Master Metal Grate Material Sourcing: Your Comprehensive

Introduction: Navigating the Global Market for metal grate material

Navigating the complexities of the global market for metal grate materials is essential for international B2B buyers engaged in infrastructure, construction, and industrial projects. Metal grates are foundational components in various applications, including flooring systems, safety walkways, and drainage solutions, offering strength, durability, and versatility. As urbanization accelerates in Africa, infrastructure development expands in South America, and industrial demands grow in the Middle East and Europe, the need for high-quality metal grates becomes increasingly critical.

This guide serves as a comprehensive resource tailored specifically for B2B buyers. It covers a wide array of topics, including the different types of metal grates—such as welded, press-locked, and perforated options—alongside their respective materials, manufacturing processes, and quality control standards. By understanding these elements, buyers can make informed choices that align with their project requirements and regional regulations.

Additionally, the guide provides actionable insights into supplier selection, cost benchmarking, and current market trends. It addresses common challenges faced by buyers in diverse regions, offering expert responses to frequently asked questions. By leveraging this information, decision-makers can optimize their sourcing strategies, mitigate risks, and enhance supplier relationships. Empower yourself with the knowledge to navigate the metal grate market confidently and ensure the success of your projects across continents.

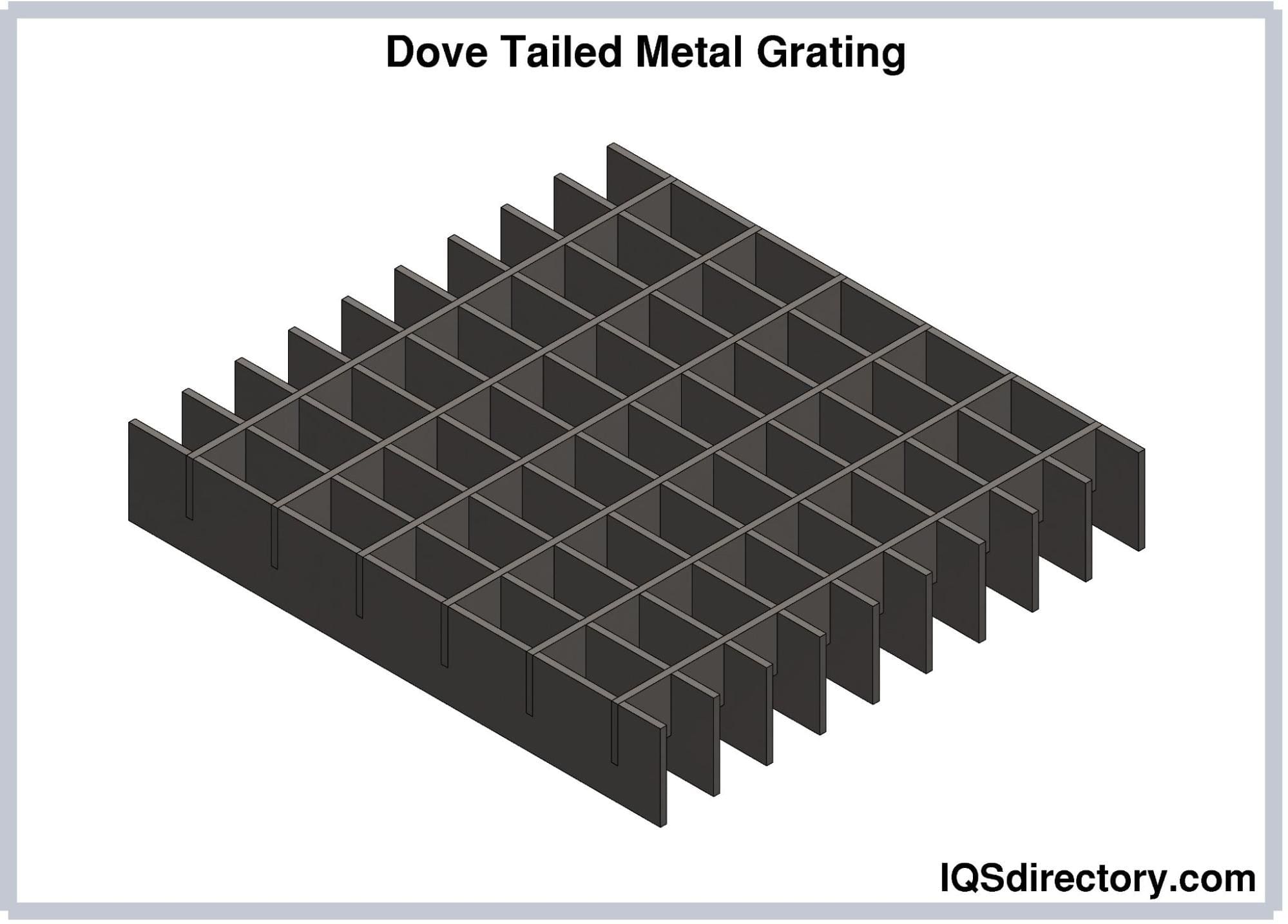

Understanding metal grate material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

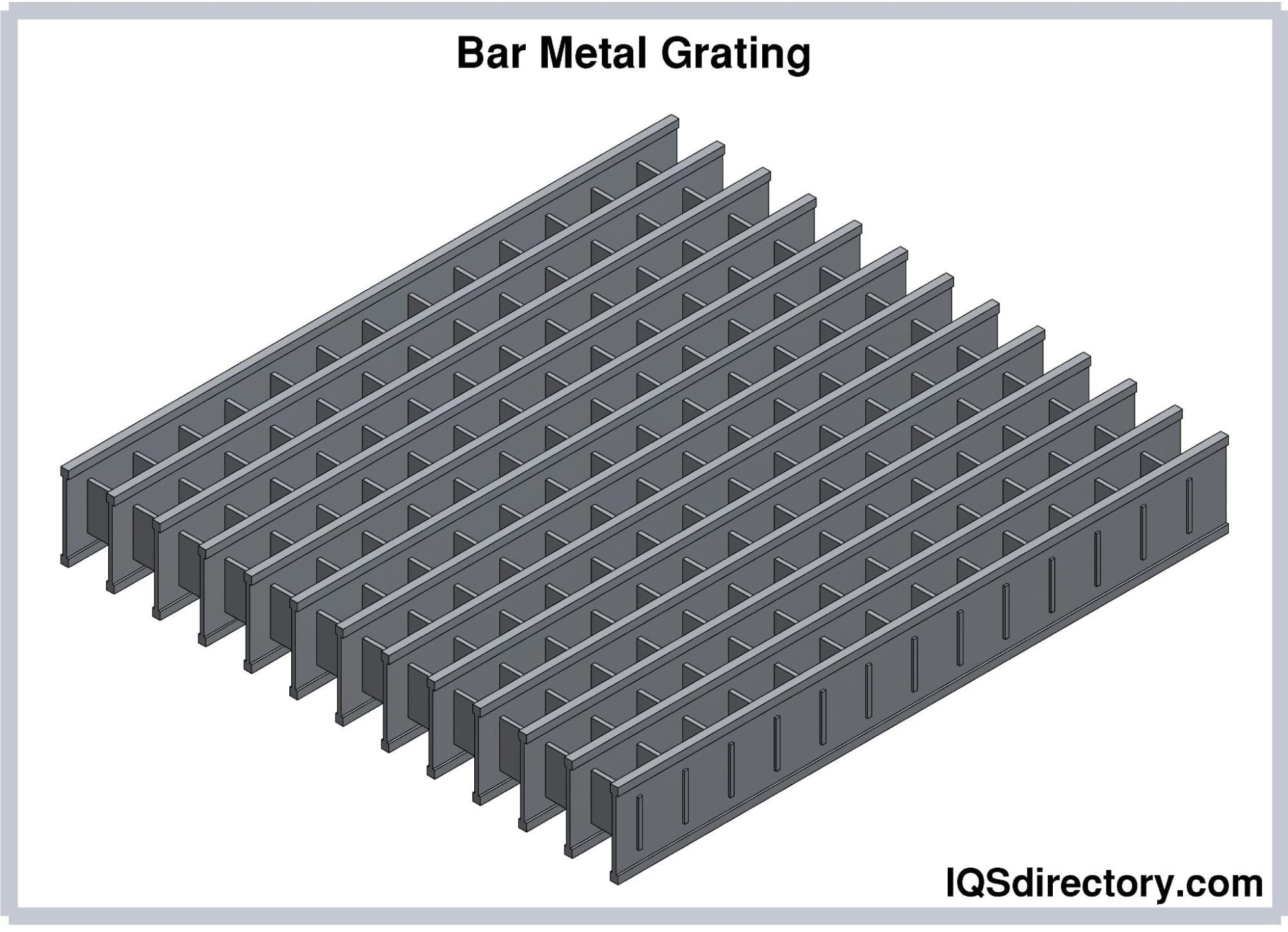

| Welded Bar Grating | Crossbars welded to bearing bars at each intersection | Industrial flooring, walkways, platforms | Pros: Strong, cost-effective; Cons: Less customizable than other types |

| Press-Locked Grating | Bearing and cross bars pressure-locked without welding | Architectural facades, public spaces | Pros: Clean aesthetics, precise tolerance; Cons: Higher cost, not for heavy loads |

| Swage-Locked Grating | Crossrods swaged through bearing bars, creating a secure joint | Oil & gas, marine, chemical processing | Pros: Lightweight, corrosion-resistant; Cons: May need special orders for large spans |

| Riveted Grating | Components fastened by riveting at bar intersections | Vintage renovations, bridges, heavy-duty use | Pros: Outstanding durability; Cons: Generally higher cost and weight |

| Perforated Metal Grating | Sheet metal punched with patterns of holes or slots | Slip-resistant flooring, filtration, ventilation | Pros: Superior drainage, anti-slip; Cons: Lower load-bearing than bar gratings |

Welded Bar Grating

Welded bar grating is the most prevalent type, characterized by crossbars welded to bearing bars at every intersection. This construction offers significant strength and rigidity, making it suitable for demanding industrial applications such as factory floors and machinery spaces. B2B buyers should consider load requirements, local compliance standards, and potential anti-corrosion treatments for environments exposed to moisture or chemicals.

Press-Locked Grating

Press-locked grating utilizes high-pressure technology to interlock bars without welding, resulting in a cleaner aesthetic and precise tolerances. This type is ideal for architectural applications, including facades and public spaces. Buyers should note that while this option provides a modern look, it is generally more expensive and better suited for light to moderate loads, necessitating careful evaluation of application requirements.

Swage-Locked Grating

Swage-locked grating features crossrods pressed through pre-punched holes in the bearing bars, ensuring a secure connection. It is particularly advantageous in industries like oil and gas, where weight savings and corrosion resistance are critical. B2B purchasers must verify material certifications and may need to customize sizes for specific applications, which can lead to longer lead times and increased costs.

Riveted Grating

Riveted grating is constructed by fastening crossbars and bearing bars together with rivets, providing exceptional durability and impact resistance. This type is frequently used in historical renovations and heavy-duty industrial settings. Buyers should weigh the higher initial costs and weight against the long-term benefits of reduced maintenance and enhanced lifespan, especially in high-traffic areas.

Perforated Metal Grating

Perforated metal grating consists of sheet metal with specific hole patterns, offering excellent drainage and slip resistance. It is commonly used in environments such as food processing plants or outdoor stair treads where safety is paramount. While this type is cost-effective for light pedestrian loads, buyers must consider its lower structural strength compared to bar gratings, ensuring it meets the necessary load requirements for their specific applications.

Related Video: A Practical Introduction to Large Language Models (LLMs)

Key Industrial Applications of metal grate material

| Industry/Sector | Specific Application of metal grate material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Flooring and walkways in commercial buildings | Enhances safety and durability in high-traffic areas | Load requirements, anti-slip properties, local compliance standards |

| Oil & Gas | Grating for platforms and access points | Provides reliable access and safety in hazardous environments | Corrosion resistance, weight specifications, custom designs |

| Water Treatment | Drainage covers and filtration systems | Improves operational efficiency and safety in processing | Material choice for chemical resistance, load capacity, and maintenance needs |

| Mining | Heavy-duty grating for processing areas | Ensures worker safety and equipment longevity | Durability under heavy loads, local sourcing logistics, and environmental factors |

| Transportation & Logistics | Grating for loading docks and platforms | Increases efficiency and safety in freight handling | Slip resistance, weight capacity, and compliance with safety regulations |

Construction

In the construction sector, metal grate materials are commonly used for flooring and walkways in commercial buildings. These applications enhance safety and durability, particularly in high-traffic areas where slip hazards are prevalent. B2B buyers should focus on load requirements and anti-slip properties to ensure compliance with local standards and regulations. Additionally, it is crucial to consider the finish and treatment of the grating to withstand environmental challenges specific to the region.

Oil & Gas

Within the oil and gas industry, metal grating is essential for creating safe access points and platforms in hazardous environments. The materials must provide reliable support while being resistant to corrosion due to exposure to chemicals and extreme weather conditions. Buyers should prioritize sourcing grating with high corrosion resistance, ensuring it meets weight specifications for safety. Custom designs may also be necessary to fit unique operational requirements in remote locations.

Water Treatment

Metal grate materials are utilized extensively in water treatment facilities, particularly for drainage covers and filtration systems. These applications help improve operational efficiency and safety by allowing for effective debris clearance and drainage. For international B2B buyers, it is vital to select the right material that can withstand chemical exposure while providing the necessary load capacity. Maintenance considerations, such as ease of cleaning and replacement, should also guide sourcing decisions.

Mining

In the mining industry, heavy-duty grating is critical for processing areas where worker safety and equipment longevity are paramount. This type of grating must endure heavy loads and harsh environmental conditions, making durability a key factor for B2B buyers. Sourcing logistics can be complex, particularly in remote mining locations, so understanding local supplier capabilities and environmental factors is essential to ensure timely delivery and compliance with safety standards.

Transportation & Logistics

Metal grating finds significant application in loading docks and platforms within transportation and logistics sectors. It enhances efficiency and safety during freight handling by providing a stable and slip-resistant surface. Buyers should focus on the weight capacity and slip resistance of the grating, ensuring it complies with safety regulations relevant to their operations. Additionally, sourcing from local suppliers can help mitigate transportation costs and reduce lead times.

Related Video: Forming Sheet Metal & Metal Forming Tools – Uses Explained By Gene Winfield at SEMA

Strategic Material Selection Guide for metal grate material

When selecting metal grate materials for international B2B applications, understanding the properties and implications of different materials is essential. Below, we analyze four common materials used in metal grating, providing insights into their performance, advantages, disadvantages, and considerations for buyers in various regions.

Steel

Key Properties:

Steel is known for its high tensile strength and durability. It can withstand significant loads and is often treated for corrosion resistance through galvanization or coatings. Steel grating typically has a temperature rating that can handle moderate to high temperatures, making it suitable for industrial applications.

Pros & Cons:

Steel grating is cost-effective and widely available, making it a popular choice for heavy-duty applications. However, it is susceptible to rust and corrosion if not properly treated, which can lead to increased maintenance costs over time. Its weight can also complicate installation and handling.

Impact on Application:

Steel is compatible with various media, including water, chemicals, and heavy machinery. However, its corrosion resistance must be considered in environments with high humidity or exposure to corrosive substances.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM in the USA, DIN in Europe, or JIS in Japan. Additionally, understanding local environmental conditions is crucial for selecting the appropriate corrosion resistance treatment.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, durability, and aesthetic appeal. It can withstand extreme temperatures and pressures, making it ideal for demanding environments, including food processing and chemical industries.

Pros & Cons:

The primary advantage of stainless steel grating is its longevity and low maintenance requirements. However, it comes at a higher cost compared to regular steel, which may be a limiting factor for some projects. The manufacturing process is also more complex, potentially leading to longer lead times.

Impact on Application:

Stainless steel is suitable for applications where hygiene and corrosion resistance are paramount, such as in food and pharmaceutical industries. Its compatibility with various chemicals enhances its versatility.

Considerations for International Buyers:

Buyers must verify the grade of stainless steel (e.g., 304, 316) to ensure suitability for specific applications. Compliance with food safety standards and certifications is also critical, particularly in the EU and North America.

Aluminum

Key Properties:

Aluminum is lightweight yet strong, with excellent corrosion resistance. It is non-magnetic and can be anodized for additional protection. It typically handles lower load capacities compared to steel but is suitable for many pedestrian applications.

Pros & Cons:

The lightweight nature of aluminum simplifies installation and reduces transportation costs. However, it is generally more expensive than steel and may not be suitable for heavy-duty applications. Its lower strength can limit its use in certain industrial settings.

Impact on Application:

Aluminum grating is ideal for environments where weight is a concern, such as in portable structures or elevated walkways. It performs well in marine environments due to its corrosion resistance.

Considerations for International Buyers:

B2B buyers should be aware of local standards regarding aluminum alloys and ensure that the material meets specific load-bearing requirements. Understanding the local market’s preferences for aluminum versus steel can also inform purchasing decisions.

Fiberglass Reinforced Plastic (FRP)

Key Properties:

FRP grating is composed of a polymer matrix reinforced with fiberglass, offering high corrosion resistance and lightweight properties. It can withstand a wide range of temperatures and is non-conductive, making it suitable for electrical applications.

Pros & Cons:

FRP is highly resistant to chemicals and moisture, making it ideal for harsh environments. However, it is generally less load-bearing than metal options and can be more expensive. Its aesthetic appeal is also lower compared to metal gratings.

Impact on Application:

FRP is particularly effective in chemical processing, wastewater treatment, and marine applications. Its non-slip surface enhances safety in wet environments.

Considerations for International Buyers:

Buyers should ensure compliance with relevant safety and environmental standards. Understanding the specific chemical compatibility of FRP with intended applications is crucial for long-term performance.

Summary Table

| Material | Typical Use Case for metal grate material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial flooring, heavy machinery platforms | Cost-effective and durable | Susceptible to rust without treatment | Medium |

| Stainless Steel | Food processing, chemical industries | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Walkways, portable structures | Lightweight and easy to install | Limited load capacity | Medium-High |

| Fiberglass Reinforced Plastic | Chemical processing, marine applications | High corrosion resistance | Lower load-bearing capacity | Medium-High |

This analysis equips international B2B buyers with the necessary insights to make informed decisions when selecting metal grate materials, tailored to their specific regional needs and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for metal grate material

The manufacturing of metal grate materials is a multifaceted process that ensures the end product meets the rigorous demands of various industrial applications. Understanding this process is crucial for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, who are sourcing materials for large-scale projects. This section delves into the typical manufacturing stages, quality assurance standards, and practices that international buyers should consider.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing of metal grates involves careful selection and preparation of raw materials, primarily metals like steel, stainless steel, aluminum, or specialty alloys. Buyers should look for suppliers who perform metallurgical testing to verify the material’s properties, such as tensile strength and corrosion resistance. This ensures that the selected material will withstand the operational demands of the intended application.

Key techniques in this stage include:

– Cutting: Raw metal sheets or bars are cut to specified dimensions using plasma cutting, laser cutting, or shearing methods.

– Surface Treatment: Pre-treatment processes like shot blasting or acid cleaning are employed to remove impurities and prepare the surface for further processing.

2. Forming

Once the materials are prepared, the next step is forming them into the desired shapes. Different types of metal grates require various forming techniques:

- Welding: Commonly used for welded bar grating, this method involves joining metal pieces at high temperatures to ensure strong and durable connections.

- Press-Locking: In press-locked grating, bearing bars and cross bars are interlocked using high-pressure equipment without welding, resulting in a smooth finish.

- Swaging: This technique involves forcing cross rods through bearing bars to create a secure joint, often used for lightweight applications.

3. Assembly

After forming, the components are assembled. This stage is critical as it ensures that the grating meets specific load-bearing requirements and dimensional tolerances.

Key assembly techniques include:

– Riveting: For riveted grating, components are fastened together using rivets, providing high durability.

– Mechanical Fastening: This involves using bolts or screws to assemble components, allowing for easier disassembly and maintenance.

4. Finishing

The finishing stage enhances both the aesthetic and functional properties of the metal grates. This may involve:

– Coating: Protective coatings, such as galvanizing, powder coating, or painting, are applied to prevent corrosion and improve longevity.

– Surface Treatment: Additional treatments like passivation for stainless steel can enhance resistance to environmental factors.

Illustrative Image (Source: Google Search)

Quality Assurance

Quality assurance (QA) is paramount in the manufacturing of metal grates, as it ensures compliance with international and industry-specific standards. B2B buyers should be well-versed in these standards to assess supplier capabilities effectively.

International Standards

- ISO 9001: This is a widely recognized quality management standard that outlines requirements for a quality management system (QMS). Compliance indicates a supplier’s commitment to quality and continuous improvement.

- CE Marking: Relevant for products sold in the European Economic Area, CE marking signifies that the product meets EU safety, health, and environmental protection standards.

Industry-Specific Standards

- API Standards: For applications in the oil and gas sector, API standards ensure that materials can withstand the harsh conditions often encountered in these industries.

- ASTM Standards: These provide specifications for various metal products, including grating materials, ensuring they meet specific performance criteria.

Quality Control Checkpoints

Quality control (QC) should be integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, reducing waste and rework.

- Final Quality Control (FQC): The final product is thoroughly inspected and tested against specifications before shipping. This may include load testing and visual inspections for defects.

Common Testing Methods

To ensure the quality and durability of metal grates, several testing methods are employed, including:

– Load Testing: Evaluating the load-bearing capacity of the grating under specified conditions.

– Corrosion Resistance Testing: Assessing the material’s ability to withstand corrosive environments through salt spray tests or chemical exposure.

– Dimensional Inspection: Verifying that the grating meets specified dimensions and tolerances.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s QC processes is essential to mitigate risks associated with poor quality. Here are actionable steps buyers can take:

- Audits: Conduct regular audits of suppliers to assess their manufacturing processes and quality management systems. This can reveal insights into their operational practices and adherence to standards.

- Request Quality Reports: Suppliers should provide documentation of their QC processes, including test results and compliance certificates, to ensure transparency.

- Third-Party Inspections: Engaging independent inspection agencies can provide unbiased assessments of the supplier’s product quality and compliance with international standards.

QC and Certification Nuances for International Buyers

When sourcing from different regions, B2B buyers should be aware of the nuances in quality control and certification. For instance:

- Regional Standards: Buyers must ensure that suppliers comply with local regulations and standards that may differ from international norms.

- Documentation Requirements: Different countries may have specific documentation requirements for importing metal products, including certifications and compliance reports.

- Cultural Differences in Quality Perception: Understanding regional attitudes towards quality can help buyers set realistic expectations and foster better supplier relationships.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for metal grate materials is vital for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring the procurement of high-quality materials that meet their project requirements while mitigating risks associated with sourcing in a global market.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for metal grate material Sourcing

Understanding the cost structure and pricing dynamics of metal grate material sourcing is essential for international B2B buyers. The procurement process involves multiple cost components that influence the final price, alongside various factors that affect negotiations and overall cost efficiency.

Cost Components

-

Materials: The choice of metal significantly affects cost. Common materials include carbon steel, stainless steel, aluminum, and specialty alloys. Prices fluctuate based on market conditions, availability, and regional demand. For instance, stainless steel tends to be more expensive due to its corrosion resistance and durability.

-

Labor: Labor costs encompass the workforce required for manufacturing, assembly, and quality checks. Regions with lower labor costs may offer competitive pricing, but it’s crucial to ensure that quality is not compromised.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help minimize overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific designs can lead to significant initial investments. However, these costs can be amortized over larger production runs, making it essential to consider order volumes when evaluating tooling expenses.

-

Quality Control (QC): Rigorous QC processes are vital for ensuring product standards and compliance with safety regulations. The cost of QC can vary based on the complexity of the product and the certifications required.

Illustrative Image (Source: Google Search)

-

Logistics: Transportation and handling costs are crucial, especially for international shipments. Factors such as distance, shipping method, and local customs duties can add to overall expenses.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding market norms for margins can aid in negotiating better prices.

Price Influencers

-

Volume/MOQ: Larger orders typically command lower per-unit prices due to economies of scale. Buyers should evaluate their needs and consider bulk purchasing to optimize costs.

-

Specifications/Customization: Custom designs and specific tolerances can increase costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Materials and Quality/Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can result in increased costs. However, they often provide long-term savings through durability and reduced maintenance.

-

Supplier Factors: Supplier reliability, reputation, and geographic location can influence pricing. Establishing strong relationships with suppliers may lead to better pricing and favorable terms.

-

Incoterms: Understanding Incoterms is vital as they define the responsibilities of buyers and sellers in shipping. Different terms can significantly impact total costs, including insurance, transport, and customs duties.

Buyer Tips

-

Negotiation: Leverage volume purchases and long-term contracts to negotiate better prices. Building relationships with suppliers can also enhance negotiation outcomes.

-

Cost-Efficiency: Conduct a thorough analysis of the Total Cost of Ownership (TCO), which includes not only the purchase price but also installation, maintenance, and lifecycle costs. This approach ensures that decisions are based on comprehensive financial implications rather than initial costs alone.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and geopolitical factors that may influence pricing.

-

Disclaimer for Indicative Prices: Prices for metal grate materials can vary widely based on the factors discussed. Buyers are encouraged to obtain multiple quotes and conduct due diligence to ensure they receive competitive pricing reflective of their specific requirements.

By understanding these cost structures and pricing influences, B2B buyers can make informed sourcing decisions that align with their operational needs and budget constraints.

Spotlight on Potential metal grate material Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘metal grate material’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for metal grate material

Key Technical Properties of Metal Grate Material

Understanding the technical specifications of metal grate materials is vital for B2B buyers to ensure the right fit for their projects. Here are some critical specifications to consider:

-

Material Grade

– Definition: This refers to the classification of the metal based on its chemical composition and mechanical properties. Common grades include carbon steel, stainless steel, and aluminum.

– B2B Importance: Different projects require specific grades to withstand environmental conditions, load capacities, and corrosion levels. Selecting the appropriate material grade can enhance durability and performance, thereby reducing long-term costs. -

Load Capacity

– Definition: The maximum load a grate can support without failure, often measured in pounds or kilograms per square foot.

– B2B Importance: Understanding load capacity is critical for ensuring safety and compliance with local regulations. Buyers must evaluate the expected loads in their applications to choose a suitable grate that minimizes the risk of structural failure. -

Tolerance

– Definition: This specification indicates the allowable variation in dimensions, which can affect fit and assembly.

– B2B Importance: Accurate tolerances are essential for ensuring proper installation and function. Too loose or too tight a fit can lead to safety hazards or increased maintenance costs. Buyers should specify their tolerance requirements clearly to manufacturers. -

Corrosion Resistance

– Definition: The ability of the material to withstand degradation due to chemical or electrochemical reactions in its environment.

– B2B Importance: In regions with high humidity or exposure to chemicals, selecting a corrosion-resistant material can significantly extend the life of the grating. Buyers should consider the environmental conditions their products will face and choose materials accordingly. -

Finish

– Definition: The surface treatment applied to the metal to enhance appearance, durability, or corrosion resistance, such as galvanizing or powder coating.

– B2B Importance: The finish not only affects the aesthetic but also the maintenance requirements and lifespan of the grating. Buyers should assess the balance between cost and the expected longevity of the finish in their specific applications. -

Weight

– Definition: The overall mass of the grating, typically measured in pounds per square foot.

– B2B Importance: Weight impacts transportation costs, ease of installation, and overall structural load. Buyers must consider the implications of weight on their logistics and installation processes.

Common Trade Terminology

Familiarity with industry terminology can streamline communication and enhance procurement processes. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding the role of OEMs is crucial for buyers seeking quality components that meet specific standards for their projects. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of product that a supplier is willing to sell.

– Significance: Knowing the MOQ helps buyers gauge whether a supplier can meet their project needs without incurring excessive costs or inventory. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Significance: Using RFQs effectively allows buyers to compare offers from multiple suppliers, facilitating better decision-making based on cost and service levels. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce that define responsibilities of buyers and sellers in international transactions.

– Significance: Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risk management in global sourcing. -

Lead Time

– Definition: The time taken from placing an order to delivery.

– Significance: Accurate lead time estimates are vital for project planning and inventory management. Buyers should clarify lead times with suppliers to ensure timely project execution. -

Certification

– Definition: Documentation proving that a product meets specific standards or regulations.

– Significance: Certifications ensure that the materials used comply with safety and quality standards, which is particularly important in regulated industries. Buyers should verify the relevant certifications for their specific applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their project requirements and regional market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the metal grate material Sector

Market Overview & Key Trends

The global market for metal grate materials is experiencing significant growth driven by rapid urbanization, industrial expansion, and infrastructural development across various regions, particularly in Africa, South America, the Middle East, and Europe. Buyers are increasingly focused on sourcing materials that offer durability, cost-efficiency, and adaptability to local conditions. Key trends influencing this market include the rise of digital procurement tools, which facilitate easier comparison of suppliers and products, and the adoption of advanced manufacturing technologies like 3D printing, which allow for customized solutions that meet specific project requirements.

In addition, the demand for lightweight materials such as aluminum and composite gratings is on the rise, reflecting a shift towards efficiency in transportation and installation. Sustainability has emerged as a pivotal consideration, with many buyers seeking products that not only meet performance standards but also align with environmental goals. The use of recycled materials and the implementation of circular economy principles are becoming standard practices within the sector. Furthermore, international buyers are increasingly looking for suppliers that provide transparency in their supply chains, ensuring compliance with regional regulations and ethical standards.

Sustainability & Ethical Sourcing in B2B

As the global focus on sustainability intensifies, the metal grate material sector is undergoing a transformation towards more environmentally friendly practices. The production of metal gratings can have a considerable environmental impact, particularly concerning energy consumption and waste generation. Thus, it is essential for B2B buyers to prioritize suppliers who demonstrate a commitment to sustainable manufacturing processes, such as utilizing recycled materials and minimizing carbon footprints.

Ethical sourcing is equally important, as it encompasses not only the environmental aspects but also the social implications of procurement. Buyers should seek suppliers who adhere to ethical labor practices and are transparent about their supply chain operations. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and social responsibility. Additionally, exploring options for “green” materials, such as those produced from recycled metals, can help companies meet their sustainability goals while still ensuring product performance and reliability.

Brief Evolution/History

The use of metal gratings dates back to ancient civilizations where they were primarily employed for functional purposes such as drainage and access. Over the years, advancements in metallurgy and manufacturing processes have enhanced the versatility and performance of metal gratings, allowing them to serve a broader range of applications across industries. The introduction of modern materials and fabrication techniques in the 20th century, such as welded and press-locked gratings, revolutionized the sector, offering improved strength-to-weight ratios and aesthetic options. Today, the focus has shifted towards sustainability and ethical sourcing, marking a significant evolution in how metal gratings are produced and procured in the B2B marketplace.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of metal grate material

-

How can I effectively vet suppliers of metal grate materials?

Vetting suppliers is essential to ensure quality and reliability. Start by assessing their industry reputation through online reviews and testimonials. Check for relevant certifications, such as ISO standards, which indicate adherence to quality management systems. Request references from previous clients, especially those in your region. Additionally, consider conducting site visits or virtual audits to evaluate their production capabilities and quality control processes. This thorough approach helps mitigate risks associated with supplier selection. -

Can I customize metal grate materials to meet specific project requirements?

Yes, many suppliers offer customization options for metal grate materials. You can specify dimensions, load-bearing capacities, materials (like stainless steel or aluminum), and surface treatments (such as anti-slip finishes). When discussing customization, ensure you clearly communicate your project’s requirements and deadlines. Be aware that custom orders may involve longer lead times and potentially higher costs, so factor these into your project budget and timeline. -

What are the typical minimum order quantities (MOQs) and lead times for metal grate materials?

Minimum order quantities can vary significantly between suppliers and based on the type of metal grate material. Commonly, MOQs range from 100 to 500 square meters, but some suppliers may accommodate smaller orders. Lead times also depend on factors like material availability, production schedules, and customization requirements. Standard lead times can range from 4 to 12 weeks. Always confirm these details with suppliers to ensure they align with your project timelines. -

What payment terms should I expect when sourcing metal grate materials internationally?

Payment terms can vary widely among suppliers, influenced by factors such as order size, buyer-supplier relationship, and regional practices. Common payment methods include letters of credit, bank transfers, or upfront deposits (usually 30-50%). It is advisable to negotiate terms that protect your interests, such as partial payments upon order confirmation and final payments upon delivery. Ensure that you have clear agreements in place to avoid misunderstandings. -

How can I ensure quality assurance and certifications for metal grate materials?

To ensure quality assurance, request documentation of compliance with relevant industry standards and certifications. Common certifications include ISO 9001 for quality management and ASTM standards for material specifications. Inquire about the supplier’s quality control processes, including testing methods and inspection protocols. Additionally, consider requesting samples before placing a large order to evaluate the material’s quality firsthand. -

What logistics considerations should I keep in mind when sourcing metal grate materials?

Logistics is critical in international sourcing. Consider shipping methods (air vs. sea), as well as the associated costs and transit times. Understand customs regulations and import duties in your country, as these can significantly impact overall costs. Collaborate with logistics partners who have experience in handling industrial materials to ensure smooth transportation and delivery. It’s also wise to factor in potential delays caused by geopolitical factors or supply chain disruptions. -

How should I handle disputes with suppliers over metal grate materials?

To effectively handle disputes, maintain clear communication and documentation throughout the procurement process. If issues arise, first attempt to resolve them amicably through direct negotiation. If necessary, refer to the contract terms, which should outline dispute resolution processes, such as mediation or arbitration. In cases of significant disagreement, consider involving legal counsel familiar with international trade law to protect your interests and navigate potential resolutions. -

What are the key factors influencing the pricing of metal grate materials?

The pricing of metal grate materials is influenced by several factors, including the type of material (steel, aluminum, etc.), manufacturing processes, and market demand. Additionally, fluctuations in raw material prices and transportation costs can impact overall pricing. Regional economic conditions, tariffs, and trade agreements may also play a role. To secure competitive pricing, consider obtaining quotes from multiple suppliers and evaluating them based on total cost of ownership rather than just initial price.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal grate material

In conclusion, strategic sourcing of metal grate materials is pivotal for B2B buyers engaged in diverse sectors across Africa, South America, the Middle East, and Europe. Understanding the various types of grating—such as welded, press-locked, swage-locked, riveted, and perforated—enables buyers to make informed decisions that align with their specific project needs and environmental conditions. Buyers should prioritize factors such as material properties, load requirements, and supplier capabilities to optimize cost and performance.

The value of strategic sourcing extends beyond mere procurement; it encompasses risk mitigation, compliance with regional standards, and the establishment of long-term supplier relationships that can lead to significant operational efficiencies. As markets continue to evolve and demand for durable, high-performance materials rises, buyers must stay ahead of industry trends and innovations.

Looking forward, now is the time for international B2B buyers to enhance their sourcing strategies. Engaging with suppliers who demonstrate expertise and adaptability will be key to navigating future challenges and seizing opportunities in the global marketplace. Take action today to ensure that your sourcing decisions today set the foundation for your success tomorrow.