Master Sourcing Capacitive Touch Panels: A Complete B2B

Introduction: Navigating the Global Market for capacitive touch panel

In today’s digital landscape, the capacitive touch panel stands as a cornerstone of user interaction, driving innovation across multiple industries, from consumer electronics to industrial applications. This technology has transformed the way users engage with devices, offering a seamless interface that enhances functionality and user experience. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of capacitive touch panels is essential for making informed sourcing decisions that align with market demands.

This comprehensive guide delves into the multifaceted world of capacitive touch panels, exploring various types and their respective applications. We examine critical raw materials, the manufacturing and quality control processes, and the leading suppliers that shape this market. Buyers will find detailed insights into cost considerations and market trends, providing a holistic view that aids in strategic decision-making.

Additionally, the guide addresses frequently asked questions, ensuring that buyers are equipped with the knowledge needed to navigate potential challenges. By leveraging this information, businesses can enhance their procurement strategies, capitalize on emerging opportunities, and ultimately drive growth in their respective markets. Embrace the future of technology with confidence as you explore the capacitive touch panel landscape, tailored specifically for the needs of international buyers.

Understanding capacitive touch panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Projected Capacitive | Multi-touch support, high durability, and responsiveness | Smartphones, tablets, kiosks, industrial controls | Pros: High sensitivity, versatile design. Cons: Costly compared to resistive types. |

| Surface Capacitive | Single touch detection, simple structure | ATMs, vending machines, simple touch interfaces | Pros: Lower cost, easy to integrate. Cons: Limited functionality, less sensitive to multiple touches. |

| Self-Capacitance | Measures individual electrodes, ideal for small areas | Wearable devices, small gadgets, remote controls | Pros: Compact design, good for miniaturization. Cons: Limited to single touch detection. |

| Mutual-Capacitance | Detects multiple touches simultaneously | Touch screens, gaming devices, interactive displays | Pros: High accuracy, supports complex gestures. Cons: More complex design and higher manufacturing costs. |

| Glass Capacitive | Utilizes glass as a substrate, enhances aesthetics | High-end smartphones, luxury appliances | Pros: Premium look, durable surface. Cons: Heavier, may require additional protective layers. |

Projected Capacitive Touch Panels

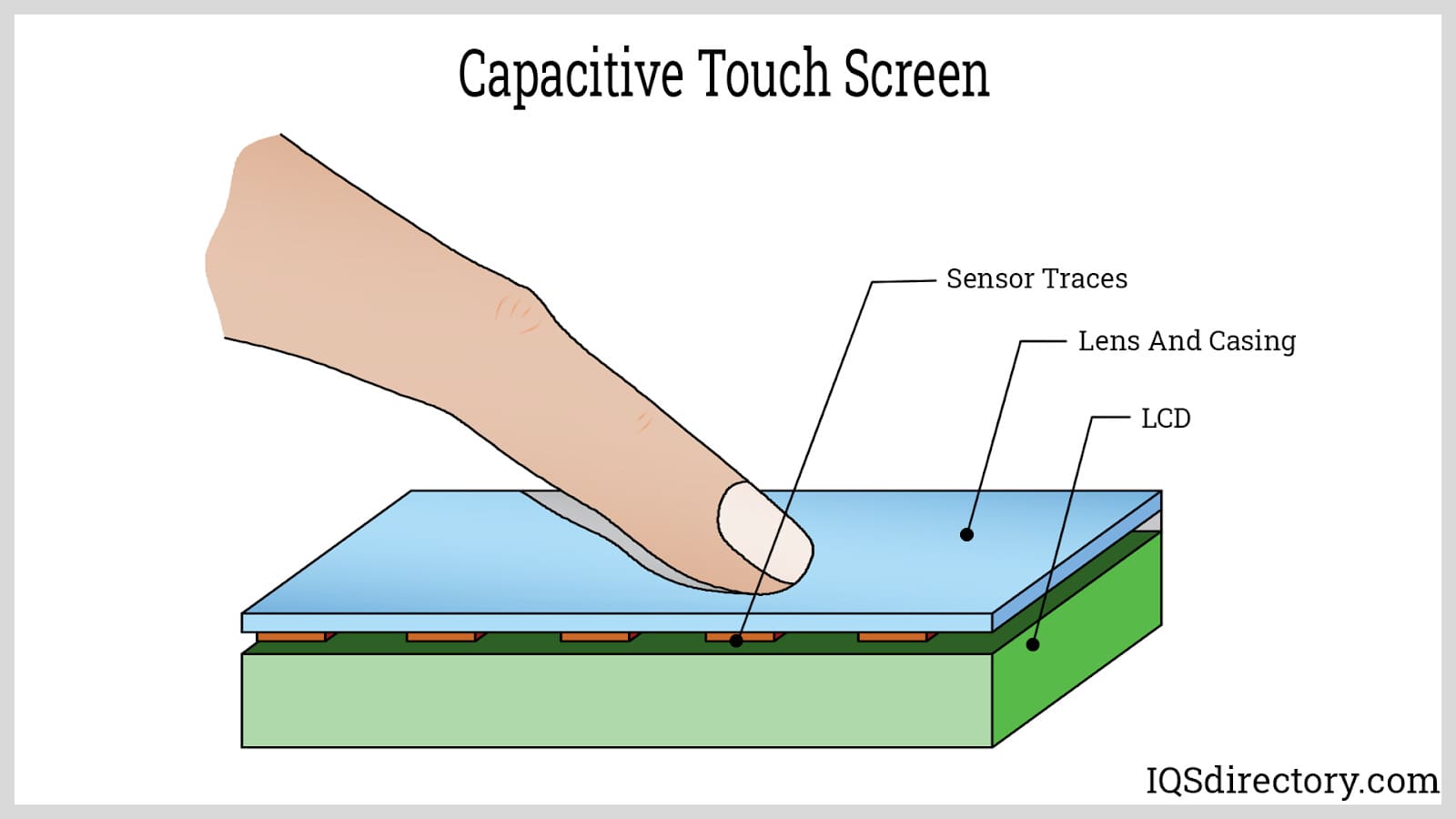

Projected capacitive touch panels are the most advanced type, allowing for multi-touch capabilities. They utilize a grid of electrodes to detect touch through the glass surface, making them highly responsive and durable. B2B buyers should consider their application environment—these panels are ideal for smartphones, tablets, and industrial controls due to their robustness. However, they come at a higher price point, so businesses should weigh the cost against the potential for increased user engagement.

Surface Capacitive Touch Panels

Surface capacitive touch panels are characterized by their simpler design and are generally more affordable. They work by detecting a change in capacitance when a finger touches the surface. These panels are commonly used in ATMs and vending machines, where a limited touch interface suffices. While they are cost-effective, their inability to support multi-touch interactions can be a drawback for applications requiring more complex input.

Self-Capacitance Touch Panels

Self-capacitance touch panels measure the capacitance of each individual electrode, making them suitable for applications where space is limited, such as in wearable devices and remote controls. Their compact design allows for integration into smaller gadgets. However, they only support single touch detection, which may not meet the needs of applications requiring multi-touch capabilities. Buyers must assess whether the compactness outweighs the limitations in functionality.

Mutual-Capacitance Touch Panels

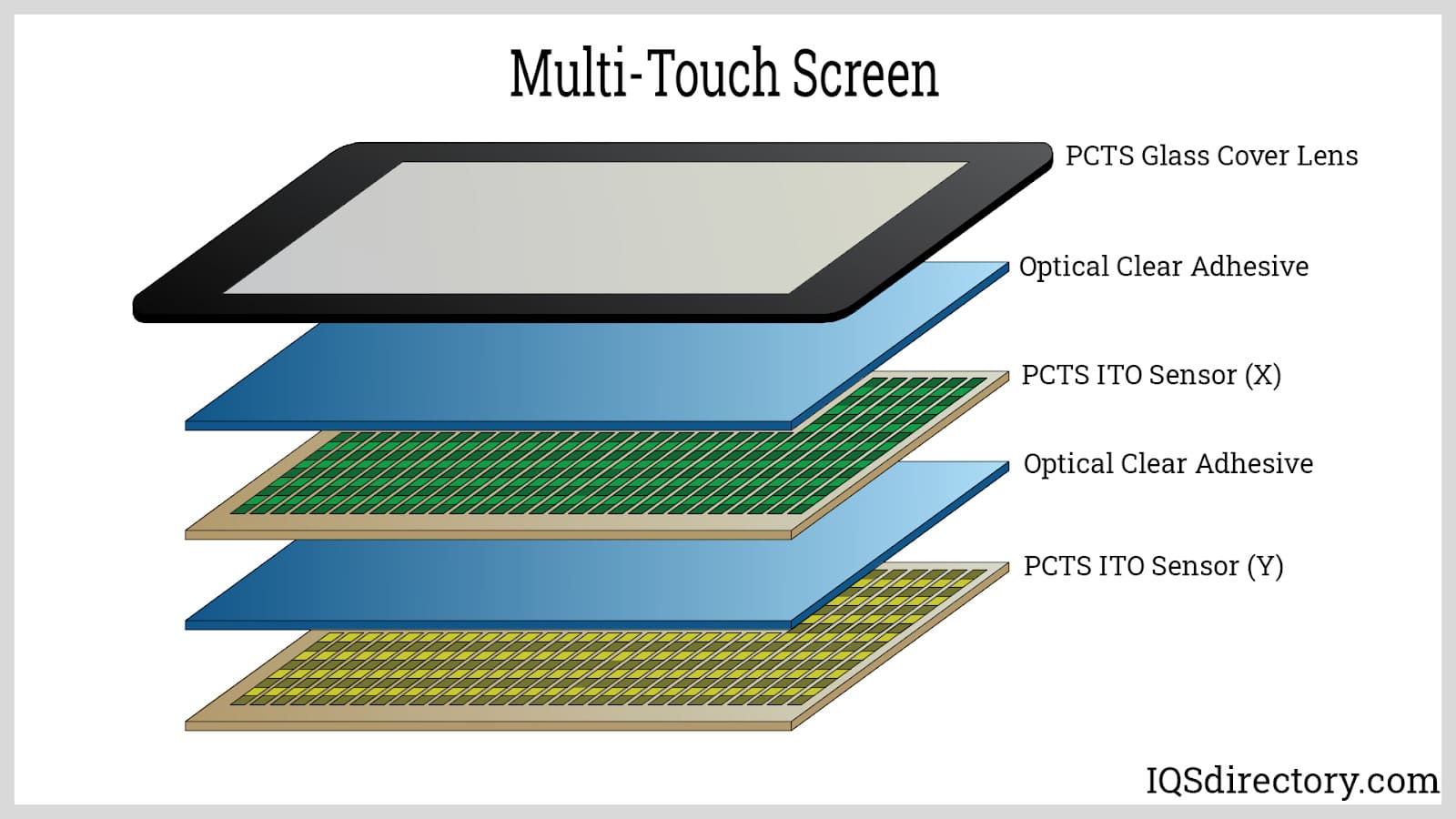

Mutual-capacitance touch panels excel in detecting multiple touches simultaneously, making them ideal for interactive displays and gaming devices. They provide high accuracy and can recognize complex gestures, which enhances user experience. However, their design complexity can lead to higher manufacturing costs. B2B buyers should consider the end-user experience and potential market demand for multi-touch capabilities when opting for this type.

Glass Capacitive Touch Panels

Glass capacitive touch panels use glass substrates, enhancing the aesthetic appeal and durability of the device. They are often found in high-end smartphones and luxury appliances where a premium look is desired. While they offer a sleek design and are resistant to scratches, they tend to be heavier and may require additional protective layers. Buyers should evaluate whether the aesthetic benefits align with their branding and product positioning.

Key Industrial Applications of capacitive touch panel

| Industry/Sector | Specific Application of capacitive touch panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Smartphones and Tablets | Enhanced user experience with responsive touch | Reliable suppliers with high-quality manufacturing processes |

| Automotive | Infotainment Systems | Improved user interaction and safety features | Compliance with automotive standards and durability tests |

| Industrial Automation | Control Panels for Machinery | Streamlined operations and reduced physical wear | Customization options for specific industrial environments |

| Healthcare | Medical Devices and Equipment | Increased hygiene and easy user interface | Certifications for medical use and high durability standards |

| Retail | Point of Sale (POS) Systems | Faster transactions and improved customer service | Integration capabilities with existing systems and software |

Consumer Electronics

In the consumer electronics sector, capacitive touch panels are integral to smartphones and tablets, providing a seamless and intuitive user interface. These panels solve the problem of user engagement by allowing for multi-touch gestures and quick responsiveness. For international buyers, sourcing high-quality touch panels requires attention to the manufacturer’s reputation and the technology used in production, ensuring compatibility with various operating systems and devices.

Automotive

Capacitive touch panels are increasingly being integrated into automotive infotainment systems, enhancing user interaction while driving. They enable drivers to control navigation, music, and communication features with minimal distraction. Buyers in this sector must consider the durability and reliability of touch panels, as they need to withstand extreme temperatures and vibrations. Compliance with automotive safety standards is also critical for sourcing decisions.

Industrial Automation

In industrial automation, capacitive touch panels are utilized in control panels for machinery, providing operators with an efficient way to manage complex systems. These panels help reduce physical wear and tear associated with mechanical buttons and switches. Buyers should focus on customizability to fit specific industrial environments and ensure that panels are designed for high-frequency use. Additionally, sourcing from manufacturers with robust testing processes is essential to guarantee long-term performance.

Healthcare

Capacitive touch panels are essential in medical devices and equipment, offering an easy-to-use interface that promotes hygiene by eliminating the need for physical buttons. They address challenges in maintaining cleanliness and ease of use in clinical settings. Buyers must prioritize sourcing panels that meet medical device certifications and are built to endure frequent cleaning and disinfecting. Ensuring high durability standards will also be vital in this sector.

Retail

In the retail industry, capacitive touch panels are widely employed in Point of Sale (POS) systems, facilitating faster and more efficient transactions. These systems enhance customer service by allowing for quick access to product information and payment processing. For B2B buyers, key considerations include the integration capabilities of touch panels with existing retail software and hardware, as well as the overall reliability of the technology to minimize downtime during peak shopping periods.

Related Video: How Capacitive Touch Screens Work

Strategic Material Selection Guide for capacitive touch panel

When selecting materials for capacitive touch panels, international B2B buyers must consider various factors that influence performance, durability, and cost. Below, we analyze four common materials used in capacitive touch panels, highlighting their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Indium Tin Oxide (ITO)

Key Properties:

ITO is a transparent conducting oxide that exhibits excellent electrical conductivity and optical transparency. It can operate effectively under a wide range of temperatures and has a relatively high corrosion resistance.

Pros & Cons:

Pros include its high transmittance of visible light and its ability to be deposited in thin films, making it ideal for touch sensors. However, ITO is brittle and can crack under mechanical stress, limiting its durability in rugged applications. Additionally, the cost of indium, a rare material, can make ITO expensive.

Impact on Application:

ITO is compatible with various media, including glass and plastic overlays. Its transparency allows for high-resolution displays, which is critical for consumer electronics.

Considerations for Buyers:

Buyers should ensure compliance with environmental regulations regarding rare materials. Standards such as ASTM and JIS may apply, particularly concerning the sourcing and recycling of indium.

2. Glass

Key Properties:

Glass is known for its excellent hardness and scratch resistance, along with good thermal stability. It can withstand high temperatures and is chemically inert, making it resistant to corrosion.

Pros & Cons:

The primary advantage of glass is its durability and aesthetic appeal, providing a premium look and feel. However, it is heavier than alternative materials and can be more prone to shattering upon impact. The manufacturing process can also be complex and costly.

Impact on Application:

Glass is suitable for applications requiring high durability and aesthetic quality, such as smartphones and tablets. Its compatibility with various coatings further enhances its utility.

Considerations for Buyers:

International buyers should be aware of shipping costs associated with heavier glass materials and ensure compliance with safety standards to prevent breakage during transport.

3. Polyethylene Terephthalate (PET)

Key Properties:

PET is a lightweight, flexible plastic known for its excellent chemical resistance and thermal stability. It can endure a wide range of temperatures and is less prone to shattering than glass.

Pros & Cons:

PET is cost-effective and easy to manufacture, making it a popular choice for budget-sensitive applications. However, it may not offer the same level of scratch resistance as glass or ITO, potentially leading to quicker wear and tear.

Impact on Application:

PET is suitable for applications where flexibility and weight savings are critical, such as in portable devices. Its compatibility with various printing techniques allows for customization.

Considerations for Buyers:

Buyers should consider the environmental impact of PET, including recycling options, and verify compliance with local regulations regarding plastic use in electronics.

4. Conductive Polymers

Key Properties:

Conductive polymers are organic compounds that exhibit electrical conductivity. They can be engineered to provide flexibility, lightweight characteristics, and good thermal stability.

Pros & Cons:

These materials offer significant design flexibility and can be produced at lower costs than traditional conductive materials. However, their performance can vary significantly based on formulation, and they may not provide the same level of durability as ITO or glass.

Impact on Application:

Conductive polymers are particularly useful in applications where weight and flexibility are prioritized, such as wearable technology. They can also be tailored for specific electrical properties.

Considerations for Buyers:

Buyers should assess the reliability of suppliers and the consistency of material performance. Compliance with international standards for electronic components is essential, especially in regions with strict regulations.

Summary Table

| Material | Typical Use Case for capacitive touch panel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Indium Tin Oxide (ITO) | Touch sensors in smartphones and tablets | High transparency and conductivity | Brittle, expensive due to indium | High |

| Glass | Premium devices, high-end electronics | Durable and scratch-resistant | Heavy, prone to shattering | Med |

| Polyethylene Terephthalate (PET) | Budget devices, flexible applications | Lightweight and cost-effective | Lower scratch resistance | Low |

| Conductive Polymers | Wearable technology, flexible displays | Design flexibility and lightweight | Variable performance based on formulation | Med |

This strategic material selection guide provides B2B buyers with crucial insights into the materials used in capacitive touch panels, enabling informed decisions that align with their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for capacitive touch panel

Manufacturing Processes for Capacitive Touch Panels

The manufacturing of capacitive touch panels involves several critical stages, each requiring precise execution to ensure high-quality end products. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these processes is essential for making informed procurement decisions.

1. Material Preparation

The initial stage focuses on sourcing and preparing raw materials, primarily glass substrates and Indium Tin Oxide (ITO). The quality of these materials directly impacts the performance of the touch panel. Buyers should ensure that suppliers provide materials that meet international standards, such as ASTM or ISO specifications.

- Glass Substrates: Typically, high-quality aluminosilicate glass is used due to its durability and optical clarity.

- ITO Films: These are critical for the touch sensitivity of the panel. The ITO pattern must be uniformly coated on the glass to ensure accurate touch detection.

2. Forming

This stage involves several sophisticated techniques to create the touch panel’s structure.

- ITO Pattern Formation: Utilizing methods like vacuum evaporation, magnetron sputtering, or chemical vapor deposition, manufacturers deposit a thin layer of ITO onto the glass substrate. The choice of technique can affect the uniformity and quality of the ITO film.

- Layer Formation: The touch panel consists of multiple layers, including the touch sensor, LCD, and cover glass. Each layer is processed under controlled conditions to prevent contamination, which could affect performance.

3. Assembly

The assembly phase is critical for ensuring that all components fit together seamlessly.

- Lamination: Utilizing Optical Channel Analyzers (OCA) and Optical Character Recognition (OCR) systems, manufacturers bond the layers together. This step is crucial as it influences the touch sensitivity and visual clarity of the final product.

- Flexible Printed Circuit (FPC) Bonding: The FPC is bonded to the patterned glass, connecting the touch sensor to the processing unit. This process requires precision to maintain the integrity of the electrical connections.

4. Finishing

The finishing stage encompasses final adjustments and coatings that enhance the panel’s durability and usability.

- UV Hardening: Cover glass undergoes UV curing to improve scratch resistance and durability.

- Final Quality Checks: Before shipment, the panels undergo rigorous testing to ensure they meet the specified performance criteria.

Quality Assurance

Quality assurance is paramount in the manufacturing of capacitive touch panels, especially for B2B buyers who require reliable products.

International Standards

Manufacturers often adhere to several international standards to ensure quality:

- ISO 9001: This standard focuses on quality management systems and is crucial for maintaining consistency in manufacturing processes.

- CE Marking: For products sold in Europe, CE marking indicates compliance with safety, health, and environmental protection standards.

- API Standards: In certain applications, compliance with American Petroleum Institute (API) standards may be necessary, particularly for rugged environments.

QC Checkpoints

Quality Control (QC) is integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process ensure that any defects are identified and rectified immediately.

- Final Quality Control (FQC): At this final checkpoint, completed panels are subjected to comprehensive testing, including functionality tests, durability assessments, and visual inspections.

Common Testing Methods

Several testing methods are employed to ensure the functionality and durability of capacitive touch panels:

- Electrical Testing: Verifying the responsiveness of touch sensors to ensure they detect touch accurately.

- Durability Testing: Assessing resistance to scratches, drops, and environmental factors (like humidity and temperature).

- Optical Testing: Ensuring that the display quality meets standards for clarity and color accuracy.

Verifying Supplier Quality Control

For international buyers, verifying a supplier’s quality control processes is essential for mitigating risks associated with product quality.

- Supplier Audits: Conducting on-site audits can provide insight into a supplier’s manufacturing processes and quality control measures. This is particularly important for buyers from regions with varying manufacturing standards.

- Quality Reports: Requesting detailed quality reports from suppliers can help assess their compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of product quality before shipment.

Navigating QC Nuances

B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific QC nuances:

- Cultural Differences in Standards: Different regions may have varying expectations regarding quality standards. Understanding these differences is crucial for effective communication with suppliers.

- Regulatory Compliance: Ensure that products comply with local regulations in the buyer’s country, which may require additional certifications beyond international standards.

By thoroughly understanding the manufacturing processes and quality assurance measures associated with capacitive touch panels, B2B buyers can make informed decisions that align with their operational needs and quality expectations. This knowledge not only helps in selecting reliable suppliers but also in establishing long-term partnerships that can drive mutual growth and success.

Related Video: The Most Sophisticated Manufacturing Process In The World Inside The Fab | Intel

Comprehensive Cost and Pricing Analysis for capacitive touch panel Sourcing

The cost structure for capacitive touch panels is multifaceted, encompassing various components that collectively influence the final price. Understanding these elements is crucial for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary raw materials for capacitive touch panels include Indium Tin Oxide (ITO) for touch sensors and substrate glass. The quality and source of these materials can significantly impact costs. For instance, ITO prices can fluctuate based on market demand and availability.

-

Labor: Labor costs vary by region, influenced by local wage standards and the skill level required for manufacturing. Automated processes in developed countries may reduce labor costs per unit, while regions with lower labor costs might offer competitive pricing but may lack advanced manufacturing technologies.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance of equipment. Efficient manufacturing processes can lower overhead costs, which is essential for competitive pricing.

-

Tooling: Initial setup costs for molds and specialized equipment can be significant, particularly for custom designs. Buyers should factor in these costs when assessing the overall price, especially for low-volume orders.

-

Quality Control (QC): High-quality standards often necessitate rigorous QC processes, adding to the overall cost. Certifications (like ISO) can also influence pricing, as they require additional compliance measures.

-

Logistics: Shipping and handling costs are vital, particularly for international transactions. Factors such as distance, shipping method, and Incoterms can significantly affect these costs.

-

Margin: Suppliers typically include a margin that reflects their desired profitability. This can vary widely depending on market competition and product differentiation.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally attract lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on anticipated volumes.

-

Specifications/Customization: Custom designs or specific technical requirements often lead to higher costs. Buyers should clearly define their needs to avoid unexpected charges.

-

Quality/Certifications: Higher quality products with certifications will usually command a premium price. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers in shipping. This can impact the overall cost, including insurance and customs duties.

Buyer Tips

-

Negotiation: Always negotiate prices and terms, especially for larger orders. Leverage volume and long-term relationships to secure better deals.

-

Cost-Efficiency: Evaluate the total cost of ownership, which includes not only the purchase price but also shipping, installation, and long-term maintenance costs.

-

Pricing Nuances: Be aware that prices may vary significantly between regions. For example, suppliers in Europe may offer higher quality but at a premium, while those in Asia may provide cost-effective options with varying quality levels.

-

Market Trends: Stay informed about market trends, such as fluctuations in raw material costs, which can affect pricing. Engage with industry reports and supplier communications to anticipate changes.

Disclaimer

The prices and cost structures mentioned are indicative and can vary based on numerous factors, including market conditions, supplier capabilities, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential capacitive touch panel Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘capacitive touch panel’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for capacitive touch panel

When considering the procurement of capacitive touch panels, international B2B buyers must understand the essential technical properties and industry terminology that can influence their purchasing decisions. This knowledge is crucial for ensuring the right fit for specific applications and for negotiating favorable terms with suppliers.

Key Technical Properties

- Material Grade

– Capacitive touch panels are primarily made of Indium Tin Oxide (ITO), which is known for its high conductivity and transparency. The quality of ITO can significantly impact the panel’s responsiveness and durability. Buyers should seek panels with high-grade ITO for optimal performance in various environments.

Illustrative Image (Source: Google Search)

-

Tolerance

– Tolerance refers to the acceptable range of variation in the dimensions of the touch panel. For instance, a typical tolerance for thickness might be ±0.1 mm. Tight tolerances ensure that the touch panel fits perfectly within the device casing, which is critical for maintaining the aesthetic and functional integrity of the product. -

Touch Sensitivity

– Touch sensitivity is a measure of how responsive the panel is to touch inputs. This property can be quantified in terms of mutual capacitance and self-capacitance. High sensitivity ensures that the panel registers inputs accurately and quickly, which is vital for user experience, particularly in high-traffic applications. -

Durability and Hardness

– The durability of capacitive touch panels is often assessed using the Mohs hardness scale. A hardness rating of 6 or higher is desirable as it indicates resistance to scratches and impacts. Buyers in sectors like automotive or industrial applications should prioritize panels with enhanced durability to minimize replacement costs. -

Operating Temperature Range

– Understanding the operating temperature range is essential, particularly for buyers in regions with extreme climates. Panels should be able to function effectively in a specified range, typically from -20°C to 70°C. This property is crucial for ensuring the longevity and reliability of the touch panels in various environments. -

Overlay Thickness

– The overlay thickness affects both the tactile feel and the optical clarity of the touch panel. Thicker overlays can offer better protection but may slightly reduce sensitivity. Buyers must balance the need for protection with the requirement for responsiveness, especially in consumer electronics.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces components or products that are purchased by another company and sold under that company’s brand name. Understanding OEM relationships is important for buyers looking for reliable suppliers who can provide customized solutions. -

MOQ (Minimum Order Quantity)

– MOQ refers to the minimum number of units that a supplier is willing to sell in a single order. This term is critical for buyers, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their production needs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing information for specific products or services. This process is vital for buyers to compare costs and ensure they receive competitive pricing. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms helps buyers manage shipping costs and risks effectively. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). -

Lead Time

– Lead time is the time taken from placing an order to receiving the goods. This period can vary based on supplier capabilities and logistics. Buyers should consider lead time when planning production schedules to avoid delays. -

Warranty Period

– The warranty period indicates the time frame during which the manufacturer guarantees the functionality of the touch panel. A longer warranty period can provide buyers with peace of mind regarding product reliability and performance.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions, negotiate effectively, and ensure that they procure the right capacitive touch panels for their applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the capacitive touch panel Sector

Market Overview & Key Trends

The capacitive touch panel market is experiencing significant growth driven by advancements in technology, increasing consumer demand for interactive devices, and the expansion of the Internet of Things (IoT). Globally, the market is projected to reach USD 36 billion by 2027, with a CAGR of approximately 8.5% from 2020 to 2027. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, key trends include the adoption of multi-touch capabilities, rising demand for flexible and curved displays, and the integration of touch technology in various sectors such as automotive, healthcare, and industrial applications.

Emerging technologies such as haptic feedback and gesture recognition are shaping the future of capacitive touch panels, providing enhanced user experiences. Buyers should also focus on sourcing components that support high durability and water resistance, as these features are increasingly demanded in consumer electronics. Furthermore, the shift towards smart appliances and wearable technology offers new opportunities, particularly for suppliers from regions with developing tech ecosystems. Understanding these trends will enable B2B buyers to make informed sourcing decisions and stay competitive in a rapidly evolving market.

Sustainability & Ethical Sourcing in B2B

As environmental concerns rise, sustainability in the capacitive touch panel sector is becoming a crucial consideration for B2B buyers. The manufacturing processes often involve materials like Indium Tin Oxide (ITO), which raises issues related to mining practices and resource depletion. To mitigate these impacts, companies are increasingly looking for suppliers who adhere to ethical sourcing practices and can provide transparency in their supply chains.

The importance of certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) cannot be overstated. These certifications ensure that suppliers are committed to reducing environmental impact and complying with international standards. Additionally, the use of eco-friendly materials and recyclable components is gaining traction, with an increasing number of manufacturers exploring alternatives to ITO, such as graphene and silver nanowires. By prioritizing suppliers with sustainable practices, B2B buyers can not only meet regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious consumers.

Brief Evolution/History

The capacitive touch panel technology has evolved significantly since its inception in the early 1980s. Initially used in simple applications like watches, the technology gained prominence with the advent of smartphones, particularly with Apple’s introduction of the iPhone in 2007. This marked a pivotal moment, transitioning capacitive touch panels into mainstream consumer electronics.

Over the years, advancements in materials science and manufacturing processes have led to thinner, more responsive, and durable touch panels. Modern developments include multi-touch capabilities and integration with haptic feedback systems, enhancing user interaction. As the technology continues to evolve, B2B buyers must stay informed about innovations that could impact their sourcing strategies, ensuring they leverage the latest advancements in capacitive touch panel technology.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of capacitive touch panel

-

What criteria should I use to vet suppliers of capacitive touch panels?

When vetting suppliers, prioritize those with a proven track record in capacitive touch panel manufacturing. Check their certifications, such as ISO 9001, which indicates a commitment to quality management. Request references from previous clients, especially those within your industry. Additionally, assess their production capabilities, including technology used, capacity for customization, and ability to meet international standards. Finally, ensure they have robust after-sales support to address any potential issues post-purchase. -

Can I customize the capacitive touch panels to meet my specific requirements?

Yes, many manufacturers offer customization options for capacitive touch panels. You can specify features such as size, shape, sensitivity levels, and overlay materials. Discuss your requirements during the initial conversations to understand the extent of customization available. Be aware that extensive customization may affect lead times and costs, so it’s essential to clarify these aspects upfront. -

What are the typical minimum order quantities (MOQs) and lead times for capacitive touch panels?

Minimum order quantities can vary significantly by supplier, ranging from as low as 100 units to thousands, depending on the complexity and customization of the panels. Lead times typically range from 4 to 12 weeks, influenced by factors such as order size, customization requirements, and the supplier’s production schedule. Always confirm these details before placing an order to ensure they align with your project timelines. -

What payment terms should I expect when sourcing capacitive touch panels?

Payment terms can vary, but common practices include a 30% deposit upon order confirmation and the balance upon delivery or before shipment. Some suppliers may also offer payment through letters of credit, especially for larger orders. Be sure to negotiate terms that are favorable and provide security for both parties. Understand the implications of your chosen payment method, particularly in terms of transaction fees and currency exchange rates.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certifications for the capacitive touch panels I purchase?

Request documentation of quality assurance processes and certifications from your supplier. Look for compliance with international standards such as CE, RoHS, or UL, which indicate safety and environmental compliance. You can also ask for sample products to conduct your own quality checks. Additionally, consider third-party quality audits or inspections to provide an unbiased assessment of the manufacturing process and end products. -

What logistics considerations should I keep in mind when sourcing capacitive touch panels?

Logistics play a crucial role in the timely delivery of your capacitive touch panels. Evaluate the supplier’s shipping options, including air freight for faster delivery or sea freight for cost efficiency. Understand any potential customs duties or tariffs that may apply when importing goods into your country. Plan for potential delays in transit and ensure that your supplier provides tracking information for transparency. -

How should I handle disputes with suppliers regarding capacitive touch panels?

Dispute resolution should begin with clear communication. Document all agreements and correspondences to provide a reference in case of misunderstandings. If issues arise, discuss them directly with the supplier to find a mutually agreeable solution. If necessary, refer to the terms outlined in your contract regarding dispute resolution procedures, which may include mediation or arbitration. Having a legal advisor familiar with international trade can also be beneficial. -

What are the best practices for integrating capacitive touch panels into my products?

Successful integration of capacitive touch panels requires careful consideration of design and layout. Follow guidelines provided by the manufacturer regarding PCB routing and electrode design to optimize performance. Ensure that your product’s software is compatible with the touch panel’s specifications. Conduct thorough testing during the prototyping phase to identify any potential issues early on. Collaborating closely with the supplier throughout the integration process can also enhance the final product’s quality and usability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for capacitive touch panel

In conclusion, the capacitive touch panel market presents a wealth of opportunities for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By leveraging strategic sourcing, businesses can enhance their supply chains, ensuring access to high-quality materials and advanced manufacturing processes. Key takeaways include the importance of understanding the intricate manufacturing stages, such as ITO pattern formation and modularization, which directly influence the performance and durability of touch panels.

Investing in relationships with reliable suppliers who adhere to stringent quality control measures will not only optimize costs but also foster innovation within your product offerings. Additionally, staying abreast of technological advancements and design guidelines is crucial for maintaining competitiveness in a rapidly evolving market.

As the demand for capacitive touch panels continues to grow, now is the time for buyers to act decisively. Embrace strategic sourcing to secure partnerships that will propel your business forward, ensuring you are well-positioned to meet future market demands and technological advancements. Engage with suppliers today to explore tailored solutions that cater to your specific needs, paving the way for mutual growth and success.