Master Sourcing High-Quality Coil of Wire for Your Business

Introduction: Navigating the Global Market for coil of wire

In today’s globalized economy, coil of wire is a vital component that underpins numerous industries, from electrical engineering to renewable energy and electronics manufacturing. Its applications span across producing transformers, motors, inductors, and electromagnets, making it indispensable for both infrastructure and technological advancements. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the intricacies of sourcing high-quality wire is crucial for maintaining a competitive edge and ensuring product reliability.

This guide offers a comprehensive overview of the coil of wire market, addressing key topics such as various wire types—including bare, tinned, and insulated options—material specifications, manufacturing processes, and quality control standards. It also delves into supplier landscapes and provides actionable insights on cost evaluation, navigating import/export regulations, and understanding technical standards.

By equipping buyers with essential knowledge and strategic approaches, this resource empowers you to make informed sourcing decisions. Whether you are looking to establish new supplier relationships or optimize existing supply chains, this guide serves as a valuable tool to identify reliable partners, comprehend market dynamics, and leverage technical expertise. Embrace the opportunity to enhance your procurement strategies and drive growth in a competitive global marketplace.

Understanding coil of wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Enamelled (Magnet Wire) | Insulated with a thin enamel coating, highly flexible | Transformers, motors, inductors | Pros: Excellent insulation; Cons: Higher cost, requires careful handling |

| Bare Copper Wire | No insulation, high electrical conductivity | Power cables, busbars, grounding systems | Pros: Cost-effective, high conductivity; Cons: Risk of short circuits |

| Tinned Copper Wire | Copper wire coated with tin, corrosion-resistant | Marine, outdoor, high-humidity environments | Pros: Enhanced corrosion resistance; Cons: Slightly higher cost |

| Silver-Plated Copper Wire | Copper core with a thin layer of silver | High-frequency transformers, RF applications | Pros: Superior conductivity; Cons: Significantly more expensive |

| High-Temperature Copper Wire | Specially alloyed or coated for elevated temperature resistance | Aerospace, high-temperature electronics | Pros: Maintains performance under thermal stress; Cons: Costlier |

Enamelled (Magnet) Copper Wire

Enamelled copper wire, commonly known as magnet wire, features a thin insulation layer that allows for efficient winding in compact electromagnetic devices. This wire type is particularly suitable for applications in transformers and motors, where space is a premium. B2B buyers should focus on suppliers who guarantee consistent insulation quality and compliance with electrical standards, as these factors directly impact device reliability. While the initial cost may be higher due to insulation processes, the long-term benefits of reduced maintenance and increased efficiency often justify the investment.

Bare Copper Wire

Bare copper wire is uninsulated, providing excellent electrical conductivity and making it a preferred choice for applications where insulation is either unnecessary or provided separately. This wire type is widely used in power distribution and grounding systems. For B2B buyers, sourcing high-purity copper is essential to ensure compliance with international standards. The cost-effectiveness of bare copper wire makes it attractive for large-scale projects, but buyers must also consider the risks associated with short circuits, necessitating careful planning in electrical installations.

Tinned Copper Wire

Tinned copper wire is coated with a thin layer of tin, enhancing its corrosion resistance, which is crucial for outdoor and marine applications. This wire type retains high conductivity while being easy to solder, making it ideal for environments with high humidity. Buyers should evaluate the quality of tin plating to ensure it meets their specific manufacturing needs. While the cost is slightly higher than bare copper, the durability and ease of assembly provided by tinned wire can lead to long-term savings, especially in challenging conditions.

Silver-Plated Copper Wire

Silver-plated copper wire combines a copper core with a thin layer of silver, resulting in superior conductivity and minimal signal loss. This wire type is particularly suited for high-frequency transformers and RF applications, where performance is critical. B2B buyers should be aware of the significantly higher costs associated with silver-plated wire and assess whether the performance benefits align with their budget constraints. Sourcing from suppliers who maintain strict quality controls on plating thickness is crucial to ensure reliable performance in sensitive applications.

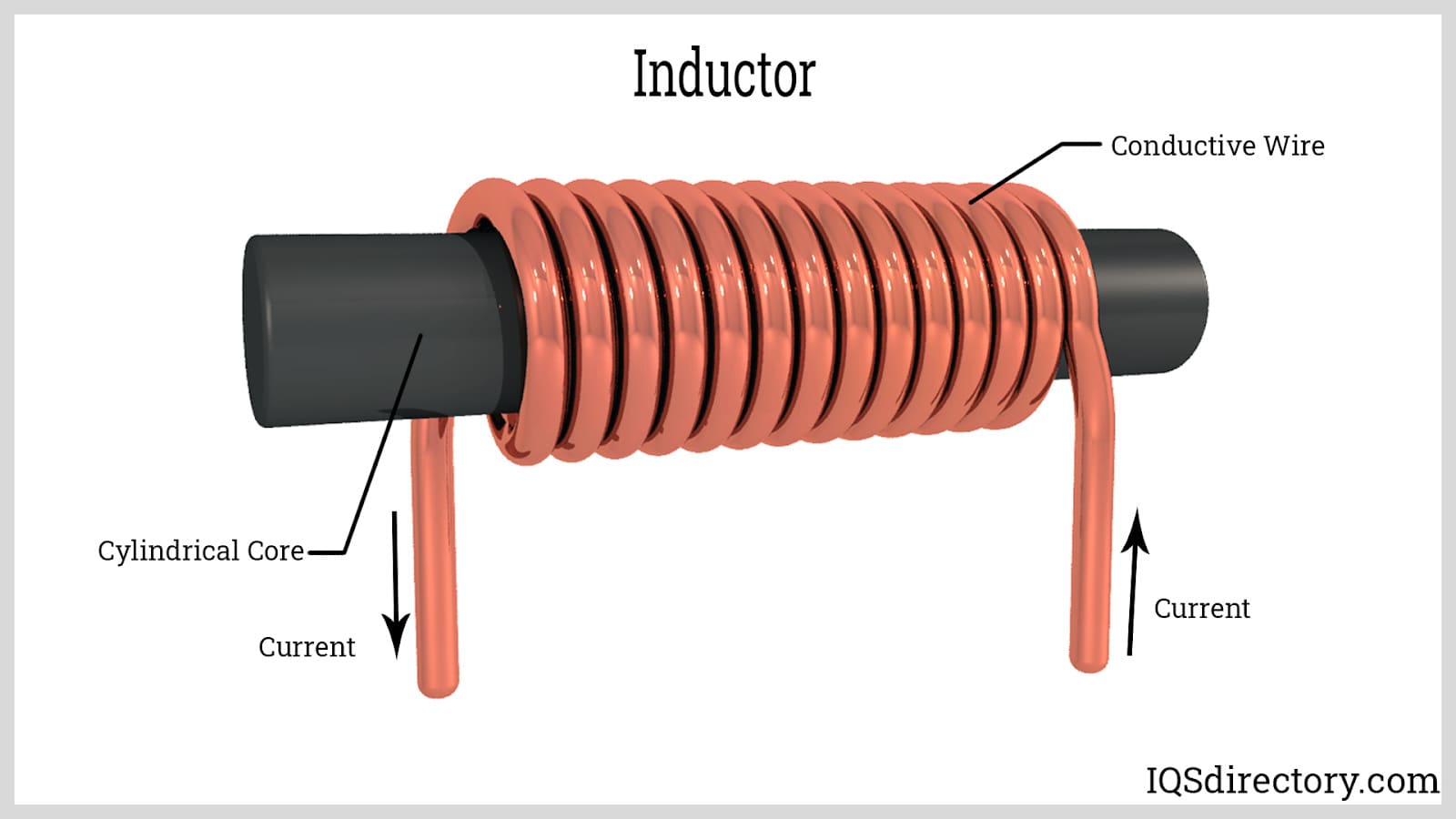

Illustrative Image (Source: Google Search)

High-Temperature Copper Wire

High-temperature copper wire is engineered to withstand elevated temperatures, making it suitable for aerospace and high-temperature electronics applications. This wire type often utilizes specialized alloys or coatings to maintain performance under thermal stress. For B2B buyers, understanding the specific temperature ratings and compliance with industry standards is vital when sourcing this wire type. While the higher costs and specialized handling requirements may be a consideration, the reliability and performance in demanding environments can significantly enhance product longevity and safety.

Key Industrial Applications of coil of wire

| Industry/Sector | Specific Application of coil of wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Engineering | Transformers and Inductors | Enhances power efficiency and reliability in electrical systems | Ensure compliance with international standards and certifications |

| Renewable Energy | Wind Turbine Generators | Supports sustainable energy production and reduces costs | Look for high-quality, corrosion-resistant wire for outdoor applications |

| Electronics Manufacturing | Electromagnetic Devices | Enables the production of compact and efficient devices | Prioritize suppliers with consistent quality and technical specifications |

| Automotive Industry | Electric Motors and Coil Windings | Improves vehicle efficiency and performance | Source from suppliers with expertise in high-temperature applications |

| Aerospace | High-Temperature Coils | Ensures safety and reliability in critical applications | Verify material specifications and certifications for extreme conditions |

Electrical Engineering

In the electrical engineering sector, coil of wire is essential for the construction of transformers and inductors, which are crucial for efficient power distribution. These components rely on high-quality winding to minimize energy losses and enhance performance. International buyers, particularly from regions like Africa and the Middle East, should focus on sourcing wire that meets international standards, ensuring reliability in power systems. Additionally, understanding the wire’s conductivity, gauge, and insulation properties is critical for optimizing transformer design.

Renewable Energy

Coil of wire plays a pivotal role in renewable energy applications, particularly in wind turbine generators. These generators utilize coil windings to convert mechanical energy into electrical energy, thus supporting sustainable energy production. B2B buyers from South America and Europe should seek suppliers that provide high-quality, corrosion-resistant wire to withstand harsh environmental conditions. Ensuring compliance with environmental regulations and selecting suppliers with a robust supply chain can significantly enhance project viability and cost-effectiveness.

Electronics Manufacturing

In electronics manufacturing, coil of wire is fundamental for creating electromagnetic devices, including inductors and transformers. These components are essential for a wide range of applications, from consumer electronics to industrial machinery. Buyers should prioritize sourcing from suppliers who can guarantee consistent quality and adherence to technical specifications. This is especially important for international buyers in Europe and Africa, as they navigate varying standards and regulations that can impact product reliability.

Automotive Industry

The automotive industry increasingly relies on coil of wire for electric motors and coil windings, which are vital for vehicle efficiency and performance. As electric and hybrid vehicles become more prevalent, the demand for high-quality coil wire has surged. Buyers should focus on suppliers with expertise in high-temperature applications, as automotive environments can be demanding. Ensuring that the wire meets specific automotive standards will enhance safety and performance, providing a competitive edge in the market.

Aerospace

In aerospace applications, high-temperature coils are critical for ensuring safety and reliability in various systems, including engines and avionics. The coil of wire used in this sector must withstand extreme conditions and maintain performance under thermal stress. International buyers from regions like the Middle East should verify the material specifications and certifications of their suppliers to ensure compliance with aerospace standards. This diligence not only mitigates risks but also supports the long-term viability of aerospace projects.

Related Video: How a Tesla Coil Works ⚡ How to Make a Tesla Coil ⚡ Nikola Tesla

Strategic Material Selection Guide for coil of wire

When selecting materials for coil wire, understanding the properties, advantages, and limitations of various options is crucial for B2B buyers, particularly those operating in diverse environments like Africa, South America, the Middle East, and Europe. Here’s an analysis of four common materials used in coil wire manufacturing: copper, aluminum, stainless steel, and silver-plated copper.

Copper

Key Properties:

Copper is renowned for its exceptional electrical conductivity, thermal conductivity, and ductility. It can withstand temperatures up to 200°C and has a high resistance to corrosion, especially when coated or alloyed.

Pros & Cons:

The primary advantage of copper wire is its superior conductivity, making it ideal for applications requiring efficient power transmission. However, it is relatively expensive compared to alternatives like aluminum. Additionally, copper wire can be prone to oxidation if not properly insulated, which may affect performance over time.

Impact on Application:

Copper is widely used in transformers, motors, and inductors due to its reliability and efficiency. Its compatibility with various media makes it suitable for both indoor and outdoor applications.

Considerations for International Buyers:

B2B buyers must ensure compliance with international standards such as ASTM B3 and IEC 60228. In regions like Africa and South America, where environmental conditions can be harsh, selecting high-quality copper with appropriate insulation is critical.

Aluminum

Key Properties:

Aluminum wire is lightweight, has good electrical conductivity (approximately 60% that of copper), and offers excellent corrosion resistance. It can operate effectively at temperatures up to 150°C.

Pros & Cons:

Aluminum is significantly cheaper than copper, making it a cost-effective option for large-scale projects. However, its lower conductivity means that larger diameters are required to achieve the same performance as copper. Additionally, aluminum can be more brittle and less ductile, which may complicate manufacturing processes.

Impact on Application:

Aluminum is often used in overhead power lines and applications where weight is a concern. Its resistance to corrosion makes it suitable for outdoor installations.

Considerations for International Buyers:

Buyers should be aware of the need for specialized connectors and fittings when using aluminum wire. Compliance with standards such as ASTM B800 is essential, especially in regions with specific regulatory requirements.

Stainless Steel

Key Properties:

Stainless steel wire is known for its high tensile strength, corrosion resistance, and ability to withstand high temperatures (up to 800°C). It is less conductive than copper and aluminum, making it suitable for specific applications.

Pros & Cons:

The durability and corrosion resistance of stainless steel make it an excellent choice for harsh environments. However, its lower conductivity limits its use in electrical applications, and it is generally more expensive than copper and aluminum.

Impact on Application:

Stainless steel is ideal for applications in the aerospace and automotive industries, where strength and resistance to extreme conditions are paramount.

Considerations for International Buyers:

Buyers must consider the specific grade of stainless steel (e.g., 304, 316) for their applications and ensure compliance with relevant standards such as ASTM A313. Understanding the local market for stainless steel can also help in sourcing competitively.

Silver-Plated Copper

Key Properties:

Silver-plated copper wire combines the high conductivity of copper with the superior conductivity and corrosion resistance of silver. It can operate effectively at high frequencies and temperatures.

Pros & Cons:

The primary advantage is its excellent electrical performance, making it ideal for high-frequency applications. However, the cost is significantly higher than both copper and aluminum, which may limit its use in budget-sensitive projects.

Impact on Application:

This material is often used in RF applications, high-frequency transformers, and sensitive electronic devices due to its low signal loss.

Considerations for International Buyers:

Buyers should ensure that the silver plating is consistent and meets standards such as ASTM B298. The higher cost may necessitate careful evaluation of the application to justify the investment.

Summary Table

| Material | Typical Use Case for coil of wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Transformers, motors, inductors | Superior electrical conductivity | Higher cost, prone to oxidation | High |

| Aluminum | Overhead power lines, outdoor wiring | Cost-effective, lightweight | Lower conductivity, brittleness | Medium |

| Stainless Steel | Aerospace, automotive applications | High strength, excellent corrosion resistance | Lower conductivity, higher cost | High |

| Silver-Plated Copper | RF applications, high-frequency devices | Excellent electrical performance | Significantly more expensive | High |

By carefully evaluating these materials and their properties, B2B buyers can make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for coil of wire

The manufacturing processes and quality assurance protocols for coil wire are critical for B2B buyers seeking reliable and high-performance products. Understanding these processes can help buyers make informed decisions when sourcing wire from various international suppliers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Manufacturing Processes

The production of coil wire involves several key stages, each with specific techniques and considerations. Below are the main stages of manufacturing coil wire:

1. Material Preparation

The first step in coil wire production is sourcing high-quality raw materials. The choice of materials, such as copper or aluminum, significantly impacts the wire’s conductivity, flexibility, and overall performance. Buyers should ensure that suppliers utilize high-purity metals that comply with international standards.

- Key Techniques:

- Copper Refining: Ensuring the copper is free from impurities through electrolysis or other refining methods.

- Alloying: For specialized wires, alloys may be created to enhance specific properties like thermal resistance or corrosion resistance.

2. Forming

Once the raw materials are prepared, they undergo various forming processes to create the desired wire shape and gauge.

- Key Techniques:

- Drawing: This process reduces the diameter of the wire by pulling it through a series of dies. It increases tensile strength and ensures uniformity in gauge.

- Stranding: For stranded wire, multiple strands are twisted together to enhance flexibility and reduce breakage risk.

3. Assembly

In this stage, additional features such as insulation or coatings are applied. This step is crucial for applications requiring electrical insulation or enhanced corrosion resistance.

- Key Techniques:

- Insulation Application: Techniques like enameling or extrusion are used to apply insulation, depending on the wire type (e.g., enamelled vs. insulated wire).

- Coating: For tinned or silver-plated wires, a thin layer of tin or silver is applied to enhance conductivity and prevent oxidation.

4. Finishing

The final stage involves cutting the wire to specified lengths, spooling it appropriately, and preparing it for shipment. This stage also includes quality checks to ensure that the wire meets all specifications.

- Key Techniques:

- Cutting: Precision cutting machines ensure that wire lengths are accurate.

- Spooling: Proper spooling techniques prevent tangling and damage during transport.

Quality Assurance

Quality assurance is a critical component of the manufacturing process for coil wire. Implementing rigorous quality control measures ensures that the wire meets industry standards and customer requirements.

Relevant International Standards

B2B buyers should be familiar with various international standards that govern the quality of coil wire:

- ISO 9001: This standard outlines criteria for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for wire used in the oil and gas industry, API standards ensure safety and performance.

Quality Control Checkpoints

Quality control should occur at multiple stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial inspection checks raw materials for quality and conformity to specifications.

- In-Process Quality Control (IPQC): Ongoing checks during production monitor parameters like wire gauge, conductivity, and insulation quality.

- Final Quality Control (FQC): The final inspection assesses the finished product, ensuring it meets all specifications before shipping.

Common Testing Methods

B2B buyers should be aware of the various testing methods used to verify quality:

- Electrical Testing: Tests like resistance measurement and insulation resistance testing assess electrical performance.

- Mechanical Testing: Tensile strength tests evaluate the wire’s durability under stress.

- Environmental Testing: Tests for corrosion resistance and high-temperature performance ensure suitability for specific applications.

Verifying Supplier Quality Control

For international buyers, ensuring supplier quality is paramount. Here are actionable strategies to verify supplier QC:

- Supplier Audits: Conduct on-site audits to assess manufacturing processes, quality control measures, and compliance with international standards.

- Quality Reports: Request detailed quality reports that outline inspection results and testing methods used during production.

- Third-Party Inspections: Engage third-party inspection services to validate quality claims and ensure impartial assessments of the manufacturing process.

Quality Control and Certification Nuances for International Buyers

When sourcing coil wire from international suppliers, particularly in emerging markets in Africa and South America, buyers should be aware of specific nuances:

- Regulatory Compliance: Ensure that suppliers understand and comply with local regulations and international standards, which may vary significantly across regions.

- Cultural Differences: Be mindful of cultural differences that may affect communication and quality expectations. Establish clear specifications and maintain open lines of communication.

- Supply Chain Considerations: Evaluate the entire supply chain, including logistics and delivery timelines, to mitigate risks associated with international shipping and customs.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for coil wire is essential for B2B buyers. By focusing on material quality, manufacturing techniques, and rigorous quality control measures, buyers can secure reliable suppliers and ensure that their products meet the highest standards of performance and safety.

Related Video: Do You Know How Cable Made? Factory Wire Cable Manufacturing Process is Amazing

Comprehensive Cost and Pricing Analysis for coil of wire Sourcing

The cost structure for sourcing coil of wire is multifaceted, encompassing several key components that directly influence the pricing. Understanding these components is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver is the raw materials used in wire production. For copper wire, fluctuations in copper prices significantly impact overall costs. Buyers should monitor commodity markets and consider sourcing from suppliers that offer stable pricing agreements to mitigate volatility.

-

Labor: Labor costs vary widely based on geographic location and the complexity of manufacturing processes. Countries with lower labor costs may provide competitive pricing, but quality assurance and manufacturing standards should not be compromised.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce these costs, making it essential for buyers to evaluate suppliers’ operational efficiencies.

-

Tooling: The cost of specialized machinery and tools required for wire production can be significant, especially for custom specifications. Buyers should inquire about tooling costs and consider how they are factored into the overall pricing.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to the cost but is vital for maintaining reliability. Buyers should seek suppliers with established QC standards and certifications, as this can justify higher prices due to the assurance of quality.

-

Logistics: Transportation and shipping costs can vary significantly based on distance, mode of transport, and local tariffs. Buyers should consider Incoterms (International Commercial Terms) that clearly define responsibilities for shipping costs and risks, which can impact overall pricing.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can fluctuate based on market demand, competition, and supplier relationships.

Price Influencers

Several factors influence the final pricing of coil wire:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower unit prices due to economies of scale. Buyers should negotiate for favorable terms based on their purchasing capacity.

-

Specifications/Customization: Custom specifications can increase costs due to additional processing and materials. Buyers should clearly define their needs upfront to avoid unexpected costs later in the process.

-

Materials and Quality Certifications: Higher quality materials or specific certifications (e.g., ISO, RoHS) can raise costs. Buyers must balance the need for quality against budget constraints.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can affect pricing. Long-term partnerships with trustworthy suppliers often yield better pricing arrangements.

Buyer Tips

To navigate the complexities of coil wire sourcing effectively, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger orders or long-term contracts. Transparency about your purchasing intentions can lead to better deals.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. This includes considering maintenance costs, potential downtime, and the reliability of the wire in your applications.

-

Pricing Nuances for International Buyers: Be aware of additional costs such as tariffs, taxes, and customs duties that may apply when importing wire into your country. It is advisable to work with logistics providers familiar with these regulations.

-

Local Market Conditions: Understand the economic conditions and market dynamics in your region. For example, fluctuations in currency exchange rates can affect pricing for international purchases.

Disclaimer

Prices can vary widely based on market conditions and specific supplier agreements. The information provided serves as a general guide, and buyers are encouraged to conduct thorough market research and supplier evaluations to obtain accurate and up-to-date pricing information.

Spotlight on Potential coil of wire Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘coil of wire’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for coil of wire

Key Technical Properties of Coil Wire

Understanding the essential technical properties of coil wire is crucial for B2B buyers to ensure they procure the right materials for their applications. Here are several critical specifications to consider:

-

Material Grade

– Definition: The quality and type of material used, such as copper, aluminum, or specialized alloys.

– Importance: Material grade directly affects electrical conductivity, thermal resistance, and overall performance in applications like motors and transformers. Buyers should prioritize high-grade materials to enhance product reliability and efficiency. -

Wire Gauge (AWG)

– Definition: The American Wire Gauge (AWG) system measures the diameter of the wire. A lower number indicates a thicker wire.

– Importance: The wire gauge influences current-carrying capacity and flexibility. Buyers must select the appropriate gauge for their specific application to prevent overheating and ensure optimal performance. -

Insulation Type

– Definition: The material used to coat the wire, such as enamel, PVC, or nylon.

– Importance: Different insulation types offer varying levels of thermal resistance, flexibility, and chemical resistance. Buyers should match insulation properties to environmental conditions and application requirements to ensure longevity and safety. -

Tolerance

– Definition: The permissible limit of variation in wire dimensions, including diameter and resistance.

– Importance: Tolerance affects the compatibility of wire in assemblies and its electrical performance. Tight tolerances are essential for precision applications, while looser tolerances may suffice for more general uses. -

Current Rating

– Definition: The maximum amount of electrical current the wire can safely carry.

– Importance: Exceeding the current rating can lead to overheating and failure. Buyers need to ensure that the selected wire can handle the expected load in their applications to avoid costly downtime or damage. -

Thermal Rating

– Definition: The maximum temperature the wire can withstand during operation.

– Importance: Thermal ratings are crucial for applications in high-temperature environments, such as automotive or aerospace industries. Understanding thermal limits helps buyers choose wires that will not degrade under operational stress.

Illustrative Image (Source: Google Search)

Common Trade Terminology

Familiarity with industry jargon can enhance communication and negotiation processes. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Usage: B2B buyers should identify OEMs when sourcing components to ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Usage: Understanding MOQ is vital for budget planning and inventory management. Buyers should negotiate MOQs to align with their purchasing needs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Usage: Utilizing RFQs allows buyers to compare offers effectively and make informed sourcing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC).

– Usage: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, facilitating smoother international transactions. -

Lead Time

– Definition: The amount of time between placing an order and receiving the product.

– Usage: Buyers must account for lead times in project planning to avoid delays. Clear communication with suppliers regarding lead times can enhance supply chain efficiency. -

Certification Standards

– Definition: Industry-specific quality and safety standards that products must meet, such as ISO or ASTM.

– Usage: Buyers should verify that their suppliers adhere to relevant certification standards to ensure product quality and compliance with regulatory requirements.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ultimately improving their sourcing strategies and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the coil of wire Sector

In the coil of wire sector, international B2B buyers are navigating a complex landscape shaped by various market dynamics and technological advancements. The growing demand for electric vehicles, renewable energy sources, and advanced electronics is driving the need for high-quality coil winding copper wire. Buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly prioritizing the sourcing of specialized wire types, including enamelled and tinned copper wire, to meet industry-specific requirements.

Key Trends in B2B Sourcing

-

Digital Transformation: The adoption of Industry 4.0 technologies is revolutionizing the coil of wire manufacturing process. Automation and IoT integration are enhancing production efficiency, allowing suppliers to offer more competitive pricing and faster turnaround times.

-

Supply Chain Resilience: Recent global disruptions have highlighted the importance of resilient supply chains. B2B buyers are now seeking suppliers that can demonstrate flexibility and reliability in their sourcing strategies, particularly in regions with fluctuating political or economic conditions.

-

Quality Assurance: Buyers are increasingly focused on sourcing wire that meets stringent international standards. This includes certifications for electrical conductivity, insulation integrity, and environmental compliance, ensuring that their products remain competitive in the global market.

-

Customization: As industries evolve, so do their needs. Suppliers that offer customizable wire solutions tailored to specific applications are gaining a competitive edge, making it essential for buyers to engage in detailed discussions about their requirements.

Sustainability & Ethical Sourcing in B2B

The coil of wire sector is under increasing scrutiny regarding its environmental impact. B2B buyers must prioritize sustainability in their sourcing decisions, seeking suppliers committed to reducing their carbon footprint and employing ethical practices. This includes:

-

Sourcing Recycled Materials: Utilizing recycled copper and other materials can significantly lower the environmental impact of production. Buyers should inquire about suppliers’ use of recycled content in their wire offerings.

-

Green Certifications: Certifications such as ISO 14001 for environmental management and other “green” labels provide assurance that suppliers adhere to sustainable practices. Buyers should favor suppliers with these certifications to enhance their own sustainability credentials.

-

Transparent Supply Chains: Ethical sourcing involves not only environmental considerations but also the social implications of supply chains. Buyers should evaluate suppliers based on their labor practices and commitment to fair trade, ensuring that their sourcing aligns with their corporate social responsibility goals.

Evolution of the Coil of Wire Sector

The coil of wire sector has evolved significantly over the decades, driven by technological advancements and the increasing complexity of applications. Initially dominated by basic copper wire, the market has expanded to include a variety of specialized wire types, such as enamelled and high-temperature wires. Innovations in manufacturing processes and materials have enabled the production of wires that cater to specific industry needs, such as those found in renewable energy, automotive, and electronics sectors. This evolution highlights the importance of staying informed about market trends and technological developments for B2B buyers seeking to maintain a competitive edge.

By understanding these dynamics, B2B buyers can make informed decisions that align with their strategic goals, ultimately enhancing their operational efficiency and market positioning.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of coil of wire

-

What criteria should I use to vet suppliers of coil wire?

When vetting suppliers, focus on their industry experience, reputation, and compliance with international quality standards. Request references from previous clients and investigate their manufacturing capabilities, including certifications such as ISO 9001 or specific electrical standards relevant to your industry. Additionally, assess their financial stability and capacity to meet your volume demands. For international buyers, understanding local regulations and trade practices in the supplier’s country is also crucial. -

Can I customize my coil wire orders?

Yes, many suppliers offer customization options for coil wire orders. You can specify the wire type, gauge, insulation material, and length based on your application requirements. Ensure you communicate your needs clearly and confirm the supplier’s ability to meet these specifications. Discussing potential impacts on pricing and lead times for customized orders is essential, as these factors can vary significantly compared to standard products. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary by supplier and product type, typically ranging from a few hundred meters to several kilometers, depending on the wire specifications and the supplier’s production capabilities. Lead times also differ based on order size and complexity but generally range from a few weeks to several months. Always confirm these details upfront to avoid supply chain disruptions, especially when planning for large projects. -

What quality assurance measures and certifications should I look for?

Seek suppliers that adhere to international quality standards, such as ISO certifications, which indicate a commitment to quality management practices. Request documentation proving compliance with relevant electrical and safety standards (e.g., UL, CE) for your specific market. Additionally, inquire about their quality control processes, including testing protocols for conductivity, insulation integrity, and mechanical properties, ensuring that the products meet your performance requirements. -

How can I ensure smooth logistics and shipping processes?

To ensure efficient logistics, collaborate with suppliers that have established shipping processes and partnerships with reliable freight forwarders. Discuss shipping methods, costs, and potential delays, especially for international shipments. Be aware of import/export regulations in your country and ensure that all necessary documentation (such as customs declarations and invoices) is accurately prepared. Consider using Incoterms to clarify responsibilities for shipping and delivery between you and the supplier. -

What should I do if there is a dispute with my supplier?

In the event of a dispute, start by reviewing the terms of your contract and any agreed-upon dispute resolution processes. Communicate openly with the supplier to address the issue and seek an amicable resolution. If necessary, involve a third-party mediator to facilitate discussions. Ensure that you document all communications and agreements during this process, as this information may be vital if legal action becomes necessary. -

Are there specific payment terms I should negotiate?

Payment terms can significantly affect cash flow and risk management. Common options include advance payment, letters of credit, or payment upon delivery. Negotiate terms that align with your financial capabilities and risk tolerance. For international transactions, consider using secure payment methods that offer buyer protection. Ensure that payment terms are clearly defined in your contract to avoid misunderstandings later. -

How can I assess the supplier’s capacity for ongoing supply?

Evaluate a supplier’s capacity by examining their production capabilities, workforce size, and historical performance in fulfilling large orders. Request information about their inventory management practices and their ability to scale production based on your future needs. Regular communication regarding your requirements and any potential market changes will help establish a reliable partnership, ensuring they can consistently meet your supply demands as your business grows.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for coil of wire

In summary, strategic sourcing of coil winding copper wire is pivotal for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Understanding the various wire types—such as enamelled, bare, tinned, silver-plated, and high-temperature copper wire—equips buyers to select the right product for their specific applications. Key takeaways include the importance of assessing supplier reliability, ensuring compliance with international quality standards, and evaluating cost implications in the context of total ownership.

As global supply chains continue to evolve, leveraging local suppliers while exploring international partnerships can enhance resilience and cost efficiency. It is vital for buyers to stay informed about market trends, technological advancements, and regulatory changes that could impact sourcing strategies.

Moving forward, prioritize building robust relationships with suppliers who not only meet your technical specifications but also understand your market dynamics. By adopting a proactive approach to sourcing, you can ensure that your business remains competitive and well-positioned for growth in the ever-changing global landscape. Embrace the opportunities ahead, and take decisive action to optimize your sourcing strategies for coil winding copper wire.