Master Sourcing Bracket Metal: Your Comprehensive B2B

Introduction: Navigating the Global Market for bracket metal

In today’s interconnected world, bracket metal plays a pivotal role in various industries, serving as a fundamental component for structures, machinery, and equipment. As international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of bracket metal procurement is crucial for maintaining competitive advantage. The demand for reliable and high-quality bracket metal is on the rise, driven by the growing construction, automotive, and manufacturing sectors.

This guide is designed to empower you with comprehensive insights into the global market for bracket metal. We delve into various types of bracket metal, explore the diverse materials used in production, and discuss essential aspects of manufacturing and quality control. Additionally, we provide an overview of suppliers, pricing strategies, and market trends, ensuring you are well-equipped to navigate the complexities of sourcing.

By addressing common FAQs and procurement challenges, this guide aims to enhance your decision-making process, enabling you to forge strong partnerships with suppliers who meet your specific needs. Whether you are looking to optimize costs, ensure quality, or mitigate supply chain disruptions, our insights will help you make informed sourcing decisions that align with your business objectives. Embrace the opportunity to elevate your procurement strategy in the dynamic landscape of bracket metal.

Understanding bracket metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Brackets | High strength, durability, and corrosion resistance | Construction, automotive, heavy machinery | Pros: Cost-effective, widely available. Cons: Heavier than alternatives, may require protective coating. |

| Aluminum Brackets | Lightweight, good corrosion resistance, and high strength-to-weight ratio | Aerospace, electronics, automotive | Pros: Lightweight, easy to machine. Cons: More expensive than steel, lower tensile strength. |

| Stainless Steel Brackets | Excellent corrosion resistance and aesthetic appeal | Food processing, medical equipment | Pros: High durability, hygienic. Cons: Higher cost, can be more difficult to weld. |

| Plastic Brackets | Non-conductive, lightweight, and resistant to chemicals | Electronics, plumbing, HVAC systems | Pros: Cost-effective, versatile. Cons: Limited load-bearing capacity, can degrade under UV exposure. |

| Composite Brackets | Combination of materials for enhanced properties | Aerospace, automotive, high-performance applications | Pros: Tailored properties, lightweight. Cons: Higher production costs, complex sourcing. |

Steel Brackets

Steel brackets are renowned for their high strength and durability, making them a staple in construction and heavy machinery applications. They are often used in structural support, providing reliable performance under significant loads. When purchasing, buyers should consider the cost-effectiveness of steel, which is widely available, but also be aware of its weight and potential need for protective coatings to prevent corrosion in harsh environments.

Aluminum Brackets

Aluminum brackets are favored for their lightweight nature and good corrosion resistance, making them ideal for aerospace and automotive applications. Their high strength-to-weight ratio allows for efficient designs in applications where weight is critical. Buyers should consider the higher costs associated with aluminum compared to steel, as well as its machinability, which can facilitate custom designs but may not support the same load capacities as steel.

Stainless Steel Brackets

Stainless steel brackets offer excellent corrosion resistance and are often used in industries like food processing and medical equipment where hygiene is paramount. Their aesthetic appeal and durability make them suitable for visible applications. However, buyers should be prepared for the higher costs associated with stainless steel and the potential challenges in welding, which may require specialized techniques.

Plastic Brackets

Plastic brackets are lightweight and non-conductive, making them suitable for electronics and plumbing applications. Their resistance to chemicals enhances their utility in various environments. While they are often cost-effective, buyers should be aware of their limited load-bearing capacity and potential degradation from UV exposure, which may necessitate careful selection based on application needs.

Composite Brackets

Composite brackets combine materials to achieve tailored properties that enhance performance in specific applications, such as aerospace and automotive. These brackets can be designed to be lightweight while maintaining strength, making them attractive for high-performance needs. However, buyers should consider the higher production costs and the complexity of sourcing composite materials, which can complicate procurement processes.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of bracket metal

| Industry/Sector | Specific Application of bracket metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural support brackets for buildings and bridges | Enhances structural integrity and safety | Compliance with local building codes and standards |

| Automotive | Mounting brackets for engine components | Reduces vibration, improving vehicle performance and longevity | Material specifications, weight considerations, and durability |

| Electronics | Brackets for mounting circuit boards and components | Ensures stability and protection of sensitive electronics | Precision machining capabilities and quality control measures |

| Aerospace | Brackets for aircraft assembly | Critical for weight reduction and safety compliance | Aerospace-grade materials and certification requirements |

| Manufacturing Equipment | Brackets for machinery and equipment assembly | Improves operational efficiency and equipment longevity | Customization options and lead time flexibility |

Construction

In the construction industry, bracket metal is primarily used for structural support in buildings and bridges. These brackets are crucial for enhancing the integrity and safety of structures, ensuring they can withstand various loads and stresses. International buyers, particularly from regions like Africa and Europe, should prioritize suppliers who comply with local building codes and standards, as this ensures the brackets meet necessary safety and performance benchmarks.

Automotive

In the automotive sector, bracket metal serves as mounting components for engine parts and other critical systems. These brackets play a vital role in reducing vibrations, which not only enhances vehicle performance but also extends the lifespan of components. Buyers must focus on sourcing materials that meet specific weight and durability standards to optimize vehicle efficiency, especially in competitive markets in South America and the Middle East.

Electronics

Bracket metal is essential in the electronics industry for securely mounting circuit boards and other delicate components. This application ensures stability and protection for sensitive electronics, which is critical in preventing damage during operation. For international buyers, particularly in Europe, it is important to work with suppliers that offer precision machining capabilities and stringent quality control measures to maintain high standards of reliability.

Aerospace

In the aerospace industry, bracket metal is used in the assembly of aircraft, where it is vital for both weight reduction and safety compliance. These components must meet rigorous standards due to the high-stakes nature of aviation. Buyers should ensure that their suppliers provide aerospace-grade materials and possess the necessary certifications to meet industry regulations, particularly in regions like Turkey and the Middle East, where aerospace manufacturing is rapidly growing.

Manufacturing Equipment

Bracket metal is frequently utilized in the assembly of various machinery and equipment across manufacturing sectors. These brackets help improve operational efficiency and extend the longevity of equipment by providing necessary support and stability. For international B2B buyers, customization options and flexibility in lead times are critical considerations when selecting suppliers to ensure they can meet specific operational needs effectively.

Related Video: Forming Sheet Metal & Metal Forming Tools – Uses Explained By Gene Winfield at SEMA

Strategic Material Selection Guide for bracket metal

Material Analysis for Bracket Metal

When selecting materials for bracket metal, international B2B buyers must consider various factors, including performance properties, cost, and compliance with regional standards. Below is an analysis of four common materials used in the production of bracket metal, focusing on their key properties, advantages and disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Steel (Carbon Steel and Stainless Steel)

Key Properties:

Steel is known for its high tensile strength and durability. Carbon steel is less resistant to corrosion compared to stainless steel, which contains chromium to enhance its corrosion resistance. Both types can withstand high temperatures and pressures, making them suitable for various applications.

Pros & Cons:

– Pros: High strength, excellent durability, and relatively low cost (especially carbon steel). Stainless steel offers superior corrosion resistance.

– Cons: Carbon steel can rust if not properly coated or maintained. Stainless steel is more expensive and can be more challenging to machine.

Impact on Application:

Steel brackets are widely used in construction and automotive applications due to their strength. Stainless steel is preferred in environments exposed to moisture or chemicals.

Considerations for Buyers:

Buyers should ensure compliance with local standards such as ASTM for the U.S. or EN standards in Europe. In regions like Africa and the Middle East, sourcing stainless steel may be more expensive due to import tariffs.

2. Aluminum

Key Properties:

Aluminum is lightweight, resistant to corrosion, and has good thermal and electrical conductivity. It is also relatively easy to machine and form into complex shapes.

Pros & Cons:

– Pros: Lightweight, excellent corrosion resistance, and good strength-to-weight ratio.

– Cons: Lower tensile strength compared to steel, which may limit its use in high-load applications.

Impact on Application:

Aluminum brackets are ideal for applications where weight savings are critical, such as in aerospace and automotive industries.

Considerations for Buyers:

International buyers should be aware of the various grades of aluminum and their corresponding standards (e.g., ASTM B221). In regions like South America, local availability may influence costs.

3. Plastic (Polymer-Based Materials)

Key Properties:

Plastic brackets are lightweight, resistant to corrosion, and can be molded into complex shapes. They have a lower temperature tolerance compared to metals.

Pros & Cons:

– Pros: Very lightweight, resistant to corrosion and chemicals, and low manufacturing costs.

– Cons: Limited load-bearing capacity and temperature resistance compared to metals.

Impact on Application:

Plastic brackets are often used in electronic applications or environments where moisture is present but mechanical strength is not critical.

Considerations for Buyers:

Buyers should verify the specific type of plastic being used (e.g., ABS, PVC) and ensure compliance with relevant standards, especially in the EU where regulations on materials can be stringent.

4. Composite Materials

Key Properties:

Composite materials, such as fiberglass or carbon fiber, offer high strength while being lightweight. They are resistant to corrosion and can be designed to meet specific performance criteria.

Pros & Cons:

– Pros: Excellent strength-to-weight ratio, corrosion resistance, and customizable properties.

– Cons: Higher manufacturing costs and complexity in production.

Impact on Application:

Composites are often used in high-performance applications, such as aerospace and automotive sectors, where weight savings and strength are critical.

Considerations for Buyers:

Buyers must consider the specific certifications required for composite materials, which may vary by region. In Turkey and other parts of Europe, compliance with specific industry standards is crucial.

Summary Table

| Material | Typical Use Case for bracket metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel (Carbon/Stainless) | Construction, automotive | High strength and durability | Corrosion risk (carbon steel) | Medium |

| Aluminum | Aerospace, automotive | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Plastic | Electronics, moisture-prone areas | Very lightweight and low cost | Limited load-bearing capacity | Low |

| Composite Materials | Aerospace, high-performance sectors | Excellent strength-to-weight ratio | Higher manufacturing complexity | High |

This guide provides a comprehensive overview of the materials available for bracket metal, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for bracket metal

Manufacturing bracket metal involves a series of detailed processes that ensure the final product meets both functional and quality standards. Understanding these processes is crucial for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This section delves into the manufacturing stages, key techniques, and quality assurance measures associated with bracket metal production.

Manufacturing Processes

The manufacturing of bracket metal typically encompasses four main stages: material preparation, forming, assembly, and finishing. Each stage is integral to producing a high-quality product that meets specific applications and standards.

Material Preparation

The first step in the manufacturing process is material preparation. This involves selecting the appropriate type of metal, often steel or aluminum, based on the intended application. The metal is then cut into specified dimensions using techniques such as:

- Shearing: A process that uses a blade to cut metal sheets.

- Laser cutting: Provides precision cuts with minimal waste.

- Waterjet cutting: Uses high-pressure water to cut through materials without affecting their structural integrity.

Before proceeding, the metal is also inspected for defects and impurities to ensure quality.

Forming

Once the material is prepared, it undergoes forming processes to achieve the desired shape. Common techniques include:

- Bending: Utilizing press brakes to create angles and curves.

- Stamping: A method that uses dies to create complex shapes through pressure.

- Machining: Involves removing material to achieve precise dimensions, often using CNC machines.

These processes are critical for ensuring that the brackets fit their intended applications, whether in construction, automotive, or aerospace industries.

Assembly

After forming, components may require assembly. This can include welding, riveting, or bolting parts together, depending on the design requirements.

- Welding: A common method for creating strong, permanent joints.

- Riveting: Often used in applications where a non-welded joint is preferred.

- Mechanical fastening: Provides flexibility for disassembly.

Careful attention during this stage is crucial, as improper assembly can lead to structural weaknesses.

Finishing

The final stage is finishing, which enhances the bracket’s durability and appearance. Techniques include:

- Powder coating: Provides a protective layer that is both decorative and functional.

- Anodizing: Increases corrosion resistance for aluminum brackets.

- Plating: Involves applying a layer of metal (like zinc) to improve strength and corrosion resistance.

Finishing processes not only improve aesthetics but also extend the lifespan of the brackets.

Quality Assurance

Quality assurance (QA) is paramount in the manufacturing of bracket metal. It ensures that products meet international standards and customer specifications.

Relevant International Standards

For B2B buyers, understanding the applicable quality standards is essential. Some key standards include:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries. Compliance indicates a commitment to quality and continuous improvement.

- CE Marking: Particularly important for products sold within the European Economic Area, it signifies compliance with EU safety, health, and environmental protection standards.

- API Standards: For brackets used in the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial.

Quality Control Checkpoints

Quality control (QC) checkpoints are implemented at various stages of production to catch defects early. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitors processes during manufacturing to ensure adherence to standards.

- Final Quality Control (FQC): Conducts thorough inspections of finished products before shipping.

Common Testing Methods

Several testing methods are employed to verify the integrity of bracket metal, including:

- Visual inspections: To detect surface defects.

- Dimensional checks: Ensuring that components meet specified measurements.

- Destructive testing: Such as tensile tests to assess material strength.

- Non-destructive testing (NDT): Techniques like ultrasonic or X-ray testing to identify internal flaws without damaging the component.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control measures is vital to mitigate risks. Here are actionable steps to ensure supplier compliance:

-

Conduct Supplier Audits: Regular audits can assess compliance with quality standards and manufacturing processes. Look for certifications like ISO 9001.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and inspection reports.

-

Engage Third-Party Inspectors: Consider hiring third-party inspection services to conduct independent checks on product quality before shipment.

-

Evaluate QC Nuances: Different regions may have specific quality standards. Understand the local regulations and certifications required in your target market to ensure compliance.

-

Build Relationships: Establishing strong relationships with suppliers can facilitate better communication about quality standards and expectations.

Conclusion

Understanding the manufacturing processes and quality assurance measures for bracket metal is essential for B2B buyers. By familiarizing themselves with these processes, buyers can make informed decisions when selecting suppliers, ensuring that they receive high-quality products that meet international standards. This knowledge not only enhances procurement strategies but also strengthens supply chain resilience, which is critical in today’s dynamic global market.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for bracket metal Sourcing

Understanding the cost structure and pricing for bracket metal sourcing is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will explore the key components of costs, the factors that influence pricing, and provide actionable tips for buyers to optimize their sourcing strategy.

Cost Components

-

Materials: The primary cost driver in bracket metal sourcing is the raw material. The choice of metal (e.g., steel, aluminum, or specialty alloys) significantly affects pricing. Prices can fluctuate based on market demand, geopolitical stability, and trade tariffs. Buyers should stay informed on global commodity prices to anticipate changes.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs can provide competitive pricing, but this can sometimes lead to concerns regarding quality and consistency. Understanding the labor market in the supplier’s country can help buyers evaluate potential risks and benefits.

-

Manufacturing Overhead: This includes expenses associated with factory operations, such as utilities, equipment depreciation, and administrative costs. A supplier with high operational efficiency may pass on lower overhead costs to buyers, making them more competitive in pricing.

-

Tooling: Custom brackets often require specific tooling, which can be a significant upfront cost. Buyers should inquire about tooling costs and whether these costs are amortized over the production run, as this can affect the overall pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Suppliers that provide certifications and adhere to international quality standards may charge a premium, but this can be justified by the reduction in defects and returns.

-

Logistics: Transportation costs can significantly impact the total price, particularly for international shipments. Factors include distance, shipping method, customs duties, and handling fees. Buyers should evaluate logistics options and consider Incoterms that suit their operational needs.

-

Margin: Supplier profit margins can vary widely based on market conditions and competition. Understanding the margin expectations of suppliers can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Larger orders often result in lower per-unit costs. Buyers should evaluate their needs and consider negotiating minimum order quantities (MOQ) to benefit from economies of scale.

-

Specifications/Customization: Custom specifications can drive up costs due to additional engineering and tooling requirements. Clear communication of specifications can help avoid unexpected costs.

-

Materials: The choice of materials directly influences pricing. High-performance materials may be more expensive but can provide long-term savings through durability.

-

Quality/Certifications: Suppliers offering certifications (like ISO) may charge more, but these certifications can ensure compliance with industry standards, which is critical for international buyers.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can influence pricing. It’s wise to evaluate multiple suppliers to find the best fit for your needs.

-

Incoterms: Understanding Incoterms can help buyers manage costs associated with shipping and delivery. Choosing the right terms can minimize unexpected charges and clarify responsibilities.

Buyer Tips

-

Negotiation: Always negotiate pricing and terms. Leverage competitive quotes from multiple suppliers to enhance your bargaining position.

-

Cost-Efficiency: Focus on total cost of ownership rather than just initial purchase price. Consider factors like maintenance, durability, and logistics when evaluating suppliers.

-

Pricing Nuances: Be aware of regional pricing variations. For example, suppliers in Turkey may offer competitive rates due to lower labor costs, while European suppliers may provide higher quality assurance.

-

Long-term Relationships: Building long-term relationships with suppliers can lead to better pricing and terms over time. Consider establishing contracts that provide stability for both parties.

Disclaimer

The pricing insights provided here are indicative and can vary based on market conditions, supplier negotiation, and specific project requirements. It is advisable for buyers to conduct thorough market research and engage in discussions with potential suppliers to obtain accurate pricing for their specific needs.

Spotlight on Potential bracket metal Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘bracket metal’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bracket metal

Key Technical Properties of Bracket Metal

When sourcing bracket metal, understanding its technical specifications is crucial for ensuring compatibility with your applications and maintaining quality standards. Here are some essential properties:

-

Material Grade

The material grade indicates the type of metal used, such as stainless steel, aluminum, or carbon steel. Each grade has unique characteristics, such as strength, corrosion resistance, and weight, which directly impact performance in various applications. Selecting the right grade is vital for durability and cost-effectiveness. -

Tolerance

Tolerance refers to the permissible limit of variation in dimensions and physical properties. Tight tolerances ensure that the brackets fit perfectly into their intended applications, reducing the risk of failure. For manufacturers, maintaining specified tolerances minimizes rework and waste, thereby optimizing production efficiency. -

Yield Strength

Yield strength measures the maximum stress a material can withstand without permanent deformation. This property is crucial for ensuring that the bracket can support the intended loads without bending or breaking. Understanding yield strength helps buyers assess whether the selected material will perform safely under operational conditions.

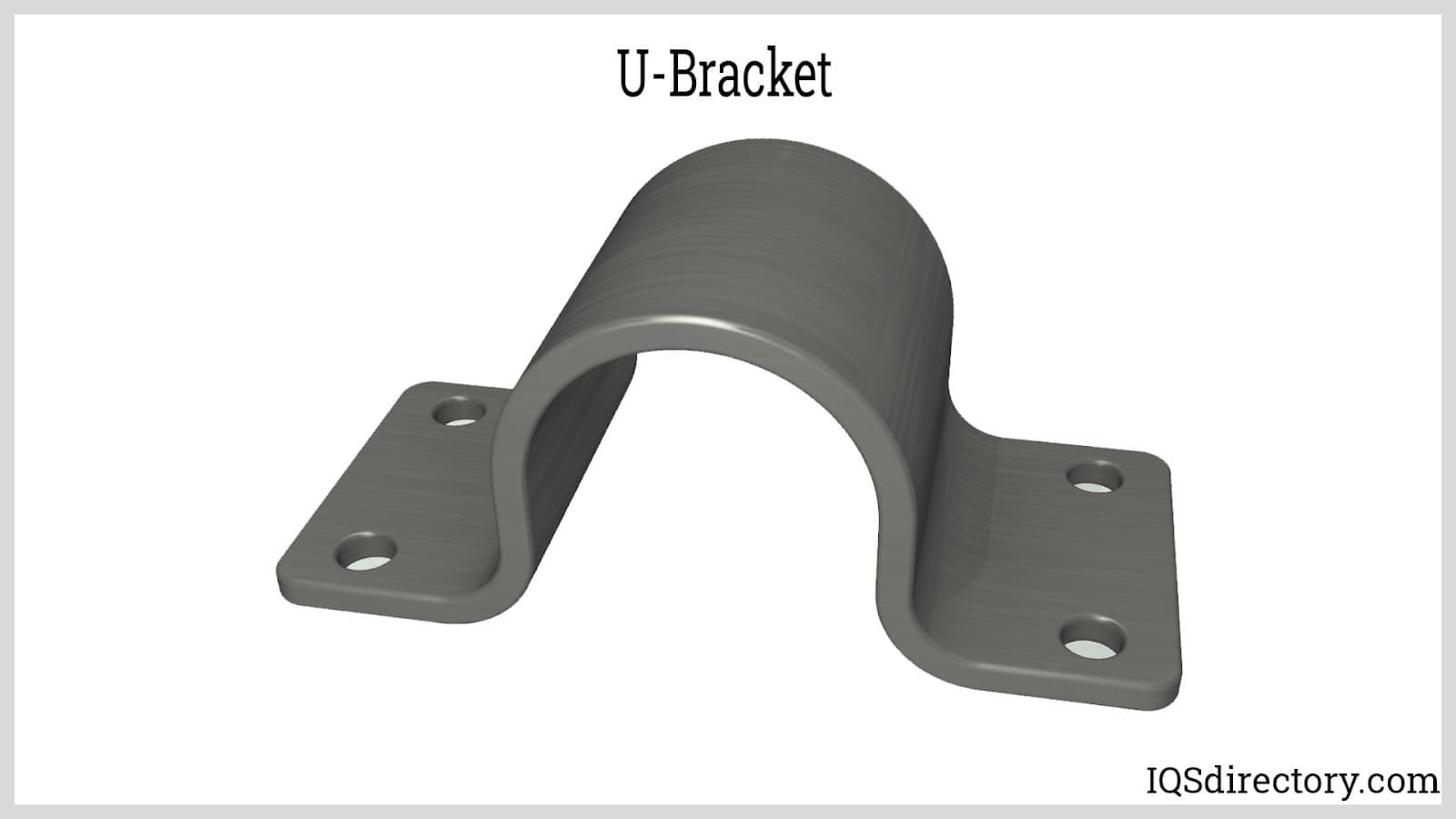

Illustrative Image (Source: Google Search)

-

Surface Finish

The surface finish affects both the aesthetics and functionality of the bracket metal. Common finishes include anodized, powder-coated, or untreated. A proper finish can enhance corrosion resistance and wear performance, making it essential to align surface treatments with environmental exposure and use-case scenarios. -

Weight

The weight of the bracket metal is an important consideration, especially in applications where weight savings are critical, such as aerospace or automotive industries. Understanding the weight helps in logistics planning and ensures that the final product meets design specifications without compromising structural integrity. -

Weldability

Weldability describes how easily a material can be welded. This property is significant for buyers who plan to join brackets with other components. Materials with high weldability allow for stronger, more reliable joints, which is essential for the overall performance of the assembly.

Common Trade Terminology

Familiarity with industry jargon can enhance communication and streamline the procurement process. Here are some common terms used in the bracket metal trade:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers looking to procure high-quality components tailored to specific applications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and cost. Knowing the MOQ helps businesses plan their purchases and negotiate better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of products. This process is critical for buyers to compare offers, negotiate prices, and ensure they receive competitive bids from multiple vendors. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for determining shipping costs, responsibilities, and risk management. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Knowledge of lead times is vital for effective production planning and inventory management, helping businesses meet customer expectations and avoid delays. -

Certification

Certification denotes that a product meets specific standards set by regulatory bodies or industry organizations. For B2B buyers, ensuring that bracket metals are certified can guarantee quality, safety, and compliance with local and international regulations.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing bracket metal, ensuring they meet their operational needs while optimizing procurement strategies.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bracket metal Sector

Market Overview & Key Trends

The bracket metal sector is witnessing significant transformations driven by global demand for lightweight and durable materials, particularly in construction, automotive, and electronics industries. Key trends influencing this market include the increased adoption of Industry 4.0 technologies, which enhance manufacturing efficiency through automation, data exchange, and IoT. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these technological advancements is crucial for maintaining competitive advantage.

Additionally, sourcing trends are shifting towards more localized supply chains to mitigate risks associated with global disruptions, such as those seen during the COVID-19 pandemic. Buyers are increasingly favoring suppliers who can demonstrate resilience and flexibility, ensuring consistent quality and timely delivery. This trend is particularly pertinent for buyers in countries like Egypt and Turkey, where local suppliers are becoming more competitive through innovations in production techniques and sustainable practices.

Another important dynamic is the fluctuating costs of raw materials, influenced by geopolitical tensions and economic shifts. B2B buyers must stay vigilant and adopt strategic procurement practices, such as engaging in long-term contracts with suppliers, to hedge against price volatility. Furthermore, the growing emphasis on customization and tailored solutions means that suppliers who can offer specific adaptations in bracket metal products will stand out in the market.

Sustainability & Ethical Sourcing in B2B

As global awareness of environmental issues increases, the demand for sustainable practices in the bracket metal sector is becoming a priority for B2B buyers. The environmental impact of metal production, including carbon emissions and resource depletion, necessitates a shift towards more sustainable sourcing methods. Buyers are encouraged to evaluate their suppliers based on sustainability metrics and certifications, such as ISO 14001, which focuses on effective environmental management systems.

Ethical sourcing is also crucial, as it ensures that materials are obtained responsibly, with considerations for labor practices and community impact. B2B buyers should seek suppliers who prioritize transparency in their supply chains and demonstrate a commitment to ethical practices. This includes utilizing green certifications and materials, such as recycled metals or those sourced from environmentally responsible operations, which not only reduce the carbon footprint but also appeal to a growing segment of environmentally-conscious consumers.

By integrating sustainability into procurement strategies, buyers can enhance their brand reputation and meet regulatory requirements while contributing to a more sustainable future.

Brief Evolution/History

The bracket metal industry has evolved significantly over the decades, transitioning from basic production methods to advanced manufacturing techniques that emphasize precision and efficiency. Historically, bracket metal components were primarily produced through traditional machining processes. However, the advent of technologies like CNC machining and additive manufacturing has revolutionized the sector, enabling high-volume production with reduced waste.

This evolution has been driven by the increasing complexity of applications in various sectors, necessitating more sophisticated designs and materials. As industries continue to innovate, the demand for high-quality bracket metal products that meet stringent performance and sustainability standards will only grow, shaping the future landscape of B2B procurement in this sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of bracket metal

-

What criteria should I use to vet suppliers of bracket metal?

When vetting suppliers, consider their industry experience, reputation, and certifications. Check for ISO certifications or other relevant quality assurance standards. Request references from previous clients and assess their production capabilities. Additionally, evaluate their financial stability to ensure they can fulfill large orders over time. Look for suppliers who demonstrate transparency in their operations and provide clear communication throughout the procurement process. -

Can I customize bracket metal products to meet specific requirements?

Yes, many suppliers offer customization options for bracket metal products. Engage in discussions with potential suppliers about your specific needs, including dimensions, materials, and finishes. Request samples or prototypes to ensure that the final product meets your expectations. Be clear about your specifications early in the negotiation process to avoid misunderstandings and ensure timely delivery. -

What are the typical minimum order quantities (MOQs) and lead times for bracket metal?

Minimum order quantities can vary significantly based on the supplier and the complexity of the product. Common MOQs range from a few hundred to several thousand units. Lead times can also differ; expect anywhere from 2 to 12 weeks, depending on production schedules and customization requests. Always confirm these details with your supplier upfront to align your production timelines with their capabilities. -

What payment terms should I expect when sourcing bracket metal?

Payment terms typically vary by supplier and may include options such as upfront deposits, milestone payments, or net payment terms (e.g., net 30 or net 60). International buyers should consider the implications of currency exchange rates and transaction fees. Negotiate favorable terms that protect your cash flow while ensuring the supplier has enough incentive to fulfill the order promptly.

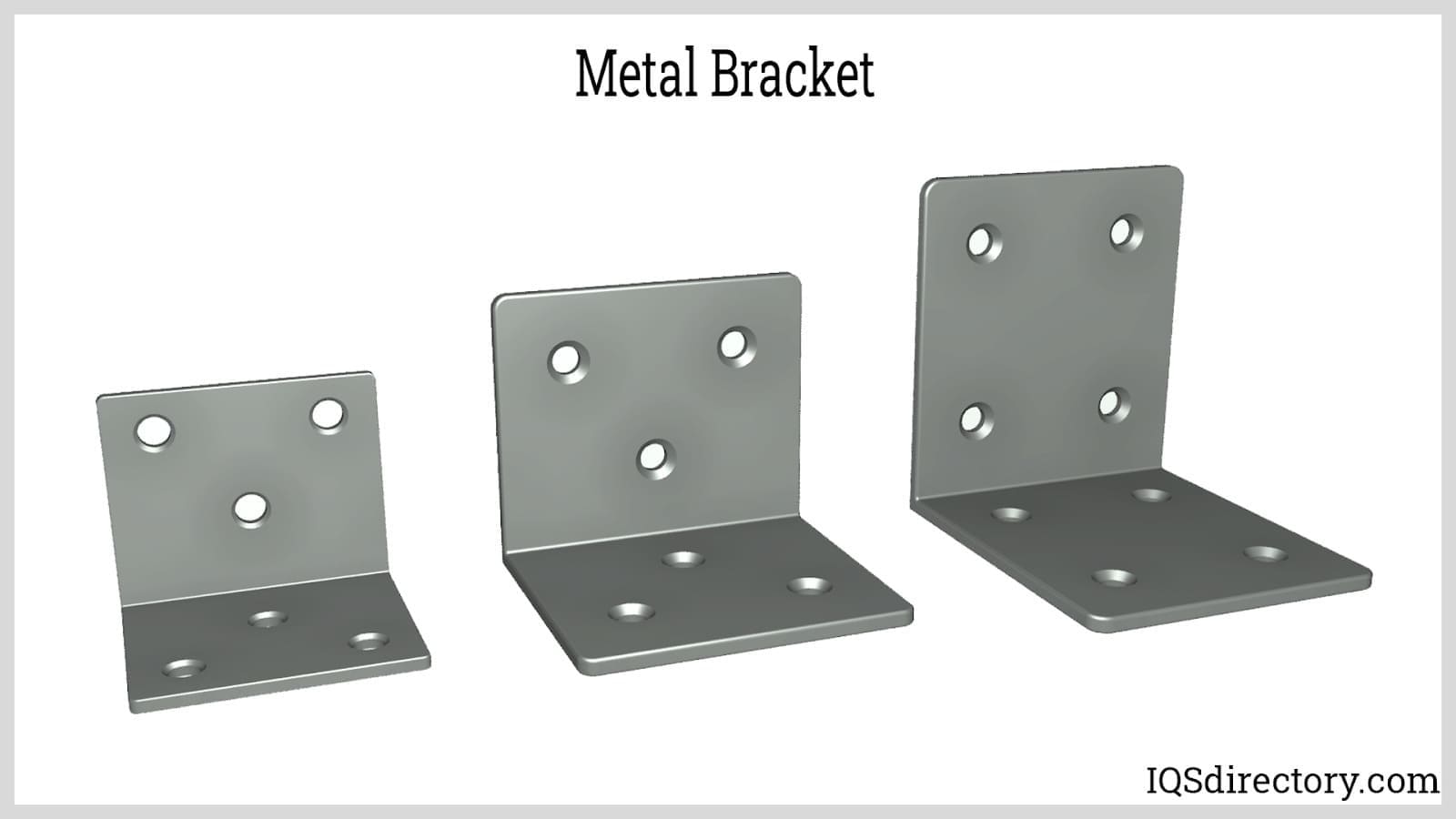

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certifications for bracket metal?

Request detailed information about the supplier’s quality control processes, including inspection methods and testing protocols. Look for suppliers that hold relevant certifications, such as ISO 9001, which indicates adherence to quality management standards. Ask for documentation of past inspections and certifications for the specific materials used in your order. Establish clear quality expectations in your contract to ensure accountability. -

What logistics considerations should I keep in mind when sourcing bracket metal internationally?

Logistics play a crucial role in international sourcing. Factor in shipping methods, costs, and delivery times when selecting a supplier. Understand the customs regulations and tariffs applicable to your product in your region. It’s advisable to work with suppliers who have experience in international shipping and can provide you with transparent tracking information throughout the process. -

How should I handle disputes with my bracket metal supplier?

Disputes can arise from quality issues, delivery delays, or payment disagreements. Establish a clear contract that outlines the terms of service, including dispute resolution procedures. Consider including clauses for mediation or arbitration to resolve conflicts amicably. Maintain open communication with your supplier to address issues promptly and seek mutually beneficial solutions before escalating the matter. -

What are the best practices for maintaining a long-term relationship with bracket metal suppliers?

Building a strong relationship with your suppliers involves regular communication and collaboration. Share forecasts and production needs to help suppliers plan their capacities. Provide feedback on product quality and performance to foster improvement. Consider developing strategic partnerships through long-term contracts or joint ventures, which can lead to better pricing, priority service, and a stronger commitment to meeting your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bracket metal

Effective strategic sourcing of bracket metal is crucial for international B2B buyers navigating complex procurement landscapes. Key takeaways include the importance of robust supplier networks to mitigate supply chain disruptions, implementing stringent quality control measures to ensure product reliability, and establishing long-term agreements to combat cost fluctuations. Additionally, addressing lead time variability and capacity constraints through collaborative planning can significantly enhance operational efficiency.

As you move forward, consider leveraging technology and innovation to strengthen your sourcing strategies. Engaging with suppliers who prioritize transparency and adaptability will not only secure a steady supply of bracket metal but also foster resilience against unforeseen market challenges.

Looking ahead, the global market for bracket metal is poised for growth, driven by increasing demand across various sectors. Now is the time for buyers in Africa, South America, the Middle East, and Europe, particularly in regions like Egypt and Turkey, to reassess their sourcing strategies. Embrace proactive procurement practices and build partnerships that align with your long-term business objectives. Together, we can navigate the complexities of the metal supply chain and capitalize on emerging opportunities for sustainable growth.