Master Membrane Switches: A Comprehensive Sourcing Guide

Introduction: Navigating the Global Market for membrane switches

In an increasingly interconnected world, membrane switches have emerged as vital components in a diverse range of electronic devices, from medical equipment to consumer electronics. Their ability to provide a seamless user interface not only enhances product functionality but also significantly impacts the overall user experience. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including Nigeria and Germany) seek to elevate their product offerings, understanding the nuances of membrane switches becomes paramount.

This comprehensive guide delves into the essential aspects of membrane switches, covering various types, materials, manufacturing processes, quality control standards, and supplier considerations. We will explore the critical role of customization in meeting specific application needs and the importance of compliance with international standards to ensure product reliability and safety. Additionally, buyers will gain insights into cost factors and market trends, equipping them with the knowledge to make informed sourcing decisions.

By empowering B2B buyers with actionable insights, this guide serves as a valuable resource for navigating the global market for membrane switches. Whether you are looking to enhance product designs, ensure compliance, or select the right supplier, the information herein will help you achieve your objectives while driving innovation and efficiency in your operations.

Understanding membrane switches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tactile Membrane Switches | Provide physical feedback (click sensation) upon activation. | Medical devices, industrial controls | Pros: Enhanced user experience; clear feedback. Cons: Generally more expensive; may require more maintenance. |

| Non-Tactile Membrane Switches | Lack physical feedback but may include visual indicators (e.g., LEDs). | Consumer electronics, appliances | Pros: Sleek design; lower production costs. Cons: Less user assurance; potential confusion without feedback. |

| Graphic Overlay Membrane Switches | Customizable graphic overlays for branding and user interaction. | Automotive, consumer products | Pros: High customization; enhances aesthetics. Cons: Can be costlier due to design complexity. |

| Sealed Membrane Switches | Designed to withstand environmental factors (water, dust). | Outdoor equipment, medical devices | Pros: Durable and reliable; ideal for harsh conditions. Cons: Higher manufacturing costs; limited design flexibility. |

| Flex Circuit Membrane Switches | Combines flexible circuits with membrane technology for compact designs. | Wearable devices, compact electronics | Pros: Space-saving; lightweight. Cons: May have limitations in tactile feedback; potentially less robust. |

Tactile Membrane Switches

Tactile membrane switches are characterized by their ability to provide a noticeable physical response when pressed, often described as a click sensation. This feature enhances user interaction by offering immediate feedback, making them suitable for applications where user assurance is critical, such as in medical devices and industrial controls. When considering a supplier, buyers should evaluate the durability and lifespan of the tactile feedback mechanism, as well as the switch’s resilience in demanding environments.

Non-Tactile Membrane Switches

Non-tactile membrane switches do not provide physical feedback upon activation but may include visual indicators such as LEDs. These switches are often used in consumer electronics and household appliances where aesthetic design is prioritized over tactile feedback. Buyers should consider the implications of user experience, particularly in terms of intuitiveness and potential confusion during operation. Cost-effectiveness is a significant advantage, but ensuring clarity in user interaction is crucial.

Graphic Overlay Membrane Switches

Graphic overlay membrane switches allow for extensive customization, providing an opportunity for branding and unique user interfaces. Commonly utilized in the automotive and consumer products sectors, these switches can be tailored to reflect a company’s identity while enhancing the user experience. Buyers should focus on the manufacturer’s ability to deliver high-quality graphics and durable materials, as these factors directly impact the switch’s performance and longevity.

Sealed Membrane Switches

Sealed membrane switches are engineered to resist environmental challenges such as moisture and dust, making them ideal for outdoor equipment and medical devices. Their robust construction ensures reliability in harsh conditions. Buyers must assess the switch’s sealing standards and compliance with relevant certifications, as these factors are vital for maintaining operational integrity in demanding applications. Although these switches may come at a higher price point, their long-term durability often justifies the investment.

Flex Circuit Membrane Switches

Flex circuit membrane switches integrate flexible circuit technology, allowing for lightweight and compact designs suitable for wearable devices and other small electronics. While their space-saving benefits are significant, buyers should consider the trade-offs regarding tactile feedback and overall robustness. It’s essential to evaluate the flexibility of the circuit in relation to the intended application, as well as the manufacturer’s experience in producing reliable flex circuit solutions.

Key Industrial Applications of membrane switches

| Industry/Sector | Specific Application of membrane switches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Control panels for diagnostic machines | Enhances user interaction, ensuring precise control in critical environments. | Compliance with medical standards (e.g., ISO 13485), durability in medical settings. |

| Consumer Electronics | User interfaces for home appliances | Provides a sleek design while ensuring ease of use and functionality. | Customization options for branding, tactile vs. non-tactile feedback preferences. |

| Industrial Equipment | Control interfaces for machinery | Increases operational efficiency and reduces the risk of user error. | Material selection for harsh environments, long lifespan, and robust design. |

| Automotive | Dashboard controls and infotainment systems | Improves user experience with intuitive controls and aesthetic appeal. | Compliance with automotive standards, ability to withstand temperature variations. |

| Telecommunications | Keypads for communication devices | Ensures reliable performance and user-friendly interaction in critical communications. | Custom designs for branding, responsiveness to user inputs, and material durability. |

Medical Devices

Membrane switches are integral to medical devices, serving as control panels for diagnostic machines and monitoring systems. They provide a user-friendly interface that enhances interaction during critical operations, ensuring precise control and minimizing user error. International buyers, particularly in regions like Africa and Europe, should prioritize manufacturers who comply with medical standards such as ISO 13485. Additionally, durability in medical environments is paramount, as switches must withstand frequent use and potential exposure to fluids.

Consumer Electronics

In the consumer electronics sector, membrane switches are commonly used in user interfaces for home appliances, such as microwaves and washing machines. Their slim design allows for aesthetic integration while ensuring functional ease of use. B2B buyers from South America and Europe should consider customization options for branding, as well as the choice between tactile and non-tactile feedback to enhance the user experience. This adaptability can significantly influence consumer satisfaction and product marketability.

Industrial Equipment

Membrane switches are utilized in the control interfaces of industrial machinery, where they play a crucial role in operational efficiency. By providing clear and intuitive controls, they help reduce the risk of user error, which can be costly in industrial settings. Buyers in Africa and the Middle East should focus on sourcing switches made from materials that can endure harsh environments and have a long lifespan. This ensures reliable performance even in demanding conditions.

Automotive

In the automotive industry, membrane switches are found in dashboard controls and infotainment systems, where they contribute to a seamless user experience. These switches enhance both functionality and aesthetics, making vehicles more appealing to consumers. European buyers should ensure that their suppliers comply with automotive standards and can provide products that withstand temperature variations, which are common in automotive applications.

Telecommunications

Membrane switches are vital in telecommunications, particularly as keypads for communication devices. They ensure reliable performance and user-friendly interaction, which is critical in high-stakes communication scenarios. B2B buyers should look for manufacturers that can offer custom designs to reflect their branding while ensuring responsiveness to user inputs. Additionally, the durability of materials is essential to guarantee longevity and reliability in various environments.

Related Video: Membrane Switch Design Guide

Strategic Material Selection Guide for membrane switches

When selecting materials for membrane switches, it’s essential to consider their properties, advantages, disadvantages, and the specific needs of your application. Here, we analyze four common materials used in membrane switch manufacturing: polyester, polycarbonate, acrylic, and silicone. Each material has unique characteristics that can significantly influence the performance and suitability of the membrane switch for various applications.

Polyester

Key Properties:

Polyester is known for its excellent chemical resistance, flexibility, and durability. It can withstand temperatures ranging from -40°C to 120°C and has good abrasion resistance, making it suitable for various environments.

Pros & Cons:

Polyester is relatively low-cost and easy to print on, allowing for vibrant graphics. However, it can be less durable than some alternatives, particularly in high-heat or high-pressure applications. Its susceptibility to yellowing over time can also be a concern for aesthetic applications.

Impact on Application:

Polyester is ideal for consumer electronics and industrial equipment where cost-effectiveness and moderate durability are required. However, it may not be suitable for applications exposed to extreme conditions.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as RoHS and REACH, especially in Europe. In regions like Africa and South America, understanding local manufacturing capabilities and sourcing options is crucial.

Polycarbonate

Key Properties:

Polycarbonate is recognized for its high impact resistance and optical clarity. It can handle temperatures between -40°C and 125°C and is resistant to UV light, making it suitable for outdoor applications.

Pros & Cons:

The main advantage of polycarbonate is its durability and resistance to impact, which makes it ideal for high-traffic areas. However, it is generally more expensive than polyester and may require more complex manufacturing processes.

Impact on Application:

Polycarbonate is often used in medical devices and industrial machinery where durability and clarity are paramount. Its ability to withstand harsh conditions makes it a preferred choice for critical applications.

Considerations for International Buyers:

Buyers should verify that polycarbonate materials meet ASTM standards for safety and performance. In Europe, compliance with EN standards is also vital.

Acrylic

Key Properties:

Acrylic offers excellent clarity and UV resistance, with a temperature range of -30°C to 90°C. It is lightweight and has good weather resistance, making it suitable for outdoor applications.

Pros & Cons:

Acrylic is cost-effective and easy to fabricate, allowing for intricate designs. However, it is less impact-resistant than polycarbonate and can scratch easily, which may limit its use in high-wear environments.

Impact on Application:

Acrylic is commonly used in signage and decorative applications where aesthetics are critical. Its limitations in durability may restrict its use in heavy-duty applications.

Considerations for International Buyers:

International buyers should ensure that acrylic materials comply with local regulations regarding flammability and chemical resistance. Understanding regional preferences for aesthetics can also guide material selection.

Silicone

Key Properties:

Silicone is highly flexible and can operate in extreme temperatures, ranging from -60°C to 200°C. It is also resistant to moisture and chemicals, making it suitable for various environments.

Pros & Cons:

Silicone provides excellent tactile feedback and durability, making it ideal for applications requiring frequent use. However, it can be more expensive and may complicate the manufacturing process.

Impact on Application:

Silicone is widely used in medical devices and consumer electronics where user interaction is frequent. Its resilience makes it suitable for harsh environments, but the cost may be a limiting factor for some applications.

Considerations for International Buyers:

Buyers should ensure that silicone products meet relevant industry certifications, especially in sectors like healthcare. Familiarity with local sourcing options can also enhance procurement efficiency.

Summary Table

| Material | Typical Use Case for membrane switches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Consumer electronics, industrial equipment | Low-cost, vibrant graphics | Less durable, yellowing over time | Low |

| Polycarbonate | Medical devices, industrial machinery | High impact resistance | More expensive, complex manufacturing | High |

| Acrylic | Signage, decorative applications | Excellent clarity, cost-effective | Scratches easily, less durable | Medium |

| Silicone | Medical devices, consumer electronics | Excellent tactile feedback, durable | Higher cost, manufacturing complexity | High |

This guide provides essential insights into material selection for membrane switches, helping international B2B buyers make informed decisions tailored to their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for membrane switches

The manufacturing of membrane switches involves several key stages, each critical to ensuring the quality and functionality of the final product. Understanding these processes is essential for B2B buyers to make informed decisions when sourcing membrane switches. Here’s a detailed overview of the typical manufacturing processes, quality assurance practices, and relevant international standards.

Manufacturing Processes

1. Material Preparation

The first step in manufacturing membrane switches is selecting and preparing the right materials. Common materials include polyester and polycarbonate, chosen for their durability and flexibility. The preparation stage involves:

- Material Inspection: Incoming materials undergo rigorous inspection to ensure they meet specified standards. This includes checking thickness, flexibility, and resistance to environmental factors.

- Cutting: Materials are cut to size using precision machinery to ensure uniformity and reduce waste.

2. Forming

This stage involves creating the various layers that make up the membrane switch. The key techniques include:

- Screen Printing: Graphics and symbols are printed onto the upper layer using UV-curable inks, which are both durable and vibrant.

- Die-Cutting: The layers are die-cut to create the necessary shapes and openings for switches and LEDs. This step is crucial for ensuring the precise fit of components.

3. Assembly

Once the individual components are prepared, they are assembled into a complete membrane switch. The assembly process typically includes:

- Layer Stacking: The graphic overlay, spacer, and circuit layers are carefully aligned and stacked.

- Adhesive Application: Adhesive is applied to bond the layers together. This adhesive must be compatible with both the materials used and the intended application environment.

4. Finishing

The final manufacturing stage focuses on enhancing the membrane switch’s performance and appearance:

- Quality Checks: Each assembled switch undergoes initial quality checks to identify any visible defects.

- Final Coating: A protective coating may be applied to enhance durability and resistance to wear and tear.

Quality Assurance Practices

Quality assurance is a critical aspect of membrane switch manufacturing, ensuring that each product meets both client specifications and regulatory requirements. Here are the primary quality assurance practices relevant to B2B buyers:

Relevant International Standards

Several international standards govern the manufacturing and quality control of membrane switches, including:

- ISO 9001: This standard focuses on quality management systems, ensuring consistency in manufacturing processes and product quality.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- RoHS and REACH: These directives restrict the use of certain hazardous materials, particularly important for electronics in Europe.

QC Checkpoints

Quality control checkpoints are integral to the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any defects are caught early.

- Final Quality Control (FQC): This final inspection checks the completed membrane switches against predefined quality standards.

Common Testing Methods

To ensure reliability and performance, various testing methods are employed:

- Electrical Testing: Each switch is tested for functionality to ensure it activates correctly under pressure.

- Environmental Testing: Membrane switches are subjected to temperature, humidity, and chemical exposure tests to simulate real-world conditions.

- Durability Testing: This involves repeated pressing to assess the switch’s lifespan and performance over time.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some actionable steps:

- Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality management systems.

- Requesting Quality Reports: Ask for detailed quality control reports, including results from IQC, IPQC, and FQC processes.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality standards and practices.

Quality Control Nuances for International Buyers

When sourcing membrane switches internationally, buyers should be aware of specific nuances:

- Cultural Differences: Different regions may have varying approaches to quality control and manufacturing standards. Understanding these can aid in effective communication and expectation management.

- Regulatory Compliance: Ensure that suppliers are compliant with both local and international regulations, as non-compliance can lead to significant delays and increased costs.

- Logistics and Supply Chain Considerations: Evaluate the supplier’s logistics capabilities to ensure timely delivery, especially for custom orders that may require longer lead times.

Conclusion

Understanding the manufacturing processes and quality assurance practices for membrane switches is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as adhering to international quality standards, companies can ensure they source high-quality products that meet their specific needs. Additionally, verifying supplier quality control through audits, reports, and third-party inspections will further enhance the reliability of the sourcing process. This comprehensive approach will ultimately lead to successful partnerships and superior product outcomes.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for membrane switches Sourcing

Understanding the cost structure and pricing dynamics of membrane switches is crucial for international B2B buyers. This section will explore the key components of cost, the factors influencing pricing, and essential tips for optimizing procurement strategies, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components of Membrane Switches

-

Materials: The primary cost driver in membrane switches is the selection of materials. Common materials include polyester and polycarbonate, which impact durability and flexibility. Higher quality materials may increase upfront costs but can enhance the product’s lifespan and functionality.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs may offer competitive pricing; however, it’s essential to assess the skill level and experience of the workforce, as these factors directly influence product quality.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help minimize overhead, leading to better pricing for buyers.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. This cost is amortized over the production run, making larger orders more cost-effective. Buyers should discuss tooling costs upfront to understand the total financial commitment.

-

Quality Control (QC): Investing in stringent QC processes is vital for ensuring product reliability. While this may add to the overall cost, it can prevent costly defects and returns, ultimately saving money in the long run.

-

Logistics: Transportation and shipping costs can vary significantly depending on the supplier’s location and the chosen Incoterms. Buyers must consider these costs when evaluating total pricing.

-

Margin: Manufacturers typically include a profit margin in their pricing. Understanding the average margins within the industry can aid buyers in negotiating better deals.

Price Influencers

Several factors can significantly impact the pricing of membrane switches:

-

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs. Manufacturers may offer tiered pricing, so buyers should negotiate based on projected order quantities.

-

Specifications/Customization: Unique specifications or high levels of customization can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: Specialized materials or certifications (e.g., RoHS, ISO) can increase costs. Buyers should weigh the benefits of higher-quality materials against budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers optimize shipping expenses.

Buyer Tips for Cost-Efficient Sourcing

-

Negotiate: Always negotiate pricing and terms. Suppliers may have flexibility in pricing, especially for larger orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Focus on the TCO rather than just the initial purchase price. Consider factors like durability, maintenance, and potential replacement costs over the product’s lifespan.

-

Understand Pricing Nuances: International buyers should be aware of fluctuations in currency exchange rates and their impact on pricing. Additionally, customs duties and tariffs can affect the final cost.

-

Leverage Local Knowledge: Buyers from regions like Africa or South America may benefit from local representatives or agents who understand the market and can negotiate favorable terms.

-

Request Detailed Quotes: Always ask for itemized quotes that break down costs. This transparency can help identify areas for potential savings.

-

Consider Supplier Relationships: Building long-term relationships with suppliers can result in better pricing, priority service, and more favorable terms.

Disclaimer

Prices for membrane switches can vary widely based on the aforementioned factors. It is crucial for buyers to conduct thorough market research and seek multiple quotes to ensure they are getting competitive pricing tailored to their specific needs.

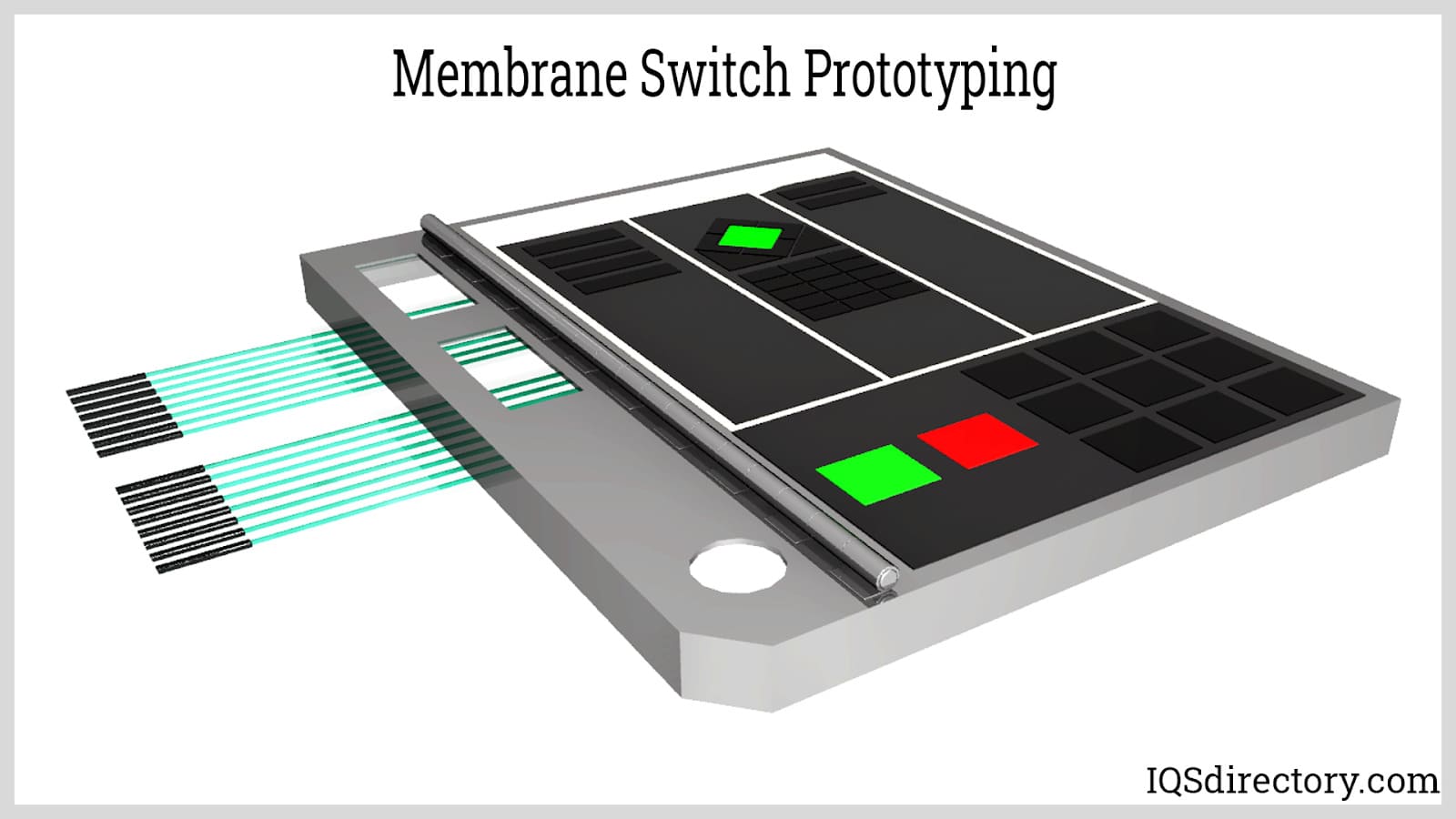

Illustrative Image (Source: Google Search)

Spotlight on Potential membrane switches Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘membrane switches’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for membrane switches

Membrane switches are pivotal in modern electronic interfaces, and understanding their technical properties and trade terminology is essential for international B2B buyers. Below, we explore the key specifications and terms that can aid decision-making during the sourcing process.

Key Technical Properties of Membrane Switches

-

Material Grade:

The primary materials used in membrane switches include polyester and polycarbonate. Polyester is generally more cost-effective and offers decent durability, while polycarbonate provides superior impact resistance and clarity. Choosing the right material is crucial as it affects the switch’s lifespan, flexibility, and overall performance in different environments. -

Tolerance Levels:

Tolerance refers to the allowable deviation in the dimensions of the membrane switch components. High tolerance levels are critical for ensuring that the switch fits correctly within its designated space and operates as intended. Inaccuracies can lead to malfunction or damage, making it important for buyers to specify tolerance requirements to manufacturers. -

Operating Temperature Range:

This specification indicates the temperature limits within which the membrane switch can operate effectively. Understanding the operating temperature range is vital for applications in extreme environments, such as industrial machinery or outdoor devices. Selecting a switch with appropriate temperature ratings can prevent failure and ensure reliability. -

Actuation Force:

Actuation force is the amount of pressure required to activate the switch. It is a critical factor that influences user experience; too much force can lead to user fatigue, while too little may result in accidental activations. Buyers should consider the intended use and user demographics when specifying actuation force. -

Lifespan:

This refers to the number of actuation cycles a membrane switch can withstand before failure. Typical lifespans range from 1 million to over 10 million cycles, depending on the design and materials used. A longer lifespan translates to lower replacement costs and higher reliability, making this an important consideration for B2B buyers. -

Feedback Type:

Membrane switches can provide either tactile or non-tactile feedback. Tactile switches give a physical response (like a click), enhancing user interaction, while non-tactile options rely on visual indicators (such as LED lights). The choice between these feedback types can significantly affect user satisfaction and should align with the application’s requirements.

Common Trade Terms in Membrane Switch Procurement

-

OEM (Original Equipment Manufacturer):

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of membrane switches, OEMs are crucial partners for businesses looking to integrate custom switches into their products. Understanding the OEM’s capabilities can help buyers ensure quality and compatibility. -

MOQ (Minimum Order Quantity):

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it can affect budgeting and inventory levels. Buyers should negotiate MOQs to align with their production needs and avoid overstocking. -

RFQ (Request for Quotation):

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It should outline the specifications, quantities, and delivery requirements for the membrane switches. A well-prepared RFQ can lead to competitive pricing and favorable terms from manufacturers. -

Incoterms (International Commercial Terms):

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for determining who bears the costs and risks associated with shipping and delivery. This knowledge can help buyers avoid unexpected expenses. -

Customization:

This term refers to the ability to tailor the membrane switch to specific design and functional requirements. Customization options may include unique graphics, sizes, and feedback types. Knowing the extent of customization available from manufacturers can help buyers create products that meet their branding and usability goals. -

Lead Time:

Lead time is the duration from placing an order to the delivery of the product. This term is critical for planning and inventory management. Buyers should inquire about lead times during the sourcing process to ensure that their production schedules align with supplier capabilities.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing membrane switches, ultimately enhancing their products and user experiences.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the membrane switches Sector

Market Overview & Key Trends

The membrane switches market is experiencing robust growth, driven by increasing demand across diverse industries such as consumer electronics, medical devices, and industrial machinery. As of 2021, the market was valued at approximately $5.7 billion, with projections indicating a rise to $12.4 billion by 2031, reflecting a compound annual growth rate (CAGR) of 8%. This growth can be attributed to the rising consumer expectations for seamless user interfaces and the need for durable, cost-effective solutions.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, several emerging trends are noteworthy. Firstly, customization is becoming a critical factor in sourcing membrane switches. Manufacturers are increasingly offering tailored solutions that meet specific design and functional requirements, allowing companies to differentiate their products in competitive markets. Secondly, there is a growing emphasis on smart technology integration, as membrane switches are being designed to accommodate touch-sensitive and haptic feedback features, enhancing user interaction.

Additionally, sustainability is influencing sourcing decisions. Buyers are prioritizing manufacturers who adopt environmentally friendly practices and materials. The shift towards digital solutions is also notable, with more companies opting for online sourcing platforms to streamline procurement processes and enhance supplier transparency. B2B buyers should leverage these trends to make informed purchasing decisions and ensure their products align with market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a paramount concern in the membrane switches sector, reflecting a broader shift in B2B procurement practices. The environmental impact of manufacturing processes and materials used in membrane switches necessitates a focus on ethical sourcing. Buyers are increasingly scrutinizing their suppliers’ practices to ensure compliance with environmental regulations and standards.

The adoption of ‘green’ certifications, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), is crucial for manufacturers aiming to demonstrate their commitment to sustainability. These certifications not only enhance product credibility but also ensure that the materials used are safe for the environment and human health.

Moreover, the choice of materials plays a significant role in sustainability. Utilizing eco-friendly substrates, such as recycled plastics or bio-based materials, can substantially reduce the carbon footprint of membrane switches. B2B buyers should prioritize suppliers that are transparent about their sourcing practices and material choices, as this will not only improve their product offerings but also align with the growing consumer demand for sustainable products.

Brief Evolution/History

Membrane switches have evolved significantly since their inception in the 1970s. Initially used in basic electronic applications, their development was propelled by advancements in materials and manufacturing techniques. The introduction of flexible circuit technology allowed for thinner designs and more complex functionalities, paving the way for widespread adoption across various sectors.

The integration of membrane switches into high-tech devices marked a turning point, as manufacturers began to appreciate their potential for enhancing user experience. The late 1990s and early 2000s saw a surge in demand for customized designs, driven by the rapid growth of consumer electronics. Today, membrane switches are not only recognized for their practicality but also for their ability to contribute to aesthetic and intuitive user interfaces, making them a staple in modern electronic devices. For international B2B buyers, understanding this evolution is essential for navigating current market dynamics and making informed sourcing decisions.

Related Video: Crude Oil Prices & Global Trade Market Seen Stabilising After Trump Announced Iran Israel Ceasefire

Frequently Asked Questions (FAQs) for B2B Buyers of membrane switches

-

What key factors should I consider when vetting a membrane switch supplier?

When vetting a membrane switch supplier, prioritize their industry experience and reputation. Look for manufacturers with proven expertise in your specific application area, whether it be medical devices or consumer electronics. Request customer references and case studies to evaluate their reliability and quality. Additionally, consider their manufacturing capabilities, technology used, and whether they adhere to international quality standards such as ISO certifications. A strong communication channel is also crucial for effective collaboration throughout the project. -

Can membrane switches be customized to fit my brand’s design requirements?

Yes, membrane switches offer extensive customization options. Manufacturers typically allow for personalized graphic overlays, colors, shapes, and button layouts to align with your branding. Ensure that the supplier you choose has a robust design process and the capability to accommodate your specific requirements. Discuss your design ideas upfront, and ask for samples or prototypes to ensure that the final product meets your expectations before full-scale production begins. -

What are the minimum order quantities (MOQs) and lead times for membrane switches?

MOQs and lead times can vary significantly among suppliers. Generally, MOQs can range from 100 to several thousand units, depending on the complexity of the design and the manufacturer’s capabilities. Lead times typically range from 2 to 8 weeks, influenced by factors such as production capacity and material availability. It’s advisable to discuss these specifics upfront with potential suppliers to find a partner who can meet your volume and timeline needs without compromising quality. -

What payment terms are common when sourcing membrane switches internationally?

Payment terms can vary widely by supplier and region. Common practices include upfront deposits (typically 30-50%) with the balance due upon delivery or net 30-60 days after invoice. Some suppliers may also accept letters of credit or escrow services for larger orders to mitigate risks. Clarifying payment terms before initiating the order is essential to avoid misunderstandings and ensure smooth transactions, especially when dealing with international logistics. -

How can I ensure quality assurance and certifications for my membrane switches?

To ensure quality, request documentation of the supplier’s quality management system and relevant certifications, such as ISO 9001 or compliance with RoHS and REACH standards. Ask for details about their quality control processes, including testing and inspection protocols. Additionally, consider conducting factory audits or third-party inspections to verify manufacturing practices. Establishing clear quality expectations upfront can help mitigate risks and ensure the final product meets your specifications. -

What logistics considerations should I keep in mind when importing membrane switches?

When importing membrane switches, consider shipping costs, customs duties, and potential delays in transit. Choose a reliable logistics partner with experience in international shipping to navigate customs regulations efficiently. Ensure that your supplier provides all necessary documentation, such as commercial invoices and packing lists, to facilitate smooth customs clearance. It’s also wise to discuss insurance options to protect your investment during transport. -

How can I handle disputes with my membrane switch supplier?

To manage disputes effectively, establish a clear contract outlining all terms, including quality expectations, timelines, and payment terms. Keep open lines of communication throughout the project to address any concerns promptly. If issues arise, document all correspondence and attempt to resolve them amicably through discussions. If necessary, consider mediation or arbitration as outlined in your contract. Having a well-defined dispute resolution process can help mitigate risks and maintain a positive supplier relationship. -

What are the common applications of membrane switches, and how do they influence my sourcing decision?

Membrane switches are widely used in various sectors, including medical devices, consumer electronics, automotive controls, and industrial machinery. Understanding the specific application requirements—such as durability, environmental resistance, and user interface design—will influence your sourcing decision. Evaluate potential suppliers based on their experience in your target industry and their ability to meet the unique demands of your application. This alignment is essential for ensuring product effectiveness and user satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for membrane switches

Sourcing membrane switches strategically is essential for international B2B buyers aiming to enhance product functionality and user experience. Key takeaways include the importance of defining performance requirements, exploring customization options, and ensuring compliance with industry standards. Buyers should prioritize manufacturers with a proven track record, effective communication practices, and a commitment to quality, as these factors significantly impact product success and customer satisfaction.

Moreover, understanding the diverse applications of membrane switches—from medical devices to consumer electronics—can guide buyers in selecting the right solutions tailored to their specific needs. As the global membrane switch market is projected to grow significantly, now is an opportune time for businesses in Africa, South America, the Middle East, and Europe to invest in high-quality interfaces that elevate their products.

Illustrative Image (Source: Google Search)

In conclusion, the strategic sourcing of membrane switches presents a valuable opportunity to improve user interaction and drive innovation. Engage with reputable manufacturers today to secure the best solutions that align with your business goals and market demands. Embrace the future of user interfaces and position your products for success in a competitive landscape.