Master Polyurethane Molding: Your Comprehensive B2B

Introduction: Navigating the Global Market for polyurethane molding

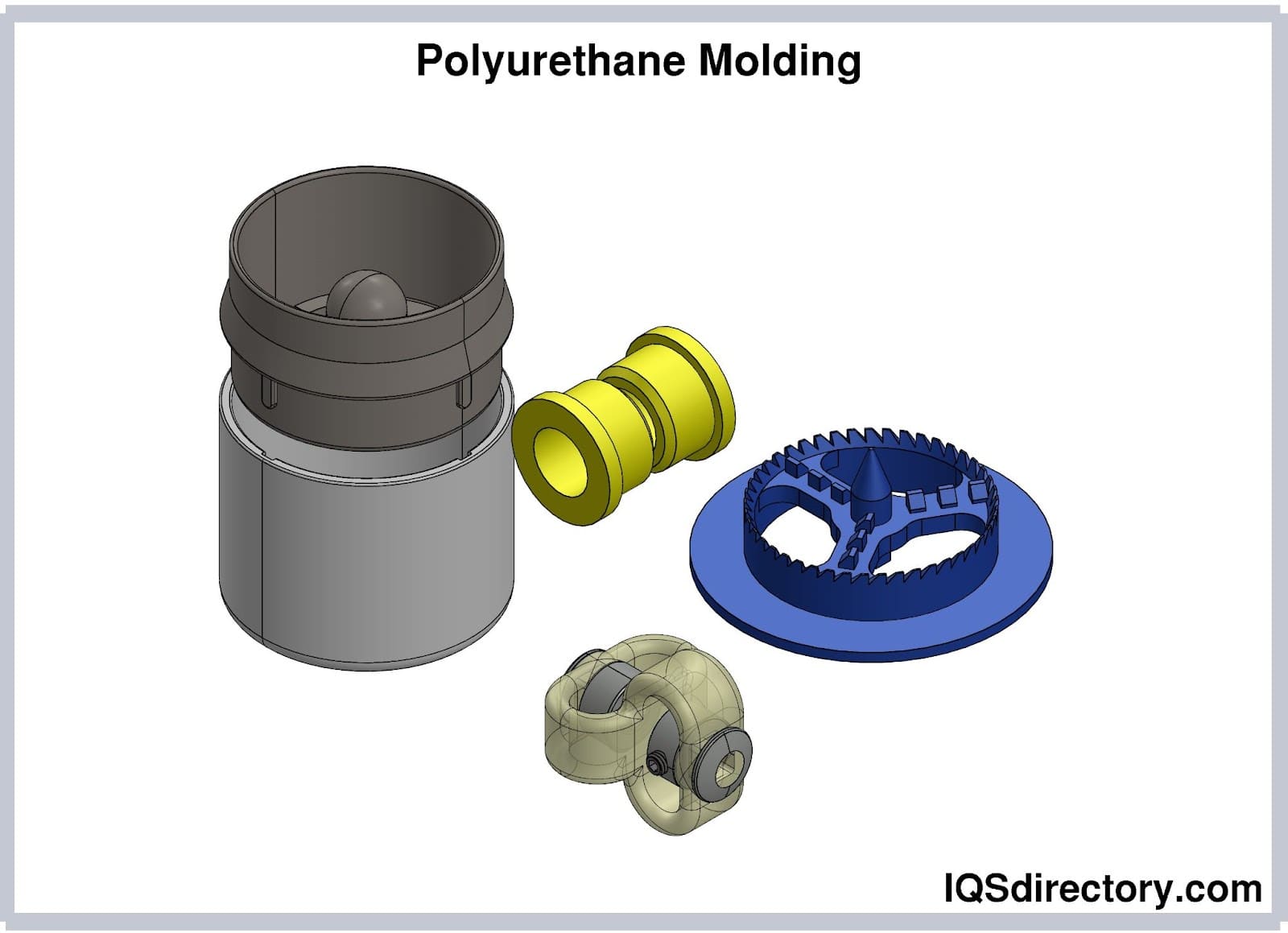

Polyurethane molding stands at the forefront of modern manufacturing, offering unparalleled versatility and performance across diverse industries. As international B2B buyers from Africa, South America, the Middle East, and Europe seek reliable solutions for high-performance components, understanding the intricacies of polyurethane molding becomes crucial. This guide delves into the various molding techniques—such as cast and injection molding—highlighting their unique advantages and applications.

By exploring the properties and uses of polyurethane, buyers can identify the best material formulations tailored to their specific needs, from automotive parts to industrial equipment. The guide will also cover essential aspects of manufacturing quality control, supplier selection, and cost considerations, ensuring a comprehensive understanding of the global polyurethane market landscape.

Moreover, this resource aims to empower buyers with the knowledge necessary to make informed sourcing decisions. With insights into market trends and frequently asked questions, stakeholders will be equipped to navigate the complexities of polyurethane molding confidently. Whether you are looking to enhance product durability, optimize production efficiency, or reduce costs, this guide is an invaluable tool for achieving your business objectives in the dynamic global marketplace.

Understanding polyurethane molding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cast Molding | Utilizes open molds; suitable for complex designs; versatile | Automotive parts, industrial components | Pros: Cost-effective for low volumes; high customization. Cons: Slower production rate compared to injection molding. |

| Injection Molding | Closed mold process; high precision; ideal for mass production | Consumer goods, medical devices, automotive parts | Pros: High efficiency; consistent quality; rapid production. Cons: Higher initial tooling costs. |

| Reaction Injection Molding (RIM) | Combines liquid polyol and isocyanate; thick-walled parts; low pressure | Large automotive components, industrial parts | Pros: Good for large parts; adaptable material properties. Cons: Limited to certain geometries; slower than injection molding. |

| Foam Molding | Produces lightweight, insulating components; can be rigid or flexible | Furniture, insulation, automotive interiors | Pros: Excellent thermal insulation; customizable density. Cons: May require additional processing for finishing. |

| Thermoplastic Polyurethane (TPU) Molding | Flexible and durable; can be remolded; suitable for varying temperatures | Footwear, medical devices, automotive applications | Pros: High elasticity; recyclable; resistant to abrasion. Cons: Limited to specific applications; can be more expensive. |

Cast Molding

Cast molding is characterized by the use of open molds where liquid polyurethane is poured and allowed to cure. This method excels in producing intricate designs and is suitable for both low and high production volumes. Buyers should consider this technique when requiring complex geometries or specific material properties like high durability or abrasion resistance. It’s a cost-effective choice for custom parts, though it may have slower production rates compared to other methods.

Illustrative Image (Source: Google Search)

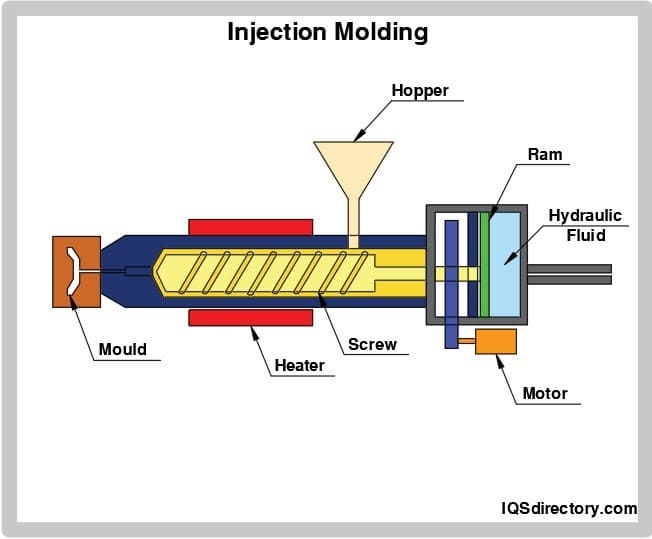

Injection Molding

Injection molding is a highly efficient process that involves injecting molten polyurethane into a closed mold at high pressure. This method is ideal for high-volume production, providing consistent quality and precision. B2B buyers looking for rapid production of components with tight tolerances will find this method advantageous, despite its higher initial tooling costs. It is particularly effective for industries like consumer goods and medical devices, where uniformity is critical.

Reaction Injection Molding (RIM)

RIM is a specialized process that combines polyol and isocyanate in a way that allows for the creation of thick-walled parts. This method is particularly suited for large automotive components and industrial parts. Buyers should consider RIM when needing parts that require specific material characteristics, as it allows for varying properties. However, it may be limited to certain geometries and has a slower production rate compared to injection molding.

Foam Molding

Foam molding produces lightweight components that can be either rigid or flexible, making it ideal for applications requiring insulation or cushioning. This method is widely used in furniture and automotive interiors. Buyers should assess the thermal insulation properties and customizable density options available in foam molding. While it offers excellent performance, additional processing may be necessary for finishing, which can affect overall production timelines.

Thermoplastic Polyurethane (TPU) Molding

TPU molding produces flexible and durable components that can be remolded and are suitable for a wide range of temperatures. This method is commonly used in applications such as footwear and medical devices. B2B buyers should note the high elasticity and abrasion resistance of TPU, making it ideal for demanding environments. However, it may be more expensive and limited to specific applications, which should be factored into purchasing decisions.

Related Video: The 6 Different Plastic Molding Processes (Explained)

Key Industrial Applications of polyurethane molding

| Industry/Sector | Specific Application of Polyurethane Molding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Bumpers, bushings, and fenders | Enhanced durability and impact resistance | Ensure compliance with automotive standards and material specifications. |

| Construction | Insulation materials and sealants | Improved energy efficiency and moisture resistance | Look for suppliers with expertise in thermal insulation properties. |

| Medical | Custom medical devices and components | High performance in demanding environments | Verify certifications and biocompatibility of materials used. |

| Furniture | Cushions and ergonomic support systems | Increased comfort and durability for end-users | Focus on suppliers offering customizable formulations for specific needs. |

| Industrial Equipment | Rollers, wheels, and machinery components | Reduced wear and tear, leading to lower maintenance costs | Assess the specific load-bearing requirements and environmental factors. |

Automotive Applications

In the automotive industry, polyurethane molding is crucial for producing components like bumpers, bushings, and fenders. These parts benefit from polyurethane’s exceptional durability and impact resistance, which are essential for protecting vehicles and enhancing safety. For international B2B buyers, particularly in Europe, it is important to ensure that suppliers adhere to stringent automotive standards and material specifications to maintain compliance and quality.

Construction Applications

Polyurethane molding plays a significant role in the construction sector, particularly in the production of insulation materials and sealants. These products help improve energy efficiency and provide moisture resistance, which are vital for modern building practices. Buyers in regions like Africa and South America should prioritize sourcing from suppliers who specialize in thermal insulation properties to ensure optimal performance in various climates.

Medical Applications

In the medical field, polyurethane molding is utilized for creating custom medical devices and components that require high performance in demanding environments. The material’s versatility allows for the production of parts that meet stringent safety and regulatory standards. For B2B buyers in the Middle East and Europe, verifying the certifications and biocompatibility of materials is crucial to ensure patient safety and compliance with health regulations.

Furniture Applications

Polyurethane molding is widely used in the furniture industry for producing cushions and ergonomic support systems. These applications benefit from the material’s ability to provide increased comfort and durability, significantly enhancing the user experience. B2B buyers should focus on suppliers who offer customizable formulations tailored to specific comfort needs, especially in competitive markets across Europe.

Industrial Equipment Applications

In industrial settings, polyurethane molding is applied in the production of rollers, wheels, and various machinery components. These parts are designed to reduce wear and tear, leading to lower maintenance costs and increased operational efficiency. Buyers should assess the specific load-bearing requirements and environmental factors to select the most suitable polyurethane formulations, ensuring optimal performance in their equipment.

Related Video: polyurethane foam molding

Strategic Material Selection Guide for polyurethane molding

Polyurethane molding is a versatile process that allows for the production of components tailored to specific applications. Selecting the right material is crucial for ensuring optimal performance and longevity of the molded parts. Below is an analysis of several common materials used in polyurethane molding, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Polyether Polyurethane

Key Properties: Polyether polyurethanes are known for their excellent flexibility, low-temperature performance, and resistance to hydrolysis. They typically have a good temperature rating, often up to 80°C, and exhibit strong abrasion resistance.

Pros & Cons: One of the main advantages of polyether polyurethane is its durability against moisture and chemicals, making it suitable for outdoor applications. However, it can be more expensive than other types of polyurethane and may not perform as well in high-temperature environments.

Impact on Application: This material is ideal for applications requiring flexibility and resistance to water, such as seals, gaskets, and cushioning materials. It is compatible with various media, including water and mild chemicals.

Considerations for International Buyers: Buyers should ensure compliance with regional standards such as ASTM in the US or DIN in Europe. The availability of polyether polyurethane may vary, so sourcing from established suppliers is essential.

2. Polyester Polyurethane

Key Properties: Polyester polyurethanes offer excellent mechanical properties and are known for their high tensile strength and resistance to wear and tear. They can withstand higher temperatures, typically up to 100°C.

Pros & Cons: The primary advantage of polyester polyurethanes is their superior strength and durability, making them suitable for heavy-duty applications. However, they have a lower resistance to moisture compared to polyether variants, which can limit their use in wet environments.

Impact on Application: These materials are often used in automotive parts, industrial wheels, and high-load applications. Their compatibility with oils and solvents makes them suitable for mechanical components.

Considerations for International Buyers: Buyers should be aware of the specific performance requirements in their region and ensure that the materials meet local compliance standards. The cost may be higher due to the enhanced properties, which should be factored into budgeting.

3. Thermoplastic Polyurethane (TPU)

Key Properties: TPU combines the elasticity of rubber with the durability of plastics, offering excellent abrasion resistance and flexibility. It can operate effectively in a temperature range from -40°C to 80°C.

Pros & Cons: The flexibility and resilience of TPU make it suitable for a wide range of applications, including medical devices and consumer goods. However, the production of TPU can be more complex and costly compared to traditional polyurethanes.

Impact on Application: TPU is particularly effective in applications requiring high elasticity and resistance to environmental factors, such as outdoor gear and automotive components. It is compatible with a variety of chemicals and oils.

Considerations for International Buyers: Due to its versatility, TPU is widely accepted across various industries. Buyers should ensure that their suppliers adhere to international standards, as TPU formulations can vary significantly.

4. Rigid Polyurethane Foam

Key Properties: Rigid polyurethane foam is characterized by its low density and high thermal insulation properties. It typically performs well in temperature ranges from -50°C to 100°C.

Pros & Cons: This material is lightweight and offers excellent insulation, making it ideal for building and construction applications. However, its rigidity may limit its use in applications requiring flexibility.

Impact on Application: Rigid foam is commonly used in insulation panels, refrigeration, and construction materials. It is compatible with various construction media but may not withstand high mechanical loads.

Considerations for International Buyers: Compliance with building codes and insulation standards is critical. Buyers should verify that the foam meets local regulations, especially in construction and insulation applications.

Summary Table

| Material | Typical Use Case for polyurethane molding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyether Polyurethane | Seals, gaskets, cushioning materials | Excellent flexibility and moisture resistance | Higher cost than other polyurethanes | Medium |

| Polyester Polyurethane | Automotive parts, industrial wheels | Superior strength and durability | Lower moisture resistance | High |

| Thermoplastic Polyurethane | Medical devices, consumer goods | High elasticity and abrasion resistance | More complex and costly production | High |

| Rigid Polyurethane Foam | Insulation panels, refrigeration | Lightweight and excellent thermal insulation | Limited flexibility | Medium |

This strategic material selection guide provides international B2B buyers with critical insights into the various types of polyurethane materials, helping them make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane molding

The manufacturing process for polyurethane molding is intricate and requires a clear understanding of both the technical stages involved and the quality assurance measures that ensure product reliability. This section will break down these components into manageable parts, providing international B2B buyers with actionable insights relevant to their procurement strategies.

Manufacturing Process for Polyurethane Molding

The manufacturing process for polyurethane molding typically consists of four main stages: material preparation, forming, assembly, and finishing. Each of these stages is crucial for producing high-quality polyurethane products.

1. Material Preparation

In this initial stage, raw materials, primarily polyols and isocyanates, are carefully measured and mixed. The specific formulation can significantly affect the final properties of the polyurethane, including flexibility, hardness, and durability. Advanced mixing techniques, such as high-shear mixing, ensure a homogeneous blend, which is vital for consistent quality.

Key Considerations:

– Material Sourcing: Ensure that suppliers provide high-quality raw materials that meet industry specifications.

– Formulation: Tailor formulations to meet specific application needs, such as temperature resistance or chemical exposure.

2. Forming

The forming stage involves one of two primary techniques: cast molding or injection molding.

-

Cast Molding: Liquid polyurethane is poured into an open mold and allowed to cure. This method is particularly effective for creating large or complex parts that require detailed geometries.

-

Injection Molding: Molten polyurethane is injected under high pressure into a closed mold. This technique is ideal for high-volume production and allows for tight tolerances and intricate designs.

Key Considerations:

– Mold Design: Invest in precision-engineered molds that can withstand the curing process and maintain dimensional accuracy.

– Temperature Control: Maintain optimal temperature conditions during the curing process to enhance material properties.

3. Assembly

Once the molded parts have cured, they may require assembly, especially if they are components of a larger system. This stage can involve processes such as bonding, fastening, or integrating with other materials.

Key Considerations:

– Compatibility: Ensure that any adhesives or bonding agents used are compatible with polyurethane to avoid degrading the material’s properties.

– Assembly Techniques: Employ methods that minimize stress on the components to maintain their integrity.

4. Finishing

The finishing stage includes any additional treatments required to enhance the product’s performance or aesthetic appeal. This can involve sanding, coating, or applying surface treatments that improve wear resistance or provide UV protection.

Key Considerations:

– Surface Treatments: Select appropriate coatings that enhance durability while maintaining the flexibility of the polyurethane.

– Quality of Finish: Ensure that finishing processes do not introduce defects that could compromise the product’s performance.

Quality Assurance in Polyurethane Molding

Quality assurance (QA) is critical in ensuring that the final products meet international standards and customer expectations. Here are the key aspects of QA for polyurethane molding.

Relevant International Standards

B2B buyers should be aware of various international quality standards that govern polyurethane manufacturing processes:

- ISO 9001: This standard focuses on quality management systems and ensures that organizations consistently meet customer and regulatory requirements.

- CE Marking: Indicates that a product complies with EU safety, health, and environmental protection standards.

- API Standards: Relevant for products used in the oil and gas industry, ensuring they meet specific performance and safety requirements.

Quality Control Checkpoints

To maintain high standards throughout the manufacturing process, several quality control (QC) checkpoints should be implemented:

- Incoming Quality Control (IQC): Inspect raw materials upon arrival to ensure they meet specified standards before entering production.

- In-Process Quality Control (IPQC): Monitor the production process at various stages to identify and correct any deviations from quality standards.

- Final Quality Control (FQC): Conduct thorough inspections of finished products before they are shipped to clients, ensuring they meet all specifications.

Common Testing Methods

Testing is a vital part of the QA process, helping to ensure that products meet required specifications. Common testing methods include:

- Mechanical Testing: Assess properties such as tensile strength, elongation, and hardness.

- Chemical Testing: Evaluate resistance to chemicals and environmental factors.

- Dimensional Inspection: Use calipers and gauges to verify that parts meet specified dimensions and tolerances.

Verifying Supplier Quality Control

B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of their suppliers:

- Conduct Audits: Regularly audit suppliers to ensure compliance with quality standards and practices. This can include on-site visits and reviews of quality management systems.

- Request Quality Reports: Ask suppliers for documentation of their quality control processes, including results from IQC, IPQC, and FQC.

- Engage Third-Party Inspectors: Consider using third-party inspection services to provide an unbiased assessment of product quality and supplier practices.

QC and Certification Nuances for International Buyers

International B2B buyers should be aware of specific nuances related to quality control and certifications that may vary by region:

- Regional Compliance: Understand local regulatory requirements that may differ from international standards, particularly in emerging markets.

- Certification Recognition: Ensure that certifications recognized in one region (e.g., CE marking in Europe) are accepted in the target market to avoid compliance issues.

Conclusion

Navigating the manufacturing processes and quality assurance protocols for polyurethane molding is essential for B2B buyers looking to source high-quality products. By understanding the intricacies of each manufacturing stage and the relevant quality standards, buyers can make informed decisions that enhance their procurement strategies and ensure product reliability. Engaging with suppliers who demonstrate robust quality control practices will further mitigate risks and foster successful international partnerships.

Related Video: Manufacturing Process Of Polyurethane PU Sponge Foam Machine

Comprehensive Cost and Pricing Analysis for polyurethane molding Sourcing

Polyurethane molding is a critical manufacturing process that presents various cost components and pricing structures, particularly important for international B2B buyers. Understanding these elements can help organizations make informed sourcing decisions.

Cost Components of Polyurethane Molding

-

Materials: The cost of polyurethane raw materials is a significant factor. Prices can vary based on the type of polyurethane (e.g., flexible vs. rigid) and the specific formulation required for the intended application. Global fluctuations in the petrochemical market can also impact material costs.

-

Labor: Labor costs include wages for skilled workers who operate molding machines and oversee production. These costs can differ widely depending on geographic location, with higher wages in developed regions such as Europe compared to some parts of Africa and South America.

-

Manufacturing Overhead: This encompasses costs associated with facility operations, utilities, maintenance, and administrative expenses. Efficient operations can lead to lower overhead, which in turn can influence pricing.

-

Tooling: Tooling costs refer to the creation of molds, which can be expensive but are essential for high-quality production. The complexity of the mold directly affects its cost; intricate designs require more precise and costly tooling.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the molded parts meet industry standards and customer specifications. While this adds to the cost, it is crucial for maintaining product integrity and reducing returns.

-

Logistics: Transportation and handling costs must be factored in, especially for international buyers. These costs can fluctuate based on distance, shipping methods, and customs duties.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand, competition, and the perceived value of the service.

Price Influencers

-

Volume/MOQ: The minimum order quantity (MOQ) significantly impacts pricing. Higher volumes usually result in lower per-unit costs due to economies of scale.

-

Specifications/Customization: Customized products often incur additional costs due to unique tooling, material requirements, and extended lead times. Standardized products can be sourced more cost-effectively.

-

Materials: The choice of materials can affect both the performance and the price of the final product. For example, using high-grade polyurethane may increase costs but also enhance durability and longevity.

-

Quality/Certifications: Products that require specific certifications (e.g., ISO, FDA) may come at a premium due to the additional testing and compliance processes involved.

-

Supplier Factors: The reputation, experience, and production capabilities of the supplier can influence pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect total costs, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

Buyer Tips

-

Negotiation: Always negotiate prices and terms with suppliers. Establishing long-term relationships can lead to better pricing and terms over time.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes not just the purchase price but also logistics, maintenance, and potential downtime costs. This approach helps in making more informed sourcing decisions.

-

Pricing Nuances for International Buyers: Be aware of regional market conditions and currency fluctuations. Prices may vary significantly based on local demand and supply dynamics.

-

Seek Local Suppliers: For buyers in Africa and South America, partnering with local suppliers can reduce logistics costs and lead times, enhancing responsiveness.

-

Evaluate Supplier Capabilities: Assess suppliers for their ability to meet specific requirements, including customization, lead times, and production capacities. This evaluation can help in choosing the right partner and securing competitive pricing.

Disclaimer

Prices mentioned in discussions with suppliers may vary based on market conditions and specific project requirements. It is advisable to obtain detailed quotes tailored to your project needs to ensure an accurate assessment of costs.

Spotlight on Potential polyurethane molding Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘polyurethane molding’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for polyurethane molding

Key Technical Properties of Polyurethane Molding

Understanding the essential technical properties of polyurethane molding is crucial for international B2B buyers. These properties directly influence product performance, manufacturing efficiency, and overall project costs. Here are several critical specifications that buyers should consider:

-

Material Grade

– Definition: Material grade refers to the classification of polyurethane based on its chemical composition and physical characteristics, such as hardness and flexibility.

– Importance: Different grades serve specific applications; for instance, softer grades are suitable for cushioning applications, while harder grades are ideal for structural components. Selecting the appropriate grade ensures optimal performance and durability. -

Tolerance

– Definition: Tolerance is the allowable deviation from a specified dimension in manufacturing parts.

– Importance: Precise tolerances are vital for components that must fit seamlessly with other parts. In industries like automotive and aerospace, where safety and functionality are paramount, understanding tolerance requirements can prevent costly rework or failures. -

Density

– Definition: Density indicates the mass of polyurethane per unit volume, typically expressed in grams per cubic centimeter (g/cm³).

– Importance: Density affects the mechanical properties and weight of the final product. For example, lower-density materials may be preferred for lightweight applications, while higher-density materials are chosen for their strength and durability. -

Hardness

– Definition: Hardness measures a material’s resistance to deformation, often assessed using the Shore durometer scale.

– Importance: The hardness of polyurethane affects its wear resistance and suitability for specific applications, such as wheels or seals. Buyers need to match hardness levels with application requirements to ensure longevity and performance. -

Tensile Strength

– Definition: Tensile strength is the maximum amount of tensile (pulling) stress that a material can withstand before failure.

– Importance: This property is crucial for parts that experience significant loads or stresses. Understanding tensile strength helps buyers select materials that will not fail under operational conditions, enhancing safety and reliability.

Common Trade Terminology in Polyurethane Molding

Familiarity with industry jargon is essential for effective communication and negotiation in the polyurethane molding market. Here are some common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify suppliers who can provide customized solutions or specific components needed for their products. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Relevance: This term is critical for budgeting and inventory management. Buyers should confirm MOQs to ensure they can meet production needs without overcommitting financially. -

RFQ (Request for Quote)

– Definition: An RFQ is a document sent to suppliers requesting a quote for specific products or services.

– Relevance: Issuing an RFQ helps buyers obtain competitive pricing and terms from multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a series of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery responsibilities, which are crucial for budgeting and logistics planning. -

Lead Time

– Definition: Lead time is the amount of time taken from the initiation of a process until its completion, often related to manufacturing and delivery.

– Relevance: Understanding lead times helps buyers plan their production schedules and manage inventory effectively, ensuring timely delivery of final products.

Illustrative Image (Source: Google Search)

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing polyurethane molded products, ultimately enhancing project outcomes and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the polyurethane molding Sector

Market Overview & Key Trends

The polyurethane molding sector is experiencing robust growth driven by several global factors, including increasing demand for lightweight, durable materials across various industries such as automotive, aerospace, and consumer goods. Notably, the rise of electric vehicles (EVs) has accelerated the need for high-performance components that polyurethane can provide, particularly in insulation and cushioning applications. Additionally, advancements in B2B technology, such as automation in manufacturing processes and the integration of Industry 4.0, are enhancing production efficiency and product customization.

International B2B buyers are increasingly prioritizing suppliers that offer innovative solutions. For example, the adoption of advanced injection molding techniques allows for the production of intricate designs with minimal waste, appealing to cost-conscious buyers in Africa and South America. Moreover, companies in Europe, particularly in Germany and the UK, are focusing on precision-engineered components that meet stringent quality and environmental standards. This trend is mirrored in the Middle East, where rapid industrialization is driving demand for high-quality polyurethane products.

Emerging sourcing trends emphasize the importance of establishing long-term partnerships with suppliers who can provide not only quality products but also insights into market dynamics and technological advancements. Buyers are encouraged to engage with manufacturers who demonstrate a commitment to continuous improvement and innovation, ensuring they remain competitive in their respective markets.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration for B2B buyers in the polyurethane molding sector. The environmental impact of polyurethane production, particularly concerning chemical waste and emissions, has led to a growing demand for sustainable practices. As a result, ethical sourcing has gained prominence, with companies increasingly seeking suppliers who prioritize eco-friendly materials and processes.

Buyers should look for manufacturers that offer ‘green’ certifications, such as ISO 14001 or those that comply with REACH regulations in Europe, ensuring that their products meet environmental standards. The development of bio-based polyurethanes, which utilize renewable resources, is a significant trend in sustainable sourcing. These materials not only reduce reliance on fossil fuels but also offer comparable performance to traditional polyurethane.

Additionally, ethical supply chains are critical for maintaining brand integrity and consumer trust. International buyers should ensure their suppliers are transparent about their sourcing practices and labor standards, aligning with global initiatives for responsible production. By prioritizing sustainability, businesses can enhance their market position and appeal to a growing segment of eco-conscious consumers.

Brief Evolution/History

The polyurethane molding industry has evolved significantly since its inception in the late 1930s. Initially developed as a synthetic substitute for rubber during World War II, polyurethane quickly gained recognition for its versatility and durability. The introduction of polyisocyanates and polyether polyols in the 1950s marked a turning point, enabling mass production and expanding applications across various sectors.

Today, advancements in polyurethane chemistry continue to drive innovation, with manufacturers focusing on enhancing material properties such as strength, flexibility, and environmental resistance. This evolution not only reflects the material’s adaptability but also aligns with the increasing demand for high-performance, sustainable solutions in the global marketplace. As the industry progresses, international B2B buyers must stay informed about these developments to leverage the benefits of modern polyurethane molding technologies effectively.

Related Video: Chapter 9: International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane molding

-

What criteria should I use to vet suppliers of polyurethane molding?

When vetting suppliers, consider their experience and expertise in polyurethane molding, specifically their track record in your industry. Look for certifications such as ISO 9001, which indicates quality management systems. Request case studies or references from previous clients to gauge their reliability. Additionally, assess their production capabilities, technology used, and their ability to meet your specific requirements for customization and volume. -

Can polyurethane molding be customized to meet specific project needs?

Yes, polyurethane molding is highly customizable. Suppliers can tailor material formulations to achieve desired properties like hardness, flexibility, and resistance to chemicals or abrasion. It’s essential to communicate your specifications clearly, including design complexity and performance requirements. Collaborate closely with your supplier during the design phase to ensure that the final product meets your expectations. -

What are the typical minimum order quantities (MOQs) and lead times for polyurethane molding?

MOQs for polyurethane molding can vary significantly based on the supplier and the complexity of the parts. Generally, low-volume projects may start at 100 units, while high-volume runs can have much higher MOQs. Lead times typically range from 4 to 12 weeks, depending on the complexity of the design and the production schedule. Always confirm these details upfront to align expectations. -

What payment terms are common in international polyurethane molding transactions?

Payment terms can differ among suppliers, but common practices include a deposit upon order confirmation (usually 30-50%) and the balance upon completion or before shipping. For international transactions, consider using letters of credit or escrow services to mitigate risk. Be sure to clarify payment methods accepted, currency exchange implications, and any additional fees that may apply. -

How can I ensure quality assurance and certifications from my polyurethane molding supplier?

Request documentation of quality assurance practices, including inspection reports and compliance certifications. Suppliers should adhere to recognized standards such as ISO 9001 or specific industry certifications. Inquire about their testing processes for raw materials and finished products, including mechanical, thermal, and chemical testing. Regular audits or site visits can also help verify adherence to quality standards. -

What logistics considerations should I keep in mind when sourcing polyurethane molding internationally?

International logistics can be complex, so consider factors such as shipping methods, customs regulations, and import duties. Work with suppliers who have experience in international shipping and can provide Incoterms to clarify responsibilities. Additionally, factor in lead times for shipping and customs clearance, as these can affect your overall project timeline. Establish clear communication with your logistics partner to avoid delays.

-

How can disputes over product quality or delivery be resolved with suppliers?

To mitigate disputes, establish clear terms and conditions in your contract, including quality benchmarks and delivery timelines. Maintain open lines of communication with your supplier throughout the production process. In case of issues, document everything—photos, emails, and reports—and engage in constructive dialogue to find a solution. Many suppliers are willing to negotiate and resolve problems amicably to maintain the business relationship. -

What are the environmental considerations when sourcing polyurethane molding?

Polyurethane production can have environmental impacts, so inquire about your supplier’s sustainability practices. Look for suppliers who utilize eco-friendly materials and processes, such as bio-based polyurethanes. Certifications like ISO 14001 can indicate a commitment to environmental management. Understanding the lifecycle of the product and its recyclability can also inform your sourcing decisions, aligning with corporate sustainability goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for polyurethane molding

In summary, strategic sourcing in polyurethane molding offers international B2B buyers a pathway to enhance product quality and operational efficiency. By understanding the nuances of various molding methods, such as cast and injection molding, buyers can make informed decisions tailored to their specific needs. Key factors to consider include production volume, part complexity, and material properties, which directly impact both cost and performance.

The value of strategic sourcing lies in its ability to foster partnerships with experienced manufacturers who can provide customized solutions and advanced technology. As polyurethane applications continue to expand across industries—from automotive to medical—buyers must remain agile and proactive in sourcing high-performance materials that meet evolving market demands.

Looking ahead, the increasing emphasis on sustainability and innovation within the polyurethane industry presents new opportunities for collaboration and growth. International buyers from Africa, South America, the Middle East, and Europe should leverage these trends to secure competitive advantages. Engage with trusted suppliers who prioritize quality, sustainability, and advanced manufacturing techniques to ensure your projects succeed in this dynamic landscape.