Master Sourcing Engine Shaft Couplings: A Comprehensive B2B

Introduction: Navigating the Global Market for engine shaft coupling

In the dynamic landscape of global industrial operations, engine shaft couplings play a pivotal role in ensuring the seamless transmission of power between machinery components. These critical components not only facilitate the alignment and connection of shafts but also mitigate the risks associated with misalignment, vibration, and mechanical failure. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of engine shaft couplings is essential for optimizing equipment performance and minimizing downtime.

This comprehensive guide delves into the diverse types of engine shaft couplings available in the market, exploring their materials, manufacturing processes, and quality control measures. Buyers will gain insights into various coupling designs, such as flexible, rigid, and torsionally elastic couplings, each tailored to specific operational needs. Additionally, the guide provides an overview of reputable suppliers, helping businesses identify trusted partners for their sourcing requirements.

Cost considerations are also addressed, equipping buyers with the knowledge to make informed financial decisions. By answering frequently asked questions and presenting a detailed market analysis, this guide empowers B2B buyers to navigate the complexities of sourcing engine shaft couplings effectively. Whether you’re in Kenya, Mexico, or any other region, this resource is designed to enhance your procurement strategy and ensure that your operations run smoothly and efficiently.

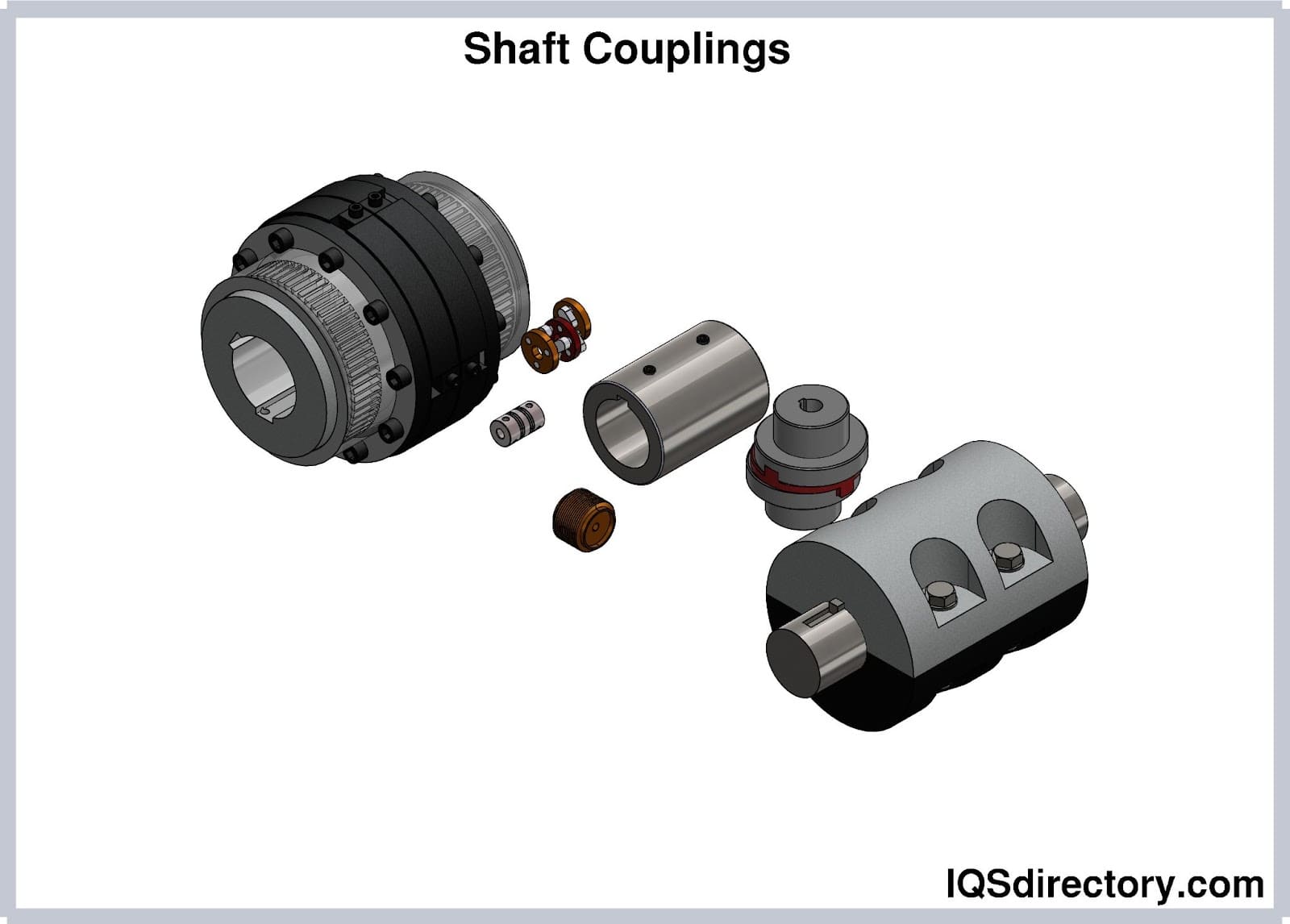

Understanding engine shaft coupling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Couplings | Accommodate misalignment and absorb shock loads. | Pumps, compressors, and conveyors. | Pros: Reduce wear, versatile. Cons: Limited torque capacity. |

| Rigid Couplings | Provide a solid connection with no flexibility. | Heavy machinery and construction equipment. | Pros: High torque transmission. Cons: Cannot compensate for misalignment. |

| Elastomer Couplings | Utilize elastomeric materials to dampen vibrations. | Electric motors and fans. | Pros: Excellent vibration damping. Cons: Temperature sensitive. |

| Gear Couplings | Feature steel gears that allow for high torque transmission. | Industrial machinery and power generation. | Pros: High load capacity, durable. Cons: More expensive and heavier. |

| Jaw Couplings | Use a spider element to connect two hubs, allowing for some misalignment. | General industrial applications. | Pros: Cost-effective, easy to install. Cons: Limited damping capabilities. |

Flexible Couplings

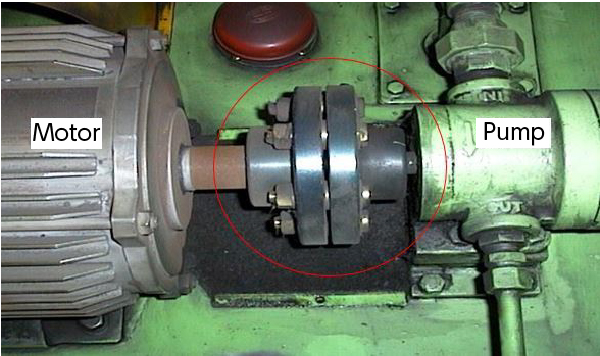

Flexible couplings are designed to accommodate minor misalignment between shafts while transmitting torque. They are ideal for applications such as pumps and compressors, where alignment issues frequently arise. When purchasing flexible couplings, buyers should consider the coupling’s torque capacity and the extent of misalignment it can handle. The ability to absorb shock loads can significantly reduce wear on equipment, making them a popular choice for many industries.

Rigid Couplings

Rigid couplings provide a solid connection between two shafts, allowing for the efficient transmission of torque without any flexibility. These couplings are best suited for heavy machinery applications, such as in construction equipment, where alignment is typically precise. Buyers should consider the installation requirements and the potential for misalignment, as rigid couplings do not accommodate any movement. Their high torque capacity makes them suitable for demanding environments but may lead to increased wear on associated components if misalignment occurs.

Elastomer Couplings

Elastomer couplings use flexible rubber or elastomeric materials to dampen vibrations and absorb shocks, making them suitable for electric motors and fans. They are particularly effective in applications where noise reduction and vibration control are essential. Buyers should evaluate the temperature range and load capacity of elastomer couplings, as these factors can affect performance. While they offer excellent vibration damping, their sensitivity to temperature changes can limit their applicability in extreme environments.

Gear Couplings

Gear couplings consist of steel gears that provide a robust connection capable of handling high torque loads. They are commonly used in industrial machinery and power generation applications where durability is critical. When selecting gear couplings, buyers should assess the required load capacity and the overall weight of the coupling, as they tend to be heavier and more expensive than other types. Their ability to handle significant loads makes them a preferred choice for heavy-duty applications.

Jaw Couplings

Jaw couplings feature a unique design that includes two hubs connected by a flexible spider element, allowing for some misalignment. They are widely used in general industrial applications due to their cost-effectiveness and ease of installation. Buyers should consider the coupling’s torque rating and the material of the spider element, as these factors can influence performance. While jaw couplings are economical, they offer limited vibration damping capabilities compared to other types, which may be a consideration for specific applications.

Related Video: Types of Shaft Coupling, Animation, Machine Design | Solidworks

Key Industrial Applications of engine shaft coupling

| Industry/Sector | Specific Application of engine shaft coupling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Connecting motors to conveyor systems | Ensures efficient power transfer and reduces wear | Compatibility with motor specifications and load capacity |

| Oil & Gas | Pumping systems in drilling operations | Enhances reliability and minimizes downtime | Resistance to harsh environments and vibration tolerance |

| Agriculture | Drive systems for tractors and harvesters | Increases operational efficiency and reduces maintenance costs | Ability to handle misalignment and torque variations |

| Power Generation | Turbine coupling in power plants | Improves energy efficiency and system stability | High torque ratings and thermal resistance |

| Construction | Coupling in heavy machinery | Enhances performance and extends equipment lifespan | Durability under extreme loads and environmental conditions |

In the manufacturing sector, engine shaft couplings are essential for connecting motors to conveyor systems. These couplings ensure efficient power transfer, minimizing wear and tear on machinery, which is crucial for maintaining production lines. International buyers should consider compatibility with specific motor specifications and the load capacity required for their operations.

In the oil and gas industry, engine shaft couplings are used in pumping systems for drilling operations. These couplings enhance the reliability of equipment, reducing the risk of downtime due to mechanical failures. Buyers should prioritize sourcing couplings that can withstand harsh environments and have high vibration tolerance, especially in remote locations common in Africa and the Middle East.

The agriculture sector benefits from engine shaft couplings in drive systems for tractors and harvesters. These couplings improve operational efficiency by allowing for minor misalignments and absorbing shock loads, which is vital during heavy-duty tasks. Buyers in regions like South America should look for couplings that can handle torque variations and are easy to maintain, given the challenging working conditions.

In power generation, engine shaft couplings are critical for connecting turbines within power plants. They improve energy efficiency and system stability by ensuring smooth power transmission, which is vital for meeting energy demands. Key considerations for buyers include high torque ratings and thermal resistance, particularly in European markets where regulatory standards are stringent.

Lastly, in the construction industry, engine shaft couplings are used in heavy machinery to enhance performance and extend the lifespan of equipment. Couplings must be durable enough to withstand extreme loads and environmental conditions. International buyers should focus on sourcing couplings that comply with local industry standards and can provide reliable service in diverse climates, from the heat of South America to the cold of Europe.

Related Video: Shaft coupling Alignment Procedure Rim and Face Method part 2

Strategic Material Selection Guide for engine shaft coupling

Material Analysis for Engine Shaft Couplings

When selecting materials for engine shaft couplings, international B2B buyers must consider several factors, including the operational environment, mechanical properties, and compliance with regional standards. Here’s a detailed analysis of four common materials used in engine shaft couplings.

1. Steel

Key Properties: Steel offers high tensile strength, excellent fatigue resistance, and good wear resistance. It can typically withstand high temperatures and pressures, making it suitable for demanding applications.

Pros & Cons: The durability of steel is a significant advantage, as it can handle heavy loads and harsh conditions. However, it is prone to corrosion unless treated or alloyed, which can add to manufacturing complexity. Steel couplings are generally more expensive than plastic or rubber options but provide superior performance in heavy-duty applications.

Impact on Application: Steel couplings are compatible with a wide range of media, including oils and fuels. However, they may not be suitable for corrosive environments without protective coatings.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or DIN 17100 is crucial, especially in regions like Europe where material certifications are strictly enforced. Buyers from Africa and South America should also consider local sourcing to reduce costs.

2. Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and offers decent strength-to-weight ratios. It can operate effectively at moderate temperatures and pressures.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can reduce overall system weight and improve efficiency. However, it has lower tensile strength compared to steel, which may limit its use in heavy-duty applications. The cost of aluminum is generally moderate, making it an attractive option for many applications.

Impact on Application: Aluminum couplings are suitable for environments where weight savings are critical, such as in aerospace or automotive applications. However, they may not perform well in high-stress situations.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 or EN AW-6060. In regions like the Middle East, where heat can be a factor, aluminum’s thermal properties should be carefully evaluated.

3. Plastic (e.g., Nylon, Polyurethane)

Key Properties: Plastics like nylon and polyurethane exhibit excellent chemical resistance, low friction, and good elasticity. They can handle moderate temperatures and pressures but are less durable than metals.

Pros & Cons: The major advantage of plastic couplings is their resistance to corrosion and chemicals, making them ideal for harsh environments. They are also lightweight and cost-effective. However, they may not withstand high torque or heavy loads, limiting their application scope.

Impact on Application: Plastic couplings are suitable for applications involving aggressive chemicals or where weight is a concern. However, they may not be compatible with high-temperature operations.

Considerations for International Buyers: Compliance with standards such as ASTM D4066 for nylon is essential. Buyers in South America and Africa should consider the availability of high-quality plastics to ensure performance.

4. Composite Materials

Key Properties: Composites, such as carbon-fiber-reinforced plastics, combine the advantages of lightweight materials with high strength and stiffness. They can operate at higher temperatures and pressures than standard plastics.

Pros & Cons: The key advantage of composite materials is their high strength-to-weight ratio, which can significantly enhance performance in demanding applications. However, they are often more expensive and can require specialized manufacturing processes.

Impact on Application: Composite couplings are ideal for high-performance applications in industries like aerospace and automotive, where weight and strength are critical. They are also resistant to corrosion and chemicals.

Considerations for International Buyers: Buyers should look for compliance with international standards like ASTM D3039. In Europe, the use of composites is often subject to stringent regulations, which must be adhered to.

Summary Table

| Material | Typical Use Case for engine shaft coupling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machinery | High durability and strength | Prone to corrosion | High |

| Aluminum | Automotive applications | Lightweight and good corrosion resistance | Lower strength than steel | Medium |

| Plastic | Chemical processing equipment | Excellent chemical resistance | Limited load capacity | Low |

| Composite | Aerospace and high-performance machinery | High strength-to-weight ratio | High cost and manufacturing complexity | High |

This material selection guide provides a framework for international B2B buyers to make informed decisions when sourcing engine shaft couplings, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for engine shaft coupling

Manufacturing Processes for Engine Shaft Coupling

The manufacturing of engine shaft couplings involves several critical stages, each designed to ensure the final product meets the required specifications for performance and durability. Understanding these processes helps B2B buyers select reliable suppliers and assess the quality of the products they intend to procure.

Illustrative Image (Source: Google Search)

Material Preparation

The manufacturing process begins with selecting appropriate materials, typically high-strength alloys, stainless steel, or specialized plastics, depending on the coupling type and application. Key considerations during this stage include:

- Material Selection: Buyers should be aware of the properties of different materials, such as tensile strength, corrosion resistance, and fatigue limits. This is crucial for applications in diverse environments, particularly in regions like Africa and South America where conditions can be harsh.

- Quality Control: Suppliers should provide certificates of material compliance, ensuring that the materials meet international standards such as ASTM or ISO specifications.

Forming

Once materials are prepared, the next step involves forming the components of the coupling. This stage may include various techniques:

- Machining: Precision machining is often employed to shape components with tight tolerances. CNC (Computer Numerical Control) machines are commonly used to ensure accuracy.

- Casting or Forging: Depending on the design, some couplings may be cast or forged. Forging, while more expensive, typically results in stronger components due to the grain structure alignment.

- Heat Treatment: This process enhances material properties, such as hardness and strength. Understanding the heat treatment methods used by suppliers can provide insights into the durability of the couplings.

Assembly

After forming, the individual components are assembled. This stage is critical for ensuring that all parts fit together perfectly to prevent misalignment and wear during operation. Key aspects include:

- Component Alignment: Proper alignment during assembly is essential to minimize angular and parallel misalignment, which can lead to premature failure.

- Use of Jigs and Fixtures: These tools help ensure that components are assembled correctly and consistently, maintaining high quality across production runs.

Finishing

The finishing stage enhances the coupling’s aesthetic and functional properties. This may involve:

- Surface Treatment: Techniques such as anodizing, plating, or coating improve corrosion resistance and surface hardness. Buyers should inquire about the specific treatments used, especially for couplings intended for corrosive environments.

- Inspection: Final inspections are conducted to check for surface defects, dimensions, and assembly integrity. This ensures that the couplings meet the specified tolerances and are free from defects.

Quality Assurance for Engine Shaft Coupling

Quality assurance (QA) is vital in the manufacturing process of engine shaft couplings. It ensures that the products are reliable and meet international standards, providing peace of mind for buyers across various regions.

International Standards

Several international standards govern the manufacturing and quality assurance of engine shaft couplings, including:

- ISO 9001: This standard outlines the requirements for a quality management system. Suppliers certified to ISO 9001 demonstrate their commitment to quality and continuous improvement.

- CE Marking: This certification indicates compliance with EU safety, health, and environmental protection standards, essential for buyers in Europe.

- API Standards: For couplings used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is crucial.

Quality Control Checkpoints

Quality control should be integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is essential. This includes checking dimensions, material properties, and assembly precision at various stages.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures it meets all specifications before shipment. This may include functional testing and dimensional verification.

Common Testing Methods

Several testing methods are employed to ensure the quality and performance of engine shaft couplings:

- Torque Testing: This assesses the coupling’s ability to transmit torque without failure.

- Vibration Analysis: This identifies potential misalignment or imbalance issues that could affect performance.

- Non-destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection help detect internal flaws without damaging the product.

Verifying Supplier Quality Control

B2B buyers must be proactive in verifying the quality control measures of potential suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices, quality control processes, and adherence to international standards.

- Quality Reports: Requesting detailed quality assurance reports, including IQC, IPQC, and FQC data, can provide insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection agencies can further validate the quality and compliance of the products before acceptance.

Regional Considerations for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, understanding regional nuances in quality assurance is vital:

- Local Regulations: Familiarize yourself with local regulations that may affect material compliance and safety standards.

- Cultural Differences: Recognize that business practices may vary across regions. Building strong relationships with suppliers can facilitate better communication regarding quality expectations.

- Logistical Challenges: Consider the potential impact of shipping and handling on product quality. Ensure that suppliers have robust packaging and transportation protocols to prevent damage during transit.

By understanding the manufacturing processes and quality assurance measures for engine shaft couplings, B2B buyers can make informed decisions, ensuring they select reliable products that meet their operational needs.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for engine shaft coupling Sourcing

When sourcing engine shaft couplings, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis will highlight the critical cost components, pricing influencers, and provide actionable buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly impacts the cost of engine shaft couplings. Common materials include steel, aluminum, and various polymers. High-performance materials designed for specific applications can raise costs but may offer better durability and efficiency.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing but could compromise on quality or lead times. It’s essential to assess the labor market in the supplier’s region.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, depreciation, and facility costs. Suppliers with optimized production processes may pass on savings to buyers, making it crucial to evaluate their operational efficiency.

-

Tooling: Custom tooling can be a significant upfront cost, especially for specialized couplings. Buyers should inquire about tooling costs and whether they can be amortized over large orders to minimize impact on unit pricing.

-

Quality Control (QC): Investing in rigorous QC processes ensures product reliability, which may come at a premium. Buyers should consider the balance between cost and quality assurance, particularly in critical applications.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and volume. Understanding Incoterms is vital for managing logistics costs effectively. Buyers should compare local suppliers against international ones to gauge total logistics expenses.

-

Margin: Suppliers will add their profit margin to the cost structure. This margin can fluctuate based on market demand, competition, and the supplier’s positioning strategy.

Price Influencers

-

Volume/MOQ: Bulk purchasing often leads to reduced per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their needs without overcommitting.

-

Specifications/Customization: Custom specifications can increase costs due to added complexity in manufacturing. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials: As mentioned, the choice of materials greatly influences pricing. Opting for standard materials can reduce costs, while high-end materials may be justified by performance requirements.

-

Quality/Certifications: Products with international quality certifications (e.g., ISO, CE) may command higher prices but offer assurance of quality. Buyers should weigh the importance of these certifications against potential cost savings.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can affect pricing. Established suppliers may offer premium pricing due to their experience, while newer entrants might provide lower prices to gain market share.

-

Incoterms: Understanding shipping terms can help buyers manage costs. FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact total landed costs.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating terms, especially for large orders. Establish long-term relationships with suppliers for better pricing.

-

Cost-Efficiency: Assess the total cost of ownership (TCO), which includes acquisition, operation, and maintenance costs. A higher upfront price may lead to lower maintenance costs over time.

-

Pricing Nuances: Be aware of regional pricing variations. For example, suppliers in Africa may have different pricing structures compared to those in Europe or South America due to local economic conditions.

-

Market Trends: Keep an eye on market trends and shifts in material costs, which can affect pricing. Engaging with industry analysts can provide insights into future pricing movements.

-

Supplier Evaluation: Conduct thorough evaluations of potential suppliers. Assess their production capabilities, quality standards, and customer service to ensure they align with your business needs.

Disclaimer

All prices mentioned are indicative and subject to market fluctuations, supplier negotiations, and specific project requirements. Always request detailed quotations and consider all cost components to make informed purchasing decisions.

Spotlight on Potential engine shaft coupling Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘engine shaft coupling’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for engine shaft coupling

When considering engine shaft couplings, understanding the essential technical properties and industry terminology is crucial for international B2B buyers. This knowledge aids in making informed purchasing decisions and ensures compatibility with specific applications.

Key Technical Properties

-

Material Grade

– Definition: This refers to the type of material used in the coupling, such as steel, aluminum, or elastomers.

– Importance: The material affects durability, weight, and resistance to environmental factors like corrosion and temperature. Buyers must select a material that aligns with their operational conditions to prevent premature failure. -

Torque Rating

– Definition: The maximum amount of torque the coupling can transmit without failing.

– Importance: Understanding torque ratings is vital for selecting a coupling that can handle the required power transmission in industrial applications. A coupling with insufficient torque rating can lead to failures, causing downtime and increased costs. -

Misalignment Capacity

– Definition: The ability of a coupling to accommodate angular, parallel, and axial misalignments between connected shafts.

– Importance: Given that perfect alignment is rarely achievable, choosing a coupling with adequate misalignment capacity minimizes wear on the coupling and connected machinery, thus extending the lifespan of the entire system. -

Bore Size and Tolerance

– Definition: The inner diameter of the coupling that fits onto the shaft, along with its manufacturing tolerance.

– Importance: Accurate bore size and tolerance are critical for ensuring proper fit and function. An incorrect bore can lead to slippage or damage, resulting in costly repairs. -

Weight and Size

– Definition: The physical dimensions and weight of the coupling.

– Importance: Size and weight considerations affect installation space and the overall weight distribution in machinery. Buyers must consider these factors to ensure compatibility with their equipment and operational efficiency.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM specifications ensures that buyers are sourcing parts that meet original design standards, which is crucial for maintaining equipment performance. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Buyers should be aware of MOQ requirements to manage inventory effectively and avoid overcommitting to purchases that exceed their immediate needs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to solicit pricing and terms for a specific quantity of products.

– Relevance: RFQs enable buyers to compare prices, terms, and conditions from multiple suppliers, ensuring they receive competitive offers. -

Incoterms (International Commercial Terms)

– Definition: Standardized trade terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs involved in international transactions, which is essential for budgeting and logistics planning. -

Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Relevance: Understanding lead times is crucial for project planning and ensuring that equipment is available when needed, minimizing production delays.

By grasping these technical properties and trade terms, international B2B buyers can effectively navigate the complexities of sourcing engine shaft couplings, ensuring they select the right products for their applications while optimizing costs and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the engine shaft coupling Sector

Market Overview & Key Trends

The global engine shaft coupling market is witnessing a transformative phase driven by technological advancements, increasing demand for efficient power transmission, and rising industrial automation. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly interested in sourcing high-quality couplings that enhance operational efficiency while minimizing downtime. Key trends shaping the market include:

-

Digitalization and Smart Manufacturing: The integration of IoT and smart technologies is enabling real-time monitoring of machinery performance. This trend allows companies to optimize coupling selection based on operational parameters, enhancing productivity.

-

Customization and Versatility: Manufacturers are increasingly offering customizable coupling solutions tailored to specific applications. This flexibility is crucial for industries such as automotive, mining, and energy, where unique operational conditions demand specialized couplings.

-

Sourcing from Diverse Regions: Global supply chains are evolving, with buyers exploring sourcing options from emerging markets that offer competitive pricing and innovative solutions. Countries like Kenya and Mexico are becoming hubs for manufacturing and distribution, presenting opportunities for international partnerships.

-

Focus on Performance and Durability: Buyers are prioritizing couplings that offer enhanced performance characteristics, such as high torque capacity and resistance to misalignment. This focus is driven by the need for reliability in critical applications, where equipment failure can lead to significant financial losses.

These dynamics indicate a robust market environment where B2B buyers must stay informed about technological advancements and sourcing strategies to make well-informed purchasing decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming increasingly vital in the engine shaft coupling sector, influencing both manufacturing practices and buyer preferences. The environmental impact of production processes and materials used in couplings is under scrutiny, prompting buyers to consider the sustainability credentials of their suppliers. Key considerations include:

Illustrative Image (Source: Google Search)

-

Environmental Impact: The production of engine shaft couplings can involve significant energy consumption and waste generation. Buyers should seek manufacturers that utilize energy-efficient processes and implement waste reduction strategies to minimize their carbon footprint.

-

Ethical Supply Chains: The importance of ethical sourcing practices cannot be overstated. Buyers are encouraged to engage with suppliers who adhere to fair labor practices and transparent supply chains. This not only enhances brand reputation but also fosters long-term relationships based on trust and accountability.

-

Green Certifications and Materials: Buyers should look for suppliers offering products made from sustainable materials or those that have received green certifications, such as ISO 14001 or similar environmental management standards. These certifications indicate a commitment to reducing environmental impact and promoting sustainability in manufacturing processes.

Incorporating sustainability into sourcing decisions not only aligns with global trends but also positions companies as responsible players in the market, appealing to environmentally conscious customers and stakeholders.

Brief Evolution/History

The evolution of engine shaft couplings dates back to the early 20th century, with the initial designs focusing primarily on mechanical connectivity and basic power transmission. As industrial applications grew more complex, the need for more versatile and efficient couplings became apparent. Innovations in materials, such as the introduction of elastomeric elements, allowed for greater flexibility and misalignment compensation.

By the late 20th century, advancements in manufacturing technologies and materials science further propelled the development of high-performance couplings. Today, with the integration of digital technologies and a focus on sustainability, the engine shaft coupling sector is poised for continuous growth, reflecting the dynamic needs of modern industries. International B2B buyers must remain aware of these historical developments to better understand the trajectory of product offerings and technological advancements in the market.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of engine shaft coupling

-

How can I effectively vet suppliers of engine shaft couplings?

When vetting suppliers, consider their industry reputation, years in business, and customer reviews. Request references from previous clients and examine their response times to inquiries. Verify if they hold relevant certifications such as ISO 9001, which indicates adherence to quality management systems. It’s also beneficial to assess their manufacturing capabilities and whether they possess the necessary technology to meet your specifications. -

Can I customize engine shaft couplings to fit my specific needs?

Yes, many suppliers offer customization options for engine shaft couplings. It’s essential to communicate your requirements clearly, including dimensions, material preferences, and any specific performance features. Discuss lead times for custom orders, as these can vary significantly based on the complexity of the customization and the supplier’s production schedule. -

What are the typical minimum order quantities (MOQs) and lead times for engine shaft couplings?

MOQs can vary widely between suppliers, typically ranging from a few pieces to hundreds, depending on the type and complexity of the coupling. Lead times also vary, often between 2-12 weeks. It’s important to confirm these details upfront to ensure they align with your project timelines. Suppliers may offer flexibility for larger orders or repeat business, so inquire about potential negotiations. -

What quality assurance practices should I expect from suppliers?

Reputable suppliers should have robust quality assurance (QA) practices in place. This includes regular inspections, testing of materials, and adherence to international quality standards. Request documentation of their QA processes and inquire about third-party certifications. Additionally, ask for test reports or certificates of compliance for the couplings you intend to purchase to ensure they meet your specifications. -

What payment options are commonly available for international purchases?

Suppliers typically offer a range of payment options, including wire transfers, letters of credit, and online payment platforms. It’s crucial to clarify payment terms before placing an order, including any upfront deposits and payment schedules. Additionally, consider the currency of transaction and any potential exchange rate fluctuations that might impact your total cost. -

How should I handle logistics and shipping for international orders?

When arranging logistics, choose a reliable freight forwarder experienced in handling industrial equipment. Confirm shipping costs, estimated delivery times, and whether the supplier will handle customs clearance. Understanding Incoterms (International Commercial Terms) is essential to clarify responsibilities for shipping, insurance, and tariffs. Ensure you have all necessary documentation for customs to avoid delays. -

What should I do if a dispute arises with a supplier?

In the event of a dispute, start by reviewing your contract for terms regarding conflict resolution. Maintain clear communication with the supplier to address the issue directly. If necessary, consider mediation or arbitration as stipulated in your agreement. Keeping detailed records of all correspondence can be invaluable if the dispute escalates and requires legal intervention. -

Are there specific certifications I should look for in engine shaft couplings?

Yes, when sourcing engine shaft couplings, look for certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and industry-specific standards like API for oil and gas applications. These certifications indicate the supplier’s commitment to quality and compliance with industry norms. Additionally, check for any relevant regional certifications that may apply in your country or the country of the supplier.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for engine shaft coupling

The landscape of engine shaft couplings is increasingly complex, yet rich with opportunities for international B2B buyers. As businesses seek to optimize their operations, understanding the diverse coupling options available is paramount. Strategic sourcing not only ensures the selection of the most suitable coupling types tailored to specific applications but also enables cost efficiencies and improved supply chain resilience.

Key takeaways include the importance of evaluating coupling types based on misalignment tolerance, torque capacity, and material compatibility. Buyers should prioritize suppliers that offer comprehensive technical support and detailed product information, facilitating informed decision-making. Furthermore, leveraging global networks can enhance sourcing strategies, particularly for buyers in regions such as Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for innovative and reliable coupling solutions will only grow. B2B buyers are encouraged to proactively engage with manufacturers and suppliers, attending industry events and exploring digital platforms to stay abreast of new technologies and trends. By doing so, they can position their operations for future success while ensuring optimal performance and longevity of their mechanical systems.