Master Motor Shaft Coupling Sourcing: Essential Insights

Introduction: Navigating the Global Market for motor shaft coupling

As industries worldwide evolve, motor shaft couplings play a pivotal role in ensuring machinery operates efficiently and reliably. These essential components are not just connectors; they are critical to the performance and longevity of motor-driven systems across diverse sectors, including manufacturing, agriculture, and logistics. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of motor shaft couplings is crucial for optimizing procurement strategies and enhancing operational efficiency.

This guide offers a comprehensive exploration of the global market for motor shaft couplings, detailing various types and their specific applications. It delves into the materials used—evaluating steel, alloys, and specialty metals—and examines the manufacturing processes and quality control standards that ensure product reliability. Additionally, buyers will find frameworks for supplier evaluation, cost analysis, and risk mitigation strategies tailored to their regional contexts.

To empower informed sourcing decisions, the guide also includes benchmark market data and answers to frequently asked questions that address the real-world challenges faced by B2B buyers. By equipping yourself with these insights, you can navigate the complexities of the motor shaft coupling market, reduce procurement risks, and ultimately drive sustained value for your organization. Whether you’re in Saudi Arabia or Colombia, understanding these components will enable you to make strategic choices that align with your operational needs and market demands.

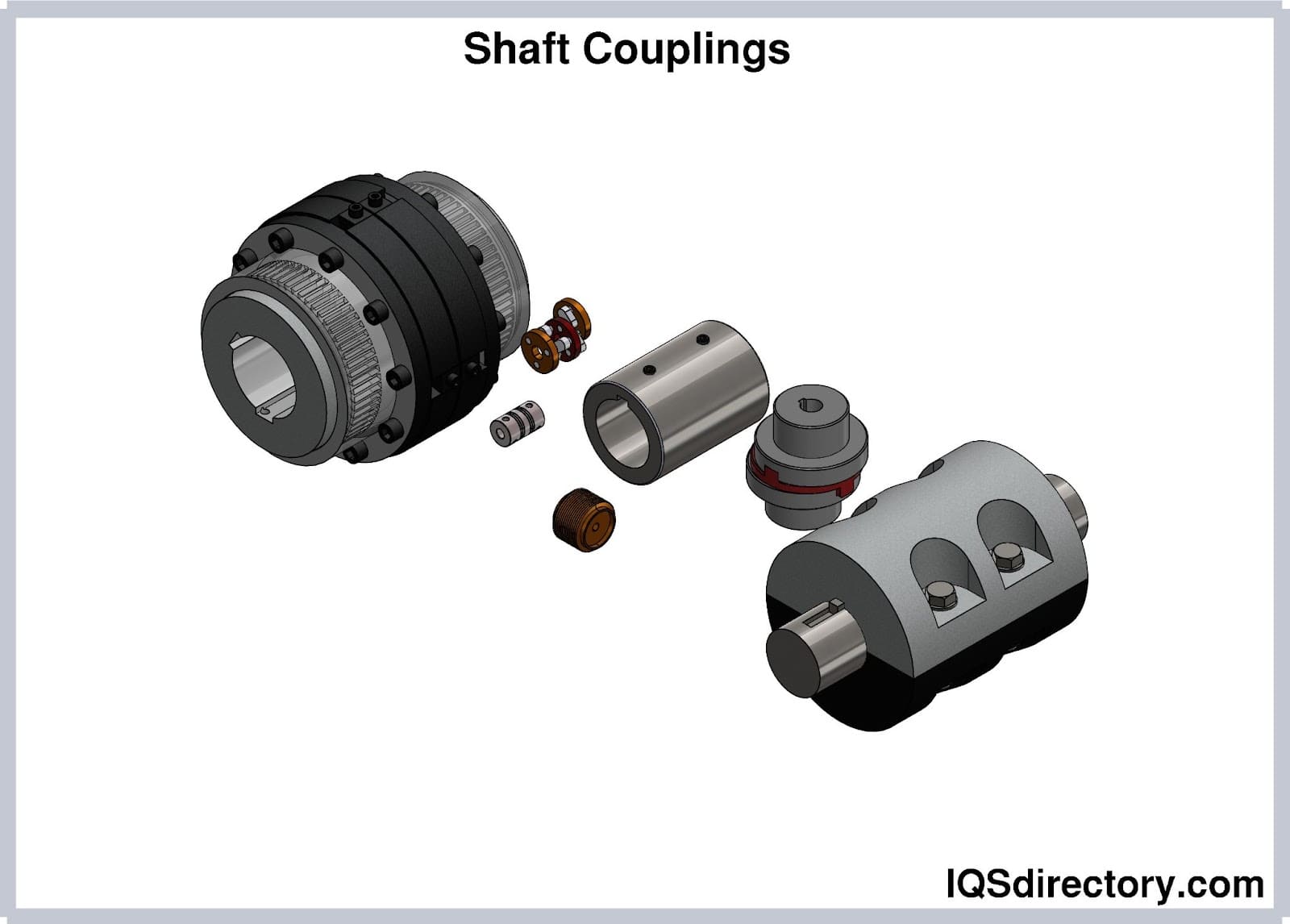

Understanding motor shaft coupling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid Couplings | No flexibility; provides solid connection | Industrial machinery, pumps, compressors | High torque capacity; limited misalignment tolerance |

| Flexible Couplings | Absorbs shock and misalignment; allows movement | Robotics, conveyors, automotive | Reduces wear; may have lower torque capacity |

| Gear Couplings | Integrates gears for torque transmission | Heavy machinery, mining, construction | Compact design; potential efficiency loss |

| Oldham Couplings | Features a sliding disc; accommodates misalignment | Packaging, food processing, textile | Simple design; limited torque capacity |

| Bellows Couplings | Flexible and torsionally rigid; accommodates misalignment | Precision machinery, CNC equipment | High precision; can be expensive |

Rigid Couplings

Rigid couplings are designed for applications where precise alignment is critical. They provide a solid connection between shafts, ensuring maximum torque transfer without any backlash. This type is ideal for industrial machinery, pumps, and compressors that operate under high load conditions. When sourcing rigid couplings, buyers should consider the material compatibility with their existing systems and ensure that the coupling can withstand the operational environment, including temperature and humidity.

Flexible Couplings

Flexible couplings are engineered to accommodate misalignment and absorb shock loads, making them suitable for applications in robotics, conveyors, and automotive industries. They come in various designs, including elastomeric and metallic options, which can help reduce wear on components and improve system longevity. B2B buyers should evaluate the specific misalignment tolerances and the environmental conditions where the coupling will operate, as well as the potential impact on torque capacity.

Gear Couplings

Gear couplings feature a pair of gears that mesh to transmit torque, making them a robust solution for heavy machinery in mining and construction. Their compact design allows for high torque transmission while minimizing the overall footprint of the assembly. Buyers should focus on the required gear ratios and load capacities when selecting gear couplings, and ensure they have access to maintenance support, especially in regions with less established industrial infrastructure.

Oldham Couplings

Oldham couplings utilize a sliding disc mechanism to accommodate angular and parallel misalignments, making them a versatile choice for applications such as packaging and food processing. This design offers a simple and effective solution for maintaining operational efficiency. When purchasing Oldham couplings, buyers should assess the torque capacity and ensure that the coupling material is suitable for the specific environment, particularly in food-related applications where hygiene is paramount.

Bellows Couplings

Bellows couplings are designed to provide high precision and torsional rigidity while accommodating some misalignment. They are commonly used in precision machinery and CNC equipment, where accuracy is critical. The flexibility of the bellows allows for slight movements without compromising performance. B2B buyers should consider the coupling’s load ratings and potential cost implications, as bellows couplings can be more expensive than other types but offer significant advantages in precision applications.

Related Video: Types of Shaft Coupling, Animation, Machine Design | Solidworks

Key Industrial Applications of motor shaft coupling

| Industry/Sector | Specific Application of Motor Shaft Coupling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhances operational efficiency and reduces downtime | Ensure compatibility with existing systems and load capacity |

| Agriculture | Irrigation Pumps | Increases reliability and longevity of equipment | Consider environmental factors like moisture and corrosion resistance |

| Automotive | Electric Vehicle Drive Systems | Improves torque transfer and reduces vibrations | Focus on lightweight materials and compliance with safety standards |

| Oil & Gas | Pumping Stations | Ensures consistent performance under high pressure | Evaluate supplier certifications and local support services |

| Mining | Heavy Machinery Drives | Maximizes productivity and reduces maintenance costs | Assess durability against harsh conditions and availability of spare parts |

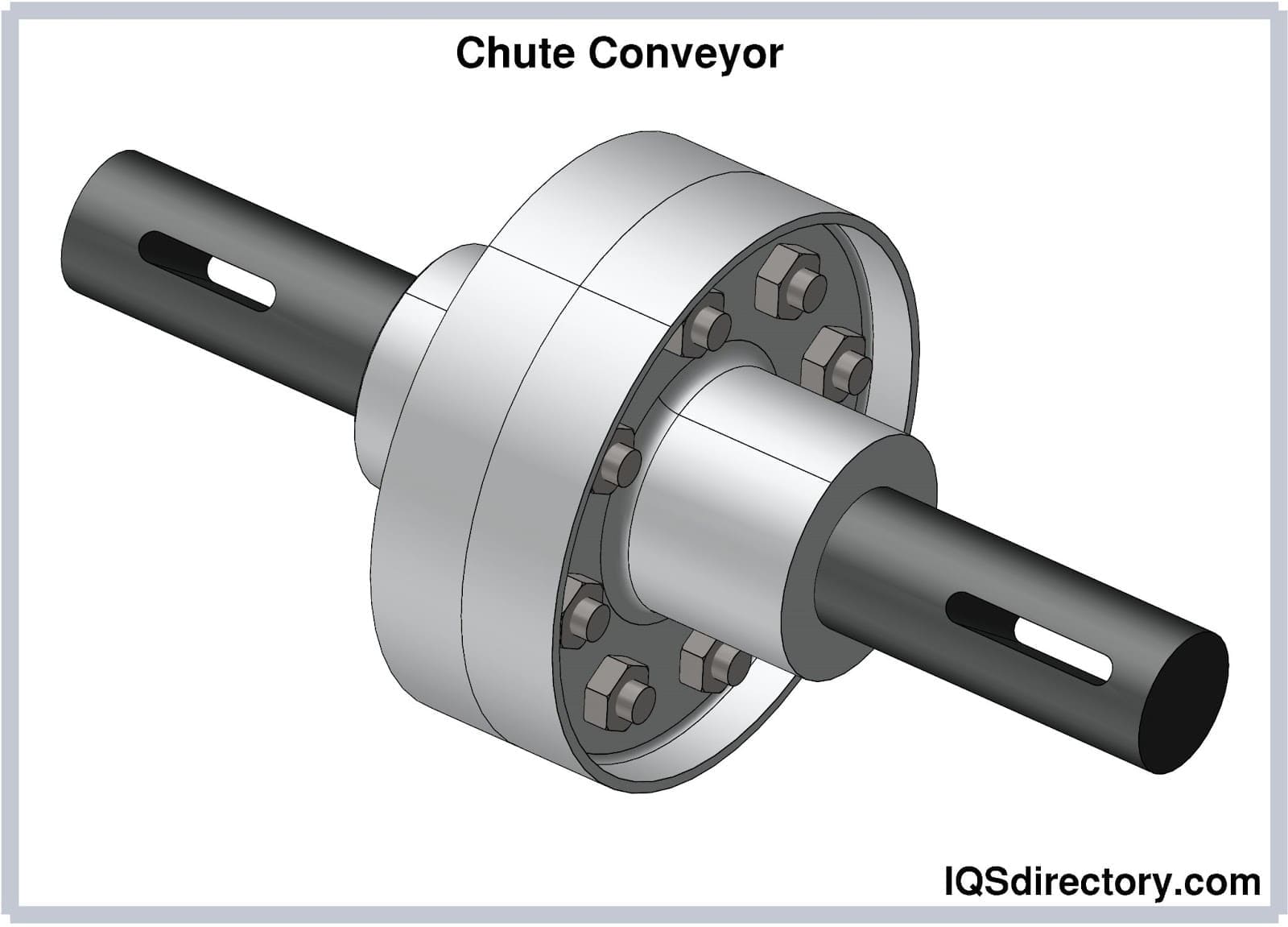

Manufacturing – Conveyor Systems

Motor shaft couplings are critical in conveyor systems, which are integral to many manufacturing processes. They connect the motor shaft to the conveyor drive, ensuring efficient power transmission. This application minimizes downtime and enhances operational efficiency, vital for competitive production environments. Buyers in regions like Europe and South America should ensure that couplings are compatible with existing machinery and can handle the specific load capacities required for their operations.

Agriculture – Irrigation Pumps

In agricultural settings, motor shaft couplings are used in irrigation pumps to facilitate the transfer of power from the motor to the pump effectively. This application is crucial for maintaining consistent water supply in farming operations. Reliability and longevity are paramount, especially in regions like Africa where agricultural productivity is essential. Buyers should consider environmental factors such as moisture levels and potential corrosion, ensuring that couplings are made from suitable materials that withstand these conditions.

Automotive – Electric Vehicle Drive Systems

Motor shaft couplings play a pivotal role in electric vehicle (EV) drive systems, connecting electric motors to the drivetrain. This application enhances torque transfer and reduces vibrations, which is crucial for performance and driver comfort. For buyers in the Middle East and Europe, sourcing lightweight materials that comply with safety standards is essential to optimize vehicle efficiency and meet regulatory requirements.

Oil & Gas – Pumping Stations

In the oil and gas industry, motor shaft couplings are essential for the operation of pumping stations, where they ensure reliable performance under high-pressure conditions. This application is critical for maintaining the flow of oil and gas, which directly impacts productivity and profitability. International buyers should evaluate supplier certifications and the availability of local support services to mitigate risks associated with sourcing and maintenance.

Mining – Heavy Machinery Drives

Motor shaft couplings are vital components in the drive systems of heavy machinery used in mining operations. They facilitate the efficient transfer of power from motors to various equipment, maximizing productivity while minimizing maintenance costs. Buyers in regions with harsh mining conditions, such as South America and Africa, should assess the durability of couplings against extreme environments and ensure that spare parts are readily available to avoid operational disruptions.

Related Video: Selecting a Coupling for a Shaft

Strategic Material Selection Guide for motor shaft coupling

When selecting materials for motor shaft couplings, international B2B buyers must consider various factors, including the mechanical properties, environmental conditions, and specific application requirements. Below is an analysis of four common materials used in motor shaft couplings, focusing on their properties, advantages, disadvantages, and considerations for buyers from diverse regions.

Steel

Key Properties:

Steel is known for its high tensile strength and durability. It can withstand significant loads and is suitable for high-pressure applications. Steel couplings can also be heat-treated to enhance their hardness and wear resistance.

Pros & Cons:

Steel offers excellent durability and is relatively cost-effective. However, it is susceptible to corrosion unless properly treated or coated. The manufacturing complexity is moderate, often requiring machining for precision.

Impact on Application:

Steel is compatible with various media, making it suitable for industrial applications where strength is paramount, such as in mining or heavy machinery.

Considerations for Buyers:

Buyers must ensure compliance with local standards such as ASTM or DIN. In regions like South America and Africa, where environmental conditions may lead to corrosion, opting for galvanized or stainless steel may be necessary.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance. It performs well under moderate temperature and pressure conditions, making it suitable for applications where weight reduction is critical.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can lead to energy savings in applications like automotive and aerospace. However, it is less durable than steel and may not be suitable for high-load applications.

Impact on Application:

Aluminum couplings are ideal for applications requiring frequent movement or where reducing overall weight is essential, such as in electric vehicles or robotics.

Considerations for Buyers:

International buyers should be aware of the specific grades of aluminum that meet their application needs and ensure that they comply with relevant standards. In Europe, for instance, EN standards may apply.

Composite Materials

Key Properties:

Composite materials, such as reinforced plastics, offer a unique combination of strength and lightweight characteristics. They exhibit excellent corrosion resistance and can operate in a wide range of temperatures.

Pros & Cons:

The major advantage of composites is their resistance to corrosion and chemicals, making them suitable for harsh environments. However, they can be more expensive and may require specialized manufacturing processes.

Impact on Application:

Composites are particularly useful in the chemical processing and food industries, where contamination and corrosion are significant concerns.

Considerations for Buyers:

Buyers should assess the specific chemical compatibility of composite materials with the media they will encounter. Additionally, they should verify that suppliers adhere to industry standards for composite materials.

Stainless Steel

Key Properties:

Stainless steel is highly resistant to corrosion and oxidation, making it suitable for challenging environments. It maintains its strength at high temperatures and is often used in food and pharmaceutical applications.

Pros & Cons:

The key advantage of stainless steel is its durability and resistance to corrosion. However, it is typically more expensive than carbon steel, and its manufacturing process can be more complex.

Impact on Application:

Stainless steel couplings are ideal for applications in industries such as food processing, pharmaceuticals, and marine environments, where hygiene and corrosion resistance are critical.

Considerations for Buyers:

Buyers must ensure compliance with international standards such as ASTM A276 for stainless steel grades. In regions like the Middle East, where humidity can lead to corrosion, stainless steel is often preferred.

Summary Table

| Material | Typical Use Case for motor shaft coupling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, industrial applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Automotive, robotics | Lightweight | Less durable than steel | Medium |

| Composite | Chemical processing, food industry | Excellent corrosion resistance | Higher cost, specialized mfg | High |

| Stainless Steel | Food processing, pharmaceutical | Corrosion resistant, durable | Higher cost, complex mfg | High |

This guide serves as a strategic resource for international B2B buyers, enabling them to make informed decisions on material selection for motor shaft couplings based on their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for motor shaft coupling

Motor shaft couplings are critical components in various industries, ensuring the effective transmission of power between motors and shafts. Understanding the manufacturing processes and quality assurance measures is essential for international B2B buyers to make informed decisions. This section explores the typical manufacturing stages, techniques, and quality control standards relevant to motor shaft couplings.

Manufacturing Processes

The manufacturing of motor shaft couplings involves several key stages, each crucial for ensuring the final product meets industry standards and customer specifications.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials for motor shaft couplings include:

- Steel Alloys: Known for their strength and durability, steel alloys are often used for heavy-duty applications.

- Aluminum: Lightweight and corrosion-resistant, aluminum is used in applications where weight savings are critical.

- Plastic Composites: These are used in environments where corrosion resistance is essential, and loads are relatively low.

Material preparation includes processes such as cutting, machining, and heat treatment to enhance the material properties.

2. Forming

Forming techniques shape the prepared materials into the desired coupling configuration. Common techniques include:

- Machining: Precision machining is used to create exact dimensions and tolerances. CNC (Computer Numerical Control) machines are often employed to achieve high accuracy.

- Forging: This technique involves shaping the material using compressive forces, resulting in a strong and dense structure.

- Casting: Used for more complex shapes, casting involves pouring molten material into a mold.

Each technique has its advantages, and the choice depends on factors such as the complexity of the design, production volume, and material properties.

3. Assembly

Once the components are formed, they are assembled to create the final coupling. This step may involve:

- Joining Techniques: Welding, bolting, or using adhesive bonding to secure components.

- Alignment: Ensuring that the coupling aligns properly with both the motor and the shaft to prevent wear and mechanical failure.

Assembly quality is critical, as misalignment can lead to significant operational issues.

4. Finishing

The final stage involves finishing processes that enhance the appearance and functionality of the couplings. This may include:

- Surface Treatment: Techniques such as anodizing, plating, or painting improve corrosion resistance and surface hardness.

- Balancing: Dynamic balancing is performed to reduce vibrations during operation, which can prolong the lifespan of the coupling and connected equipment.

Quality Assurance

Quality assurance is paramount in manufacturing motor shaft couplings, ensuring that products meet specific standards and perform reliably in their applications.

International Standards

Several international standards govern the quality of motor shaft couplings:

- ISO 9001: This standard outlines the requirements for a quality management system, emphasizing customer satisfaction and continuous improvement.

- CE Marking: Required in the European Union, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) provides standards for couplings used in the oil and gas industry, ensuring safety and reliability.

Quality Control Checkpoints

Quality control is integrated into various stages of the manufacturing process, with specific checkpoints including:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify defects early.

- Final Quality Control (FQC): The finished products undergo rigorous testing to confirm they meet all design and performance specifications.

Common Testing Methods

To ensure the quality and reliability of motor shaft couplings, several testing methods are employed:

- Dimensional Inspection: Using calipers and micrometers to verify dimensions against specifications.

- Material Testing: Tensile, hardness, and impact tests to confirm material properties.

- Performance Testing: Evaluating the coupling under operational conditions to assess performance characteristics such as torque capacity and vibration levels.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are actionable steps to assess supplier quality:

- Supplier Audits: Conduct regular audits of potential suppliers to evaluate their manufacturing processes and quality management systems.

- Request Quality Reports: Ask suppliers for detailed reports on their quality control measures, including testing results and certifications.

- Third-Party Inspections: Engage independent third-party organizations to conduct inspections of manufacturing facilities and products before shipment.

QC and Certification Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe must be aware of the nuances in quality control and certification:

- Regional Regulations: Different regions may have specific regulations regarding product certification. For instance, products sold in the EU must comply with CE marking requirements.

- Cultural Considerations: Understanding the local business culture and communication styles can facilitate better supplier relationships and quality assurance practices.

- Logistics and Supply Chain: Be mindful of the logistics involved in shipping products internationally, as delays can impact product quality and compliance.

By comprehensively understanding the manufacturing processes and quality assurance standards for motor shaft couplings, international B2B buyers can make informed decisions that enhance operational efficiency and product reliability.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for motor shaft coupling Sourcing

Understanding the cost structure and pricing dynamics of motor shaft couplings is crucial for international B2B buyers. This analysis will cover the main components of cost, the factors influencing pricing, and provide actionable insights for effective negotiation and sourcing.

Cost Components

-

Materials: The choice of materials significantly impacts the cost of motor shaft couplings. Common materials include stainless steel, aluminum, and various alloys. Specialty materials may be required for specific applications, adding to the cost. Buyers should consider the long-term benefits of more durable materials versus upfront costs.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. Regions with lower labor costs may offer cheaper products, but this could come at the expense of quality. Understanding the labor market in the supplier’s country can provide insights into the potential quality and pricing of the couplings.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Suppliers with streamlined operations may offer competitive pricing, while those with higher overheads may need to pass costs onto buyers.

-

Tooling: Custom couplings often require specialized tooling, which can be a significant upfront investment for manufacturers. Buyers should inquire about tooling costs when considering custom designs, as these can affect overall pricing.

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Implementing stringent QC processes ensures that products meet required specifications and standards. This can add to the cost but is essential for ensuring reliability, especially in critical applications. Buyers should weigh the cost of QC against potential risks associated with low-quality components.

-

Logistics: Shipping and transportation costs can vary widely based on location and method. Buyers in Africa, South America, the Middle East, and Europe must account for these costs, especially when sourcing from overseas suppliers. Understanding Incoterms can help in negotiating who bears the shipping risk and cost.

-

Margin: Suppliers will mark up prices to maintain profit margins. Understanding the typical margin in the industry can help buyers identify whether a quoted price is reasonable.

Price Influencers

-

Volume/MOQ: Higher order volumes typically lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQ) to achieve better pricing.

-

Specifications/Customization: Custom couplings or those with specific features (e.g., higher torque ratings) will generally cost more. Buyers must balance the need for customization with budget constraints.

-

Materials: As noted, the choice of material affects pricing. Buyers should specify their material requirements clearly to avoid unexpected costs.

-

Quality/Certifications: Products that meet international standards or have specific certifications often come at a premium. However, investing in quality can reduce long-term operational costs due to fewer failures and maintenance needs.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Building relationships with trusted suppliers may yield better terms over time.

-

Incoterms: Understanding Incoterms is crucial for determining the final price. Different terms can affect shipping costs and responsibilities, impacting the total cost of ownership.

Buyer Tips

-

Negotiate Wisely: Leverage volume discounts and long-term contracts to negotiate better prices. Develop strong relationships with suppliers to facilitate more favorable terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but all associated costs, including maintenance, downtime, and logistics. A slightly higher initial cost may lead to lower overall expenses if the coupling is more reliable.

-

Pricing Nuances: Be aware that prices can fluctuate based on market conditions, currency exchange rates, and geopolitical factors. Regularly review and update procurement strategies to adapt to these changes.

-

Conduct Benchmarking: Regularly compare prices and offerings from various suppliers to ensure competitive pricing. Use industry reports and market analyses to inform your negotiations.

-

Regional Considerations: Buyers from regions like Saudi Arabia and Colombia should be mindful of local regulations, tariffs, and trade agreements that may affect pricing and availability.

Disclaimer

Prices are indicative and can vary based on market conditions, supplier negotiations, and specific requirements. Always consult with multiple suppliers and conduct thorough due diligence to ensure the best value for your sourcing needs.

Spotlight on Potential motor shaft coupling Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘motor shaft coupling’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for motor shaft coupling

Understanding the technical properties and terminology associated with motor shaft couplings is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances negotiations and supplier interactions.

Critical Specifications

-

Material Grade

– Definition: This refers to the specific type of material used in the coupling, often designated by a grade that signifies its mechanical properties, such as strength and corrosion resistance.

– B2B Importance: Selecting the right material grade is vital for ensuring the coupling can withstand operational stresses and environmental conditions. For example, stainless steel grades are preferred in corrosive environments, common in sectors like agriculture in South America or oil and gas in the Middle East. -

Torque Capacity

– Definition: Torque capacity indicates the maximum torque that a coupling can transmit without failure.

– B2B Importance: Understanding torque capacity helps buyers choose couplings that match the demands of their specific applications, thereby preventing premature failure and costly downtimes. This is particularly important in heavy machinery used in African mining operations. -

Tolerance

– Definition: Tolerance refers to the allowable deviation in dimensions of the coupling components, which ensures proper fit and function.

– B2B Importance: High tolerance levels are essential for precision applications, such as in servo motors used in European manufacturing. Poor tolerances can lead to misalignment and operational inefficiencies. -

Shaft Diameter

– Definition: This specification indicates the diameter of the shaft that the coupling is designed to fit.

– B2B Importance: Proper sizing is crucial for effective power transmission. Buyers must ensure that couplings fit the shafts of their motors and machinery to avoid operational disruptions, especially in the diverse industrial setups across Africa and the Middle East. -

Angular Misalignment Capacity

– Definition: This property defines the ability of a coupling to accommodate angular misalignments between connected shafts.

– B2B Importance: In real-world applications, misalignments are common due to thermal expansion or installation errors. Couplings with high angular misalignment capacity can help maintain performance and reduce wear, which is essential for long-term operational reliability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is critical for buyers looking for quality assurance and compatibility with existing systems, especially when sourcing components globally. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their procurement strategy effectively, ensuring they meet supplier requirements while managing inventory costs. -

RFQ (Request for Quotation)

– Definition: A document that a buyer sends to suppliers to request pricing and terms for specific goods or services.

– Importance: An RFQ is a vital tool for comparing quotes from multiple suppliers, enabling buyers to negotiate better pricing and terms, especially in competitive markets across Europe and South America. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is essential for international transactions, as they clarify shipping responsibilities and risks, which is particularly relevant for buyers in regions with complex logistics, such as Africa and the Middle East. -

Lead Time

– Definition: The amount of time that passes from the initiation of a process until its completion.

– Importance: Understanding lead times is crucial for effective project planning. Buyers must account for manufacturing and shipping times, especially when sourcing from overseas suppliers.

By grasping these essential properties and terminologies, international B2B buyers can enhance their procurement processes, mitigate risks, and ensure they select the most suitable motor shaft couplings for their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the motor shaft coupling Sector

In the evolving landscape of motor shaft couplings, international B2B buyers are faced with a dynamic market driven by several key factors. Global demand for efficient energy solutions and automation technologies is escalating, particularly in sectors such as manufacturing, logistics, and renewable energy. Countries in Africa, South America, the Middle East, and Europe are increasingly investing in infrastructure and industrialization, which in turn fuels the need for reliable motor and shaft systems. Technological advancements such as IoT integration in motor systems are reshaping sourcing strategies, enabling predictive maintenance and enhanced operational efficiency.

Illustrative Image (Source: Google Search)

Emerging trends include a shift towards customization and modular designs that cater to specific application needs, allowing for greater flexibility and efficiency. Furthermore, the rise of online marketplaces and digital procurement platforms is revolutionizing sourcing, enabling buyers to compare products and suppliers quickly. Buyers must also navigate regional regulatory requirements, which can impact sourcing decisions, especially in regions with varying standards and compliance measures. Understanding these dynamics is crucial for making informed purchasing decisions that align with both operational goals and market expectations.

Sustainability & Ethical Sourcing in B2B

As environmental concerns become increasingly paramount, sustainability in sourcing motor shaft couplings is essential for B2B buyers. The environmental impact of manufacturing processes, including energy consumption and waste production, necessitates a closer examination of supplier practices. Buyers should prioritize suppliers that demonstrate a commitment to sustainable practices, including the use of recycled materials and energy-efficient manufacturing processes.

Ethical supply chains are also critical, as buyers seek to ensure that their sourcing practices align with corporate social responsibility goals. This includes evaluating suppliers based on their labor practices and adherence to fair trade principles. Furthermore, obtaining green certifications such as ISO 14001 or using materials that are certified as sustainable can enhance a company’s reputation and compliance with international standards. By focusing on sustainability, B2B buyers not only contribute to environmental stewardship but also position themselves competitively in an increasingly eco-conscious market.

Brief Evolution/History

The history of motor shaft couplings reflects the broader advancements in engineering and manufacturing. Initially designed for basic mechanical connections, couplings have evolved significantly with the advent of advanced materials and precision engineering. The introduction of high-performance materials and computer-aided design (CAD) technologies has allowed manufacturers to create couplings that are not only more durable but also capable of handling higher loads and speeds. This evolution continues today, with ongoing research and development aimed at enhancing the performance and sustainability of motor shaft couplings, ensuring that they meet the demands of modern industrial applications.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of motor shaft coupling

-

What should I consider when vetting suppliers for motor shaft couplings?

When vetting suppliers, prioritize their industry experience, production capabilities, and reputation in the market. Verify their compliance with international quality standards (e.g., ISO certifications) and assess their ability to provide documentation and references from previous clients. Additionally, inquire about their manufacturing processes and the materials used, especially for regions with specific environmental conditions, such as corrosion resistance in coastal areas of Africa or extreme temperatures in the Middle East. -

Can I customize motor shaft couplings to meet specific requirements?

Yes, many suppliers offer customization options for motor shaft couplings. You can request specific dimensions, materials, or performance characteristics tailored to your machinery’s needs. When discussing customization, provide detailed specifications and any relevant operational conditions. Be prepared for potential lead times to increase, as custom products may require additional design and testing phases before production. -

What are the typical minimum order quantities (MOQ) and lead times for motor shaft couplings?

MOQs for motor shaft couplings can vary significantly based on the supplier and the complexity of the product. Generally, standard products might have lower MOQs, while customized items may necessitate larger orders. Lead times typically range from a few weeks to several months, depending on production schedules and your location. Always clarify these terms with suppliers during initial discussions to align with your project timelines. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should implement rigorous quality assurance (QA) protocols throughout their manufacturing process. Expect to receive certifications proving compliance with international standards, such as ISO 9001. Inquire about their testing methods, including stress tests and inspections for dimensional accuracy. Request samples or pilot batches to assess quality firsthand before placing larger orders. -

How can I handle logistics and shipping for international orders?

Logistics for international orders can be complex, requiring careful planning. Discuss shipping options with your supplier, including Incoterms that define responsibilities for costs and risks during transit. Consider working with freight forwarders experienced in your region to navigate customs regulations efficiently. Additionally, confirm lead times and shipping methods to ensure timely delivery aligned with your operational needs. -

What should I do if there is a dispute with a supplier?

In the event of a dispute, maintain clear and open communication with your supplier to resolve issues amicably. Document all agreements and correspondence to support your position. If necessary, refer to the terms outlined in your contract, including any arbitration clauses. Depending on the severity, you may consider involving a legal advisor familiar with international trade laws to explore your options for resolution. -

What certifications should I look for when sourcing motor shaft couplings?

When sourcing motor shaft couplings, look for certifications that demonstrate compliance with international standards. Key certifications include ISO 9001 for quality management systems and ISO 14001 for environmental management. Additionally, industry-specific certifications may be relevant, such as API or ANSI for oil and gas applications. These certifications can provide assurance of the supplier’s commitment to quality and sustainability. -

How can I ensure the compatibility of couplings with my existing equipment?

To ensure compatibility, provide your supplier with detailed specifications of your existing equipment, including shaft dimensions, torque requirements, and operating conditions. It may also be beneficial to share schematics or installation manuals. Collaborate with your supplier’s engineering team to validate that the selected coupling meets all operational requirements, including alignment and load capacities, to prevent performance issues post-installation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for motor shaft coupling

In conclusion, strategic sourcing of motor shaft couplings is essential for international B2B buyers to enhance operational efficiency and reduce long-term costs. By understanding the diverse types of couplings available—ranging from rigid to flexible options—and their specific applications, buyers can select components that align with their operational needs. It is imperative to evaluate suppliers based on their manufacturing standards, material quality, and after-sales support to mitigate risks associated with sourcing.

B2B buyers in regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships that offer not only competitive pricing but also robust technical expertise and logistical capabilities. By fostering these relationships, companies can ensure reliable supply chains and superior product performance, which are crucial in today’s dynamic market.

Looking ahead, the demand for high-quality motor shaft couplings will only grow as industries continue to innovate and expand. Now is the time to leverage strategic sourcing practices that emphasize quality and value. Engage with suppliers who are committed to sustainability and technological advancements, ensuring your business is well-equipped for future challenges and opportunities.