Master Sourcing Ceramic Heating Elements: A Comprehensive

Introduction: Navigating the Global Market for ceramic heating element

Navigating the global market for ceramic heating elements is essential for international B2B buyers seeking reliable heating solutions for various industrial applications. Ceramic heating elements are vital in sectors such as manufacturing, electronics, and food processing, thanks to their efficiency, durability, and ability to withstand extreme temperatures. These components convert electrical energy into heat through advanced ceramic materials, ensuring uniform heat distribution and high thermal efficiency.

This comprehensive guide serves as an invaluable resource for B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like South Africa and the UAE. It covers essential topics such as the types of ceramic heating elements, the materials used in their production, and the manufacturing and quality control processes that ensure product reliability. Additionally, the guide provides insights into supplier selection, cost considerations, and market trends, empowering buyers to make informed sourcing decisions.

By leveraging the insights contained within this guide, international B2B buyers can confidently navigate the complexities of the ceramic heating element market. Understanding the nuances of these products will not only enhance operational efficiency but also drive competitive advantage in today’s fast-paced global economy. Equip yourself with the knowledge needed to select the best heating solutions for your business needs and stay ahead in the market.

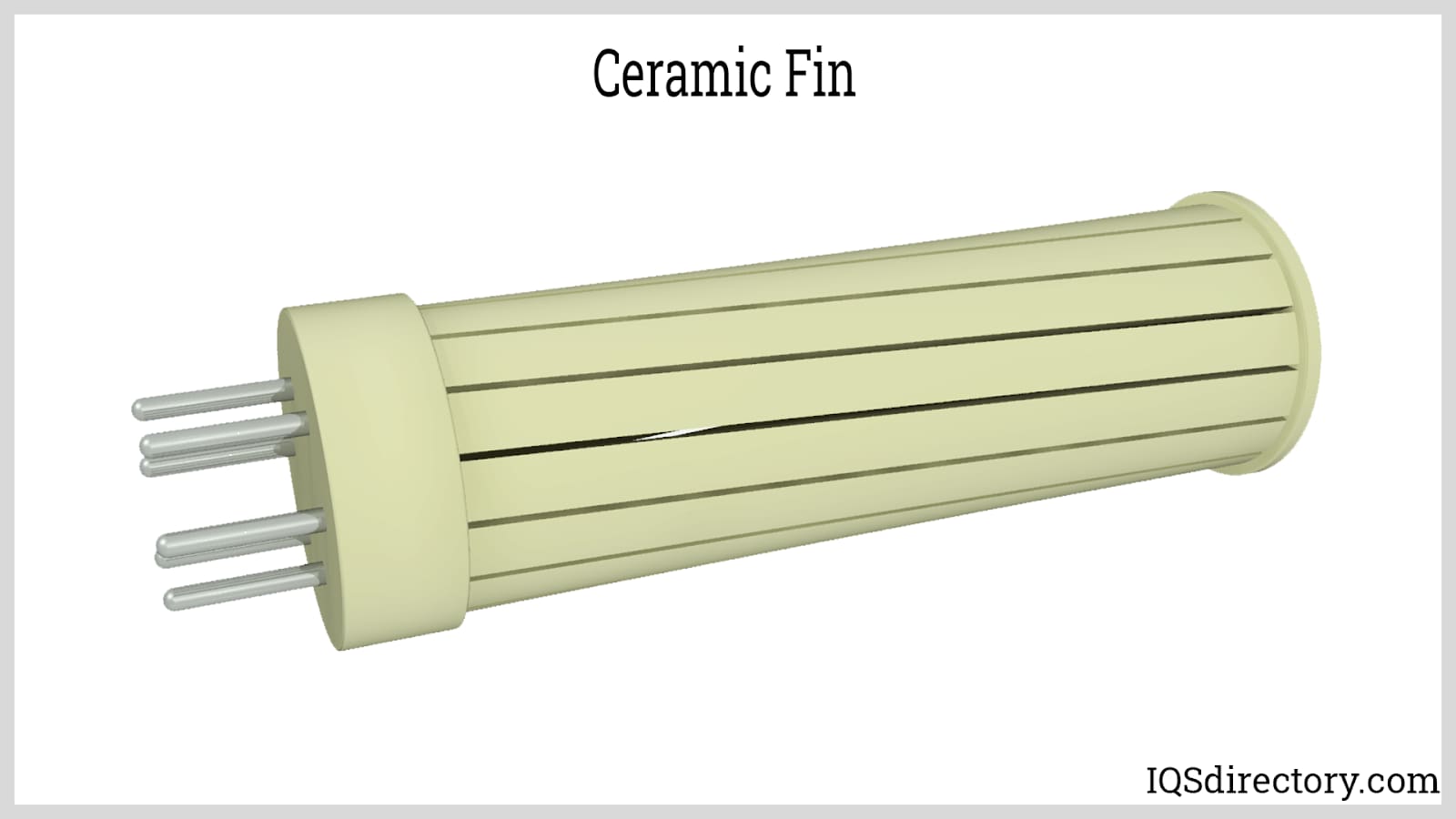

Understanding ceramic heating element Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MCH (Metal-Ceramic Heater) | Rapid heating, compact design, embedded metal circuits | Hair straighteners, soldering tools, medical devices | Pros: Fast heat-up, high efficiency; Cons: Higher initial cost. |

| Tubular Heating Elements | Versatile shapes, high durability, custom lengths | Industrial ovens, HVAC systems, water heaters | Pros: Customizable, durable; Cons: May require more space. |

| Infrared Ceramic Heaters | Emit infrared radiation, efficient energy use | Food processing, drying applications | Pros: Quick heating, energy-efficient; Cons: Limited penetration depth. |

| Cartridge Heating Elements | Compact, easy installation, precise temperature control | 3D printers, laboratory equipment | Pros: Space-saving, precise; Cons: Limited to specific applications. |

| Flexible Heating Elements | Bendable, lightweight, adaptable to various surfaces | Medical equipment, automotive applications | Pros: Versatile installation, lightweight; Cons: May be less durable than rigid options. |

MCH (Metal-Ceramic Heater)

MCH elements are known for their rapid heating capabilities and compact design, making them ideal for applications that require quick temperature changes, such as hair straighteners and soldering tools. The integration of metal circuits within the ceramic allows for precise temperature control, which is critical in medical devices. When purchasing MCH heaters, buyers should consider the specific power requirements and ensure compatibility with their existing systems to maximize efficiency.

Tubular Heating Elements

These elements are highly versatile and can be manufactured in various shapes and lengths, making them suitable for a wide range of applications, including industrial ovens and HVAC systems. Their durability and resistance to high temperatures make them a reliable choice for long-term use. Buyers should assess their space requirements and the specific heating needs of their application, as tubular elements can take up more room compared to other types.

Infrared Ceramic Heaters

Infrared ceramic heaters are designed to emit infrared radiation, which provides efficient heating by directly warming objects rather than the air. This makes them particularly useful in food processing and drying applications. Buyers should consider the heating area and energy consumption, as infrared heaters can offer significant savings in energy costs but may have limitations in penetration depth, affecting their efficiency in larger spaces.

Cartridge Heating Elements

Cartridge heaters are compact and easy to install, making them suitable for applications like 3D printing and laboratory equipment where space is at a premium. They provide precise temperature control, which is essential for maintaining the quality of sensitive processes. B2B buyers should evaluate the watt density and thermal stability of cartridge heaters to ensure they meet the specific requirements of their applications.

Flexible Heating Elements

These elements are lightweight and can be bent to fit various surfaces, making them ideal for applications in medical equipment and automotive industries. Their adaptability allows for innovative designs, but buyers should be mindful of their potential limitations in durability compared to more rigid heating solutions. When sourcing flexible heating elements, it’s important to consider the operating environment and the specific application needs to ensure optimal performance.

Key Industrial Applications of ceramic heating element

| Industry/Sector | Specific Application of ceramic heating element | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial ovens and kilns for ceramics and metal processing | High thermal efficiency and rapid heat-up times | Ensure high-temperature resistance and durability |

| Food Processing | Bakery ovens and food dehydrators | Consistent heating for quality control | Look for energy efficiency and precise temperature control |

| Automotive | Soldering and welding equipment | Enhanced precision in assembly processes | Verify compatibility with existing systems and safety standards |

| Medical Devices | Heating elements in sterilizers and diagnostic equipment | Reliable performance under high standards | Focus on compliance with medical regulations and certifications |

| Textiles | Drying machines and heat treatment processes | Improved product quality and reduced cycle times | Consider space-saving designs and energy efficiency |

Manufacturing

Ceramic heating elements are integral to industrial ovens and kilns used in ceramics and metal processing. Their ability to withstand high temperatures and provide uniform heat distribution ensures optimal material properties. For international buyers, particularly from regions like Africa and South America, sourcing elements with high durability and thermal efficiency is critical to minimize downtime and enhance productivity.

Food Processing

In the food processing sector, ceramic heating elements are commonly found in bakery ovens and food dehydrators. They offer consistent heating, which is essential for maintaining product quality and safety. Buyers in Europe and the Middle East should prioritize energy-efficient models that not only reduce operational costs but also comply with local food safety regulations.

Automotive

In the automotive industry, ceramic heating elements are utilized in soldering and welding equipment. Their precise heating capabilities enhance the accuracy of assembly processes, which is vital for meeting stringent quality standards. B2B buyers should ensure that the heating elements are compatible with existing machinery and meet safety regulations to avoid operational risks.

Medical Devices

Ceramic heating elements are used in sterilizers and diagnostic equipment within the medical field. Their reliable performance is crucial for maintaining the high standards required in medical applications. Buyers, particularly from Africa and the Middle East, should focus on sourcing elements that comply with international medical device regulations to ensure safety and efficacy.

Textiles

In the textile industry, ceramic heating elements are employed in drying machines and heat treatment processes. Their efficient heating contributes to improved product quality and reduced cycle times, which are essential for maintaining competitiveness. Buyers from Europe and South America should consider energy-efficient and compact designs that can easily integrate into existing production lines.

Related Video: How PTC Heating Element Technology Works

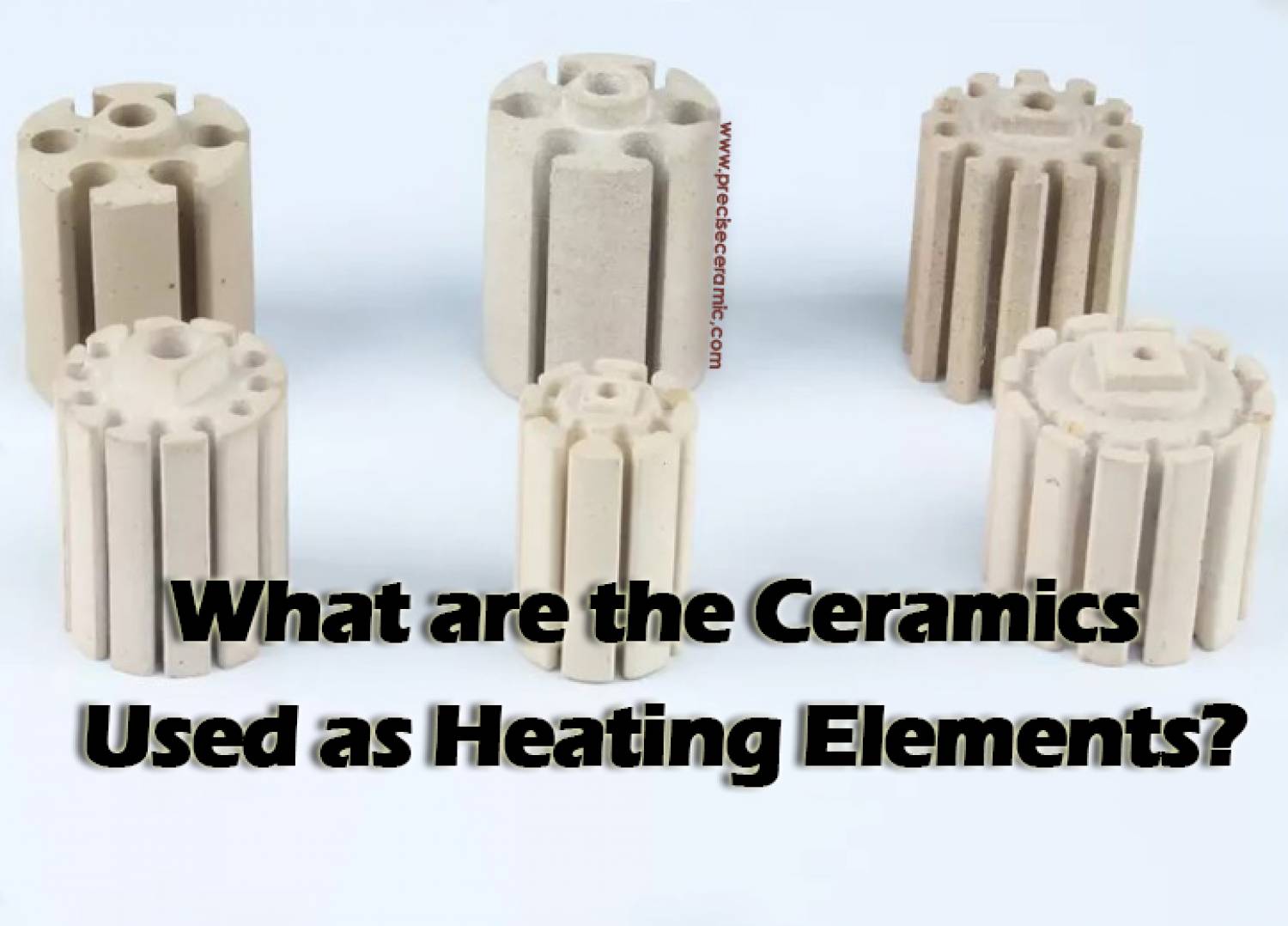

Strategic Material Selection Guide for ceramic heating element

Ceramic heating elements are integral to various industrial applications, and the choice of material significantly influences their performance and suitability. Below, we analyze four common materials used in ceramic heating elements, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Silicon Carbide (SiC)

Key Properties:

Silicon carbide is known for its high thermal conductivity and excellent thermal shock resistance. It can operate at temperatures exceeding 1,600°C and withstand significant mechanical stress. SiC also exhibits good chemical resistance, making it suitable for harsh environments.

Pros & Cons:

Silicon carbide’s durability and high-temperature performance make it ideal for applications like high-temperature furnaces. However, it is relatively expensive to manufacture, which can increase the overall cost of the heating element. Additionally, the brittleness of SiC can pose challenges during handling and installation.

Impact on Application:

SiC is particularly effective in applications involving molten metals or aggressive chemical processes, where other materials may degrade. Its compatibility with a wide range of media enhances its usability in diverse industrial sectors.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure that their suppliers comply with relevant standards such as ASTM and DIN, particularly for high-temperature applications. Understanding local regulations regarding material safety and environmental impact is also crucial.

Alumina (Al2O3)

Key Properties:

Alumina is characterized by its high electrical resistance and excellent thermal stability, withstanding temperatures up to 1,500°C. It also has good mechanical strength and is resistant to oxidation and corrosion.

Pros & Cons:

The primary advantage of alumina is its cost-effectiveness compared to other ceramic materials. It is widely available and can be manufactured in various forms, making it versatile for different applications. However, its thermal conductivity is lower than that of silicon carbide, which may limit its efficiency in some high-performance applications.

Impact on Application:

Alumina is commonly used in household appliances, industrial heaters, and electronic devices. Its compatibility with various heating environments makes it a popular choice among manufacturers.

Considerations for International Buyers:

B2B buyers should verify the alumina grade and ensure it meets specific application requirements. Compliance with international standards is essential, especially for products exported to Europe, where regulations may be stringent.

Zirconia (ZrO2)

Key Properties:

Zirconia offers exceptional thermal insulation and can operate at temperatures up to 2,500°C. It has low thermal conductivity and excellent resistance to thermal shock, making it suitable for extreme environments.

Pros & Cons:

The primary advantage of zirconia is its ability to maintain structural integrity at high temperatures. However, it is one of the more expensive ceramic materials, and its manufacturing process can be complex, potentially leading to longer lead times.

Impact on Application:

Zirconia is ideal for applications requiring high thermal insulation, such as in aerospace and advanced manufacturing processes. Its unique properties make it suitable for specialized heating elements.

Considerations for International Buyers:

Buyers should consider the availability of zirconia and the associated costs. Understanding the supply chain dynamics in regions like South America can help mitigate delays due to sourcing challenges.

Mullite (3Al2O3·2SiO2)

Key Properties:

Mullite is known for its excellent thermal stability and low thermal expansion, withstanding temperatures up to 1,600°C. It has good mechanical strength and thermal shock resistance.

Pros & Cons:

Mullite’s combination of properties makes it suitable for a variety of applications, including kilns and furnaces. However, it is less thermally conductive than silicon carbide, which may limit its efficiency in certain scenarios.

Impact on Application:

Mullite is often used in the ceramics and glass industries, where high-temperature stability is crucial. Its ability to resist thermal shock makes it valuable in environments with rapid temperature changes.

Considerations for International Buyers:

When sourcing mullite, buyers should ensure that the material meets industry-specific standards and regulations. This is particularly important for buyers in Europe, where compliance with environmental and safety standards is mandatory.

Summary Table

| Material | Typical Use Case for ceramic heating element | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Carbide | High-temperature furnaces | High thermal conductivity | Expensive and brittle | High |

| Alumina | Household appliances, industrial heaters | Cost-effective and widely available | Lower thermal conductivity | Medium |

| Zirconia | Aerospace, advanced manufacturing | Exceptional thermal insulation | High cost and complex manufacturing | High |

| Mullite | Ceramics and glass industries | Excellent thermal stability | Less thermally conductive than SiC | Medium |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding ceramic heating elements, ensuring they choose the right material for their specific applications while considering cost, performance, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic heating element

Ceramic heating elements are critical components in various industrial applications, and understanding their manufacturing processes and quality assurance measures is essential for international B2B buyers. This section delves into the stages of manufacturing, key techniques employed, and the quality control measures that ensure the reliability and performance of ceramic heating elements.

Manufacturing Processes

The production of ceramic heating elements involves several key stages, each crucial for ensuring the efficiency and durability of the final product.

Material Preparation

-

Raw Material Selection: The primary materials used in ceramic heating elements include silicon carbide, alumina, and other specialized ceramics. The choice of material directly affects the thermal and electrical properties of the heating element.

-

Material Processing: Raw materials are processed into fine powders to enhance their homogeneity. This often includes milling and sieving to achieve the desired particle size.

-

Additives: During this stage, additives such as binders, plasticizers, and surfactants may be incorporated to improve the flowability and moldability of the material.

Forming

-

Shaping Techniques: The processed ceramic powder is shaped using various methods such as:

– Dry Pressing: Involves compacting the powder into molds under high pressure.

– Injection Molding: A more complex process that allows for intricate designs.

– Extrusion: Suitable for producing long, uniform shapes. -

Green Body Formation: The shaped components are referred to as “green bodies” and are fragile. They undergo a drying process to remove moisture before firing.

Assembly

-

Electrical Components Integration: For elements like MCH (Metal-Ceramic Heaters), metal circuits are embedded during the forming stage. This integration must be precise to ensure optimal performance.

-

Joining Techniques: In some cases, additional components such as terminals or connectors are attached. Techniques may include soldering or adhesive bonding, depending on the design specifications.

Finishing

-

Firing: The green bodies are subjected to high-temperature firing in a controlled environment. This process densifies the ceramic, enhancing its strength and thermal properties.

-

Surface Treatments: Post-firing, elements may undergo surface treatments to improve their thermal efficiency or resistance to wear and corrosion.

-

Final Machining: This may include grinding or polishing to achieve the required dimensions and surface quality.

Quality Assurance

Quality assurance is a critical aspect of the manufacturing process for ceramic heating elements. Adherence to international standards and rigorous testing protocols ensures that the products meet the specific requirements of various industries.

International Standards

-

ISO 9001: Many manufacturers adhere to ISO 9001, which outlines quality management system requirements. Certification indicates a commitment to consistent quality and customer satisfaction.

-

CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

-

Industry-Specific Standards: Depending on the application, additional certifications like API (American Petroleum Institute) for oil and gas applications or IEC (International Electrotechnical Commission) standards may apply.

Quality Control Checkpoints

-

Incoming Quality Control (IQC): Raw materials undergo inspection upon receipt to ensure they meet specified standards. This includes checking for purity, particle size, and moisture content.

-

In-Process Quality Control (IPQC): During manufacturing, various checkpoints monitor the production process. This includes verifying the integrity of the shaping process and monitoring firing temperatures.

-

Final Quality Control (FQC): Finished products are subjected to rigorous testing to confirm they meet performance specifications. This includes thermal cycling tests, electrical resistance measurements, and visual inspections for defects.

Common Testing Methods

- Thermal Conductivity Testing: Ensures the element can effectively transfer heat.

- Electrical Resistance Testing: Verifies that the element operates within specified resistance ranges.

- Mechanical Strength Testing: Assesses the durability and integrity of the ceramic material.

Verification of Supplier Quality Control

International B2B buyers should take proactive measures to verify the quality control processes of their suppliers. Here are some actionable steps:

-

Supplier Audits: Conduct regular audits of suppliers to assess their adherence to quality standards and manufacturing processes. This includes reviewing their ISO certifications and quality management systems.

-

Request Quality Reports: Ask suppliers for detailed quality reports that outline their testing protocols, results, and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engage third-party quality assurance firms to conduct independent inspections of manufacturing facilities. This adds an extra layer of credibility to the supplier’s claims.

-

Certification Verification: Verify the authenticity of certifications provided by suppliers. This can often be done through the issuing bodies or industry associations.

Considerations for International Buyers

When sourcing ceramic heating elements from suppliers in Africa, South America, the Middle East, and Europe, it’s crucial to understand the regional nuances in quality standards and regulations.

-

Local Regulations: Ensure that suppliers comply with local regulations and standards specific to your region. This may include environmental regulations and safety standards.

-

Cultural and Communication Factors: Establish clear communication channels with suppliers to mitigate misunderstandings related to quality expectations and specifications.

-

Long-Term Partnerships: Building long-term relationships with reliable suppliers can lead to better quality control practices, as established partners are more likely to prioritize your needs and concerns.

In conclusion, understanding the manufacturing processes and quality assurance measures for ceramic heating elements is vital for international B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source high-quality, reliable products that meet their operational needs.

Related Video: Ceramic tiles manufacturing process by Ceratec – How it’s made?

Comprehensive Cost and Pricing Analysis for ceramic heating element Sourcing

When sourcing ceramic heating elements, understanding the comprehensive cost structure and pricing is crucial for international B2B buyers. The cost of ceramic heating elements can vary significantly based on several factors, including materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

Cost Components

-

Materials: The primary materials used in ceramic heating elements include silicon carbide and various ceramic composites. The price of these materials fluctuates based on global supply and demand dynamics, so it’s essential to monitor market trends.

-

Labor: Labor costs encompass the wages of skilled workers involved in the production process. Regions with lower labor costs can offer competitive pricing, but this may come at the expense of quality.

-

Manufacturing Overhead: This includes costs related to factory operations, equipment maintenance, and utilities. Efficient manufacturing processes can reduce these overheads, impacting the final pricing.

-

Tooling: Initial investments in specialized tooling and molds are significant, particularly for custom designs. Buyers should consider these costs when evaluating quotes from suppliers.

-

Quality Control (QC): Rigorous testing and certification processes ensure product reliability and safety, particularly for industrial applications. High-quality QC can increase costs but is crucial for minimizing long-term failures.

-

Logistics: Shipping and handling costs vary based on the supplier’s location and the destination. Factors such as distance, shipping methods, and customs duties can significantly influence overall costs.

-

Margin: Suppliers typically add a profit margin on top of their costs. This margin can vary based on market conditions and the competitiveness of the supplier.

Price Influencers

Several factors can influence the pricing of ceramic heating elements:

-

Volume/MOQ: Suppliers often offer discounts for bulk purchases. Understanding minimum order quantities (MOQs) can help buyers negotiate better pricing.

-

Specifications/Customization: Custom designs or specific specifications may lead to increased costs. Buyers should clarify their needs upfront to avoid unexpected charges.

-

Materials: The choice of materials directly affects the price. Higher-quality materials may offer better performance but at a higher cost.

-

Quality/Certifications: Products that meet international quality standards or certifications may come at a premium. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: Established suppliers with a track record of reliability may charge higher prices due to their reputation. Newer suppliers might offer lower prices to attract business but may lack proven quality.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is essential, as they define the responsibilities of buyers and sellers in terms of shipping costs, insurance, and risk transfer.

Buyer Tips

To navigate the complexities of pricing in the ceramic heating element market, international buyers can consider the following strategies:

-

Negotiation: Leverage volume purchases or long-term contracts to negotiate better pricing. Highlighting potential for repeat business can incentivize suppliers to offer discounts.

-

Cost Efficiency: Assess the total cost of ownership (TCO), including initial costs, maintenance, and operational efficiency. Cheaper products may not always be the most cost-effective in the long run.

-

Understanding Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences. Exchange rates, import tariffs, and local market conditions can affect final prices.

-

Seek Multiple Quotes: Obtain quotes from several suppliers to compare pricing and services. This practice not only helps in finding the best deal but also provides leverage during negotiations.

In conclusion, while sourcing ceramic heating elements, understanding the multifaceted cost structure and the influencing factors can empower international buyers to make informed decisions. Always keep in mind that prices are indicative and subject to change based on market conditions and specific supplier terms.

Spotlight on Potential ceramic heating element Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ceramic heating element’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ceramic heating element

Ceramic heating elements are essential components in various industrial applications, and understanding their technical specifications and industry terminology is crucial for making informed purchasing decisions. Here’s a breakdown of the key technical properties and trade terms relevant to international B2B buyers.

Key Technical Properties

-

Material Grade

– Definition: This refers to the specific type of ceramic material used in the heating element, such as silicon carbide or alumina.

– B2B Importance: The material grade affects thermal conductivity, resistance to thermal shock, and overall durability. Selecting the right material ensures that the heating element meets operational demands, particularly in high-temperature applications. -

Power Rating (Wattage)

– Definition: The power rating indicates the maximum electrical power the heating element can handle, usually expressed in watts.

– B2B Importance: Choosing the correct wattage is critical for achieving desired heating performance. Insufficient wattage may lead to inadequate heating, while excessive wattage can result in overheating and premature failure. -

Tolerance

– Definition: Tolerance indicates the acceptable deviation in dimensions and performance specifications.

– B2B Importance: Understanding tolerance levels is vital for ensuring compatibility with existing equipment. High tolerance levels can improve efficiency and safety in operations by reducing the risk of misalignment or failure. -

Temperature Range

– Definition: This property defines the minimum and maximum temperatures the heating element can withstand.

– B2B Importance: Knowing the temperature range helps buyers select elements that can function effectively in specific environments. This is particularly important in industries like manufacturing and food processing, where temperature control is crucial. -

Insulation Resistance

– Definition: This measures how well the ceramic material can insulate against electrical leakage.

– B2B Importance: High insulation resistance is essential for safety and efficiency, preventing energy loss and minimizing the risk of electric shock. -

Heating Element Configuration

– Definition: This refers to the design and shape of the heating element, such as tubular or cartridge types.

– B2B Importance: The configuration affects installation, heating efficiency, and the application suitability. Buyers need to ensure that the configuration aligns with their specific equipment requirements.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

– Importance for Buyers: Understanding OEM specifications helps in sourcing high-quality components that are compatible with existing systems, ensuring reliability and performance. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Importance for Buyers: Knowing the MOQ helps businesses manage their inventory and budget effectively. It’s crucial for buyers to negotiate MOQs that align with their operational needs without incurring unnecessary costs. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document that solicits price bids from suppliers for specific quantities of products.

– Importance for Buyers: Issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, enabling better decision-making and cost management. -

Incoterms

– Definition: International Commercial Terms (Incoterms) are pre-defined commercial terms published by the International Chamber of Commerce, outlining responsibilities for shipping, insurance, and tariffs.

– Importance for Buyers: Familiarity with Incoterms is essential for understanding shipping logistics and costs, which can significantly impact overall procurement expenses. -

Lead Time

– Definition: Lead time is the duration between placing an order and receiving the goods.

– Importance for Buyers: Knowing lead times is critical for planning and ensuring that production schedules are not disrupted. It allows businesses to synchronize supply chain activities effectively. -

Certification

– Definition: This refers to the validation that a product meets specific industry standards and regulations.

– Importance for Buyers: Certifications ensure that the heating elements comply with safety and performance standards, which is crucial for minimizing liability and ensuring quality assurance in production processes.

Illustrative Image (Source: Google Search)

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions when sourcing ceramic heating elements, ultimately enhancing operational efficiency and safety in their respective industries.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ceramic heating element Sector

Market Overview & Key Trends

The ceramic heating element market is experiencing significant growth, driven by advancements in technology and an increasing demand for energy-efficient heating solutions. Global market drivers include the rising need for high-performance heating elements in various industrial applications, such as manufacturing, automotive, and medical devices. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of several emerging trends that shape sourcing strategies.

One prominent trend is the shift towards smart heating solutions that incorporate IoT technology for enhanced control and efficiency. Buyers should consider suppliers that offer ceramic heating elements equipped with smart features, allowing for real-time monitoring and energy management. Additionally, there is a growing preference for customized solutions tailored to specific application needs, which can enhance operational efficiency and reduce waste.

Market dynamics also reflect a competitive landscape, with manufacturers focusing on innovation to differentiate their products. Buyers should look for suppliers who not only provide high-quality ceramic heating elements but also demonstrate a commitment to research and development. Collaborations between manufacturers and tech companies are becoming more common, leading to the creation of hybrid heating systems that combine ceramic elements with other materials for improved performance.

Furthermore, as global supply chains evolve, buyers must navigate the complexities of sourcing from diverse markets. Understanding regional regulations, tariffs, and logistical challenges is crucial for successful procurement. Buyers from regions like South Africa and the UAE should prioritize suppliers with robust export capabilities and a clear understanding of their local market dynamics.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical consideration in the ceramic heating element sector, impacting both production practices and sourcing decisions. The environmental footprint of ceramic heating elements involves energy consumption during manufacturing and the sourcing of raw materials. B2B buyers are increasingly evaluating suppliers based on their sustainability credentials, including energy-efficient manufacturing processes and waste reduction initiatives.

Illustrative Image (Source: Google Search)

Ethical sourcing is essential for fostering a responsible supply chain. Buyers should seek manufacturers that comply with international environmental standards and promote fair labor practices. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the use of green materials in the production of ceramic heating elements is gaining traction. Suppliers that utilize recycled or sustainably sourced materials can provide buyers with environmentally friendly options. This focus on sustainability not only meets regulatory requirements but also enhances brand reputation and appeal to eco-conscious consumers.

To align with sustainability goals, buyers should also consider the lifecycle of ceramic heating elements. Investing in high-quality, durable products can reduce the frequency of replacements, minimizing waste. Engaging with suppliers who prioritize circular economy principles—such as recycling old heating elements—can further contribute to a sustainable business model.

Brief Evolution/History

The evolution of ceramic heating elements dates back to the early 20th century when the first resistive heating technologies were developed. Initially used in niche applications, advancements in materials science led to the widespread adoption of ceramics due to their superior thermal properties and durability. Over the decades, the integration of technologies such as Positive Temperature Coefficient (PTC) heating has enhanced safety and efficiency.

As industries evolved, so did the applications for ceramic heating elements, expanding from traditional heating tasks to more specialized uses in sectors like medical and aerospace. Today, the focus is on developing energy-efficient and smart solutions that cater to the growing demands of modern manufacturing and consumer products. This historical context underscores the importance of innovation and adaptability in the ceramic heating element market, particularly for B2B buyers seeking reliable and advanced heating solutions.

Related Video: Trade and tariffs | APⓇ Microeconomics | Khan Academy

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic heating element

-

What should I consider when vetting suppliers for ceramic heating elements?

When vetting suppliers, assess their manufacturing capabilities, certifications, and experience in the ceramic heating element sector. Verify their compliance with international quality standards such as ISO 9001 or IEC certifications. Request references and case studies from previous clients, particularly those in your industry or region. Additionally, consider their customer support and responsiveness, as these factors can significantly impact your purchasing experience and ongoing relationship. -

Can ceramic heating elements be customized for specific applications?

Yes, many manufacturers offer customization options for ceramic heating elements to meet specific operational requirements. This may include modifications in size, shape, wattage, or materials used. Engage in detailed discussions with potential suppliers about your specific needs, including any industry standards you must comply with. Custom solutions can enhance efficiency and performance, but ensure that you understand the implications for lead times and costs. -

What are typical minimum order quantities (MOQ) and lead times?

Minimum order quantities for ceramic heating elements can vary significantly by supplier and product type. Generally, MOQs can range from a few dozen to several hundred units. Lead times are typically between 4 to 12 weeks, depending on customization, production capacity, and shipping logistics. Always clarify these details upfront and request a written commitment to avoid unexpected delays that could impact your operations. -

What payment terms are common in international B2B transactions for ceramic heating elements?

Payment terms can vary widely among suppliers, but common practices include advance payment, letters of credit, or net 30/60 days after delivery. Some suppliers may also offer discounts for early payments or larger orders. It’s crucial to negotiate terms that protect your interests while maintaining a good relationship with the supplier. Ensure all terms are documented in the contract to avoid disputes later. -

How can I ensure quality assurance and certification for ceramic heating elements?

To ensure quality assurance, request documentation of the supplier’s quality control processes and relevant certifications. This may include third-party testing reports or compliance with industry standards. It’s beneficial to conduct factory audits or request samples for testing before placing large orders. Establishing clear specifications and performance criteria in your contract can also help maintain quality throughout the production process. -

What logistics considerations should I keep in mind when sourcing ceramic heating elements internationally?

Logistics play a crucial role in the sourcing process. Consider shipping methods, costs, and timeframes, as well as the supplier’s ability to handle customs and duties. Ensure that your supplier is experienced in international shipping and can provide tracking for your shipments. Additionally, assess the risk of delays and damages during transport, and consider purchasing insurance for high-value orders to mitigate potential losses. -

How should I handle disputes with suppliers regarding ceramic heating elements?

Establish a clear dispute resolution process in your contract, outlining steps for negotiation, mediation, and arbitration if necessary. Maintain open lines of communication with your supplier to address issues as they arise. Document all correspondence and agreements to support your position if disputes escalate. Familiarize yourself with international trade laws relevant to your transaction, which can provide additional avenues for resolution. -

What are the common applications for ceramic heating elements in various industries?

Ceramic heating elements are widely used in industries such as manufacturing, automotive, and food processing. They are ideal for applications requiring high-temperature resistance and precise temperature control, such as industrial ovens, soldering equipment, and infrared heating systems. Understanding the specific applications relevant to your business can guide your purchasing decisions and help you select the most suitable heating elements for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ceramic heating element

In summary, the strategic sourcing of ceramic heating elements is pivotal for businesses seeking efficiency, reliability, and cost-effectiveness in their operations. B2B buyers must prioritize suppliers that offer high-quality products, robust customer support, and the capability for customization to meet specific industrial requirements. Understanding the distinct types of ceramic heating elements, their applications, and the benefits of advanced technologies, such as Positive Temperature Coefficient (PTC) materials, can significantly enhance purchasing decisions.

Furthermore, as global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, fostering relationships with reputable manufacturers and suppliers will be essential for maintaining a competitive edge. Engaging in strategic partnerships can lead to innovative solutions that align with market demands and sustainability goals.

Looking ahead, B2B buyers are encouraged to actively explore the latest developments in ceramic heating technology and leverage these advancements to optimize their operations. By embracing strategic sourcing practices, businesses can not only improve performance but also contribute to a more sustainable future. Take the next step in your sourcing journey by assessing your current suppliers and exploring new opportunities in the ceramic heating elements market.