Master Sourcing Fasteners with Crouch Sales Co: A B2B

Introduction: Navigating the Global Market for crouch sales co

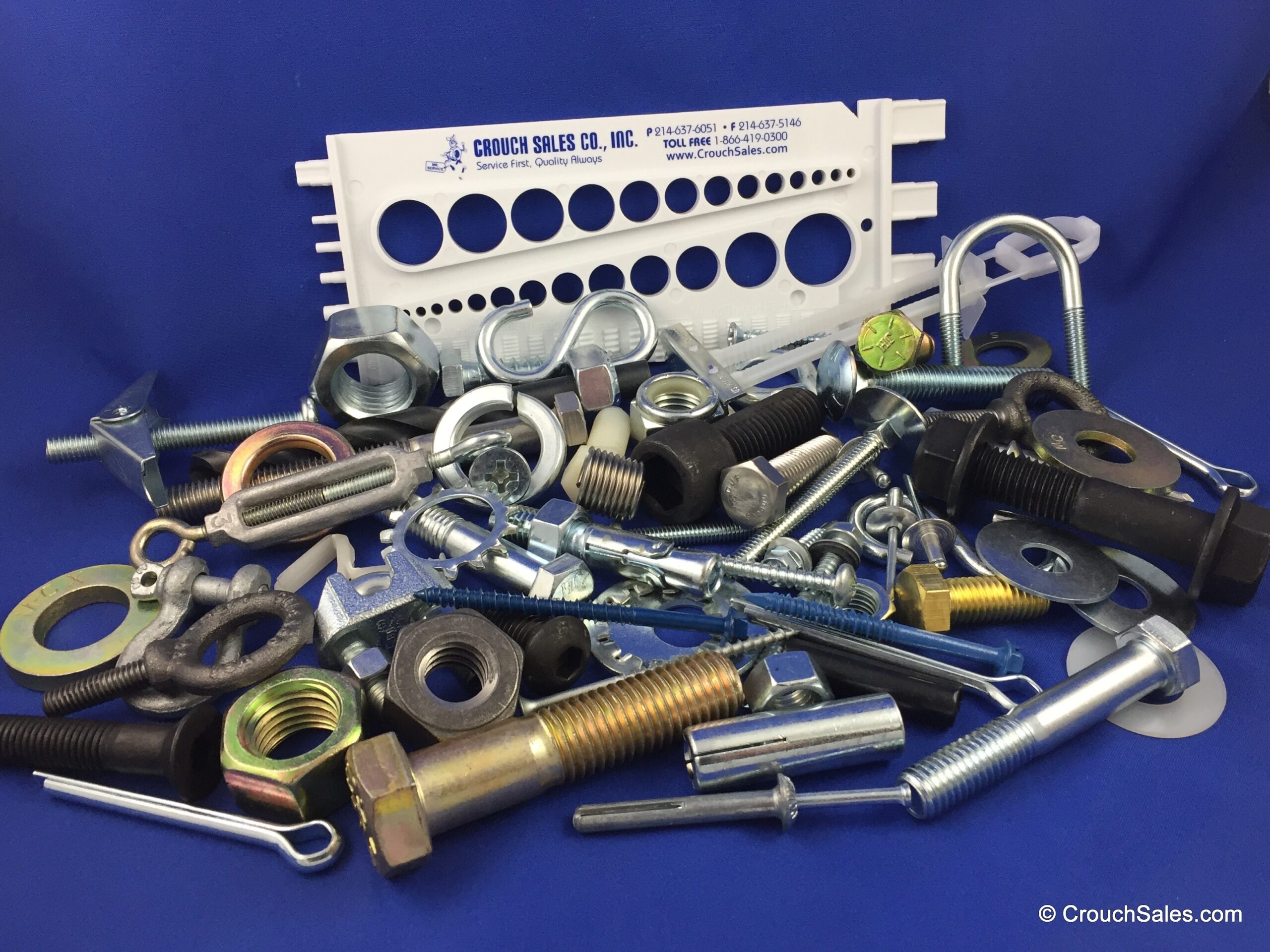

In today’s interconnected world, sourcing high-quality fasteners is essential for businesses across various industries, including construction, manufacturing, and food production. Crouch Sales Co, a seasoned distributor established in 1966, stands out as a trusted partner for international B2B buyers seeking reliable fastener solutions. With a vast inventory that includes bolts, nuts, screws, and anchors, Crouch Sales Co is committed to a “Service First, Quality Always” philosophy, ensuring that customers receive not just products but exceptional service and expertise.

This comprehensive guide is designed specifically for international buyers from regions such as Africa, South America, the Middle East, and Europe. It will delve into the diverse types of fasteners available, the materials used in manufacturing, and the stringent quality control measures in place to ensure durability and reliability. Additionally, the guide will explore supplier dynamics, pricing strategies, and key market trends that influence sourcing decisions.

By equipping B2B buyers with actionable insights and industry knowledge, this guide empowers informed sourcing decisions, enabling businesses to maintain operational efficiency and competitiveness. Whether you are in Kenya looking to enhance your construction projects or in Vietnam aiming to streamline manufacturing processes, understanding the offerings of Crouch Sales Co will be pivotal in meeting your fastener needs effectively.

Understanding crouch sales co Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Fasteners | Wide variety of bolts, screws, nuts, and washers. | Construction, manufacturing, and automotive. | Pros: Versatile, widely available. Cons: Generic options may lack specific requirements. |

| Specialty Fasteners | Tailored designs for unique applications. | Aerospace, medical devices, and high-tech industries. | Pros: Customized solutions. Cons: Higher cost and longer lead times. |

| Stainless Steel Fasteners | Corrosion-resistant, ideal for outdoor use. | Marine, food processing, and chemical industries. | Pros: Durability and longevity. Cons: More expensive than standard options. |

| Anchors and Supports | Designed for securing fixtures to various substrates. | Construction, renovation, and heavy machinery. | Pros: Essential for stability. Cons: Installation complexity can vary. |

| Drill Bits and Cutting Tools | Specialized tools for creating holes and shaping materials. | Manufacturing, construction, and woodworking. | Pros: Precision and efficiency. Cons: Requires proper matching to the material type. |

Standard Fasteners

Standard fasteners encompass a broad range of products, including bolts, screws, nuts, and washers. These items are essential in various industries such as construction and manufacturing, where they provide foundational support for structures and machinery. Buyers should consider the material specifications, dimensions, and tensile strength to ensure compatibility with their projects. While standard fasteners are widely available and versatile, they may not meet the unique requirements of specialized applications.

Specialty Fasteners

Specialty fasteners are engineered for specific applications and industries, such as aerospace or medical devices. These fasteners often feature unique designs, materials, or coatings that enhance performance in demanding environments. When purchasing specialty fasteners, buyers must evaluate their exact specifications, including load requirements and environmental conditions. Although these fasteners can be more expensive and may have longer lead times, they provide critical solutions that standard fasteners cannot.

Stainless Steel Fasteners

Stainless steel fasteners are known for their exceptional corrosion resistance, making them ideal for outdoor applications or environments exposed to moisture and chemicals. They are widely used in the marine, food processing, and chemical industries. Buyers should assess the grades of stainless steel, as different grades offer varying levels of corrosion resistance and strength. While these fasteners provide long-term reliability, they typically come at a premium compared to standard options.

Anchors and Supports

Anchors and supports are essential components used to secure fixtures to walls, ceilings, and floors. They play a crucial role in construction, renovation, and heavy machinery applications. Buyers must consider the type of substrate they will be working with, as different anchors are designed for various materials such as concrete, drywall, or masonry. Although these products are vital for ensuring stability and safety, the complexity of installation can vary significantly depending on the type of anchor chosen.

Drill Bits and Cutting Tools

Drill bits and cutting tools are specialized fasteners designed for creating holes and shaping materials in construction, manufacturing, and woodworking. These tools are essential for achieving precision and efficiency in various applications. When selecting drill bits, buyers should pay attention to the material compatibility and the type of cutting required. While high-quality drill bits can enhance productivity and reduce downtime, they often require careful matching to the specific material being worked on for optimal results.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of crouch sales co

| Industry/Sector | Specific Application of Crouch Sales Co | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Fasteners for structural frameworks | Ensures durability and safety in buildings | Quality certifications, compliance with local standards |

| Manufacturing | Fasteners for machinery assembly | Increases efficiency and reduces downtime | Bulk purchasing options, compatibility with existing machinery |

| Food Industry Manufacturing | Fasteners in food processing equipment | Maintains hygiene and operational efficiency | Corrosion resistance, ease of cleaning |

| Elevator Construction & Maintenance | Fasteners for elevator installations | Enhances safety and reliability of elevators | Load-bearing specifications, installation standards |

| Metal Recycling | Fasteners for recycling machinery | Supports sustainable practices and operational efficiency | Material specifications, environmental compliance |

In the construction sector, Crouch Sales Co provides essential fasteners for structural frameworks, which are critical for ensuring the durability and safety of buildings. Buyers need to consider the quality certifications of fasteners to ensure compliance with local building codes, especially in regions like Africa and South America where regulations may vary significantly.

Within manufacturing, Crouch Sales Co’s fasteners are pivotal for machinery assembly, enhancing efficiency and minimizing downtime. International buyers should focus on bulk purchasing options and ensure that the fasteners are compatible with their existing machinery to avoid costly disruptions.

In the food industry manufacturing, fasteners are used in food processing equipment, where hygiene is paramount. Crouch Sales Co offers corrosion-resistant fasteners that support operational efficiency while adhering to health standards. Buyers in this sector must prioritize materials that are easy to clean and meet food safety regulations.

For elevator construction and maintenance, Crouch Sales Co supplies fasteners that enhance the safety and reliability of elevators. Buyers should pay attention to load-bearing specifications and installation standards, particularly in regions with stringent safety regulations, such as Europe and the Middle East.

Lastly, in the metal recycling industry, fasteners are crucial for the operation of recycling machinery. Crouch Sales Co’s products support sustainable practices while enhancing operational efficiency. Buyers should ensure that the fasteners meet material specifications and environmental compliance standards, especially in markets that emphasize sustainability.

Related Video: Introduction to Uses and Gratifications Theory

Strategic Material Selection Guide for crouch sales co

Material Analysis for Crouch Sales Co.

When selecting materials for fasteners, it’s crucial to consider the properties that will impact performance, durability, and application suitability. Below are analyses of four common materials used by Crouch Sales Co. in their product offerings, focusing on their key properties, advantages, disadvantages, and considerations for international buyers.

1. Carbon Steel

Key Properties: Carbon steel is known for its high strength and hardness. It typically has a temperature rating up to 400°F (204°C) and can withstand moderate pressure. However, it is susceptible to corrosion if not properly treated.

Pros & Cons: Carbon steel fasteners are durable and cost-effective, making them suitable for a wide range of applications. However, they require protective coatings to enhance corrosion resistance, which can increase manufacturing complexity.

Impact on Application: Carbon steel is ideal for general construction and manufacturing applications, where strength is paramount. However, its susceptibility to rust limits its use in environments with high humidity or exposure to corrosive substances.

International Buyer Considerations: Buyers should ensure compliance with standards such as ASTM A307 or DIN 933. In regions like Africa and South America, where humidity may be high, additional corrosion protection may be necessary.

2. Stainless Steel

Key Properties: Stainless steel is renowned for its corrosion resistance and can withstand temperatures exceeding 800°F (427°C). It also maintains structural integrity under varying pressures.

Pros & Cons: The main advantage of stainless steel is its longevity and resistance to rust, making it suitable for outdoor and marine applications. However, it is more expensive than carbon steel and can be more challenging to machine.

Impact on Application: Stainless steel fasteners are ideal for applications in the food industry, marine environments, and any setting where hygiene and corrosion resistance are critical.

International Buyer Considerations: Compliance with standards like ASTM A276 or JIS G4303 is essential. Buyers in the Middle East and Europe may prefer stainless steel due to stringent regulations regarding corrosion resistance in construction and manufacturing.

3. Brass

Key Properties: Brass is a copper-zinc alloy that exhibits excellent corrosion resistance and thermal conductivity. It can handle moderate temperatures and pressures, typically up to 300°F (149°C).

Pros & Cons: Brass fasteners are aesthetically pleasing and resistant to tarnishing, making them suitable for decorative applications. However, they are softer than steel and may not be suitable for high-stress applications.

Impact on Application: Commonly used in plumbing and electrical applications, brass is ideal for environments where conductivity and corrosion resistance are necessary.

International Buyer Considerations: Buyers should consider compliance with standards such as ASTM B16 or DIN 17660. In regions like Africa, where electrical applications are growing, the demand for brass fasteners is increasing.

4. Nylon

Key Properties: Nylon is a synthetic polymer known for its lightweight and flexibility. It is resistant to corrosion and can operate effectively in temperatures up to 200°F (93°C).

Pros & Cons: The key advantage of nylon fasteners is their non-conductive properties, making them suitable for electrical applications. However, they are not as strong as metal fasteners and may not withstand high loads.

Impact on Application: Nylon is widely used in electronic applications, automotive components, and situations where weight reduction is essential.

International Buyer Considerations: Compliance with standards such as ASTM D4066 is important for quality assurance. Buyers in Europe and South America may prefer nylon for applications requiring lightweight materials.

Summary Table

| Material | Typical Use Case for Crouch Sales Co | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General construction and manufacturing | High strength and cost-effective | Susceptible to corrosion without coating | Low |

| Stainless Steel | Food industry, marine environments | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Brass | Plumbing and electrical applications | Aesthetic appeal and corrosion resistance | Softer than steel, limited high-stress use | Medium |

| Nylon | Electrical applications, automotive | Lightweight and non-conductive | Lower strength compared to metals | Medium |

This comprehensive analysis provides international B2B buyers with crucial insights into material selection, helping them make informed decisions based on performance, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for crouch sales co

Crouch Sales Company has established a robust manufacturing and quality assurance framework that is critical for B2B buyers. Understanding these processes can help international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, make informed decisions when sourcing fasteners and related products.

Manufacturing Processes

Crouch Sales employs several key stages in their manufacturing processes for fasteners, which include:

-

Material Preparation

– Material Selection: The process begins with selecting high-quality raw materials such as steel, brass, and nylon. These materials are crucial for ensuring the strength and durability of the fasteners.

– Cutting and Shaping: Raw materials are cut to specific dimensions and prepped for further processing. This stage ensures that each component meets precise specifications. -

Forming

– Forging and Machining: Techniques such as forging, which involves shaping metal using compressive forces, and machining, where material is removed to achieve desired shapes, are employed. These methods enhance the strength of the fasteners and ensure uniformity.

– Cold Heading: This technique is often used for creating heads on bolts and screws. It minimizes waste and allows for precise control over the final dimensions. -

Assembly

– Component Integration: For products that require multiple parts, the assembly stage involves integrating various components. This might include attaching nuts to bolts or integrating washers.

– Automated Assembly Lines: Crouch Sales utilizes automated systems for efficiency and consistency in production. This can lead to higher output and reduced lead times.

Illustrative Image (Source: Google Search)

- Finishing

– Surface Treatments: After assembly, fasteners undergo finishing processes like plating, coating, or anodizing. These treatments enhance corrosion resistance and improve the aesthetic appeal of the products.

– Quality Checks: Finishing stages incorporate quality checks to ensure that surface treatments meet industry standards.

Quality Assurance

Quality assurance is a critical aspect of the manufacturing process at Crouch Sales. The company adheres to various international and industry-specific standards to guarantee the reliability of its products.

- International Standards:

- ISO 9001: This standard outlines the criteria for a quality management system. Crouch Sales ensures compliance with ISO 9001, which enhances customer satisfaction through effective system implementation and continuous improvement.

-

CE Marking: For products sold within the European Economic Area, CE marking demonstrates compliance with health, safety, and environmental protection standards.

-

Industry-Specific Standards:

- API (American Petroleum Institute): Fasteners used in the oil and gas industry must meet stringent API standards, ensuring safety and reliability in critical applications.

- ASTM Standards: Compliance with ASTM standards for materials and testing procedures ensures that fasteners meet the necessary performance criteria.

Quality Control Checkpoints

Crouch Sales implements a multi-tiered quality control approach, which includes:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet required specifications. Any non-conforming materials are rejected to prevent defects in the final products.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted at various stages. This helps in identifying and rectifying issues early, minimizing waste and rework.

-

Final Quality Control (FQC): Before products are shipped, a final inspection is performed. This includes dimensional checks, functional testing, and verification of surface finishes.

Testing Methods

Crouch Sales employs various testing methods to validate product quality:

- Mechanical Testing: Tensile strength, hardness, and impact tests ensure that fasteners can withstand operational stresses.

- Corrosion Testing: Accelerated corrosion tests assess the longevity of surface treatments.

- Dimensional Verification: Automated measurement systems verify that products adhere to specified dimensions.

Verifying Supplier Quality Control

International B2B buyers can ensure they are sourcing from a reliable supplier like Crouch Sales by conducting the following:

- Supplier Audits: Regular audits of the manufacturing facilities can provide insights into the quality management systems in place and adherence to standards.

- Requesting Quality Reports: Buyers should ask for documentation of quality assurance processes, including IQC, IPQC, and FQC results, as well as compliance certificates.

- Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the manufacturing and quality control processes.

Quality Assurance Nuances for International Buyers

For international buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, understanding quality assurance nuances is vital:

- Cultural Considerations: Buyers should be aware of regional differences in quality expectations and standards. It’s beneficial to communicate clearly about quality requirements and compliance needs.

- Logistics and Delivery: Understanding local logistics can help mitigate risks associated with shipping delays or customs issues, which can impact the delivery of quality products.

- Documentation: Ensure all quality assurance documentation is available in the buyer’s preferred language, and confirm that it meets local regulatory requirements.

By grasping the manufacturing processes and quality assurance measures employed by Crouch Sales, international B2B buyers can make informed purchasing decisions, ensuring they receive high-quality fasteners that meet their operational needs.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for crouch sales co Sourcing

When analyzing the cost structure and pricing strategy of Crouch Sales Co, international B2B buyers must consider various components that contribute to the overall pricing of fasteners and related products. A clear understanding of these cost components and price influencers can help buyers make informed purchasing decisions.

Cost Components

-

Materials: The primary cost driver for Crouch Sales Co is the raw materials used in manufacturing fasteners. Steel, stainless steel, brass, and nylon are common materials, and fluctuations in the global commodities market can affect pricing.

-

Labor: Labor costs encompass the wages of employees involved in production, sales, and logistics. Skilled labor is essential for quality assurance, especially in manufacturing processes that require precision.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes and technology can help minimize these overheads.

-

Tooling: The investment in specialized tools and machinery is significant for producing high-quality fasteners. Initial tooling costs can be substantial, particularly for custom orders.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection incurs additional costs. Buyers should consider suppliers with robust QC processes, as this can lead to long-term savings by reducing defects and returns.

-

Logistics: Shipping costs are crucial, especially for international buyers. Factors include freight charges, customs duties, and handling fees. Efficient logistics management can lead to significant cost savings.

-

Margin: Crouch Sales Co must maintain a profit margin to sustain operations. This margin is influenced by competition, demand, and the value proposition of their products.

Price Influencers

Several factors can influence the pricing of fasteners at Crouch Sales Co:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts. Buyers should assess their needs to optimize order sizes for better pricing.

-

Specifications and Customization: Custom products may incur higher costs due to specialized manufacturing processes. Clear communication of specifications can help avoid costly modifications later.

-

Material Quality and Certifications: Products with higher material quality or specific certifications (e.g., ISO standards) may command higher prices. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for quality assurance and customer service.

-

Incoterms: Understanding Incoterms is critical for international transactions, as they define the responsibilities and liabilities of buyers and sellers during transport. This knowledge can help buyers negotiate better terms and avoid unexpected costs.

Buyer Tips

To maximize cost-efficiency when sourcing from Crouch Sales Co, international buyers should consider the following strategies:

-

Negotiation: Engage in discussions regarding pricing and terms. Suppliers often have flexibility, especially for bulk orders or long-term contracts.

-

Total Cost of Ownership (TCO): Evaluate the TCO by considering not just the purchase price but also logistics, maintenance, and potential downtime due to quality issues. A lower upfront cost may lead to higher long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of potential additional costs such as tariffs, taxes, and exchange rates when importing goods. These can significantly affect the overall budget.

-

Request for Quote (RFQ): Utilize RFQs to obtain detailed pricing tailored to specific needs. This process allows for better comparison among different suppliers.

Disclaimer

Prices may vary based on market conditions, order specifications, and other factors. Buyers are encouraged to consult directly with Crouch Sales Co for the most accurate and up-to-date pricing information.

Spotlight on Potential crouch sales co Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘crouch sales co’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for crouch sales co

Key Technical Properties

Understanding the technical properties of fasteners is crucial for B2B buyers, especially when sourcing products from international suppliers like Crouch Sales Co. Here are essential specifications to consider:

-

Material Grade

Fasteners are made from various materials, including steel, stainless steel, brass, and nylon. The material grade indicates the strength and corrosion resistance of the fastener. For example, stainless steel (e.g., 304 or 316 grade) offers excellent corrosion resistance, making it suitable for harsh environments. Selecting the right material grade is vital for ensuring the longevity and reliability of your projects. -

Tolerance

Tolerance refers to the permissible limit of variation in a fastener’s dimensions. This specification is critical because it affects how well the components fit together in assembly. Inaccurate tolerances can lead to mechanical failure or increased wear and tear. B2B buyers should ensure that the tolerances meet their engineering requirements to avoid costly mistakes in production. -

Coating

Many fasteners come with protective coatings, such as zinc plating or powder coating, which enhance their corrosion resistance and aesthetic appeal. The choice of coating can influence the fastener’s performance in specific environments. Buyers should consider the environmental conditions their products will face when selecting fasteners. -

Strength Rating

Fasteners are categorized by their strength ratings, which indicate their load-bearing capacity. For instance, bolts may be rated as Grade 2, Grade 5, or Grade 8, with higher grades denoting greater tensile strength. Understanding the strength rating is crucial for ensuring the fasteners can withstand the stresses of their application without failure. -

Head Styles

The head style of a fastener affects its installation method and appearance. Common head styles include hex, socket, and flat. Each style has specific applications and may require different tools for installation. Buyers should consider head styles based on their assembly requirements and tool availability. -

Finish

The finish of a fastener can affect its performance and appearance. Options include plain, galvanized, or black oxide finishes. A suitable finish can enhance corrosion resistance and compatibility with other materials. Buyers should evaluate the finish based on their specific application needs and environmental factors.

Common Trade Terminology

Navigating the B2B landscape requires familiarity with specific trade terminology. Here are some essential terms relevant to fastener procurement:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring that fasteners meet the required standards for compatibility and performance in your equipment. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This term is vital for B2B buyers to understand as it affects inventory costs and order planning. Knowing the MOQ can help businesses manage their cash flow and storage capabilities effectively. -

RFQ (Request for Quote)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. It is a critical step in the procurement process, allowing buyers to compare offers and select the best option based on price and service. Properly formulating an RFQ can lead to better pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms can help B2B buyers clarify shipping responsibilities, risks, and costs, ensuring smoother transactions across borders. -

Lead Time

Lead time is the time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for inventory management and project planning. This knowledge helps in setting realistic timelines for product availability and project execution. -

Product Certification

Product certification refers to the validation that a product meets specific standards or regulations. Certifications can include ISO, ASTM, or ANSI standards, depending on the industry. Buyers should verify certifications to ensure compliance with safety and quality standards, particularly in regulated industries.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing fasteners from Crouch Sales Co. This knowledge not only streamlines the procurement process but also enhances product reliability and project success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the crouch sales co Sector

Market Overview & Key Trends

The fastener industry, particularly in the context of Crouch Sales Co., is influenced by several global drivers, including increased construction activities, the growth of manufacturing sectors, and rising demand for automation. The ongoing infrastructure development in regions such as Africa and South America is a significant catalyst for growth, creating opportunities for international B2B buyers to source reliable and high-quality fasteners.

Current and emerging trends include the integration of technology in sourcing processes. B2B buyers are increasingly leveraging digital platforms for procurement, enabling them to access a broader range of suppliers and products. Key technologies such as artificial intelligence and data analytics are transforming how companies manage inventory and predict demand, allowing for more efficient supply chain operations. Moreover, sustainability is becoming a priority, with buyers seeking suppliers who can offer eco-friendly products and practices.

For international buyers, understanding local market dynamics is essential. In Africa and the Middle East, for instance, there is a growing emphasis on local sourcing to reduce lead times and transportation costs. Conversely, European buyers may prioritize suppliers that demonstrate compliance with stringent regulatory standards. As such, B2B buyers should align their sourcing strategies with regional market trends while also considering global shifts toward digitalization and sustainability.

Sustainability & Ethical Sourcing in B2B

Sustainability in the fastener sector is not just a trend; it has become a core component of business strategy. Crouch Sales Co. can play a pivotal role by offering products that meet environmentally friendly standards. This includes utilizing materials that are recyclable or made from recycled content, thereby reducing the environmental impact associated with production and disposal.

Ethical sourcing is equally critical. B2B buyers are increasingly scrutinizing supply chains to ensure that their suppliers adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management or the Global Recycled Standard can provide reassurance to buyers regarding the sustainability of their sourcing decisions.

By prioritizing sustainable practices, Crouch Sales Co. not only enhances its brand reputation but also aligns with the values of an increasing number of international buyers from regions like Europe and South America, where sustainability is a decisive factor in procurement processes. This focus on sustainability can lead to stronger partnerships and customer loyalty, as businesses increasingly prefer suppliers that share their commitment to ethical practices.

Brief Evolution/History

Crouch Sales Co., established in 1966, has evolved from a local fastener distributor to a key player in the online marketplace. The company has consistently focused on a “Service First, Quality Always” philosophy, which has guided its operations and customer interactions. Over the decades, it has expanded its inventory to include a wide range of fasteners and related products, catering to diverse industries such as construction, manufacturing, and food processing. This historical commitment to quality and service has positioned Crouch Sales Co. as a trusted source for international B2B buyers seeking reliable fastener solutions.

Related Video: How Global Trade Runs on U.S. Dollars | WSJ

Frequently Asked Questions (FAQs) for B2B Buyers of crouch sales co

-

What is the process for vetting suppliers like Crouch Sales Co?

Vetting suppliers is critical for international B2B buyers. Start by reviewing Crouch Sales Co’s online presence, including their website and customer testimonials. Check their experience in the industry, which dates back to 1966, and assess their product range. Request references from current clients, particularly those in your region, to understand their reliability and service quality. Additionally, consider conducting a background check on their compliance with international standards and regulations, especially if you’re sourcing for specialized industries. -

Can Crouch Sales Co customize products to meet specific requirements?

Yes, Crouch Sales Co offers customization options for various fasteners. If you have specific needs regarding dimensions, materials, or finishes, contact their sales team directly. Provide detailed specifications to facilitate the customization process. Ensure to discuss any potential impacts on pricing and lead times. Custom solutions can be beneficial for projects requiring unique fastener specifications, so don’t hesitate to explore these options. -

What are the minimum order quantities (MOQ) and lead times for international orders?

Crouch Sales Co has a minimum purchase requirement of $20 for all orders, which is relatively accessible for international buyers. Lead times can vary based on product availability and shipping logistics. Typically, standard orders may ship within a few days, while customized orders could take longer. For precise timelines, it’s best to consult their sales team directly, particularly when planning projects with tight schedules. -

What payment options are available for international buyers?

Crouch Sales Co accepts various payment methods, including credit cards, wire transfers, and possibly PayPal, depending on your location. For larger orders, discussing payment terms upfront is advisable to ensure that both parties are aligned. Inquire about any additional fees associated with international transactions, such as currency conversion or bank charges. Understanding these details can help you manage your budget effectively.

Illustrative Image (Source: Google Search)

-

Does Crouch Sales Co provide quality assurance and certifications for their products?

Yes, Crouch Sales Co emphasizes quality in their operations. They provide quality assurance through rigorous testing and adherence to industry standards. When placing an order, ask about specific certifications relevant to your industry, such as ISO or ASTM standards. This information is crucial for sectors like construction and manufacturing, where compliance with safety and quality regulations is essential. -

What logistics options are available for shipping to international destinations?

Crouch Sales Co offers various shipping methods, including UPS and USPS, which can cater to international deliveries. Discuss your shipping needs with their sales staff, who can recommend the best options based on your location and urgency. Consider the implications of customs duties and tariffs when calculating total costs, and ensure that the logistics provider can handle the necessary paperwork for smooth customs clearance. -

How does Crouch Sales Co handle disputes or issues with orders?

Crouch Sales Co has a clear policy for addressing disputes, which typically involves direct communication with their sales team. If you encounter issues such as incorrect items or damaged goods, notify them promptly to initiate a resolution process. Keep records of all correspondence and order details to facilitate effective communication. Understanding their return policy and dispute resolution process can help mitigate risks when sourcing internationally. -

What resources are available for international buyers seeking additional information?

Crouch Sales Co provides various resources on their website, including product catalogs, industry insights, and contact information for their sales team. They also have a FAQ section that addresses common inquiries. For more tailored advice, consider reaching out directly to their sales staff, who can provide insights specific to your industry and region. Engaging with their knowledgeable team can enhance your purchasing experience and ensure you receive the best products for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for crouch sales co

In conclusion, Crouch Sales Co. stands out as a reliable partner in the fastener industry, offering an extensive inventory that caters to various sectors including construction, manufacturing, and food services. The company’s commitment to a “Service First” philosophy ensures that international B2B buyers receive not only high-quality products but also exceptional customer support. By leveraging their knowledgeable sales staff, buyers can navigate the complexities of sourcing fasteners with confidence, ensuring that their projects remain on schedule and within budget.

Strategic sourcing is essential for maximizing efficiency and minimizing costs in today’s competitive market. For businesses in Africa, South America, the Middle East, and Europe, establishing a relationship with Crouch Sales Co. can enhance procurement processes and improve supply chain resilience.

As we look to the future, international buyers are encouraged to explore the myriad of fastener solutions offered by Crouch Sales Co. Engage with their experienced team to discover tailored options that meet your specific needs. Together, we can build a foundation for sustainable growth and innovation in the fastener supply chain. Reach out today to start a partnership that will elevate your operations.