Master Sourcing Flow Measurement Devices for Enhanced

Introduction: Navigating the Global Market for flow measurement devices

In today’s global economy, effective flow measurement is a cornerstone of operational efficiency across various industries, including manufacturing, oil and gas, water management, and food processing. Accurate measurement of liquids, gases, and slurries not only ensures compliance with industry standards but also drives cost savings and enhances product quality. As international B2B buyers from Africa, South America, the Middle East, and Europe seek to optimize their supply chains and production processes, understanding the landscape of flow measurement devices becomes imperative.

This guide serves as a comprehensive resource for navigating the complex market of flow measurement devices. It covers essential topics such as types of flowmeters (Coriolis, electromagnetic, vortex, and variable area), materials used in their construction, and manufacturing and quality control practices that ensure reliability and performance. Additionally, the guide examines key suppliers in the industry, provides insights into cost factors, and analyzes current market trends.

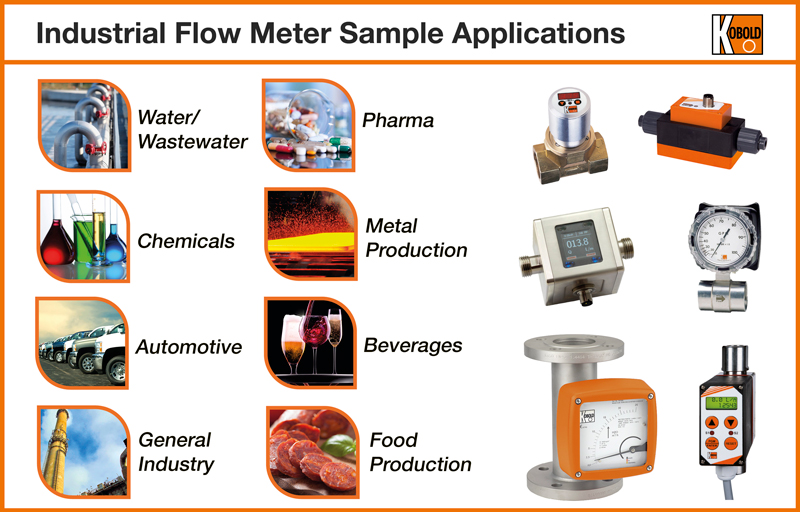

Illustrative Image (Source: Google Search)

By addressing frequently asked questions and offering actionable insights, this guide empowers B2B buyers to make informed sourcing decisions. Whether you are in South Africa, Brazil, or anywhere in between, understanding the nuances of flow measurement technology will enhance your operational capabilities and competitive edge in the global marketplace.

Understanding flow measurement devices Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Coriolis Flowmeters | Measures mass flow, density, and temperature; high accuracy; requires no straight pipe. | Oil & gas, food & beverage, pharmaceuticals | Pros: High precision, versatile; Cons: Higher cost, complex installation. |

| Magnetic Flowmeters | Based on electromagnetic induction; suitable for conductive fluids; no pressure drop. | Water & wastewater, chemical processing | Pros: No moving parts, durable; Cons: Limited to conductive liquids, installation constraints. |

| Vortex Flowmeters | Utilizes Karman vortex principle; measures liquids, gases, and steam; wide rangeability. | HVAC, steam measurement, oil & gas | Pros: Simple design, cost-effective; Cons: Less accurate at low flow rates. |

| Variable Area Flowmeters | Float position in a tapered tube indicates flow rate; basic design; versatile. | Laboratory applications, gas flow measurement | Pros: Easy to read, low cost; Cons: Limited accuracy, not suitable for high pressures. |

| Ultrasonic Flowmeters | Non-intrusive; uses sound waves to measure flow; can handle various fluids. | Water distribution, HVAC, chemical industries | Pros: No pressure loss, versatile; Cons: Sensitive to changes in fluid properties. |

Coriolis Flowmeters

Coriolis flowmeters are renowned for their ability to measure mass flow, density, and temperature simultaneously. This makes them ideal for applications in industries such as oil and gas, food and beverage, and pharmaceuticals, where precision is critical. When purchasing, B2B buyers should consider the higher upfront costs and the complexity of installation, particularly in retrofitting existing systems. However, their accuracy and versatility can justify the investment, especially for high-value applications.

Magnetic Flowmeters

Magnetic flowmeters operate on the principle of electromagnetic induction and are particularly effective for measuring conductive fluids. They are widely used in water and wastewater management and chemical processing. Buyers should note that while these flowmeters are durable and require minimal maintenance due to their lack of moving parts, they are limited to conductive liquids and may face installation challenges due to their specific requirements for pipe conditions.

Vortex Flowmeters

Utilizing the Karman vortex principle, vortex flowmeters can measure the flow of liquids, gases, and steam with a simple design that promotes cost-effectiveness. They find extensive applications in HVAC systems and steam measurement in the oil and gas industry. When considering vortex flowmeters, B2B buyers should weigh the benefits of their wide rangeability against the potential for reduced accuracy at lower flow rates. This trade-off is crucial for applications requiring precise low-flow measurements.

Variable Area Flowmeters

Variable area flowmeters, commonly known as rotameters, utilize a float within a tapered tube to indicate flow rates. Their straightforward design makes them suitable for laboratory applications and gas flow measurement. While they are cost-effective and easy to read, buyers should be aware of their limitations regarding accuracy and pressure handling. This type of flowmeter is best suited for less demanding applications where budget constraints are a priority.

Ultrasonic Flowmeters

Ultrasonic flowmeters are non-intrusive devices that measure flow by sending sound waves through the fluid. They are versatile and can handle a wide range of fluids, making them popular in water distribution and HVAC applications. B2B buyers should consider the advantages of no pressure loss and flexibility against the sensitivity of these devices to changes in fluid properties, which can affect measurement accuracy. Proper selection and installation are essential to maximize their effectiveness in varying operational conditions.

Related Video: Flow Measurement Devices (Venturimeter, Rotameter & Orificemeter) Explanation and Experiment

Key Industrial Applications of flow measurement devices

| Industry/Sector | Specific Application of flow measurement devices | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Monitoring crude oil flow rates at extraction sites | Enhances operational efficiency and reduces losses | Ensure devices can handle high pressures and corrosive fluids |

| Water and Wastewater | Measuring flow in treatment plants to ensure regulatory compliance | Improves water quality and compliance with environmental laws | Look for reliability and accuracy in varying conditions |

| Food and Beverage | Controlling ingredient flow in processing lines | Ensures product consistency and quality | Consider sanitary design and ease of cleaning |

| Pharmaceuticals | Measuring fluid flow in drug formulation processes | Guarantees accurate dosing and quality assurance | Focus on precision and regulatory compliance |

| Chemical Manufacturing | Monitoring chemical flow rates in reaction vessels | Increases safety and optimizes production efficiency | Evaluate compatibility with various chemicals and temperatures |

Industry-Specific Applications of Flow Measurement Devices

Oil and Gas

In the oil and gas industry, flow measurement devices play a critical role in monitoring crude oil flow rates at extraction sites. These devices help operators ensure that the flow is consistent and within the expected parameters, thereby enhancing operational efficiency and reducing losses due to leaks or inaccuracies. Buyers should prioritize flow meters that can withstand high pressures and corrosive environments, which are common in this sector.

Water and Wastewater

Flow measurement devices are essential in water and wastewater treatment plants, where they measure the flow of water to ensure compliance with regulatory standards. Accurate flow data is crucial for maintaining water quality and ensuring that treatment processes are effective. International B2B buyers in this sector should look for devices that offer reliability and accuracy under varying conditions, including changes in pressure and temperature.

Food and Beverage

In the food and beverage industry, flow measurement devices are used to control ingredient flow in processing lines, which is vital for maintaining product consistency and quality. These devices help ensure that the right quantities of ingredients are used, minimizing waste and ensuring compliance with food safety regulations. Buyers should consider devices with sanitary designs that allow for easy cleaning to prevent contamination.

Pharmaceuticals

Flow measurement is critical in the pharmaceutical sector, particularly in drug formulation processes, where precise fluid flow is necessary for accurate dosing. These devices help guarantee that the correct amount of active ingredients is used, thus ensuring product quality and safety. B2B buyers should focus on devices that offer high precision and are compliant with industry regulations, which often require rigorous testing and validation.

Chemical Manufacturing

In chemical manufacturing, monitoring flow rates in reaction vessels is crucial for safety and optimizing production efficiency. Accurate flow measurement helps prevent overflows or shortages that can lead to hazardous situations. Buyers should evaluate flow meters for compatibility with various chemicals and their ability to operate at different temperatures, ensuring that they can meet the specific requirements of their processes.

Strategic Material Selection Guide for flow measurement devices

When selecting materials for flow measurement devices, it’s essential to consider the specific properties and performance characteristics of each material. This section analyzes four common materials used in flow measurement devices, providing insights into their advantages, disadvantages, and implications for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 400°C and can handle pressures exceeding 200 bar, depending on the grade.

Pros & Cons: The durability of stainless steel makes it suitable for a wide range of applications, including corrosive environments. However, it can be more expensive than other materials and may require complex manufacturing processes, especially for custom shapes or sizes.

Impact on Application: Stainless steel is compatible with various media, including water, oils, and chemicals, making it a versatile choice. Its resistance to corrosion is particularly beneficial in industries such as food and beverage, pharmaceuticals, and petrochemicals.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for material specifications. Additionally, they should be aware of the availability of specific grades in their region, as this can affect lead times and costs.

PVC (Polyvinyl Chloride)

Key Properties: PVC is a lightweight and cost-effective plastic with good chemical resistance. It can handle temperatures up to 60°C and pressures around 10 bar, making it suitable for low-pressure applications.

Pros & Cons: The primary advantage of PVC is its low cost and ease of fabrication, which allows for quick production and installation. However, its lower temperature and pressure ratings limit its use in high-demand applications.

Impact on Application: PVC is ideal for measuring flow in water treatment, irrigation, and some chemical processes. However, it is not suitable for high-temperature or high-pressure applications.

Considerations for International Buyers: Buyers must verify that the PVC used meets local regulations regarding chemical resistance and safety standards. In regions with stringent environmental regulations, the choice of PVC can be scrutinized, so compliance with local standards is crucial.

Hastelloy

Key Properties: Hastelloy is a high-performance alloy known for its exceptional corrosion resistance, particularly in harsh environments. It can withstand temperatures up to 1,100°C and high pressures, making it suitable for extreme applications.

Pros & Cons: The main advantage of Hastelloy is its ability to perform reliably in aggressive chemical environments. However, it is significantly more expensive than other materials, and its manufacturing can be complex, requiring specialized techniques.

Impact on Application: Hastelloy is commonly used in the chemical processing industry, particularly for corrosive fluids. Its durability and resistance to pitting and stress corrosion cracking make it an excellent choice for critical applications.

Considerations for International Buyers: Buyers should consider the availability of Hastelloy in their region and its compliance with international standards. The cost implications of using such a premium material should also be evaluated against the potential for reduced maintenance and downtime.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a temperature rating of up to 200°C and pressure capabilities around 15 bar. Its low density makes it easy to handle and install.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which reduces shipping and installation costs. However, it can be less durable than stainless steel and may not perform well in highly corrosive environments.

Impact on Application: Aluminum is suitable for applications involving non-corrosive fluids and gases, such as air and water. It is often used in HVAC systems and low-pressure applications.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local standards for pressure and temperature ratings. Additionally, they should be aware of potential corrosion issues in specific environments, particularly in coastal areas.

Summary Table

| Material | Typical Use Case for flow measurement devices | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food & beverage, pharmaceuticals, petrochemicals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| PVC | Water treatment, irrigation | Low cost and easy fabrication | Limited temperature and pressure ratings | Low |

| Hastelloy | Chemical processing | Exceptional corrosion resistance | Very high cost and complex manufacturing | High |

| Aluminum | HVAC systems, low-pressure applications | Lightweight and easy to handle | Less durable in corrosive environments | Medium |

This guide provides a strategic overview of material selection for flow measurement devices, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for flow measurement devices

Manufacturing Processes for Flow Measurement Devices

Flow measurement devices are critical in various industries, including oil and gas, pharmaceuticals, water treatment, and food processing. Understanding their manufacturing processes helps international B2B buyers make informed decisions. Here’s a detailed breakdown of typical manufacturing stages and key techniques involved.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: The manufacturing process begins with selecting suitable materials such as stainless steel, plastic, or ceramics. The choice depends on the fluid being measured, operating conditions, and regulatory requirements.

– Material Testing: Before production, raw materials undergo testing for properties like tensile strength, corrosion resistance, and thermal stability. This ensures they meet industry standards and specifications. -

Forming

– Machining: This involves cutting, drilling, and shaping the raw materials into the required components. CNC (Computer Numerical Control) machines are often employed for precision.

– Casting and Molding: For complex shapes, casting (metal) or molding (plastic) techniques are used. This is particularly common for parts like housings and flow tubes. -

Assembly

– Component Integration: Various components, including sensors, transmitters, and electronics, are assembled. This stage requires skilled labor to ensure that all parts fit accurately and function as intended.

– Calibration: After assembly, devices are calibrated to ensure accurate flow measurement. This involves adjusting the sensors and verifying their performance against known standards. -

Finishing

– Surface Treatment: To enhance durability and performance, components often undergo surface treatments such as anodizing, plating, or painting. This step is crucial for devices exposed to harsh environments.

– Final Assembly and Packaging: Once finished, the devices undergo a final assembly and are packaged for shipment. Packaging must protect the instruments during transit and storage.

Quality Assurance in Manufacturing

Quality assurance is vital in manufacturing flow measurement devices to ensure reliability and compliance with international standards. Here’s how it typically unfolds:

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and continual improvement. Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European Economic Area (EEA), CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: In the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial, ensuring that flow meters can withstand the rigors of the environment.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This initial checkpoint involves inspecting raw materials and components upon receipt. Suppliers are often required to provide certificates of conformity to verify compliance with specifications. -

In-Process Quality Control (IPQC)

– During the manufacturing process, periodic inspections are conducted to monitor the quality of work and the accuracy of machinery. This includes checks on dimensions, tolerances, and assembly integrity. -

Final Quality Control (FQC)

– After the assembly is complete, final tests are performed. This may involve functional testing under simulated operating conditions, ensuring that all specifications are met before the product is shipped.

Common Testing Methods

- Flow Calibration: Devices are tested using calibrated flow rigs to measure their accuracy and response time.

- Pressure Testing: Ensures that the devices can withstand the maximum operating pressures without leakage.

- Temperature Testing: Validates performance in various temperature ranges, which is critical for applications in extreme environments.

Verifying Supplier Quality Control

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are several methods to ensure compliance:

- Supplier Audits: Conducting regular audits helps assess the manufacturing processes and quality control measures in place. Buyers can check for certifications, documentation, and adherence to quality standards.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s quality management practices and any issues encountered during production.

- Third-Party Inspections: Engaging independent third-party inspection services can validate the quality of products before shipment, ensuring they meet specified standards and requirements.

Quality Control Nuances for International B2B Buyers

International buyers face unique challenges regarding quality assurance. Here are a few considerations:

- Regulatory Compliance: Different regions have varying regulations and standards. Understanding these nuances is critical for compliance and successful market entry.

- Cultural Differences: Communication styles and business practices vary across regions. Building strong relationships with suppliers can lead to better transparency in quality control processes.

- Supply Chain Reliability: Assessing the reliability of the supply chain is essential. Disruptions can impact quality and delivery times, so understanding suppliers’ capabilities and contingency plans is vital.

Conclusion

The manufacturing processes and quality assurance for flow measurement devices are intricate and multifaceted. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, gaining a comprehensive understanding of these processes is crucial. By focusing on key manufacturing stages, quality control checkpoints, and verification methods, buyers can ensure they procure reliable and compliant flow measurement devices that meet their operational needs.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for flow measurement devices Sourcing

Understanding the Cost Structure of Flow Measurement Devices

When sourcing flow measurement devices, international B2B buyers must be aware of the various cost components that contribute to the overall pricing. The primary components include:

-

Materials: The quality and type of materials used significantly impact costs. High-performance materials (like stainless steel or specialized plastics) for demanding environments (e.g., corrosive fluids) can increase expenses.

-

Labor: Manufacturing labor costs vary by region. Countries with lower labor costs might offer more competitive pricing; however, this can come with trade-offs in quality or reliability.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these expenses.

-

Tooling: The initial setup for custom devices can require significant investment. This includes molds and specialized tools for unique designs, which can be amortized over larger production runs.

-

Quality Control (QC): Stringent QC processes ensure product reliability and compliance with industry standards, impacting overall costs. Buyers should consider the value of quality assurance in their procurement decisions.

-

Logistics: Transportation and warehousing costs can vary based on location and shipping methods. Incoterms play a crucial role in determining who bears these costs.

-

Margin: Supplier margins will vary based on market conditions and competition. Understanding a supplier’s margin structure can provide insights into their pricing flexibility.

Influencers of Pricing

Several factors can influence the pricing of flow measurement devices:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their needs and budgets.

-

Specifications/Customization: Customized solutions typically carry a premium. Buyers should clarify their requirements upfront to avoid unexpected costs.

-

Materials: As mentioned, the type of materials used can significantly affect pricing. Opting for standard materials may reduce costs, while specialized materials may be necessary for specific applications.

-

Quality/Certifications: Devices that meet international standards (like ISO, API, or CE certifications) often come at a higher price due to the rigorous testing involved.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but offer better support and warranties.

-

Incoterms: Understanding Incoterms (e.g., FOB, CIF) is crucial for determining cost responsibilities in international trade, affecting total landed costs.

Buyer Tips for Cost-Efficiency

To navigate the complexities of pricing in the flow measurement devices market, buyers should consider the following strategies:

-

Negotiate Terms: Always seek to negotiate prices, payment terms, and delivery schedules. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Assess Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider maintenance, operational efficiency, and potential downtime costs associated with the devices.

-

Understand Pricing Nuances: Different markets may have varying pricing structures. For example, buyers in Africa may face additional import duties, while those in Europe might benefit from more competitive local suppliers.

-

Evaluate Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, more favorable terms, and priority service.

-

Stay Informed on Market Trends: Keeping abreast of technological advancements and market dynamics can provide leverage in negotiations and help identify cost-saving opportunities.

Conclusion

Sourcing flow measurement devices requires a comprehensive understanding of the cost structure and pricing dynamics. By considering the various cost components and price influencers, as well as employing strategic buyer tips, international B2B buyers can make informed purchasing decisions that align with their operational goals. Always remember that prices can vary widely based on specifications, supplier capabilities, and market conditions, so it’s essential to approach procurement with a strategic mindset.

Spotlight on Potential flow measurement devices Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘flow measurement devices’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for flow measurement devices

Key Technical Properties for Flow Measurement Devices

Understanding the technical specifications of flow measurement devices is crucial for international B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. Here are essential properties to consider:

-

Material Grade

– Definition: Refers to the quality and type of materials used in manufacturing flow measurement devices, such as stainless steel, plastic, or exotic alloys.

– Importance: The material grade affects durability, corrosion resistance, and suitability for specific fluids. Buyers must ensure that the materials used meet the standards required for their application, especially when dealing with aggressive chemicals or high temperatures. -

Measurement Range

– Definition: The span of flow rates that a device can accurately measure, typically expressed in units like liters per minute (L/min) or cubic meters per hour (m³/h).

– Importance: Selecting a device with the appropriate measurement range ensures accurate readings for the specific flow conditions of the application. An inadequate range can lead to measurement errors or equipment failure. -

Accuracy and Tolerance

– Definition: Accuracy is the degree to which the measured value reflects the true value, while tolerance refers to the acceptable range of deviation from this true value.

– Importance: High accuracy and low tolerance are critical in industries where precise flow measurement is essential, such as pharmaceuticals or food processing. Buyers should evaluate these specifications to ensure compliance with industry standards. -

Operating Temperature and Pressure

– Definition: The maximum and minimum temperatures and pressures the device can handle during operation.

– Importance: Understanding these limits is vital for ensuring the device’s reliability and longevity in various environments. Buyers must select devices that can withstand the specific conditions of their application, especially in extreme environments. -

Installation Requirements

– Definition: Guidelines regarding the necessary space, piping configuration, and additional components required for proper installation.

– Importance: Knowledge of installation requirements can prevent costly modifications or delays in projects. Buyers should ensure that the chosen flow measurement device fits within their existing infrastructure. -

Power Supply and Communication Protocols

– Definition: The type of power source needed for operation (e.g., battery, AC, or DC) and the communication protocols used for data transfer (e.g., Modbus, HART).

– Importance: Compatibility with existing systems is essential for seamless integration and operation. Buyers should verify that the flowmeter’s power requirements and communication capabilities align with their operational setup.

Common Trade Terminology in Flow Measurement

Familiarity with industry jargon can enhance communication and streamline procurement processes. Here are key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that manufactures products that are sold under another company’s brand.

– Importance: Understanding OEM relationships can help buyers identify quality assurance and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers manage inventory costs and aligns purchasing strategies with production needs, especially in bulk procurement. -

RFQ (Request for Quotation)

– Definition: A formal document requesting prices from suppliers for specific products or services.

– Importance: An RFQ streamlines the procurement process, ensuring that buyers receive competitive pricing and detailed information on specifications. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping, insurance, and delivery responsibilities, minimizing disputes and ensuring smoother transactions. -

Calibration

– Definition: The process of adjusting and verifying the accuracy of a measuring instrument.

– Importance: Regular calibration is crucial for maintaining the precision of flow measurement devices, directly impacting operational efficiency and compliance with regulatory standards. -

Flow Profile

– Definition: The distribution of flow velocities across a cross-section of a pipe or duct.

– Importance: Understanding flow profiles is essential for selecting appropriate measurement devices to ensure accurate readings, as different profiles can influence measurement results.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and product quality in their respective industries.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the flow measurement devices Sector

Market Overview & Key Trends

The flow measurement devices market is undergoing significant transformation driven by technological advancements and increasing demand for precision in industrial processes. Key global drivers include the rise of automation, the Internet of Things (IoT), and Industry 4.0, which necessitate accurate flow measurement for optimal operational efficiency. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking smart flow measurement solutions that integrate seamlessly with existing systems and provide real-time data analytics.

Emerging trends include the adoption of Coriolis and electromagnetic flowmeters due to their accuracy and versatility across various applications, including water treatment and oil and gas. The demand for portable and battery-operated flowmeters is rising, especially in developing markets where infrastructure may be limited. Additionally, the increasing importance of data-driven decision-making is prompting buyers to consider flow measurement devices equipped with advanced connectivity features, enabling remote monitoring and predictive maintenance.

Moreover, as industries strive for operational excellence, the emphasis on reliability and compliance with international standards is shaping procurement strategies. B2B buyers are prioritizing suppliers with proven track records of delivering high-quality, certified products that meet specific industry regulations. This trend is particularly salient in highly regulated sectors such as pharmaceuticals and food processing.

Sustainability & Ethical Sourcing in B2B

The environmental impact of manufacturing and using flow measurement devices is becoming a pivotal consideration for international B2B buyers. Companies are increasingly held accountable for their carbon footprints, prompting a shift towards sustainable sourcing practices. This includes selecting suppliers that adhere to ethical standards and utilize environmentally friendly materials in their manufacturing processes.

Buyers should look for green certifications such as ISO 14001 (Environmental Management) and certifications from recognized organizations that validate sustainable practices. Additionally, the use of recyclable materials and energy-efficient manufacturing processes is gaining traction in the flow measurement sector. Implementing these practices not only enhances a company’s corporate social responsibility profile but also aligns with global efforts to mitigate climate change.

Ethical sourcing also encompasses ensuring transparency throughout the supply chain. Buyers are encouraged to engage with suppliers who can provide traceability of materials and demonstrate compliance with labor rights and environmental regulations. This approach not only safeguards brand reputation but also fosters long-term partnerships built on trust and shared values.

Brief Evolution/History

The evolution of flow measurement devices dates back to the late 19th century, with early devices primarily designed for water flow measurement. Over the decades, advancements in technology have led to the development of various types of flowmeters, including mechanical, magnetic, and mass flowmeters, each tailored for specific applications and industries. The introduction of digital technologies in the late 20th century revolutionized the sector, enabling enhanced accuracy, data processing capabilities, and integration with automation systems.

Today, the flow measurement devices market is characterized by innovation and adaptability, with manufacturers continually seeking to meet the evolving needs of industries worldwide. This historical context is crucial for B2B buyers as it highlights the importance of selecting devices that not only meet current operational requirements but also have the capacity for future upgrades and integration with emerging technologies.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of flow measurement devices

-

What should I consider when vetting suppliers for flow measurement devices?

When vetting suppliers, prioritize their industry experience, reputation, and certifications. Investigate their track record by reviewing client testimonials and case studies. Ensure they comply with international standards such as ISO and have relevant certifications for the specific flow measurement devices you require. Additionally, assess their ability to provide technical support and after-sales service, which can be crucial for complex installations and maintenance. -

Can flow measurement devices be customized to meet specific requirements?

Yes, many suppliers offer customization options to cater to unique operational needs. This can include modifications in size, material, measurement range, and additional features like integrated data logging or remote monitoring capabilities. When discussing customization, clearly communicate your specifications and operational environment to ensure the device meets your precise requirements and functions optimally in your application. -

What are the typical minimum order quantities (MOQ) and lead times for flow measurement devices?

MOQs can vary widely depending on the supplier and the type of flow measurement device. Some manufacturers may have MOQs as low as one unit for standard devices, while custom solutions may require larger orders. Lead times typically range from a few weeks to several months, depending on the complexity of the order and the supplier’s production capacity. Always clarify these details upfront to manage expectations and ensure timely delivery. -

What payment terms should I expect when purchasing flow measurement devices?

Payment terms can vary among suppliers, but common practices include partial upfront payments with the balance due upon delivery or after installation. International transactions may involve letters of credit or escrow services to protect both parties. It’s essential to discuss and negotiate these terms early in the procurement process to avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance and certifications for the devices I purchase?

Request copies of quality assurance certifications and inspection reports from your suppliers. Look for compliance with international standards such as ISO 9001 for quality management systems and industry-specific certifications related to flow measurement devices. Additionally, inquire about the supplier’s quality control processes and whether they conduct third-party testing to validate their products’ performance and reliability.

Illustrative Image (Source: Google Search)

-

What logistics considerations should I keep in mind when sourcing flow measurement devices internationally?

Consider shipping methods, lead times, and customs regulations when planning logistics. Working with suppliers who have experience in international shipping can streamline the process. Ensure that the supplier provides all necessary documentation for customs clearance, including commercial invoices and certificates of origin. Also, evaluate the total landed cost, including shipping fees, tariffs, and taxes, to assess the overall budget accurately. -

How should I handle disputes that may arise during the procurement process?

To mitigate disputes, establish clear terms and conditions in the purchase agreement, including warranties, return policies, and dispute resolution procedures. If a disagreement occurs, initiate communication with the supplier to seek a resolution amicably. Consider involving a neutral third party, such as a mediator, if direct discussions do not yield results. Having a legally binding contract can also facilitate a smoother resolution process. -

What are the key factors to consider regarding the maintenance and support of flow measurement devices?

Ensure that your supplier offers comprehensive maintenance and technical support options. This includes regular calibration services, troubleshooting assistance, and access to spare parts. Inquire about the availability of training for your staff to operate and maintain the devices effectively. A solid support plan can enhance device longevity and ensure optimal performance, ultimately contributing to your operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for flow measurement devices

In conclusion, the strategic sourcing of flow measurement devices presents an invaluable opportunity for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. By understanding the diverse range of flow measurement technologies—such as Coriolis, electromagnetic, vortex, and variable area flowmeters—buyers can make informed decisions that align with their operational needs and budget constraints.

Key takeaways include the importance of selecting devices that provide accuracy and reliability while accommodating specific fluid types and measurement conditions. Investing in high-quality flow measurement devices not only enhances operational efficiency but also drives compliance with industry standards and regulations.

As the global market evolves, staying abreast of technological advancements and supplier capabilities will be crucial. We encourage B2B buyers to engage with trusted suppliers, explore innovative solutions, and leverage strategic sourcing to optimize their flow measurement processes. The future is bright for organizations that prioritize effective sourcing strategies, ensuring they remain competitive and resilient in an ever-changing landscape.