Master Sourcing for Dies and Stamping: A Complete B2B Guide

Introduction: Navigating the Global Market for dies and stamping

In today’s dynamic global marketplace, the manufacturing sector increasingly relies on dies and stamping as a fundamental process for producing high-quality metal components. This technique not only ensures precision and consistency but also significantly enhances production efficiency, making it a go-to choice for industries ranging from automotive to aerospace. As international B2B buyers from Africa, South America, the Middle East, and Europe (including key markets like Saudi Arabia and Spain) seek reliable suppliers, understanding the nuances of dies and stamping is essential for informed sourcing decisions.

This comprehensive guide delves into the critical aspects of dies and stamping, covering various types of stamping techniques, such as progressive, deep draw, and four-slide stamping, as well as the materials commonly used in the process. It also addresses manufacturing and quality control standards, helping buyers navigate the complexities of supplier selection. Additionally, insights into cost considerations and market trends will empower buyers to make strategic decisions that align with their business objectives.

By providing a thorough understanding of the stamping process and its applications, this guide equips B2B buyers with the knowledge necessary to identify suitable suppliers and maximize their investment in tooling. Whether you are looking to streamline production or enhance product quality, this resource will serve as your roadmap to successfully navigating the global market for dies and stamping.

Understanding dies and stamping Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Progressive Die Stamping | Multiple stations for sequential operations | High-volume production of complex parts | Pros: High efficiency, reduced labor costs. Cons: Higher initial tooling costs. |

| Transfer Die Stamping | Transfers parts between stations without a connected strip | Larger or deep-drawn components | Pros: Ideal for complex shapes. Cons: More complex setup than simple dies. |

| Deep Draw Stamping | Shapes metal sheets into deeper forms | Automotive parts, cookware, electronic housings | Pros: Material efficiency, versatile applications. Cons: Requires precise tooling. |

| Four-Slide Stamping | Uses four slides for simultaneous bending operations | Complex parts with frequent design changes | Pros: High versatility, efficient for small runs. Cons: Can be costly for larger runs. |

| Short Run Stamping | Cost-effective for small batch production | Prototyping, limited production runs | Pros: Lower upfront tooling costs. Cons: Higher unit costs compared to mass production. |

Progressive Die Stamping

Progressive die stamping involves multiple stations where each station performs a specific operation on a metal strip. This method is ideal for producing high volumes of intricate components with consistent quality. B2B buyers should consider the initial tooling costs, which can be significant, but the efficiency and reduced labor costs often justify the investment. This technique is particularly beneficial for industries like automotive and electronics, where precision and speed are critical.

Transfer Die Stamping

Transfer die stamping is characterized by its ability to move parts between different stations during the stamping process. Unlike progressive dies, the components are not connected to a continuous strip, allowing for deeper and more complex shapes. This method is suited for larger components and is often used in industries like aerospace and automotive. Buyers should evaluate the complexity of the components they need, as well as the setup requirements, which can be more intricate than simpler stamping methods.

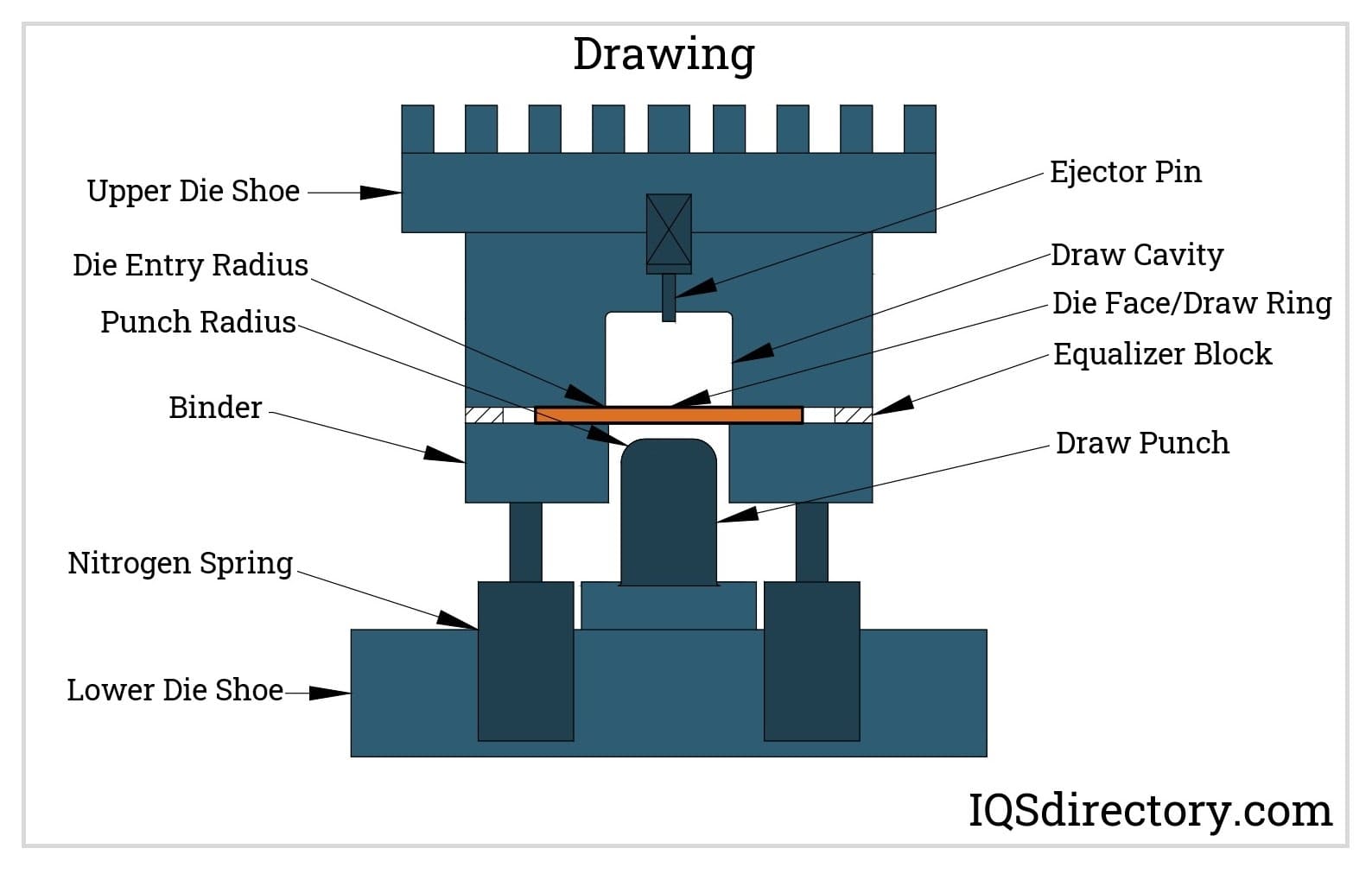

Deep Draw Stamping

Deep draw stamping is a specialized process that pulls a metal sheet into a die, creating parts with greater depth than diameter. This method is particularly effective for items such as automotive components and cookware. Buyers should consider the material efficiency of deep draw stamping, as it often results in less waste compared to other methods. However, the precision required for tooling can increase costs, making it essential to partner with experienced manufacturers.

Four-Slide Stamping

Four-slide stamping utilizes four slides to perform multiple bending operations simultaneously, making it an efficient method for producing complex parts. This technique is particularly advantageous for projects requiring frequent design alterations and is commonly used in the electronics and hardware sectors. Buyers should assess the flexibility of their design needs, as this method can be more cost-effective for smaller runs. However, the initial setup may require more investment compared to traditional stamping methods.

Short Run Stamping

Short run stamping is ideal for B2B buyers looking to produce small batches or prototypes without incurring high tooling costs. This method allows for quick turnarounds and customization, making it a popular choice for testing new designs. While unit costs may be higher than in mass production, the lower initial investment makes it accessible for businesses wanting to innovate without substantial risk. Buyers should focus on suppliers that offer flexible tooling options to maximize their investment.

Key Industrial Applications of dies and stamping

| Industry/Sector | Specific Application of dies and stamping | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of body panels and components | High-volume production with consistent quality and precision | Supplier’s experience with automotive standards and certifications |

| Aerospace | Manufacturing of aircraft parts | Lightweight and durable components that meet stringent regulations | Compliance with aerospace certifications and material specifications |

| Electronics | Fabrication of connectors and housings | Rapid prototyping and high-volume production of intricate designs | Advanced tooling capabilities and flexibility in design alterations |

| Consumer Goods | Production of kitchenware and appliances | Cost-effective manufacturing of complex shapes and designs | Supplier’s ability to handle varying production runs and customization |

| Industrial Equipment | Creation of machine housings and structural components | Enhanced durability and performance through precision engineering | Availability of specialized dies for heavy-duty applications |

Automotive Sector

In the automotive industry, dies and stamping are crucial for producing body panels and various components like brackets and supports. This process allows manufacturers to achieve high-volume production while ensuring consistent quality and precision. International buyers should prioritize suppliers with experience in automotive standards, such as ISO/TS 16949, to ensure compliance and reliability in their sourcing.

Aerospace Sector

Aerospace applications require the manufacturing of lightweight and durable components, such as fuselage parts and engine casings. Stamping processes must adhere to stringent regulations to ensure safety and performance. Buyers in this sector should consider suppliers who can demonstrate compliance with aerospace certifications like AS9100 and possess a strong understanding of material specifications to meet rigorous industry standards.

Electronics Sector

In electronics, dies and stamping are used for fabricating connectors, housings, and other intricate components. This method supports rapid prototyping and high-volume production, which is essential in a fast-paced market. For international buyers, sourcing from suppliers with advanced tooling capabilities is critical, as they can provide flexibility in design alterations and ensure the precision necessary for electronic applications.

Consumer Goods Sector

The consumer goods industry utilizes dies and stamping for producing kitchenware and various appliances. This process enables manufacturers to create complex shapes and designs cost-effectively. Buyers should look for suppliers that can handle varying production runs and offer customization options, ensuring that products meet specific market demands and consumer preferences.

Industrial Equipment Sector

In industrial equipment, dies and stamping are employed to create machine housings and structural components that require enhanced durability and performance. Precision engineering is vital in this sector to ensure that components can withstand heavy usage. Buyers should seek suppliers with specialized dies for heavy-duty applications and a proven track record in producing robust industrial components.

Related Video: F-BOMB OF PEACE: Trump uses colorful language after Israel, Iran continue to drop bombs

Strategic Material Selection Guide for dies and stamping

When selecting materials for dies and stamping, international B2B buyers must consider several factors that impact performance, durability, and cost. Here, we analyze four common materials used in die and stamping applications, providing insights into their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

Tool Steel

Key Properties:

Tool steel is known for its hardness, wear resistance, and ability to withstand high temperatures. It typically has a high carbon content, enhancing its strength and durability under pressure.

Pros & Cons:

Tool steel is highly durable, making it suitable for high-volume stamping operations. However, it can be expensive and requires complex manufacturing processes, including heat treatment. While it excels in producing intricate shapes, the initial investment can be significant.

Impact on Application:

Tool steel is ideal for applications requiring precision and longevity, such as automotive and aerospace components. Its compatibility with various stamping processes makes it a versatile choice.

Considerations for International Buyers:

Buyers must ensure compliance with international standards such as ASTM A681 or DIN 17350. Additionally, sourcing tool steel from reputable suppliers is crucial to guarantee quality, especially in regions like Europe and the Middle East, where stringent regulations apply.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can withstand moderate temperatures and pressures, making it suitable for various applications.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can reduce shipping costs and ease handling. However, it is not as durable as tool steel, and its lower strength can limit its use in high-stress applications. Manufacturing complexity is moderate, as aluminum can be easily formed and machined.

Impact on Application:

Aluminum is commonly used in industries such as electronics and automotive for components that require lightweight materials. Its corrosion resistance makes it suitable for environments exposed to moisture.

Considerations for International Buyers:

Buyers should look for compliance with standards such as ASTM B221 or JIS H4000. In regions like South America, where corrosion can be a concern, aluminum’s properties can be particularly advantageous.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, strength, and durability. It can withstand high temperatures and pressures, making it suitable for various stamping applications.

Pros & Cons:

The key advantage of stainless steel is its longevity and ability to resist rust and corrosion, making it ideal for harsh environments. However, it is generally more expensive than other materials and can be challenging to machine, increasing manufacturing complexity.

Impact on Application:

Stainless steel is widely used in the food and beverage, medical, and automotive industries due to its hygienic properties and strength. Its compatibility with stamping processes allows for the production of complex shapes.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A240 or EN 10088. In regions like Africa and the Middle East, where environmental conditions can be harsh, the corrosion resistance of stainless steel is a significant advantage.

High-Carbon Steel

Key Properties:

High-carbon steel is known for its hardness and strength, making it suitable for high-impact applications. It can be heat-treated to enhance its properties further.

Pros & Cons:

The main advantage of high-carbon steel is its ability to maintain sharp edges and resist wear. However, it is more brittle than other materials, which can lead to cracking under extreme conditions. Manufacturing is less complex compared to tool steel but requires careful handling.

Impact on Application:

High-carbon steel is often used in applications requiring sharp edges, such as cutting tools and dies. Its hardness makes it suitable for stamping operations that demand precision.

Considerations for International Buyers:

Compliance with standards like ASTM A681 is essential. Buyers from Europe and South America should consider the availability of high-carbon steel and its suitability for specific applications in their industries.

Summary Table

| Material | Typical Use Case for dies and stamping | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tool Steel | High-volume stamping for automotive and aerospace components | Excellent durability and precision | High cost and complex manufacturing | High |

| Aluminum | Lightweight components in electronics and automotive | Low weight and corrosion resistance | Lower strength and durability | Medium |

| Stainless Steel | Food, beverage, and medical industries | Superior corrosion resistance | Higher cost and machining difficulty | High |

| High-Carbon Steel | Cutting tools and precision dies | Maintains sharp edges and wear resistance | Brittle and prone to cracking | Medium |

This guide provides a comprehensive overview of strategic material selection for dies and stamping, enabling international B2B buyers to make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for dies and stamping

Manufacturing Processes for Dies and Stamping

Manufacturing dies and stamping components involves a series of well-defined processes aimed at producing high-quality metal parts efficiently. Understanding these processes is crucial for B2B buyers, especially when sourcing from international suppliers. Here, we break down the primary stages of manufacturing and the key techniques employed in the industry.

Main Stages of Manufacturing

-

Material Preparation

– Material Selection: The first step involves selecting the appropriate raw materials, often steel, aluminum, or other alloys, based on the intended application and mechanical properties required.

– Material Cutting: Sheets or coils of metal are cut to size using shearing or blanking processes. This ensures that the material dimensions align with the design specifications. -

Forming

– Stamping Process: The prepared metal sheets are fed into stamping presses. Depending on the complexity of the part, different stamping techniques are employed:- Progressive Die Stamping: Involves multiple stations for sequential operations, allowing for complex geometries.

- Deep Draw Stamping: Utilized for parts requiring significant depth, such as automotive components.

- Four-Slide Stamping: Enables simultaneous bending, ideal for intricate designs.

- Tooling: The design and precision of the stamping die are critical. High-quality dies ensure accurate shaping and cutting, reducing defects and maximizing production efficiency.

-

Assembly

– Integration of Components: After individual parts are stamped, they may require assembly. This can involve welding, fastening, or other joining techniques, depending on the design requirements.

– Sub-assembly Inspection: Each assembled unit should be checked for fit and function to ensure that it meets the specifications before moving to the finishing stage. -

Finishing

– Surface Treatment: Processes such as coating, plating, or polishing are applied to enhance corrosion resistance and aesthetics. This is crucial for components used in demanding environments.

– Final Inspection: A comprehensive inspection is performed to ensure that all parts meet the quality standards before they are packaged and shipped.

Key Techniques in Manufacturing

- CAD/CAM Technology: Computer-aided design and manufacturing tools are used to create detailed die designs, ensuring precision and reducing the time needed for prototyping.

- Automated Presses: Modern stamping operations often utilize automated systems to enhance production speed and reduce labor costs.

- Lean Manufacturing Principles: Many manufacturers adopt lean principles to minimize waste and improve efficiency throughout the stamping process.

Quality Assurance in Dies and Stamping

Quality assurance (QA) is integral to the manufacturing of dies and stamped parts. For B2B buyers, understanding the QA processes and standards is essential for verifying supplier capabilities.

Relevant International Standards

- ISO 9001: This is a widely recognized quality management standard that ensures organizations consistently meet customer and regulatory requirements. Buyers should look for suppliers with ISO 9001 certification as it indicates a commitment to quality management.

- Industry-Specific Standards: Depending on the application, suppliers may also need to comply with additional certifications such as:

- CE Marking: Required for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: Relevant for components used in the oil and gas industry, ensuring that products meet rigorous safety and quality standards.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, reducing waste and rework.

- Final Quality Control (FQC): Comprehensive inspections of finished products before shipment ensure that they meet all specifications and quality standards.

Common Testing Methods

- Dimensional Inspection: Using tools like calipers and micrometers to verify that parts meet design specifications.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection to detect internal defects without damaging the components.

- Functional Testing: Ensuring that the finished part performs as intended under expected operational conditions.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers:

- Audits: Conducting on-site audits can provide insight into a supplier’s manufacturing processes, quality control measures, and adherence to industry standards.

- Quality Reports: Requesting detailed quality reports and documentation from suppliers can help assess their capabilities and consistency in producing high-quality components.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate supplier facilities can provide an unbiased assessment of quality control practices.

Quality Control Nuances for International Buyers

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital:

- Cultural Differences: Be aware that quality standards and practices may vary significantly across regions. Establish clear communication about expectations and requirements.

- Regulatory Compliance: Ensure that suppliers understand and comply with local regulations in your region, especially when it comes to safety and environmental standards.

- Documentation and Traceability: Request thorough documentation for all materials and processes to facilitate traceability and compliance verification.

By understanding the intricacies of manufacturing processes and quality assurance in dies and stamping, B2B buyers can make informed decisions when sourcing components globally. This knowledge not only enhances procurement strategies but also fosters long-term partnerships with reliable suppliers.

Related Video: Wire and cable factory production #machine #cablewirestrippingmachine #wirecutting #wireworks

Comprehensive Cost and Pricing Analysis for dies and stamping Sourcing

When sourcing dies and stamping services, B2B buyers must navigate a complex cost structure that can significantly influence their total expenditure. Understanding the various cost components and price influencers is essential for making informed purchasing decisions.

Cost Components

-

Materials: The choice of raw materials, such as steel, aluminum, or specialized alloys, directly impacts costs. High-quality materials may increase initial expenses but can lead to lower maintenance and replacement costs over time.

-

Labor: Labor costs vary depending on the region and skill level required for die fabrication and stamping. Skilled labor is essential for precision, particularly in complex designs, which can drive up costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, equipment maintenance, and facility management. Overhead can differ widely based on geographical location and the efficiency of the manufacturing processes.

-

Tooling: Tooling costs are significant in die and stamping projects. Custom dies require precise engineering and fabrication, which can be expensive. Buyers should consider the longevity and adaptability of the tooling to mitigate future costs.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the final products meet specified standards. While this incurs additional costs, it can prevent costly defects and rework, ultimately contributing to a better Total Cost of Ownership (TCO).

-

Logistics: Transportation and logistics can add considerable expenses, especially for international buyers. Consideration of shipping methods, tariffs, and delivery timelines is crucial.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand, competition, and the supplier’s operational efficiency.

Price Influencers

-

Volume/MOQ: The minimum order quantity (MOQ) can dramatically affect pricing. Larger orders often yield lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom designs or unique specifications can increase costs. Standardized components typically offer cost advantages, so buyers should weigh the necessity of customization against budget constraints.

-

Materials: The choice of materials not only affects initial costs but also influences durability and performance. Selecting the right material for the application can lead to long-term savings.

-

Quality/Certifications: Suppliers with industry certifications (e.g., ISO) may charge a premium due to their commitment to quality. However, this can enhance reliability and reduce the risk of defects.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer better quality and service but at a higher cost.

-

Incoterms: Understanding Incoterms is essential for international transactions as they define responsibilities for shipping, insurance, and tariffs. This knowledge can help buyers manage logistics costs effectively.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Flexibility in MOQ can lead to better terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership, not just the initial price. Consider factors such as durability, maintenance, and potential for reusability of dies.

-

International Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, regional tariffs, and import duties that can affect final costs. Establishing long-term relationships with suppliers can also provide better pricing stability.

-

Disclaimer for Indicative Prices: Prices can fluctuate based on market conditions, material availability, and geopolitical factors. It is advisable to obtain multiple quotes and conduct thorough market research before making purchasing decisions.

By comprehensively understanding these cost structures and price influencers, international B2B buyers can navigate the complexities of dies and stamping sourcing more effectively, ultimately leading to more strategic purchasing decisions.

Spotlight on Potential dies and stamping Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dies and stamping’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dies and stamping

Key Technical Properties in Dies and Stamping

Understanding the critical specifications of dies and stamping is essential for international B2B buyers. Here are some key technical properties that are vital for ensuring quality and efficiency in metal stamping projects:

-

Material Grade: The choice of material grade for dies directly influences their durability and performance. Common materials include tool steel and carbide, which offer high wear resistance and longevity. Selecting the right material ensures that the die can withstand the stresses of the stamping process, leading to consistent production quality over time.

-

Tolerance: Tolerance refers to the allowable deviation from a specified dimension in the manufacturing process. In metal stamping, tight tolerances (typically within ±0.005 inches) are crucial for ensuring that parts fit together correctly. Understanding tolerance requirements is essential for avoiding costly rework and ensuring product compatibility, especially in industries like automotive and aerospace.

-

Die Lifespan: This property indicates how long a die can be used before it requires replacement or significant maintenance. A longer die lifespan reduces downtime and increases overall productivity. B2B buyers should inquire about expected die lifespan to gauge long-term costs and maintenance schedules.

-

Finish Quality: The surface finish of stamped parts can impact both aesthetic and functional properties. Different finishes, such as mill finish or polished, may be required depending on the application. Buyers should specify finish requirements upfront to avoid delays and ensure that the final product meets industry standards.

-

Dimensional Stability: This property refers to how well a die maintains its shape and dimensions under operational stress. High dimensional stability is critical for maintaining the quality of parts, especially when producing high volumes. Buyers should assess the die design and materials used to ensure optimal stability during production.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms relevant to dies and stamping:

-

OEM (Original Equipment Manufacturer): An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers for quality components.

-

MOQ (Minimum Order Quantity): This term refers to the smallest number of units that a supplier is willing to produce or sell. Knowing the MOQ is crucial for budgeting and inventory planning, especially for smaller businesses that may not require large quantities.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. Providing detailed information in an RFQ can lead to more accurate quotes and better negotiations.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and costs associated with shipping and delivery.

-

Lead Time: This term refers to the amount of time it takes from placing an order until it is fulfilled. Understanding lead times is critical for planning production schedules and managing supply chain logistics effectively.

-

Stamping Tonnage: Stamping tonnage refers to the amount of force a stamping press can exert. It is essential to match the tonnage to the requirements of the specific stamping operation to ensure efficient and effective production.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, streamline procurement processes, and foster better relationships with suppliers in the dies and stamping industry.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dies and stamping Sector

Market Overview & Key Trends

The dies and stamping sector is witnessing significant transformation driven by technological advancements and shifting market demands. Global manufacturers are increasingly adopting Industry 4.0 technologies, including automation, IoT, and AI, to enhance production efficiency and precision. This trend is particularly pronounced in regions like Europe, where manufacturers are investing heavily in smart manufacturing systems to streamline operations and reduce costs.

Emerging sourcing trends reflect a growing preference for local suppliers to mitigate risks associated with global supply chains. For B2B buyers in Africa, South America, and the Middle East, establishing partnerships with local die manufacturers can lead to reduced lead times and transportation costs, while also fostering community engagement. Additionally, digital sourcing platforms are gaining traction, allowing buyers to connect with diverse suppliers and access a wider range of materials and technologies.

Another dynamic shaping the market is the increasing demand for customized stamping solutions. As industries evolve, companies are seeking dies that can produce complex parts with minimal waste. This necessitates close collaboration between buyers and manufacturers to ensure that tooling is designed to meet specific operational requirements. For international buyers, understanding these trends is crucial for making informed sourcing decisions that align with their strategic objectives.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a vital consideration in the dies and stamping sector, with environmental impacts prompting companies to rethink their sourcing strategies. The manufacturing process for dies and stamping can generate significant waste, making it essential for businesses to adopt practices that minimize their ecological footprint. Implementing recycling programs for scrap metal and utilizing energy-efficient machinery can significantly reduce emissions and waste.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers for compliance with ethical labor practices and environmental regulations. This scrutiny is particularly relevant in regions like Africa and South America, where supply chain transparency can be challenging. B2B buyers should prioritize suppliers who demonstrate a commitment to sustainability certifications, such as ISO 14001 or those using recycled materials in their dies and stamping processes.

Adopting green materials and processes not only enhances a company’s reputation but can also lead to cost savings in the long run. As consumers become more environmentally conscious, B2B buyers who prioritize sustainability in their sourcing decisions will likely gain a competitive advantage.

Brief Evolution/History

The dies and stamping industry has evolved significantly since its inception, transitioning from manual labor to highly automated processes. Early manufacturing relied on basic hand tools, but the introduction of mechanical presses in the 19th century revolutionized production capabilities, allowing for higher volumes and precision. Over the decades, advancements in CAD/CAM technology and computer-controlled machinery have further transformed the industry, enabling manufacturers to create intricate designs and complex geometries with ease.

Today, the focus is on integrating smart technologies into traditional stamping processes, aligning with global trends towards automation and sustainability. As the market continues to evolve, B2B buyers must stay informed about these developments to leverage the full potential of modern dies and stamping solutions.

Related Video: Exim Trade Conclave 2025 LIVE | Finance Minister Nirmala Sitharaman Delivers Keynote Address | N18L

Frequently Asked Questions (FAQs) for B2B Buyers of dies and stamping

-

What criteria should I use to vet suppliers for dies and stamping?

When vetting suppliers, prioritize their experience in die manufacturing and metal stamping. Look for certifications like ISO 9001, which indicates a commitment to quality management. Request samples of previous work to assess their precision and craftsmanship. Additionally, check for customer reviews and testimonials from similar industries, and inquire about their production capabilities and lead times to ensure they can meet your demands. -

Can dies and stamping processes be customized for specific projects?

Yes, customization is a standard aspect of the dies and stamping industry. Discuss your specific requirements with potential suppliers, including dimensions, materials, and design complexities. Many manufacturers utilize CAD/CAM technology to create precise dies tailored to your specifications. Ensure that the supplier has a strong design team capable of turning your ideas into practical tooling solutions that meet your operational needs. -

What are typical minimum order quantities (MOQs) and lead times for dies and stamping?

MOQs can vary significantly based on the complexity of the die and the stamping process. Generally, suppliers may require a minimum order of several hundred pieces for high-volume production runs. Lead times can range from a few weeks to several months, depending on the supplier’s workload, the complexity of the dies, and the materials used. Always confirm these details upfront to align your production schedule with supplier capabilities.

Illustrative Image (Source: Google Search)

-

What payment terms are common in international B2B transactions for dies and stamping?

Payment terms can vary, but most suppliers require a deposit (typically 30-50%) before starting production, with the balance due upon completion or shipment. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Discuss and agree on payment terms clearly before proceeding to avoid any disputes later in the process. -

How can I ensure quality assurance and certifications from my supplier?

Request documentation of quality assurance processes and relevant certifications from potential suppliers. ISO certifications, such as ISO 9001 and ISO 14001, indicate adherence to international quality standards. Additionally, ask about their inspection and testing protocols to ensure that the dies meet your specifications. Regular audits and third-party inspections can also provide added assurance of product quality. -

What logistics considerations should I keep in mind when sourcing dies and stamping internationally?

Logistics play a crucial role in international sourcing. Evaluate the supplier’s shipping capabilities, including their experience with customs clearance and handling international freight. Understand the associated costs, delivery timelines, and potential tariffs or duties that may apply. Establish clear communication regarding shipping terms (Incoterms) to prevent misunderstandings and ensure a smooth delivery process. -

How should I handle disputes with my supplier over dies and stamping orders?

Establish clear communication channels and a defined process for addressing disputes before they arise. Document all agreements, specifications, and communications related to the order. If a dispute occurs, first attempt to resolve it through direct negotiation. If that fails, consider mediation or arbitration as a next step, particularly if the supplier is located in another country. Always ensure that any dispute resolution mechanisms are included in the initial contract. -

What are the common challenges faced when sourcing dies and stamping internationally?

Common challenges include language barriers, cultural differences, and varying quality standards. Additionally, navigating international logistics and customs can complicate timelines and increase costs. To mitigate these risks, invest time in researching and establishing strong relationships with suppliers. Consider working with local agents or consultants who understand the regional market dynamics and can facilitate smoother transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dies and stamping

In summary, strategic sourcing in the dies and stamping sector is crucial for international B2B buyers seeking cost-effective and high-quality metal components. By understanding the various types of stamping dies—such as progressive, transfer, and compound dies—buyers can make informed decisions that align with their production needs. Prioritizing partnerships with specialized die manufacturers ensures access to expert guidance, robust tooling solutions, and optimized production processes.

Illustrative Image (Source: Google Search)

Key takeaways for B2B buyers include the importance of selecting suppliers with proven expertise in die manufacturing, the need for precise design and engineering, and the value of assessing tooling longevity and maintenance requirements. As industries in Africa, South America, the Middle East, and Europe continue to evolve, leveraging advanced stamping techniques will be essential for maintaining competitive advantage.

As you navigate the complexities of sourcing dies and stamping solutions, consider adopting a proactive approach to supplier engagement. Embrace the opportunities presented by innovative manufacturing technologies and tailored solutions to enhance your operational efficiency. The future of metal stamping is bright, and the right strategic partnerships can propel your business forward. Start exploring your options today to harness the full potential of this dynamic industry.