarks, ensuring that they can distinguish between premium products and subpar alternatives. Additionally, the guide delves into manufacturing processes and supplier evaluation, offering strategies to identify reliable partners in the global supply chain.

Furthermore, an analysis of cost structures and market pricing will empower buyers to develop competitive procurement strategies. Understanding regional market trends will also facilitate better alignment with local demands and preferences. To round out this valuable resource, practical FAQs will address common concerns regarding logistics, compliance, and after-sales support.

By leveraging this guide, B2B buyers can navigate the complexities of the helix gear market with confidence, ensuring they secure the best products for their needs while minimizing risks in their sourcing strategies.

Understanding helix gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Helix Gear | Traditional design with a uniform helix angle; suitable for general applications | Manufacturing, automotive, and general machinery | Reliable performance; widely available but may lack advanced features |

| Double Helix Gear | Features two intertwined helix profiles for smoother operation | High-precision machinery, aerospace | Reduces noise and vibration; higher cost and complexity |

| Left-Hand Helix Gear | Designed with a left-hand twist; specialized for specific applications | Conveyor systems, specialized machinery | Unique application benefits; limited availability and higher sourcing challenges |

| Right-Hand Helix Gear | Standard right-hand twist; most common variant | General industrial applications | Versatile and easy to source; may not suit niche applications |

| Modified Helix Gear | Custom-designed profiles to enhance performance characteristics | Custom machinery, robotics | Tailored for specific needs; potentially higher costs and longer lead times |

Standard Helix Gear

Standard helix gears are characterized by their uniform helix angle, making them suitable for a wide range of applications in manufacturing and automotive industries. Their simplicity and reliability make them a go-to choice for many B2B buyers. When sourcing these gears, it’s crucial to consider their compatibility with existing machinery and ensure they meet industry standards to avoid operational disruptions.

Double Helix Gear

Double helix gears feature two intertwined helix profiles, which significantly enhance their operational smoothness and reduce noise and vibration. This design is particularly beneficial in high-precision machinery and aerospace applications where performance is paramount. Buyers should evaluate the cost-benefit ratio, as these gears tend to be more expensive, but the investment may lead to longer-lasting equipment and improved efficiency.

Left-Hand Helix Gear

Left-hand helix gears are specifically designed with a left-hand twist, making them ideal for applications such as conveyor systems and specialized machinery. Their unique design can provide specific operational advantages, but they may be less commonly stocked by suppliers. B2B buyers should be prepared for potential sourcing challenges and ensure that their suppliers can meet the required specifications.

Right-Hand Helix Gear

Right-hand helix gears are the most common type, widely used in general industrial applications. Their versatility and ease of sourcing make them an attractive option for many businesses. Buyers should focus on quality and material specifications to ensure they meet performance expectations, especially in demanding environments where gear failure could lead to significant operational downtime.

Modified Helix Gear

Modified helix gears are custom-designed to enhance specific performance characteristics, making them suitable for applications in custom machinery and robotics. While these gears offer tailored solutions, they often come with higher costs and longer lead times. B2B buyers should weigh the benefits of customization against the potential delays and additional expenses, ensuring that the modifications align with their operational needs.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of helix gear

| Industry/Sector | Specific Application of helix gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Transmission systems | Improved efficiency and performance of vehicles | Ensure compatibility with existing systems and regulations |

| Industrial Machinery | Power transmission in manufacturing equipment | Enhanced durability and reliability under heavy loads | Focus on material quality and precision manufacturing |

| Renewable Energy | Gearboxes in wind turbines | Optimized energy conversion and reduced operational costs | Assess supplier’s experience in renewable sectors |

| Robotics | Drive mechanisms in automated systems | Increased precision and reduced wear in operations | Evaluate customization options for specific robotic applications |

| Aerospace | Gear systems in aircraft engines | Critical for safety and performance in flight | Compliance with stringent aerospace standards and certifications |

Automotive

In the automotive sector, helix gears are integral to transmission systems, enabling smooth gear shifting and enhancing vehicle performance. They help in efficiently transferring power from the engine to the wheels, ultimately improving fuel efficiency. For international B2B buyers, especially in regions like Africa and South America, sourcing gears that meet local automotive standards and regulations is crucial. Buyers should also prioritize suppliers with a track record in producing gears that withstand diverse environmental conditions.

Industrial Machinery

Helix gears are widely used in industrial machinery for power transmission, particularly in equipment subjected to heavy loads. Their design allows for smooth operation, reducing wear and tear, which is essential for maintaining productivity in manufacturing environments. Buyers from the Middle East and Europe should consider sourcing gears that are manufactured from high-quality materials to ensure longevity and reliability. Additionally, understanding local industry standards and certifications will facilitate successful procurement.

Renewable Energy

In the renewable energy sector, particularly within wind turbines, helix gears are vital for gearbox systems that convert rotational energy into electrical energy. Their precision and durability contribute to optimizing energy conversion and minimizing operational costs. For B2B buyers in Africa and South America, it is essential to partner with suppliers experienced in renewable technologies, as they will provide products that align with sustainability goals and local regulatory requirements.

Robotics

Helix gears play a critical role in the drive mechanisms of automated systems and robotics, where precision and reliability are paramount. These gears ensure smooth motion and reduce wear, which is essential for the longevity of robotic applications. International buyers, particularly in Europe, should seek suppliers that offer customization options to meet specific operational needs, as well as those who adhere to rigorous quality control processes to ensure performance under varying conditions.

Aerospace

In the aerospace industry, helix gears are used in various gear systems within aircraft engines. Their reliability and performance are critical for safety during flight operations. Buyers from regions like Europe and the Middle East need to ensure that their sourcing partners comply with stringent aerospace standards and certifications. Additionally, understanding the specific requirements for high-performance materials and precision engineering is vital for successful procurement in this highly regulated industry.

Related Video: Gear Types, Design Basics, Applications and More – Basics of Gears

Strategic Material Selection Guide for helix gear

When selecting materials for helix gears, international B2B buyers must consider a variety of factors, including performance characteristics, cost implications, and compliance with regional standards. Below is an analysis of four common materials used in the manufacturing of helix gears, focusing on their properties, advantages, and limitations.

1. Steel Alloys

Key Properties:

Steel alloys, particularly those treated for hardness (e.g., carbon steel, alloy steel), exhibit excellent strength, wear resistance, and toughness. They can withstand high temperatures and pressures, making them suitable for demanding applications.

Pros & Cons:

Steel gears are known for their durability and ability to handle heavy loads. However, they are susceptible to corrosion unless treated or coated, which can add to manufacturing costs. The complexity of machining steel gears may also lead to higher production times.

Impact on Application:

Steel gears are ideal for applications involving high torque and load-bearing, such as automotive and industrial machinery. Their compatibility with various lubricants and operating conditions enhances their versatility.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM A36 or DIN 17100. In regions such as Africa and South America, sourcing from local suppliers may reduce costs and lead times while ensuring adherence to local regulations.

2. Aluminum Alloys

Key Properties:

Aluminum alloys are lightweight, corrosion-resistant, and possess good thermal conductivity. They typically have lower strength compared to steel but can be engineered for specific applications.

Pros & Cons:

The primary advantage of aluminum gears is their lightweight nature, which reduces overall system weight and energy consumption. However, they may not be suitable for high-load applications due to lower tensile strength, leading to potential wear issues over time.

Impact on Application:

Aluminum gears are commonly used in applications where weight savings are critical, such as aerospace and automotive sectors. Their corrosion resistance makes them suitable for environments exposed to moisture.

Considerations for International Buyers:

Compliance with standards like ASTM B221 and JIS H4000 is essential. Buyers from the Middle East and Europe may prefer aluminum for applications requiring lightweight components, while ensuring that local suppliers can provide certified materials.

3. Plastic Composites

Key Properties:

Plastic composites, such as nylon and acetal, offer excellent wear resistance and low friction properties. They are also lightweight and can operate in a wide temperature range.

Pros & Cons:

The main advantage of plastic gears is their ability to reduce noise and vibration during operation. However, they may not withstand high loads or temperatures as effectively as metal gears, limiting their application scope.

Impact on Application:

Plastic gears are ideal for applications in consumer products, robotics, and low-load machinery. Their chemical resistance makes them suitable for environments with exposure to various media.

Considerations for International Buyers:

Buyers should verify compliance with standards like ASTM D638 and ISO 527. In regions such as South America, where cost-effective solutions are needed, plastic gears can be an attractive option, provided they meet performance requirements.

4. Bronze Alloys

Key Properties:

Bronze alloys are known for their corrosion resistance, strength, and excellent wear properties. They can handle high loads and have good thermal conductivity.

Pros & Cons:

Bronze gears are durable and can operate in harsh environments without significant wear. However, they are generally more expensive than steel and aluminum, which can impact overall project budgets.

Impact on Application:

Bronze gears are commonly used in marine applications and heavy machinery due to their resistance to corrosion and wear. They are particularly effective in environments where lubrication is minimal.

Considerations for International Buyers:

Compliance with standards such as ASTM B505 is crucial. Buyers in Europe may favor bronze for applications requiring durability in corrosive environments, while those in Africa should consider local availability and cost implications.

Summary Table

| Material | Typical Use Case for helix gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | Automotive and industrial machinery | High strength and durability | Susceptible to corrosion | High |

| Aluminum Alloys | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Plastic Composites | Consumer products and robotics | Noise reduction and low friction | Limited load capacity | Low |

| Bronze Alloys | Marine applications and heavy machinery | Excellent wear resistance | Higher cost compared to steel | High |

This strategic material selection guide provides B2B buyers with critical insights to make informed decisions when sourcing helix gears, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for helix gear

Manufacturing Processes for Helix Gears

The manufacturing of helix gears is a multi-stage process that involves precise engineering and quality control to ensure optimal performance in applications ranging from automotive to industrial machinery. Understanding these processes can empower B2B buyers to make informed decisions when sourcing helix gears.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: Helix gears are typically made from various materials, including carbon steel, alloy steel, and sometimes plastics for specific applications. The choice of material impacts the gear’s strength, wear resistance, and overall durability.

– Heat Treatment: After material selection, heat treatment processes such as quenching and tempering are often employed to enhance the mechanical properties of the material, ensuring that the gears can withstand significant loads. -

Forming

– Machining Techniques: The primary method for forming helix gears is precision machining, which can include processes like hobbing, shaping, and milling. Hobbing is particularly common, as it allows for the creation of complex gear profiles with high accuracy.

– Gear Cutting: Advanced CNC machines are utilized to cut the gear teeth to exact specifications, which is crucial for ensuring proper meshing and minimizing noise and vibration during operation. -

Assembly

– Component Integration: Once individual gears are machined, they may be assembled with other components, such as shafts and bearings, depending on the application. This stage requires precision to ensure that all parts fit together seamlessly.

– Lubrication Application: Proper lubrication is critical in this stage to reduce friction and wear during the gear’s operational life. Manufacturers often apply lubricants that meet specific industry standards to enhance performance. -

Finishing

– Surface Treatment: To enhance durability, finishing processes such as grinding, honing, or coating are applied. These processes not only improve the surface finish but also help in reducing the likelihood of wear and failure.

– Quality Checks: At this stage, gears undergo rigorous quality checks to ensure that they meet the required specifications and performance standards.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical aspect of the manufacturing process for helix gears. It involves systematic monitoring and evaluation of every stage of production to ensure compliance with international standards.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is crucial for ensuring consistent quality in manufacturing processes. Suppliers should be ISO 9001 certified to demonstrate their commitment to quality.

- CE Marking: For products sold in the European Union, CE marking is mandatory. It indicates conformity with health, safety, and environmental protection standards.

- API Standards: For gears used in the oil and gas industry, adherence to API (American Petroleum Institute) standards is essential, ensuring that products meet industry-specific requirements.

QC Checkpoints

-

Incoming Quality Control (IQC)

– Materials and components received are inspected to ensure they meet specified standards before production begins. This step helps prevent defects from entering the manufacturing process. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, regular inspections are conducted to monitor critical parameters such as dimensions, surface finish, and performance characteristics. This proactive approach allows for early detection of issues. -

Final Quality Control (FQC)

– Before products leave the manufacturing facility, a comprehensive inspection is performed to verify that all specifications and quality standards have been met. This may include functional testing and performance evaluations.

Common Testing Methods

- Dimensional Inspection: Utilizes tools such as calipers and coordinate measuring machines (CMM) to verify the accuracy of gear dimensions.

- Functional Testing: Involves operational tests to assess how gears perform under load and in actual working conditions.

- Non-Destructive Testing (NDT): Methods such as ultrasonic testing or magnetic particle inspection are employed to detect internal flaws without damaging the gear.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

-

Supplier Audits: Conducting on-site audits of suppliers allows buyers to evaluate their manufacturing processes, quality control systems, and compliance with international standards. This is particularly important for buyers from regions like Africa and South America, where local suppliers may vary in compliance.

-

Quality Reports: Requesting and reviewing quality assurance reports from suppliers can provide insights into their performance history and adherence to standards. Look for documentation that highlights defect rates, inspection results, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control measures. This is beneficial for buyers who want to ensure that the products they receive meet their specifications.

QC and Certification Nuances for International Buyers

International buyers, particularly from regions such as Africa, the Middle East, and South America, should be aware of the following nuances when sourcing helix gears:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. It’s essential to confirm that suppliers can meet the specific compliance standards of the buyer’s target market.

-

Cultural and Economic Factors: Understanding the local manufacturing landscape, including labor practices, material availability, and economic conditions, can influence supplier selection and negotiation strategies.

-

Logistics and Supply Chain: International buyers should consider the logistics involved in sourcing from different countries, including shipping times, costs, and potential tariffs. Establishing strong communication with suppliers can help mitigate risks associated with cross-border transactions.

By understanding the manufacturing processes and quality assurance practices associated with helix gears, B2B buyers can make informed decisions, ensuring they procure high-quality products that meet their specific needs. This strategic approach will not only enhance operational efficiency but also contribute to long-term business success.

Related Video: Amazing Production Process with Modern Machines and Skilful Workers

Comprehensive Cost and Pricing Analysis for helix gear Sourcing

Cost Structure of Helix Gear Sourcing

Understanding the cost components of helix gear sourcing is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-grade alloys, treated metals, and specialty plastics enhance performance but come at a premium. Buyers should assess the trade-offs between cost and durability based on their application needs.

-

Labor: Labor costs vary by region and depend on the complexity of the gear manufacturing process. Skilled labor is necessary for precision machining and assembly, particularly for custom gear designs, which can elevate costs.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, rent, and equipment maintenance. Efficient production facilities can help minimize these overheads, impacting the final price.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs or specialized gears. Buyers should factor these costs into their overall budget, particularly if they plan to order low volumes.

-

Quality Control (QC): Rigorous QC processes are essential for ensuring the performance and reliability of helix gears. Investing in quality inspection tools and personnel can lead to higher upfront costs but reduces the risk of defects and returns in the long run.

-

Logistics: Shipping and handling costs can vary significantly based on the origin of the goods, destination, and volume. International shipping may also involve customs duties and tariffs, which need to be carefully calculated.

-

Margin: Suppliers typically add a markup to cover their operating costs and profit margins. Understanding the industry standard margins can help buyers negotiate better deals.

Price Influencers

Several factors influence the pricing of helix gears:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Higher volumes can lead to significant discounts, making bulk purchasing a strategic advantage for B2B buyers.

-

Specifications/Customization: Custom designs or specific tolerances typically incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice between standard and high-performance materials can drastically affect pricing. Buyers should evaluate their needs carefully to avoid over-specifying.

-

Quality and Certifications: Gears that meet international standards or have specific certifications (like ISO) may come at a higher price. However, these certifications can also ensure reliability and performance, justifying the cost.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: The agreed terms of shipment (Incoterms) can affect the total landed cost. Understanding these terms is crucial for budgeting logistics and potential duties.

Buyer Tips for Cost-Efficiency

To maximize cost-efficiency in sourcing helix gears, buyers should consider the following strategies:

-

Negotiation: Effective negotiation can lead to better pricing, especially for bulk orders. Always be prepared to discuss terms and explore multiple suppliers to leverage competitive pricing.

-

Total Cost of Ownership (TCO): Focus on TCO rather than just the initial purchase price. Consider factors like maintenance, longevity, and performance reliability when evaluating gear options.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and geopolitical factors that may impact pricing. Working with suppliers who understand local markets can mitigate some of these risks.

-

Market Research: Stay informed about market trends and pricing shifts. Understanding regional demand can provide leverage when negotiating prices or planning future orders.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Trust and reliability can translate into favorable conditions for repeat orders.

Disclaimer

Prices for helix gears can vary widely based on specifications, volume, and market conditions. The insights provided are indicative and should be validated with suppliers for accurate quotes.

Spotlight on Potential helix gear Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘helix gear’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for helix gear

When navigating the procurement of helix gears, understanding essential technical properties and trade terminology is crucial for B2B buyers. This knowledge not only ensures compatibility and performance but also aids in strategic sourcing decisions.

Illustrative Image (Source: Google Search)

Key Technical Properties

-

Material Grade

– Definition: Refers to the type of material used in manufacturing the helix gear, often categorized by its mechanical properties such as strength, hardness, and corrosion resistance.

– B2B Importance: Selecting the appropriate material grade is essential for ensuring durability and performance under operational stresses. Buyers must consider the specific application and environmental conditions to avoid premature failure. -

Tooth Profile

– Definition: The shape and design of the gear teeth, which can influence efficiency and noise levels during operation.

– B2B Importance: A well-defined tooth profile minimizes wear and enhances the smooth operation of machinery. Buyers should assess how different profiles impact the gear’s performance in their specific application, especially in high-load scenarios. -

Pitch Diameter

– Definition: The diameter of the pitch circle, which is the theoretical circle upon which the gear teeth engage.

– B2B Importance: Accurate pitch diameter is critical for ensuring proper meshing with mating gears. Misalignment can lead to increased wear and mechanical failure, so understanding this specification aids in selecting compatible gear systems. -

Tolerance Levels

– Definition: The permissible limits of variation in the dimensions of the gear components.

– B2B Importance: Tighter tolerances often correlate with higher manufacturing costs but result in improved gear performance and longevity. Buyers should balance cost against the required precision for their application, particularly in high-speed or high-precision environments. -

Surface Finish

– Definition: The texture of the gear surface, which can affect friction, wear, and noise levels during operation.

– B2B Importance: A smoother surface finish can reduce friction and wear, enhancing efficiency and lifespan. B2B buyers should specify surface finish requirements based on the operational environment and performance expectations. -

Load Capacity

– Definition: The maximum load that a gear can handle without failure.

– B2B Importance: Understanding load capacity is vital for ensuring that the selected gear can withstand the operational demands of its application. Buyers must evaluate load ratings to prevent mechanical breakdown and ensure reliable performance.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: When sourcing helix gears, working with OEMs can ensure that parts meet original specifications and quality standards, which is crucial for maintaining equipment performance. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ helps buyers manage inventory costs and ensures that procurement aligns with production schedules. It’s particularly important for businesses operating in regions with fluctuating demand. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Relevance: An RFQ is essential for B2B buyers to compare costs and terms from multiple suppliers, enabling informed purchasing decisions and better negotiation outcomes. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in the delivery of goods.

– Relevance: Familiarity with Incoterms is crucial for understanding shipping responsibilities, costs, and risk management in international transactions, ensuring smooth logistics and compliance. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Relevance: Lead time affects inventory management and production schedules. B2B buyers must consider lead times when planning procurement to avoid disruptions in operations. -

Certification Standards

– Definition: Industry standards that products must meet to ensure quality and safety.

– Relevance: Compliance with relevant certification standards is essential for market acceptance and regulatory adherence. Buyers should verify that helix gears meet local and international standards to mitigate risks associated with non-compliance.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, optimize their sourcing strategies, and enhance their competitive edge in the helix gear market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the helix gear Sector

Market Overview & Key Trends

The global market for helix gears is experiencing robust growth driven by advancements in technology and increasing demand across various industries, including automotive, aerospace, and industrial machinery. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, must stay abreast of these dynamics to effectively source products. Key trends shaping the market include the shift towards customization and modular designs, enabling businesses to cater to specific operational needs. Enhanced manufacturing techniques, such as additive manufacturing and CNC machining, are also becoming prevalent, allowing for greater precision and efficiency in production.

Illustrative Image (Source: Google Search)

Additionally, the rise of Industry 4.0 is influencing sourcing strategies as companies increasingly adopt smart manufacturing technologies. This trend emphasizes the importance of integrating data analytics and automation into supply chain management, offering buyers real-time insights into inventory levels and production schedules. Buyers from regions like South Africa and Kenya should focus on forging partnerships with suppliers who are equipped with these technologies to enhance operational efficiency.

Moreover, sustainability is emerging as a critical factor in purchasing decisions. B2B buyers are encouraged to evaluate suppliers based on their environmental impact and commitment to sustainable practices. Understanding regional regulatory requirements and consumer expectations related to sustainability will be essential for successful market penetration and long-term competitiveness.

Sustainability & Ethical Sourcing in B2B

As environmental concerns gain prominence globally, the helix gear sector is increasingly scrutinized for its sustainability practices. The production of helix gears often involves materials that can have significant environmental impacts, such as metals and plastics. Therefore, B2B buyers should prioritize suppliers who demonstrate a commitment to ethical sourcing and sustainable manufacturing processes. This includes utilizing recycled materials, reducing waste, and minimizing energy consumption during production.

Buyers should also seek suppliers with recognized green certifications that validate their environmental efforts. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability. Implementing sustainable sourcing strategies not only enhances a company’s reputation but can also lead to cost savings through improved efficiency and reduced waste.

Furthermore, as consumers increasingly prefer eco-friendly products, sourcing sustainable helix gears can provide a competitive edge in the market. International B2B buyers should engage with suppliers who offer transparency in their supply chains, ensuring that every component of the gear is sourced responsibly and ethically.

Brief Evolution/History

The evolution of helix gears can be traced back to the early industrial revolution, where the demand for efficient power transmission mechanisms surged. Initially, gears were made from wood, but the advent of metalworking technologies allowed for the development of stronger, more durable gears. Over the years, innovations such as computer-aided design (CAD) and computer numerical control (CNC) machining have revolutionized gear production, enabling intricate designs and precise manufacturing.

In recent decades, the focus has shifted towards enhancing gear performance through advanced materials and manufacturing techniques. Today, helix gears are integral to various applications, from automotive gearboxes to industrial machinery, reflecting a significant transformation in design and functionality. This historical perspective is crucial for B2B buyers as it underlines the importance of selecting suppliers who leverage modern technologies and materials to meet evolving market demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of helix gear

-

What criteria should I use to vet suppliers of helix gear?

When vetting suppliers, prioritize their experience and reputation in the industry. Check for certifications such as ISO 9001, which indicates quality management systems are in place. Request references from previous clients, especially those in your region, to gauge reliability. Assess their production capabilities, including technology and workforce expertise. Additionally, consider their compliance with local regulations and international standards, which can vary significantly across regions like Africa, South America, and Europe. -

Can I customize helix gear for specific applications?

Yes, many suppliers offer customization options for helix gear to meet specific application requirements. This can include variations in size, material, and design features. When discussing customization, provide detailed specifications and expected performance metrics. Collaborate closely with the supplier during the design process to ensure alignment with your operational needs. Keep in mind that customization may affect lead times and costs, so factor this into your procurement strategy. -

What are typical minimum order quantities (MOQs) and lead times for helix gear?

Minimum order quantities can vary widely depending on the supplier and the complexity of the gear. Generally, MOQs for helix gear range from 50 to 500 units. Lead times can also differ based on customization, with standard orders typically taking 4-8 weeks, while customized orders may extend to 12 weeks or more. It’s essential to discuss these parameters upfront to plan your inventory and avoid disruptions in your supply chain. -

What quality assurance processes should I expect from suppliers?

Quality assurance is critical in the procurement of helix gear. Suppliers should perform rigorous testing, including dimensional accuracy and performance under load. Request documentation of their QA processes, including inspection reports and certificates of compliance with industry standards. Additionally, inquire about their procedures for handling defective products and ensuring traceability in manufacturing, which is vital for maintaining quality over time. -

What certifications should I look for when sourcing helix gear?

Look for suppliers that hold relevant industry certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and specific gear manufacturing standards like AGMA or DIN. These certifications demonstrate a commitment to quality and adherence to international standards. Additionally, regional certifications may be beneficial for compliance with local regulations, especially in markets like Africa and the Middle East. -

How can I effectively manage logistics when sourcing helix gear internationally?

Effective logistics management is crucial for international sourcing. Start by selecting a supplier with experience in exporting to your region. Discuss shipping options, including Incoterms, to clarify responsibilities for shipping costs, insurance, and customs clearance. Use a reliable freight forwarder familiar with your destination country’s regulations to facilitate smoother imports. Also, consider potential delays in customs and plan for them in your inventory strategy. -

What steps should I take if there’s a dispute with a supplier?

In the event of a dispute, first attempt to resolve the issue amicably through direct communication. Document all correspondence related to the dispute for reference. If a resolution cannot be reached, consult your contract for dispute resolution clauses, which may include mediation or arbitration. Involving a legal professional experienced in international trade law can be beneficial, especially if the supplier is based in a different jurisdiction. -

What trends should I be aware of in the helix gear market?

Stay informed about trends such as advancements in materials and manufacturing technologies that enhance performance and durability. Sustainability is increasingly important, with a shift towards eco-friendly materials and processes. Additionally, consider the growing demand for customized solutions in various industries, which may influence pricing and availability. Monitoring these trends can help you make informed sourcing decisions and identify new opportunities for growth in your markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for helix gear

Strategic sourcing in the helix gear market is pivotal for B2B buyers aiming to enhance operational efficiency and capture emerging opportunities across diverse regions. Understanding the various types of helix gears—along with their unique features and applications—enables buyers to make informed procurement decisions that align with local market demands. Emphasizing quality control and compliance with regional standards is essential to mitigating risks associated with product failures and ensuring customer satisfaction.

International buyers from Africa, South America, the Middle East, and Europe should focus on building resilient supply chains by engaging with reputable suppliers who demonstrate a commitment to innovation and quality. Leveraging market intelligence to assess cost structures and pricing trends can lead to more strategic purchasing decisions and improved profit margins.

As we look to the future, the helix gear sector is poised for growth, driven by advancements in technology and increasing demand for high-performance solutions. Now is the time for B2B buyers to capitalize on these trends by fostering partnerships that not only enhance their product offerings but also position them as leaders in their respective markets. Take proactive steps today to secure your competitive advantage in the evolving landscape of helix gear sourcing.