Master Sourcing Air Pressure Switches: Save Costs & Enhance

Introduction: Navigating the Global Market for air pressure switch

Air compressor pressure switches are essential components in a myriad of industrial applications, acting as the guardians of operational efficiency and safety. These devices ensure that compressed air systems function within designated pressure limits, preventing potential equipment failures and costly downtime. For B2B buyers, particularly those operating in diverse environments across Africa, South America, the Middle East, and Europe, understanding the intricacies of air pressure switches is vital for effective procurement.

This guide provides a thorough exploration of the global market for air pressure switches, equipping buyers with critical insights to navigate this complex landscape. It covers various types of pressure switches and their specific applications, enabling informed choices based on operational needs. Buyers will also delve into material choices and durability, ensuring that their selections align with both budgetary constraints and environmental considerations.

Additionally, the guide examines manufacturing standards and quality control, offering strategies for vetting suppliers and ensuring product reliability. It includes a detailed cost breakdown and market trends, shedding light on pricing dynamics and potential savings opportunities. Finally, a section on frequently asked questions addresses common challenges, providing actionable solutions to enhance procurement strategies.

Empowered with this knowledge, international B2B buyers can make informed sourcing decisions that not only optimize their supply chains but also drive long-term operational success.

Understanding air pressure switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

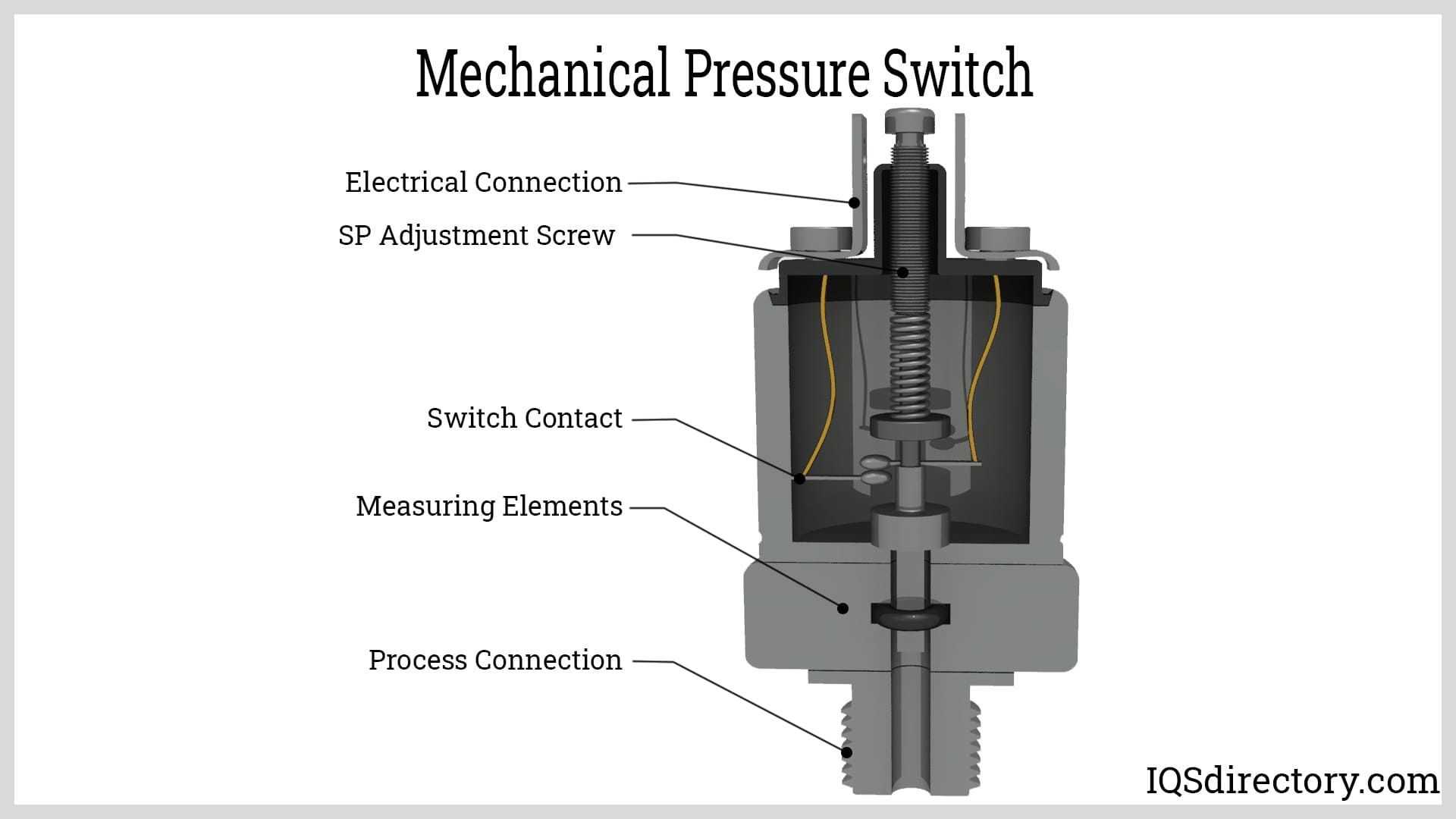

| Mechanical Pressure Switch | Utilizes mechanical components; adjustable setpoints | General industrial, light manufacturing | Pros: Reliable, cost-effective. Cons: Limited to moderate pressures, may require calibration. |

| Electronic/Digital Switch | Sensor-based, digital displays, programmable controls | Precision industries, automation | Pros: Flexible, accurate, easy data integration. Cons: Higher cost, requires stable power supply. |

| Differential Pressure Switch | Measures pressure differences between two points | Critical process control, HVAC | Pros: Highly sensitive, controls cycling. Cons: Complex setup, higher initial cost. |

| Heavy-Duty/High-Pressure Switch | Reinforced components for high max PSI (often >250 PSI) | Mining, petrochemical, large-scale factories | Pros: Robust, handles harsh conditions. Cons: More expensive, may be over-specified for light use. |

| UL/CE Certified Switch | Meets international safety/quality standards | Export markets, regulated sectors | Pros: Ensures compliance, trusted globally. Cons: May carry premium for certification. |

Mechanical Pressure Switch

Mechanical pressure switches are the industry standard for basic air compressor applications. These switches operate using mechanical components such as diaphragms or bellows to control pressure settings. They are cost-effective and reliable, making them suitable for various sectors, including manufacturing in Africa and South America. Buyers should ensure that the PSI ratings and electrical compatibility align with local standards. Regular maintenance and calibration are necessary to maintain their performance, but the simplicity of these switches often makes them an attractive choice for budget-conscious operations.

Electronic/Digital Pressure Switch

Electronic pressure switches utilize advanced sensor technology to provide precise pressure monitoring and control. They often feature digital displays and programmable setpoints, making them ideal for industries that require high accuracy and automation. These switches are particularly beneficial in European manufacturing and high-tech sectors in the Middle East, where integration with IoT systems is becoming common. While they offer flexibility and enhanced functionality, buyers must consider the higher upfront costs and ensure that their infrastructure can support the required power supply and technical support.

Differential Pressure Switch

Differential pressure switches are designed to detect and respond to pressure differences between two points. This capability is crucial in industries such as HVAC and process control, where precise pressure management is necessary to ensure operational efficiency and product quality. Their sensitivity and ability to manage system cycling make them a valuable asset for sophisticated manufacturing setups. However, buyers should be prepared for potentially complex installation processes and higher initial costs, which may necessitate specialized knowledge and support.

Heavy-Duty/High-Pressure Switch

Heavy-duty pressure switches are built to withstand extreme conditions, often operating at maximum pressures exceeding 250 PSI. These switches are essential in industries like mining and petrochemicals, where durability and reliability are paramount. While they offer robust performance and are designed for harsh environments, buyers must evaluate whether such specifications are necessary for their applications, as these switches can be more expensive and may not be required for lighter industrial uses.

UL/CE Certified Switch

UL and CE certified switches adhere to stringent international safety and quality standards, making them suitable for regulated sectors and export markets. These certifications provide buyers with assurance regarding product safety and reliability, which is particularly important for businesses operating in regions with strict compliance requirements. However, the added assurance of certification often comes at a premium, so buyers need to weigh the benefits against the costs, especially in competitive markets.

Related Video: How does an Air Pressure Switch work in a Gas Furnace – HVAC

Key Industrial Applications of air pressure switch

| Industry/Sector | Specific Application of air pressure switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Compressed Air Systems | Ensures optimal pressure control, reducing downtime and energy costs | Compatibility with existing systems, PSI ratings, and durability under local conditions |

| Oil & Gas | Wellhead Control Systems | Enhances safety and operational efficiency by preventing overpressure situations | Certification standards (UL/CE), material resistance to harsh environments, and reliability |

| HVAC | Building Automation Systems | Maintains precise pressure levels for energy efficiency and comfort | Sensitivity range, integration capabilities with existing HVAC systems, and after-sales support |

| Water Treatment | Filtration Systems | Protects equipment from damage and ensures clean water supply | Pressure ratings, adaptability to various fluids, and supplier reliability |

| Automotive | Engine Management Systems | Optimizes performance and fuel efficiency by monitoring pressure in fluid systems | Electrical compatibility, resistance to vibration, and cycle longevity |

In the manufacturing sector, air pressure switches are integral to compressed air systems, which are widely used for powering pneumatic tools and machinery. These switches monitor and control pressure levels to ensure efficient operation, thereby reducing the risk of unplanned downtime and excessive energy consumption. Buyers, particularly in regions like Africa and South America, should focus on sourcing switches that match their specific PSI requirements and are durable enough to withstand local environmental conditions.

In the oil and gas industry, air pressure switches are crucial for wellhead control systems. They help prevent overpressure situations that could lead to catastrophic failures, enhancing both safety and operational efficiency. For international buyers in the Middle East, where oil extraction is paramount, it’s vital to prioritize suppliers that offer products with necessary certifications (like UL and CE) and can withstand harsh conditions typical in drilling environments.

For the HVAC industry, air pressure switches are essential in building automation systems to maintain optimal pressure levels. This capability not only contributes to energy efficiency but also ensures comfort in indoor environments. Buyers from Europe and the Middle East must consider the sensitivity range of these switches and their integration capabilities with existing HVAC systems, as well as the availability of robust after-sales support.

In water treatment applications, air pressure switches are used in filtration systems to monitor and manage pressure levels effectively. By ensuring that pressure does not exceed specified limits, these switches protect equipment from damage and guarantee a consistent supply of clean water. International buyers should look for switches with adaptable pressure ratings and a proven track record of reliability, particularly in regions prone to variable water quality.

Finally, in the automotive sector, air pressure switches play a vital role in engine management systems. They optimize engine performance and fuel efficiency by monitoring pressure levels in various fluid systems. B2B buyers need to ensure that the switches they source are electrically compatible with their systems, resilient to vibrations, and designed for long operational cycles to minimize maintenance needs.

Related Video: Pressure Switch Explained | Types of Pressure Switches

Strategic Material Selection Guide for air pressure switch

When selecting materials for air pressure switches, international B2B buyers must consider various factors that influence performance, compatibility, and cost. Here, we analyze four common materials used in the construction of air pressure switches: brass, stainless steel, plastic, and aluminum. Each material has distinct properties that can significantly impact the switch’s functionality and suitability for specific applications.

Brass

Key Properties: Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and good thermal conductivity. It can withstand moderate pressure and temperature ranges, typically up to 150°C (302°F).

Pros & Cons: Brass is durable and has a relatively low cost compared to other metals. However, it may not be suitable for high-pressure applications, and its manufacturing process can be complex due to the need for precise machining.

Impact on Application: Brass is compatible with many gases and liquids, making it ideal for general industrial applications. However, it may not be suitable for highly corrosive environments or aggressive media.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM for material specifications. In regions like Africa and South America, where environmental conditions can vary, selecting brass switches that meet local corrosion resistance standards is essential.

Stainless Steel

Key Properties: Stainless steel offers superior corrosion resistance, high strength, and excellent durability. It can handle high temperatures (up to 300°C or 572°F) and pressures, making it suitable for demanding applications.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust and corrosion. However, it comes at a higher cost and requires more complex manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel is ideal for applications in harsh environments, such as oil and gas, where exposure to corrosive substances is common. Its robustness ensures reliable performance in critical systems.

Considerations for International Buyers: Buyers in the Middle East and Europe should look for switches that comply with international standards like DIN or JIS. The higher initial investment may be justified by the long-term savings on maintenance and replacement.

Plastic

Key Properties: Plastics, such as polycarbonate or nylon, are lightweight and resistant to corrosion. They typically have lower temperature and pressure ratings, usually up to 80°C (176°F).

Pros & Cons: The main advantage of plastic is its low cost and ease of manufacturing. However, plastics can be less durable than metals and may not withstand high-pressure applications.

Impact on Application: Plastic pressure switches are suitable for low-pressure applications and environments where corrosion is a concern, such as water treatment facilities. They are not recommended for applications involving high temperatures or aggressive media.

Considerations for International Buyers: Buyers should consider local regulations regarding plastic materials, especially in Europe, where compliance with REACH and RoHS directives is necessary. In regions like Africa, the availability of specific plastics may vary, affecting sourcing decisions.

Aluminum

Key Properties: Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It typically handles temperatures up to 150°C (302°F) and moderate pressures.

Pros & Cons: Aluminum is more affordable than stainless steel and offers a good balance of durability and weight. However, it may not be suitable for very high-pressure applications and can be prone to scratching.

Impact on Application: Aluminum pressure switches are commonly used in automotive and HVAC applications where weight savings are crucial. They are compatible with various media but should be evaluated for specific chemical interactions.

Considerations for International Buyers: Buyers should ensure that aluminum switches meet local standards for pressure ratings and corrosion resistance. In South America and Africa, understanding the local climate and environmental conditions can guide material selection.

Summary Table

| Material | Typical Use Case for air pressure switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General industrial applications | Good corrosion resistance | Limited high-pressure capability | Low |

| Stainless Steel | Oil & gas, harsh environments | Superior durability and longevity | Higher cost and complex manufacturing | High |

| Plastic | Low-pressure applications | Lightweight and cost-effective | Less durable, low-temperature rating | Low |

| Aluminum | Automotive, HVAC applications | Lightweight and corrosion-resistant | Not suitable for very high pressures | Medium |

This analysis provides a comprehensive overview of material options for air pressure switches, enabling international B2B buyers to make informed decisions that align with their operational requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air pressure switch

The manufacturing process for air pressure switches involves several critical stages, each essential for ensuring product reliability and functionality. Understanding these stages can empower B2B buyers, especially those from Africa, South America, the Middle East, and Europe, to make informed decisions when sourcing these components.

Illustrative Image (Source: Google Search)

Manufacturing Process

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials include metals such as brass or stainless steel for housings and diaphragms, along with various plastics for insulation and structural components. Suppliers must ensure that materials meet specific industry standards for durability and compatibility with the intended application. Buyers should inquire about the sourcing of materials and any certifications that guarantee their quality, especially in regions where local standards may vary.

2. Forming

Once materials are prepared, they undergo forming processes. This can include stamping, machining, and molding, depending on the complexity of the switch design. For example, diaphragms may be stamped from thin sheets of metal, while housings might be molded from plastic. The precision of these processes is critical, as it directly impacts the switch’s ability to respond accurately to pressure changes. B2B buyers should consider suppliers that utilize advanced forming techniques, such as CNC machining, which allows for tighter tolerances and higher consistency in production.

3. Assembly

The assembly stage involves putting together various components, including the housing, diaphragm, electrical contacts, and any electronic sensors for digital switches. This process often requires skilled labor to ensure that each component is correctly aligned and secured. Automated assembly systems may be employed to enhance speed and reduce human error. Buyers should look for manufacturers that adhere to standardized assembly procedures, as this can significantly affect the final product’s reliability.

4. Finishing

The finishing process includes surface treatments, painting, or plating to enhance corrosion resistance and improve aesthetics. For pressure switches used in harsh environments, protective coatings are vital. This stage may also involve the installation of seals and gaskets to ensure the switch is airtight. Buyers should verify that suppliers use high-quality finishing techniques to extend the lifespan of the switches, particularly in industries like oil and gas or manufacturing, where exposure to corrosive elements is common.

Quality Assurance

Quality assurance (QA) is a crucial aspect of the manufacturing process for air pressure switches. It ensures that the final product meets the required specifications and standards, minimizing the risk of failures that could lead to downtime or safety hazards.

International Standards

Many manufacturers adhere to internationally recognized quality management systems, such as ISO 9001. This certification demonstrates a commitment to consistent quality and continuous improvement. Additionally, industry-specific certifications, such as CE marking for compliance with European safety standards or API standards for the oil and gas sector, can be critical for certain markets. B2B buyers should prioritize suppliers who hold these certifications, as they indicate a higher level of quality assurance.

Illustrative Image (Source: Google Search)

QC Checkpoints

Quality control typically includes several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify performance against specifications.

Each of these checkpoints serves to identify and rectify issues at various stages of production, ensuring that only high-quality switches reach the market.

Common Testing Methods

Testing methods for air pressure switches can vary, but typically include:

- Functional Testing: Verifying that the switch operates correctly within specified pressure ranges.

- Leak Testing: Ensuring that there are no leaks in the assembly, which could compromise performance.

- Cycle Testing: Assessing the switch’s durability by simulating prolonged use over millions of cycles.

- Environmental Testing: Evaluating performance under extreme temperatures, humidity, and corrosive conditions.

B2B buyers should request detailed testing reports from suppliers to confirm compliance with these testing methods.

Verifying Supplier QC

To ensure that suppliers maintain high-quality standards, B2B buyers can employ several strategies:

- Supplier Audits: Conducting regular audits of manufacturing facilities can provide insights into production practices and quality control measures.

- Requesting Quality Reports: Buyers should ask for documentation that outlines quality control processes, testing results, and any certifications held.

- Third-Party Inspections: Engaging independent inspection agencies to assess product quality can add an additional layer of assurance.

Conclusion

For international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for air pressure switches is vital. By focusing on material selection, precise manufacturing techniques, and stringent quality control measures, buyers can mitigate risks associated with sourcing these critical components. Ensuring that suppliers adhere to international standards and provide transparency in their quality assurance processes will ultimately lead to more reliable and efficient operations.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for air pressure switch Sourcing

Understanding the cost structure and pricing for air pressure switches is essential for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. A comprehensive analysis of the cost components and price influencers can help buyers make informed sourcing decisions.

Cost Components

-

Materials: The primary cost driver for air pressure switches is the materials used in their construction. Common materials include stainless steel, brass, and various plastics, which can vary significantly in price based on quality and availability. Buyers should consider sourcing materials locally when possible to mitigate import costs.

-

Labor: Labor costs encompass wages for the workforce involved in manufacturing. This varies by region; for instance, labor costs may be lower in some African countries compared to Europe. Understanding the labor market in the supplier’s location can provide insights into potential cost savings.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and administrative costs. Efficient manufacturing processes and automation can reduce overhead, impacting the overall pricing of the switches.

-

Tooling: Tooling costs involve the investment in molds and machinery necessary for producing specific switch designs. Customization often requires higher tooling costs, which can affect the final price.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and compliance with industry standards. While this can increase costs, it is crucial for minimizing returns and warranty claims, ultimately leading to cost savings for buyers.

-

Logistics: Shipping and handling costs are significant, especially for international transactions. Factors such as distance, shipping method, and local tariffs can heavily influence logistics costs. Buyers should evaluate Incoterms to clarify responsibilities and costs associated with shipping.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and supplier reputation.

Price Influencers

-

Volume/MOQ: The volume of the order can significantly affect pricing. Larger orders typically qualify for bulk discounts, allowing buyers to reduce per-unit costs. Establishing long-term contracts may also yield favorable pricing.

-

Specifications/Customization: Custom-designed switches tailored to specific applications can incur higher costs due to additional engineering and tooling requirements. Buyers should assess whether standard models meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: High-quality materials and certifications (such as UL or CE) often command higher prices. However, investing in certified products can enhance reliability and safety, reducing long-term costs associated with failures.

-

Supplier Factors: The supplier’s reputation, reliability, and support services can influence pricing. Established suppliers with a history of quality may charge more, but they often provide better after-sales support and warranties.

-

Incoterms: Understanding Incoterms is critical for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact total costs.

Buyer Tips

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility, especially for larger orders or long-term partnerships.

-

Cost-Efficiency: Evaluate total cost of ownership rather than just the initial purchase price. Consider maintenance, energy consumption, and replacement frequency to determine long-term value.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and their impact on pricing. Establishing contracts in stable currencies can mitigate this risk.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Open communication about expectations can foster collaboration and trust.

-

Market Research: Conduct thorough market research to compare prices and features among different suppliers. This knowledge empowers buyers to make informed decisions and avoid overpaying.

Disclaimer

Prices and costs mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and regional factors. Buyers should conduct their due diligence to obtain accurate quotes tailored to their specific needs.

Spotlight on Potential air pressure switch Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘air pressure switch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for air pressure switch

Key Technical Properties of Air Pressure Switches

Understanding the essential technical properties of air pressure switches is crucial for B2B buyers to ensure they select the right component for their operations. Here are several critical specifications to consider:

-

Pressure Rating (PSI)

– Definition: The maximum pressure at which the switch can operate safely.

– Importance: Selecting a switch with an appropriate pressure rating is vital to avoid equipment failure or safety hazards. Buyers must ensure that the switch’s PSI aligns with their system requirements, particularly in high-demand industries like oil and gas or manufacturing. -

Electrical Ratings

– Definition: This includes voltage and current specifications that indicate the switch’s electrical load capacity.

– Importance: Understanding electrical ratings helps buyers ensure compatibility with their existing electrical systems. Overloading a pressure switch can lead to malfunctions or safety risks, making it essential to match these ratings to the application requirements. -

Material Grade

– Definition: The type of materials used in the construction of the switch, such as plastics or metals.

– Importance: Material choice impacts durability, resistance to corrosion, and overall reliability. For example, switches made from stainless steel may be preferred in harsh environments, such as those found in the petrochemical industry, where exposure to chemicals is common. -

Set Point Adjustability

– Definition: The ability to adjust the pressure set points at which the switch activates or deactivates.

– Importance: Adjustable set points allow for greater flexibility in operations, enabling businesses to fine-tune their systems for optimal performance. This feature is particularly beneficial in dynamic environments where pressure requirements may change frequently. -

Operating Temperature Range

– Definition: The range of temperatures within which the switch can function effectively.

– Importance: Knowing the operating temperature range is crucial for ensuring that the switch can perform reliably in varying environmental conditions. This is particularly relevant for buyers in regions with extreme climates. -

Cycle Life

– Definition: The number of operational cycles a switch can perform before failure.

– Importance: A higher cycle life indicates better durability and reliability. B2B buyers should assess cycle life based on their operational demands to avoid frequent replacements and minimize downtime.

Common Trade Terminology

Familiarity with industry jargon can streamline communication and negotiations for B2B buyers. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM partnerships can help buyers identify trusted suppliers whose products meet specific quality and performance standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory management. Buyers should assess their needs against supplier MOQs to avoid over-committing resources. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Importance: An RFQ helps buyers compare quotes and negotiate better deals. It is a vital step in the procurement process to ensure transparency and cost-effectiveness. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs, facilitating smoother international trade agreements. -

Lead Time

– Definition: The amount of time from placing an order to its delivery.

– Importance: Understanding lead times is critical for inventory planning and ensuring timely project execution. Buyers should factor lead times into their procurement strategy to avoid disruptions.

By mastering these technical properties and industry terms, international B2B buyers can enhance their procurement strategies and make informed purchasing decisions regarding air pressure switches.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the air pressure switch Sector

Market Overview & Key Trends

The global market for air pressure switches is driven by several key factors, including the increasing demand for automation across various industries, the need for energy efficiency, and the growing emphasis on safety standards in operations. In regions such as Africa and South America, rapid industrialization and infrastructural development are propelling the demand for reliable compressed air systems, thus boosting the air pressure switch market. Meanwhile, the Middle East is witnessing significant investments in oil and gas, further escalating the need for high-performance pressure management solutions.

Emerging trends in B2B sourcing include a shift towards digital procurement processes, which enhance visibility and streamline purchasing decisions. International buyers are increasingly leveraging data analytics to assess supplier performance and market conditions, allowing for better negotiation and risk management. Furthermore, there is a growing interest in electronic and smart pressure switches that offer advanced features such as IoT integration and remote monitoring capabilities. This trend is particularly relevant for European buyers who prioritize high-tech solutions and compliance with stringent regulatory frameworks.

Market dynamics are also influenced by supply chain complexities, particularly in sourcing components from different countries. Buyers must navigate tariffs, logistics challenges, and local regulations that can affect lead times and costs. Understanding these dynamics is critical for procurement professionals aiming to optimize their supply chains and secure reliable suppliers that can meet evolving market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming an essential consideration for B2B buyers in the air pressure switch sector. The environmental impact of manufacturing processes and materials used in pressure switches is under scrutiny, with many companies seeking to minimize their carbon footprints. Ethical sourcing practices, such as selecting suppliers who adhere to sustainable manufacturing processes and fair labor practices, are gaining traction among international buyers.

Incorporating “green” certifications into sourcing decisions can significantly enhance a company’s reputation and appeal to environmentally conscious clients. Certifications such as ISO 14001 (Environmental Management Systems) and RoHS (Restriction of Hazardous Substances) are indicators of a supplier’s commitment to sustainability. Buyers should prioritize manufacturers who utilize environmentally friendly materials, such as recyclable plastics and metals, in their products. This not only reduces environmental impact but can also lead to cost savings in waste management and energy consumption.

Moreover, as regulatory frameworks around sustainability tighten globally, staying ahead of compliance requirements will be crucial for businesses. By adopting ethical sourcing practices, companies can ensure that their supply chains are resilient, transparent, and aligned with global sustainability goals.

Brief Evolution/History

The evolution of air pressure switches can be traced back to the early days of industrial automation, where mechanical pressure switches were the primary technology used. These switches relied on simple mechanical principles to regulate pressure in pneumatic systems. As industries advanced, the demand for precision and reliability led to the development of electronic pressure switches in the late 20th century.

This shift marked a significant technological leap, enabling enhanced accuracy, programmability, and integration with digital systems. The introduction of smart technology further transformed the landscape, allowing for real-time monitoring and data analysis. Today, air pressure switches are integral components in a wide range of applications, from manufacturing to renewable energy, reflecting the ongoing innovation in this essential sector. Understanding this historical context can help B2B buyers appreciate the technological advancements and future potential of air pressure switches in their operations.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of air pressure switch

-

How can I vet suppliers for air pressure switches?

When vetting suppliers, start by checking their certifications and compliance with international standards (e.g., ISO 9001, UL, CE). Request references from previous clients and assess their experience in your industry. Utilize platforms like Alibaba or ThomasNet to read reviews and ratings. Additionally, consider visiting the supplier’s facility if feasible, or request virtual tours. Establish communication to gauge responsiveness and willingness to support your needs, which is critical for ongoing partnerships. -

What customization options are typically available for air pressure switches?

Many manufacturers offer customization options, including pressure range specifications, electrical ratings, and mounting styles. Discuss your specific requirements upfront, as some suppliers can also provide tailored solutions like unique wiring configurations or materials suited to particular environmental conditions. Always confirm the feasibility and potential cost implications of customizations, as these can affect lead times and pricing. -

What are the typical minimum order quantities (MOQ) and lead times?

MOQs can vary significantly by supplier and product type, generally ranging from 50 to 500 units. For customized orders, MOQs may be higher. Lead times typically depend on the complexity of the order; standard products can take 2-4 weeks, while customized solutions may require 6-12 weeks. Always confirm these details during negotiations to ensure they align with your project timelines and inventory needs. -

What payment terms should I expect when sourcing internationally?

Payment terms can vary widely; common practices include upfront payments, 30% deposits with the balance upon shipment, or letters of credit for large orders. Always negotiate favorable terms that protect your cash flow. Be aware of potential currency fluctuations and transaction fees associated with international payments. Establishing a good relationship with your supplier can also lead to more flexible payment arrangements. -

What quality assurance measures should I look for?

Ensure that the supplier has a robust quality control process, including in-process inspections and final testing of products. Request documentation proving adherence to relevant quality standards and any certifications that validate their manufacturing processes. Some suppliers may offer third-party testing reports, which can further assure product reliability. Regular audits of the supplier’s quality assurance practices can also help maintain standards over time. -

How can I handle logistics and shipping challenges?

Engage a reliable freight forwarder experienced in international shipping to navigate customs and logistics effectively. Discuss shipping options (air vs. sea) based on urgency and budget. Ensure that the supplier provides all necessary shipping documents, such as bills of lading and commercial invoices, to facilitate smooth customs clearance. Consider purchasing insurance for high-value shipments to mitigate risks associated with loss or damage during transit. -

What should I do if there is a dispute with the supplier?

First, attempt to resolve the issue directly through open communication. Document all interactions and agreements to have a clear record. If direct negotiations fail, refer to the contract terms, which should outline dispute resolution processes. Consider mediation or arbitration as a means to resolve conflicts without resorting to legal action, which can be costly and time-consuming. Building a relationship based on trust and transparency can help prevent disputes from arising. -

What certifications are important for air pressure switches in international markets?

Key certifications include UL and CE, which indicate compliance with safety and quality standards in North America and Europe, respectively. For markets in Africa and South America, check for local certifications that may be required. Understanding these requirements ensures that your products meet regulatory standards, which is vital for market entry and consumer trust. Always verify that the supplier can provide documentation for these certifications to avoid potential compliance issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for air pressure switch

In conclusion, strategic sourcing of air pressure switches is essential for international B2B buyers aiming to optimize operational efficiency and reduce costs. Understanding the various types of pressure switches—mechanical, electronic, differential, and heavy-duty—allows businesses to select the most suitable products for their specific applications. Key takeaways include the importance of evaluating supplier reliability, material durability, and compliance with regional standards, all of which can significantly influence both performance and total cost of ownership.

For buyers in Africa, South America, the Middle East, and Europe, leveraging a well-informed sourcing strategy can mitigate risks associated with unplanned downtime and equipment failures. As market dynamics evolve, staying abreast of technological advancements and emerging trends in pressure switch applications will be crucial.

Now is the time to act. Engage with reputable suppliers, explore innovative solutions, and ensure your procurement processes are agile enough to adapt to future demands. By prioritizing strategic sourcing, you position your organization for sustained growth and competitive advantage in the global marketplace.