Master Sourcing Capacitive Touch Technology for Competitive

Introduction: Navigating the Global Market for capacitive touch

In an increasingly digital world, capacitive touch technology stands at the forefront of user interaction, transforming how consumers and businesses engage with devices. From smartphones to industrial equipment, capacitive touch panels offer unparalleled responsiveness and sensitivity, making them indispensable across various sectors. For international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of capacitive touch sourcing is crucial for maintaining a competitive edge.

This comprehensive guide delves into the essential aspects of capacitive touch technology, including types of panels, materials used, manufacturing processes, quality control standards, supplier evaluations, pricing strategies, and market dynamics. By breaking down these components, the guide equips buyers with actionable insights to navigate the complex landscape of capacitive touch sourcing.

The knowledge shared herein empowers decision-makers to make informed choices, ensuring that they select high-quality products that meet their specific needs. Understanding the nuances of this technology not only enhances product quality but also fosters long-term partnerships with reliable suppliers. As you explore this guide, you will gain the tools necessary to optimize your procurement strategy and harness the full potential of capacitive touch technology for your organization.

Understanding capacitive touch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Projected Capacitive Touch | Supports multi-touch and gestures; high sensitivity; durable | Smartphones, tablets, kiosks | Pros: Excellent responsiveness; versatile. Cons: Higher cost; may require complex integration. |

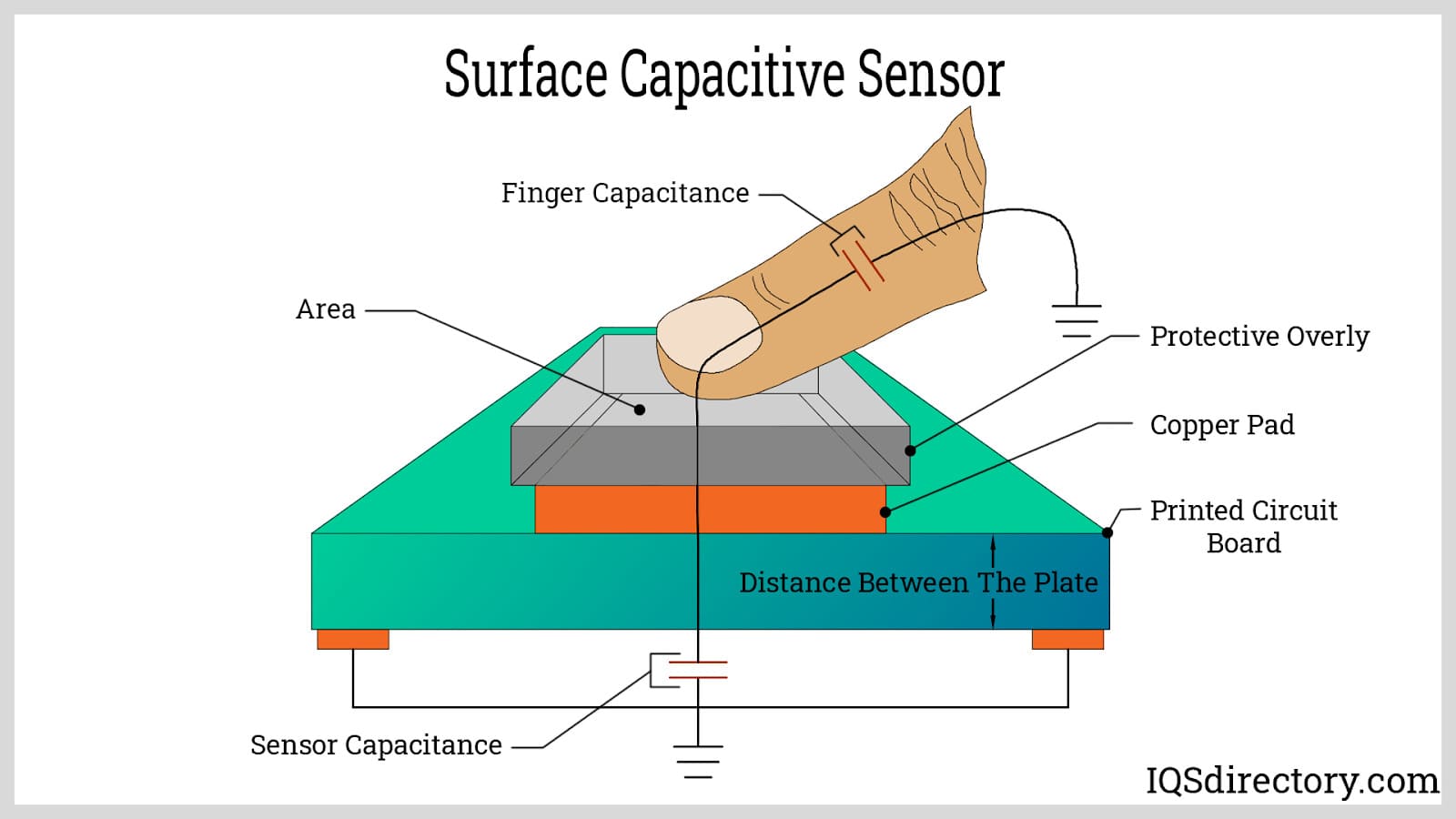

| Surface Capacitive Touch | Single touch detection; less sensitive; cost-effective | Industrial controls, POS systems | Pros: Affordable; easy to integrate. Cons: Limited functionality; not suitable for complex gestures. |

| Mutual Capacitive Touch | Detects multiple touch points; good for interactive displays | Gaming devices, automotive interfaces | Pros: Enhanced user interaction; supports gestures. Cons: More sensitive to environmental factors. |

| Self-Capacitance Touch | Measures capacitance at each electrode; highly sensitive | Wearable devices, medical equipment | Pros: High precision; compact design. Cons: Vulnerable to noise; may require shielding. |

| Transparent Capacitive Touch | Allows visibility through the touch panel; aesthetic appeal | Retail displays, automotive dashboards | Pros: Sleek design; enhances user experience. Cons: Typically lower durability; may have higher costs. |

Projected Capacitive Touch

Projected capacitive touch technology is renowned for its ability to support multi-touch interactions and gestures, making it a preferred choice for high-end consumer electronics such as smartphones and tablets. Its high sensitivity and durability are key advantages, providing users with a seamless experience. B2B buyers should consider the integration complexity and higher costs associated with this technology, as well as the necessity for proper calibration and support during installation.

Surface Capacitive Touch

Surface capacitive touch panels are cost-effective solutions primarily designed for single touch detection. They are widely utilized in industrial controls and point-of-sale (POS) systems due to their straightforward integration and affordability. However, buyers must be aware of their limitations in functionality, as they do not support multi-touch capabilities. This makes them less suitable for applications requiring complex gesture recognition.

Mutual Capacitive Touch

Mutual capacitive touch panels excel in detecting multiple touch points, making them ideal for interactive displays and gaming devices. This technology enhances user interaction by supporting gestures, thereby improving the overall user experience. B2B buyers should consider the environmental sensitivity of mutual capacitive touch panels, as they may require careful placement and protection from external elements to maintain functionality.

Self-Capacitance Touch

Self-capacitance touch technology measures the capacitance at each electrode, providing high precision in touch detection. This makes it suitable for applications like wearable devices and medical equipment, where accuracy is paramount. However, buyers must account for its vulnerability to noise and environmental interference, which may necessitate additional shielding to ensure reliable performance.

Transparent Capacitive Touch

Transparent capacitive touch panels offer a unique advantage by allowing visibility through the touch surface, making them particularly appealing for retail displays and automotive dashboards. Their aesthetic appeal enhances user engagement, but buyers should be cautious about durability issues, as these panels tend to be less robust than other types. Additionally, the costs associated with transparent capacitive touch technology can be higher, necessitating a careful evaluation of the return on investment.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of capacitive touch

| Industry/Sector | Specific Application of Capacitive Touch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Smartphones and Tablets | Enhanced user interaction and satisfaction | High sensitivity, low latency, and robust durability are crucial. |

| Industrial Equipment | Control Panels for Machinery | Improved operational efficiency and user safety | Must meet environmental standards and have multi-touch capabilities. |

| Automotive | Infotainment Systems | Streamlined user experience and intuitive navigation | High durability and resistance to environmental factors are essential. |

| Healthcare | Medical Devices and Equipment | Accurate touch response for critical applications | Compliance with healthcare regulations and high hygiene standards. |

| Retail | Point of Sale Systems | Faster transactions and improved customer engagement | Strong durability and compatibility with various software platforms. |

Consumer Electronics

In consumer electronics, capacitive touch technology is integral to smartphones and tablets, where it enables seamless user interaction. This technology enhances user satisfaction through its high sensitivity and responsiveness, allowing for quick navigation and accurate input. For international B2B buyers, sourcing panels that minimize latency and maximize durability is essential, particularly in regions with varying environmental conditions.

Industrial Equipment

Capacitive touch panels are widely used in industrial control panels, providing operators with intuitive interfaces for machinery. These panels enhance operational efficiency and safety by allowing for precise touch inputs, even in challenging environments. Buyers should prioritize sourcing panels with high ingress protection (IP) ratings to ensure durability in dusty or wet conditions, along with multi-touch capabilities for complex control operations.

Automotive

In the automotive sector, capacitive touch technology is utilized in infotainment systems, providing drivers and passengers with intuitive controls for navigation, audio, and climate settings. The benefits include a streamlined user experience and enhanced safety through hands-free operation. B2B buyers in this field must consider the durability of touch panels, as they need to withstand temperature fluctuations and vibrations typical in vehicles.

Healthcare

Capacitive touch is crucial in the development of medical devices and equipment, where accurate touch response is vital for patient monitoring and diagnostics. This technology allows healthcare professionals to interact with devices efficiently, improving patient care. Buyers need to ensure that sourced panels comply with healthcare regulations and maintain high hygiene standards, particularly in environments where cleanliness is paramount.

Retail

Point of Sale (POS) systems in retail environments leverage capacitive touch technology to facilitate faster transactions and improve customer engagement. The intuitive nature of touch screens allows cashiers to process sales swiftly, enhancing the overall shopping experience. B2B buyers must focus on sourcing touch panels that are not only durable but also compatible with various software systems to ensure seamless integration into existing retail infrastructures.

Related Video: Capacitive Sensor Explained | Different Types and Applications

Strategic Material Selection Guide for capacitive touch

When selecting materials for capacitive touch panels, it is essential to consider the properties, advantages, and limitations of various materials. This analysis focuses on four common materials used in capacitive touch technology: Glass, Polyester (PET), Indium Tin Oxide (ITO), and Conductive Silver Ink. Each material presents unique characteristics that can impact performance, manufacturing complexity, and suitability for specific applications.

Glass

Key Properties: Glass is known for its high transparency, scratch resistance, and durability. It can withstand high temperatures and pressures, making it suitable for various environments.

Pros & Cons: The primary advantage of glass is its durability and aesthetic appeal, which enhances the user experience. However, glass can be heavy and may increase the overall weight of the device. Additionally, the manufacturing process can be more complex and costly compared to other materials.

Impact on Application: Glass is compatible with a wide range of media and is often used in consumer electronics, automotive displays, and industrial applications. Its resistance to scratching makes it ideal for devices that require frequent interaction.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for safety and quality. In regions like Africa and South America, where environmental conditions can vary, selecting glass with appropriate IP ratings is crucial.

Polyester (PET)

Key Properties: Polyester, or PET, is lightweight, flexible, and has good chemical resistance. It can perform well in various temperature ranges, making it suitable for diverse applications.

Pros & Cons: PET is less expensive than glass and easier to manufacture, which can lead to lower production costs. However, it is less durable and can be more prone to scratching and wear over time compared to glass.

Impact on Application: PET is commonly used in applications where flexibility is essential, such as wearable devices and portable electronics. Its lightweight nature makes it suitable for devices that require portability.

Considerations for International Buyers: Buyers should consider the local climate and environmental conditions when selecting PET. Compliance with RoHS standards is essential to ensure that the material is free from hazardous substances, particularly in European markets.

Indium Tin Oxide (ITO)

Key Properties: ITO is a transparent conductive oxide that offers excellent electrical conductivity and optical transparency. It can operate effectively at various temperatures and is resistant to corrosion.

Pros & Cons: The key advantage of ITO is its ability to provide both conductivity and transparency, making it ideal for capacitive touch applications. However, ITO is relatively expensive and can be brittle, which may lead to challenges in manufacturing and durability.

Impact on Application: ITO is widely used in high-end consumer electronics, such as smartphones and tablets, where clarity and touch sensitivity are paramount. Its compatibility with various substrates enhances its application versatility.

Considerations for International Buyers: Due to its cost, buyers should evaluate the total cost of ownership when considering ITO. Compliance with industry certifications is vital, particularly in regions like Europe, where strict regulations apply.

Conductive Silver Ink

Key Properties: Conductive silver ink is a flexible and lightweight material that offers excellent conductivity. It can be printed onto various substrates, making it highly versatile.

Pros & Cons: The major advantage of conductive silver ink is its low manufacturing cost and ease of application through printing techniques. However, it may not offer the same level of durability and environmental resistance as glass or ITO.

Impact on Application: This material is ideal for applications where flexibility and lightweight designs are crucial, such as in smart textiles and flexible displays.

Considerations for International Buyers: Buyers should assess the long-term stability and reliability of conductive silver ink in their specific applications. Compliance with international standards is essential to ensure product safety and performance.

Summary Table

| Material | Typical Use Case for capacitive touch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Consumer electronics, automotive | High durability and scratch resistance | Heavy and complex manufacturing | High |

| Polyester (PET) | Wearable devices, portable electronics | Lightweight and cost-effective | Less durable, prone to scratching | Medium |

| Indium Tin Oxide (ITO) | High-end smartphones, tablets | Excellent conductivity and transparency | Expensive and brittle | High |

| Conductive Silver Ink | Smart textiles, flexible displays | Low manufacturing cost and flexibility | Lower durability and stability | Low |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions when sourcing capacitive touch materials, ensuring they align with their specific application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for capacitive touch

The manufacturing of capacitive touch panels involves a series of meticulously coordinated steps that ensure high-quality output and compliance with international standards. Understanding these processes is essential for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, as it enables informed sourcing decisions.

Manufacturing Process

1. Material Preparation

The first stage in the manufacturing of capacitive touch panels is the selection and preparation of raw materials. This typically involves:

- Glass Selection: High-quality glass sheets are chosen based on clarity, thickness, and durability. The selected glass must allow for optimal light transmission and resist scratches.

- Conductive Coating Preparation: Materials such as Indium Tin Oxide (ITO) are prepared for application. This conductive coating is essential for the touch sensitivity of the panel, allowing it to detect touch inputs effectively.

2. Forming

In this stage, the prepared materials undergo several processes to create the functional layers of the touch panel:

- Etching: Microscopic patterns are etched onto the glass to form electrodes. This process is crucial for establishing the capacitive touch capabilities.

- Thin Film Deposition: A thin layer of conductive material (ITO) is deposited onto the etched glass. This process is typically achieved through techniques such as sputtering or chemical vapor deposition (CVD), which ensure uniformity and adherence.

3. Assembly

The assembly phase is where different components come together to form the complete touch panel:

- Layer Lamination: Multiple layers, including the cover glass, touch sensor layer, and protective coatings, are laminated together. This process often employs transparent adhesives to minimize optical distortion and maintain sensitivity.

- Vacuum Sealing: A vacuum process is applied to eliminate air bubbles between layers, ensuring optimal touch performance and durability.

4. Finishing

Once assembled, the panels undergo finishing processes that enhance their functionality and aesthetics:

- Surface Treatment: Anti-glare and anti-fingerprint coatings may be applied to improve usability in various lighting conditions.

- Final Inspection: Each panel is subjected to rigorous quality checks to ensure it meets performance specifications. This includes verifying touch sensitivity, visual clarity, and overall integrity.

Quality Assurance

Quality assurance is a critical aspect of the manufacturing process for capacitive touch panels. B2B buyers should understand the standards and practices that manufacturers employ to ensure product quality.

Relevant International Standards

- ISO 9001: This standard outlines requirements for a quality management system and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: This indicates compliance with European health, safety, and environmental protection standards, which is crucial for products sold in Europe.

- RoHS Compliance: This standard restricts the use of specific hazardous materials in electrical and electronic equipment, ensuring environmental safety.

Quality Control Checkpoints

Quality control is implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to detect any defects or deviations from standards.

- Final Quality Control (FQC): The completed panels undergo comprehensive testing to ensure they meet all performance metrics before shipping.

Common Testing Methods

B2B buyers should be aware of the following testing methods that manufacturers commonly use:

- Touch Sensitivity Testing: Evaluates the responsiveness of the panel to touch inputs.

- Durability Testing: Assesses the panel’s resistance to scratches, impacts, and environmental factors.

- Optical Testing: Measures parameters such as brightness, color accuracy, and clarity under different lighting conditions.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in regions like Africa, South America, and the Middle East, verifying the quality control measures of suppliers is paramount. Here are actionable steps:

- Supplier Audits: Conduct on-site audits to assess the manufacturing processes and quality assurance protocols in place. This firsthand observation can provide valuable insights into the supplier’s capabilities.

- Request Quality Assurance Documentation: Ask suppliers for documentation detailing their quality control processes, certifications, and testing results. This transparency is essential for assessing product reliability.

- Third-Party Inspections: Engage third-party inspection services to conduct independent evaluations of the manufacturing facilities and the products. This can add an extra layer of assurance regarding quality standards.

QC and Certification Nuances for International Buyers

International buyers must navigate various nuances related to quality control and certification:

- Understanding Local Regulations: Familiarize yourself with the regulations and standards that apply in your region. For instance, products imported into the European Union must meet specific compliance requirements, which may differ from those in Africa or South America.

- Cultural and Language Considerations: Effective communication with suppliers is crucial. Misunderstandings can arise due to language barriers or cultural differences. Establish clear lines of communication and consider using translators or local representatives if necessary.

- Logistical Challenges: Be aware of potential logistical challenges in sourcing products internationally. Factors such as shipping times, customs regulations, and tariffs can impact delivery schedules and costs.

By understanding the intricacies of the manufacturing processes and quality assurance practices involved in capacitive touch panel production, B2B buyers can make informed decisions that align with their business needs. Prioritizing quality and compliance not only enhances product reliability but also fosters long-term supplier relationships, crucial for success in today’s competitive marketplace.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for capacitive touch Sourcing

Understanding the cost structure and pricing dynamics of capacitive touch panels is essential for B2B buyers aiming to make informed sourcing decisions. This analysis delves into the various cost components, pricing influencers, and provides actionable insights specifically tailored for international buyers, particularly those from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials for capacitive touch panels include glass, conductive coatings (like indium tin oxide), and various electronic components. The quality and source of these materials significantly impact the overall cost. For instance, high-grade glass may come at a premium but enhances durability and performance.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and the complexity of the manufacturing process. Skilled labor is essential for quality assurance and assembly, particularly in high-tech environments.

-

Manufacturing Overhead: This includes indirect costs associated with production facilities, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be a key consideration for buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs or high-volume orders. Buyers should consider these costs when evaluating the total price, particularly for unique specifications.

-

Quality Control (QC): Rigorous QC processes are crucial to ensure product reliability. The costs associated with testing and certification can vary, depending on the required industry standards and certifications.

-

Logistics: Shipping and handling costs play a significant role, especially for international buyers. Factors such as distance, shipping method, and freight rates can influence overall costs.

-

Margin: Suppliers typically include a margin that reflects their business strategy, market demand, and competitive positioning. Understanding the margin expectations of suppliers can aid in negotiations.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) often dictate pricing. Larger orders generally benefit from scale economies, reducing the per-unit cost. Buyers should assess their purchasing needs against MOQs to optimize costs.

-

Specifications/Customization: Custom features can drive up costs. Clearly defining specifications upfront can help avoid unexpected expenses during production.

-

Materials: The choice of materials can significantly affect pricing. For instance, using standard materials versus premium options can lead to considerable price differences.

-

Quality/Certifications: Products that meet higher quality standards or certifications (ISO, CE, RoHS) typically command higher prices. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: Supplier experience, reputation, and reliability can influence costs. Established suppliers may charge more but often provide better quality and service, which can justify the expense.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects logistics costs and risk allocation. Understanding these terms can help buyers negotiate better shipping arrangements and costs.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing components. Being transparent about your needs and constraints can lead to better pricing arrangements.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs over the product’s lifespan. This approach helps in making more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should consider currency fluctuations, import duties, and local market conditions that can affect pricing. Establishing relationships with local distributors can help navigate these complexities.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices across different suppliers. This will provide leverage in negotiations and help identify competitive pricing.

Disclaimer

The prices and cost structures discussed are indicative and may vary based on specific circumstances, market conditions, and supplier negotiations. Always conduct due diligence and seek multiple quotes to ensure competitive pricing.

Spotlight on Potential capacitive touch Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘capacitive touch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for capacitive touch

Understanding the technical properties and trade terminology related to capacitive touch panels is crucial for international B2B buyers. This knowledge ensures informed procurement decisions that align with specific application requirements and market demands.

Key Technical Properties of Capacitive Touch Panels

-

Material Grade

– Definition: The quality of materials used in the construction of capacitive touch panels, including glass, conductive coatings, and underlying substrates.

– B2B Importance: Higher-grade materials enhance durability and performance, reducing the risk of product failure. Buyers should prioritize suppliers that utilize high-quality materials to ensure longevity and reliability in their applications. -

Touch Sensitivity

– Definition: The panel’s ability to detect touch input, usually measured in terms of responsiveness and the minimum force required to register a touch.

– B2B Importance: High sensitivity is crucial for user experience, particularly in consumer electronics. Buyers must evaluate this specification to ensure that the touch panel meets the interactive needs of their products.

Illustrative Image (Source: Google Search)

-

Latency

– Definition: The time delay between a touch event and the corresponding response on the screen.

– B2B Importance: Low latency is essential for applications requiring immediate feedback, such as gaming or professional tools. Buyers should seek panels with minimal latency to enhance user satisfaction and maintain competitive advantages. -

Ingress Protection (IP) Rating

– Definition: A standard rating that indicates the level of protection against dust and water ingress.

– B2B Importance: Panels with higher IP ratings are suited for harsh environments, making them ideal for outdoor or industrial applications. Understanding this rating helps buyers select appropriate products for specific use cases. -

Multi-Touch Capability

– Definition: The ability of a touch panel to recognize multiple simultaneous touch points.

– B2B Importance: Essential for applications involving complex gestures, multi-touch capability enhances user interaction. Buyers must ensure that the selected panels support the required number of touch points for their intended applications. -

Display Resolution

– Definition: The clarity and detail of the visual output, typically measured in pixels.

– B2B Importance: Higher resolution displays improve user experience, especially in graphic-intensive applications. Buyers should assess the resolution to ensure that the touch panel meets visual standards and enhances functionality.

Common Trade Terms in Capacitive Touch Sourcing

-

OEM (Original Equipment Manufacturer)

– Explanation: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is vital for buyers looking to collaborate or source components for their devices. -

MOQ (Minimum Order Quantity)

– Explanation: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their procurement strategy and manage inventory effectively, especially when dealing with suppliers in various regions.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

– Explanation: A document issued by a buyer to solicit price quotes from potential suppliers.

– Relevance: Submitting an RFQ is a critical step in the procurement process, allowing buyers to compare prices and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

– Explanation: A set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is essential for international buyers to understand shipping responsibilities, costs, and risk management during transport. -

Lead Time

– Explanation: The time taken from placing an order to the delivery of goods.

– Relevance: Understanding lead times is critical for planning production schedules and managing inventory, especially in industries with tight timelines. -

Quality Control (QC)

– Explanation: The process of ensuring that products meet specified requirements and standards.

– Relevance: A robust QC process indicates a supplier’s commitment to product quality, which is vital for maintaining the reliability of capacitive touch panels in end applications.

Equipping yourself with this knowledge empowers B2B buyers to make strategic decisions, fostering successful partnerships and ensuring the procurement of high-quality capacitive touch panels suited to their specific needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the capacitive touch Sector

In the rapidly evolving landscape of capacitive touch technology, several key trends and dynamics are shaping the market. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these elements is crucial for making informed sourcing decisions.

Market Overview & Key Trends

The capacitive touch panel market is witnessing significant growth driven by the increasing demand for smart devices, interactive displays, and automation in various sectors. The global push towards digital transformation is a major catalyst, with industries such as retail, healthcare, and education adopting touch-enabled solutions to enhance user engagement and operational efficiency.

Emerging trends include the integration of multi-touch capabilities and haptic feedback technology, which improve the user experience by enabling more intuitive interactions. Furthermore, the rise of flexible and transparent touch panels is opening new avenues for applications in automotive displays and wearable devices.

From a sourcing perspective, international buyers must navigate fluctuations in raw material availability, driven by geopolitical tensions and supply chain disruptions. To mitigate these risks, diversifying supplier bases and leveraging local manufacturing capabilities can provide greater resilience. For example, Turkey’s strategic location as a bridge between Europe and Asia offers opportunities for sourcing high-quality panels with reduced lead times.

Sustainability & Ethical Sourcing in B2B

The capacitive touch sector is increasingly prioritizing sustainability, reflecting a broader industry trend towards environmentally responsible practices. The manufacturing of touch panels can have significant environmental impacts, particularly concerning resource extraction and waste management. Therefore, B2B buyers should emphasize the importance of ethical sourcing and ensure that their suppliers adhere to sustainable practices.

Buyers should look for suppliers that have obtained green certifications, such as ISO 14001 for environmental management and RoHS compliance, which restricts hazardous substances. Additionally, sourcing materials that are recyclable or made from sustainable resources can help minimize the ecological footprint.

Implementing ethical supply chain practices not only enhances brand reputation but also meets the growing consumer demand for sustainable products. By choosing suppliers committed to environmentally friendly practices, B2B buyers can contribute to a more sustainable future while ensuring the longevity and reliability of their touch panel solutions.

Brief Evolution/History

The evolution of capacitive touch technology dates back to the 1960s, but it gained significant traction with the advent of smartphones in the late 2000s. The transition from resistive to capacitive touch panels marked a pivotal moment, allowing for greater sensitivity and multi-touch capabilities. Today, capacitive touch panels are not only ubiquitous in consumer electronics but are also penetrating industrial, automotive, and medical markets. This evolution underscores the need for B2B buyers to stay abreast of technological advancements and adapt their sourcing strategies accordingly.

In summary, navigating the capacitive touch sector requires a keen understanding of market dynamics, a commitment to sustainability, and awareness of the technology’s evolution. By focusing on these areas, international B2B buyers can make strategic sourcing decisions that align with their business goals and values.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of capacitive touch

-

How do I vet potential suppliers for capacitive touch panels?

To effectively vet suppliers, start by assessing their industry experience and reputation. Look for suppliers with a proven track record in manufacturing capacitive touch panels, including client references and case studies. Verify their compliance with international quality standards such as ISO and CE certifications. Additionally, request samples to evaluate product quality firsthand and consider conducting on-site audits to observe their production processes and quality assurance practices. -

Can I customize capacitive touch panels to fit my specific needs?

Yes, many manufacturers offer customization options for capacitive touch panels. This may include adjustments in size, shape, touch sensitivity, and surface coatings. When discussing customization, clearly communicate your requirements and any specific applications you have in mind. Ensure that the supplier has the capability to meet these specifications and inquire about any additional costs or lead times associated with custom orders. -

What are the typical minimum order quantities (MOQs) and lead times for capacitive touch panels?

Minimum order quantities can vary significantly based on the supplier and the complexity of the capacitive touch panel. Generally, MOQs can range from a few hundred to several thousand units. Lead times typically range from 4 to 12 weeks, depending on customization, production schedules, and shipping logistics. It’s advisable to discuss these aspects upfront to align your procurement strategy with your operational needs. -

What quality assurance certifications should I look for when sourcing capacitive touch panels?

Key certifications to consider include ISO 9001 for quality management systems, CE marking for compliance with European health and safety standards, and RoHS certification to ensure that the products are free from hazardous substances. Additionally, consider suppliers that adhere to IPC standards for electronic manufacturing. Request documentation of these certifications to validate the supplier’s commitment to quality and safety. -

How can I ensure smooth logistics when importing capacitive touch panels?

To ensure smooth logistics, work closely with your supplier to understand shipping terms and methods. Consider factors such as shipping costs, customs duties, and insurance. It’s beneficial to partner with a logistics provider experienced in international trade who can navigate customs regulations and ensure timely delivery. Discuss potential logistical challenges upfront, including transportation delays or documentation requirements, to mitigate risks.

-

What should I do if I encounter a dispute with my supplier?

In case of a dispute, first attempt to resolve the issue through direct communication with the supplier. Clearly document your concerns and any agreements made. If the issue persists, refer to the contract terms regarding dispute resolution, which may include mediation or arbitration clauses. It’s also advisable to consult with legal counsel experienced in international trade to understand your rights and obligations under the applicable laws. -

Are there specific payment terms I should consider when sourcing capacitive touch panels?

Payment terms can vary, but common practices include upfront deposits (typically 30-50%) and the balance upon delivery or acceptance of goods. Consider using letters of credit for larger transactions to secure payment and protect both parties. Additionally, be aware of the risks associated with different payment methods and negotiate terms that provide adequate protection for your investment while maintaining a good relationship with the supplier. -

What emerging trends in capacitive touch technology should I be aware of?

Emerging trends include advancements in haptic feedback, which enhances user interaction by providing tactile responses, and the development of flexible touch panels that can be integrated into a wider array of devices. Additionally, innovations in anti-glare and anti-fingerprint coatings are improving user experience. Staying informed about these trends will help you make strategic sourcing decisions and ensure your products remain competitive in the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for capacitive touch

In conclusion, the strategic sourcing of capacitive touch panels is essential for businesses aiming to enhance their product offerings and maintain a competitive edge. Key considerations include evaluating sensitivity, durability, multi-touch capabilities, and compliance with industry standards. By prioritizing suppliers with robust quality control processes and proven experience, international B2B buyers can ensure they receive high-quality products that meet their specific needs.

Furthermore, understanding market dynamics and emerging technologies, such as haptic feedback and flexible displays, will enable companies to stay ahead of the curve. These insights are crucial for maximizing the return on investment and improving user experience across various applications, from consumer electronics to industrial devices.

As the global landscape evolves, particularly in regions like Africa, South America, the Middle East, and Europe, it is imperative for businesses to adopt a proactive approach to sourcing. By diversifying suppliers and staying informed about technological advancements, organizations can mitigate risks and capitalize on new opportunities.

Now is the time to leverage these insights and refine your sourcing strategy for capacitive touch panels. Engage with trusted suppliers, explore innovative solutions, and position your business for future success in this dynamic market.