Master Sourcing High-Quality EDM Machine Parts for Global

Introduction: Navigating the Global Market for edm machine parts

Navigating the global market for EDM (Electrical Discharge Machining) machine parts is essential for B2B buyers looking to enhance precision manufacturing capabilities. As industries across Africa, South America, the Middle East, and Europe increasingly adopt advanced machining technologies, the demand for high-quality EDM machine parts continues to rise. This guide serves as a comprehensive resource, equipping international buyers with the knowledge they need to make informed sourcing decisions.

EDM machine parts are critical components in achieving intricate geometries and superior surface finishes, especially when working with hard materials like titanium and tungsten. The guide covers an extensive range of topics, including types of EDM machines and their respective parts, materials used in manufacturing, quality control measures, and potential suppliers. It also delves into cost considerations and current market trends, providing valuable insights for strategic procurement.

By understanding the complexities of the EDM landscape, buyers can identify reliable suppliers, negotiate better pricing, and ensure the quality of their machine parts. Whether you are based in Poland, South Africa, or elsewhere, this guide empowers you to navigate the global market with confidence, ensuring that your operations remain competitive in an ever-evolving manufacturing environment. With actionable insights and expert analysis, you can optimize your sourcing strategy and drive innovation within your organization.

Understanding edm machine parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sinker EDM | Uses a shaped electrode to create complex geometries | Aerospace, Medical Devices, Tool Making | Pros: High precision, ideal for intricate shapes. Cons: Slower machining speed compared to Wire EDM. |

| Wire EDM | Employs a thin wire as the electrode, ideal for cutting | Automotive, Aerospace, Electronics | Pros: High accuracy, excellent for fine details. Cons: Limited to electrically conductive materials. |

| Die-Sinking EDM | Specialized for creating dies and molds | Mold Making, Aerospace, Automotive | Pros: Produces high-quality molds, complex designs. Cons: Requires significant setup time. |

| Fast Hole EDM | Designed for drilling precise holes in hard materials | Aerospace, Oil & Gas, Medical Devices | Pros: Capable of creating small, deep holes. Cons: Limited to specific applications. |

| Micro EDM | Focused on very small parts and intricate details | Medical Devices, Electronics, Aerospace | Pros: Exceptional precision for miniature components. Cons: Higher cost per part due to specialized processes. |

Sinker EDM

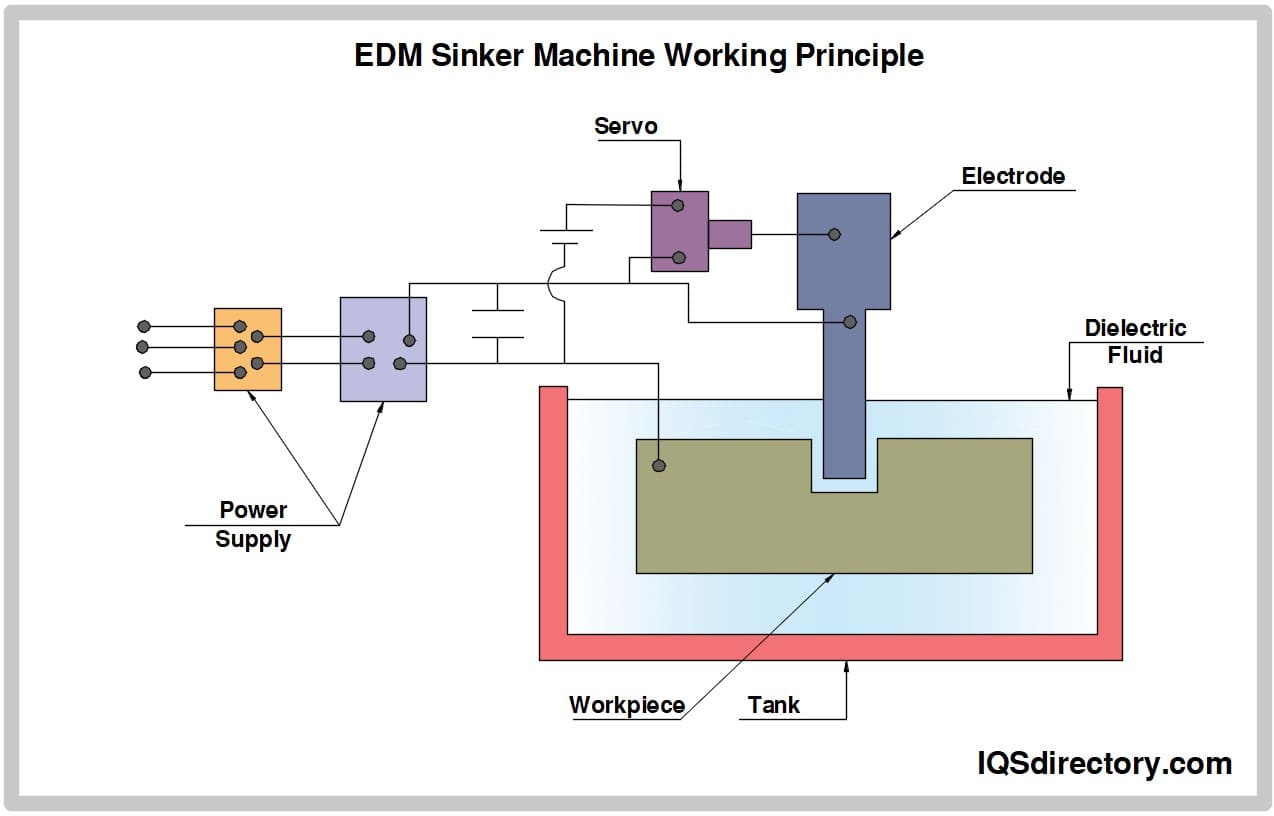

Sinker EDM, also known as cavity or plunge EDM, utilizes a shaped electrode to create intricate geometries. This type is particularly suitable for applications requiring complex designs, such as aerospace components and medical devices. B2B buyers should consider the electrode material and the required precision level, as these factors impact both performance and cost. Although sinker EDM offers high precision, it operates at a slower speed compared to Wire EDM, which may affect production timelines.

Wire EDM

Wire EDM employs a thin wire as the electrode, making it an excellent choice for cutting intricate shapes and fine details. This method is widely used in industries like automotive and electronics, where precision is critical. Buyers should evaluate the wire material and diameter, as these influence the machining capabilities. While Wire EDM provides exceptional accuracy, its limitation to electrically conductive materials may restrict its application in some sectors.

Die-Sinking EDM

Die-sinking EDM is specifically designed for creating dies and molds, making it invaluable in mold-making industries. This type excels in producing high-quality molds with complex designs, suitable for aerospace and automotive applications. B2B buyers must consider the setup time and the tooling costs associated with die-sinking EDM, as these can impact project timelines and budgets. While it offers superior quality, the initial investment and time required for setup can be significant.

Fast Hole EDM

Fast Hole EDM is specialized for drilling precise holes in hard materials, making it essential in sectors like aerospace and oil & gas. This method allows for the creation of small, deep holes that are often required in complex assemblies. Buyers should assess the machine’s capability to handle the specific material and hole size requirements. Although Fast Hole EDM provides unmatched precision, its application is often limited to specific industries, which may not suit all B2B buyers.

Micro EDM

Micro EDM focuses on manufacturing very small parts and intricate details, making it ideal for applications in medical devices and electronics. This type of EDM is characterized by its exceptional precision, allowing for the creation of miniature components that require high accuracy. Buyers should consider the cost per part, as Micro EDM processes can be more expensive due to their specialized nature. While it offers unparalleled precision, the higher costs may be a barrier for some businesses, particularly in price-sensitive markets.

Related Video: Electrical Discharge Machining wire EDM working principle, animation and application

Key Industrial Applications of edm machine parts

| Industry/Sector | Specific Application of EDM Machine Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of turbine blades and complex engine components | High precision and ability to machine hard materials like titanium | Ensure suppliers provide certified quality standards and delivery timelines |

| Automotive | Production of molds for injection molding | Enhanced design flexibility and reduced lead times | Focus on suppliers with expertise in automotive standards and certifications |

| Medical Devices | Creation of intricate surgical instruments and implants | Precision and reliability in critical medical applications | Verify compliance with health regulations and material specifications |

| Tool and Die Making | Fabrication of complex tooling and dies | Improved accuracy and reduced production waste | Seek out suppliers that offer custom solutions and rapid prototyping |

| Electronics | Manufacturing of micro-electronic components | Ability to produce fine details and tight tolerances | Look for suppliers with advanced technology and experience in electronics |

Aerospace Applications

In the aerospace sector, EDM machine parts are essential for manufacturing turbine blades and complex engine components. These parts require high precision due to the extreme conditions they operate under. EDM allows for the machining of hard materials like titanium, which are critical for aircraft performance. International buyers should prioritize suppliers who can demonstrate compliance with aerospace quality standards, as well as those who can meet stringent delivery schedules to support production timelines.

Automotive Applications

EDM is widely used in the automotive industry for producing molds for injection molding processes. This application benefits from EDM’s ability to create intricate designs and reduce lead times, which is crucial in the fast-paced automotive market. Buyers must consider suppliers that have a proven track record in automotive standards and can provide customized solutions to meet specific design requirements. Additionally, understanding the supplier’s capacity for scalability is important for accommodating fluctuating production demands.

Medical Device Applications

In the medical device industry, EDM machine parts are utilized for creating intricate surgical instruments and implants. The precision achieved through EDM is vital for ensuring the reliability and safety of medical devices. International buyers, particularly from regions with strict health regulations, should ensure that suppliers adhere to medical-grade material specifications and quality certifications. Collaborating with suppliers who have experience in the medical field can help mitigate risks associated with compliance.

Tool and Die Making Applications

EDM plays a significant role in the fabrication of complex tooling and dies used in various manufacturing processes. The ability to achieve improved accuracy with minimal waste makes EDM an attractive option for toolmakers. B2B buyers should seek suppliers that offer custom tooling solutions and rapid prototyping capabilities to facilitate quicker turnaround times. It’s also beneficial to evaluate the supplier’s technological capabilities to ensure they can meet advanced tooling requirements.

Electronics Applications

In the electronics industry, EDM is employed for the manufacturing of micro-electronic components, where precision is paramount. The process allows for the production of fine details and tight tolerances necessary for modern electronic devices. Buyers should focus on sourcing from suppliers with advanced EDM technology and experience in electronics manufacturing to ensure high-quality outcomes. Additionally, considering the supplier’s ability to innovate and adapt to new technologies can provide a competitive edge in a rapidly evolving market.

Related Video: Wire EDM – Practical Setups and Applications | Learn to Burn

Strategic Material Selection Guide for edm machine parts

When selecting materials for EDM machine parts, it is crucial to consider the specific requirements of the application, the properties of the materials, and the implications for performance and compliance. Below is an analysis of four common materials used in EDM machine parts, focusing on their key properties, advantages and disadvantages, and considerations for international B2B buyers.

1. Copper

Key Properties: Copper is known for its excellent electrical conductivity and thermal conductivity. It can withstand high temperatures, making it suitable for applications involving significant heat generation.

Pros & Cons: Copper’s high electrical conductivity allows for efficient energy transfer during the EDM process. However, it is relatively soft, which can lead to wear and deformation under high-stress conditions. The cost of copper is moderate, but its availability can fluctuate based on market demands.

Impact on Application: Copper is often used for electrode manufacturing due to its ability to produce high-quality finishes. However, its softness may limit its use in high-wear applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B152 for copper and its alloys. Additionally, sourcing copper from reliable suppliers is essential to avoid quality inconsistencies.

2. Graphite

Key Properties: Graphite is highly resistant to thermal shock and has good electrical conductivity. It can withstand high temperatures without deforming, making it ideal for EDM applications.

Pros & Cons: Graphite electrodes are lightweight and can be produced in complex shapes, which enhances machining flexibility. However, graphite is brittle and can break under excessive mechanical stress. The cost of graphite is generally lower than that of copper, making it an attractive option for many manufacturers.

Impact on Application: Graphite is particularly effective for creating intricate designs and fine details in EDM processes. Its ability to maintain shape under high temperatures makes it suitable for high-precision applications.

Considerations for International Buyers: Buyers should be aware of the differences in graphite grades and their respective performance characteristics. Compliance with standards like ASTM D7264 can also be a factor in material selection.

3. Tungsten

Key Properties: Tungsten is known for its high melting point and exceptional hardness. It exhibits excellent wear resistance and maintains its properties at elevated temperatures.

Pros & Cons: The durability of tungsten makes it ideal for high-stress applications, but its high density can make machining more complex and costly. Tungsten is one of the more expensive materials, which can impact overall project budgets.

Impact on Application: Tungsten is often used in applications requiring high precision and durability, such as aerospace and medical device manufacturing. Its performance in extreme conditions makes it a reliable choice for demanding environments.

Considerations for International Buyers: Compliance with international standards like ASTM B760 is essential for tungsten. Buyers should also consider sourcing from regions with established tungsten mining and processing industries to ensure quality.

4. Steel Alloys

Key Properties: Steel alloys, particularly those with high carbon content, offer a balance of strength, hardness, and wear resistance. They can be treated to enhance specific properties, such as corrosion resistance.

Pros & Cons: Steel alloys are versatile and can be tailored for various applications, making them a popular choice for EDM machine parts. However, they may require additional processing steps, which can increase manufacturing complexity and cost.

Impact on Application: Steel alloys are suitable for a wide range of applications, from automotive to aerospace, due to their adaptability. However, their performance can vary significantly based on the specific alloy composition.

Considerations for International Buyers: Buyers should be aware of the various steel standards (e.g., ASTM A36, DIN 1.4401) and ensure that the selected alloy meets the required specifications for their application.

Summary Table

| Material | Typical Use Case for edm machine parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrodes for high precision parts | Excellent electrical conductivity | Softness leads to wear | Medium |

| Graphite | Complex electrode shapes | Lightweight and easy to shape | Brittle, can break under stress | Low |

| Tungsten | High-stress applications | Exceptional hardness and durability | High cost and complex machining | High |

| Steel Alloys | Versatile applications across industries | Customizable properties for specific needs | Increased manufacturing complexity | Medium |

This guide provides actionable insights for international B2B buyers, emphasizing the importance of material selection in the EDM process and the implications for performance, compliance, and cost.

In-depth Look: Manufacturing Processes and Quality Assurance for edm machine parts

The manufacturing of EDM (Electrical Discharge Machining) machine parts involves several critical stages, each designed to ensure precision and quality. For international B2B buyers, understanding these processes is essential for making informed decisions. The following sections detail the typical manufacturing stages, quality control (QC) measures, and relevant international standards that govern these practices.

Manufacturing Processes for EDM Machine Parts

1. Material Preparation

The first step in manufacturing EDM machine parts is material preparation. The choice of materials is crucial, as the workpiece must be electrically conductive. Common materials include hardened steel, titanium, tungsten carbide, and aluminum alloys.

- Material Selection: Buyers should ensure that suppliers source high-quality materials that meet specific application needs.

- Cutting and Shaping: Materials are often cut into manageable sizes using traditional machining methods before being prepared for EDM. This might involve rough shaping to minimize the machining time during the EDM process.

2. Forming

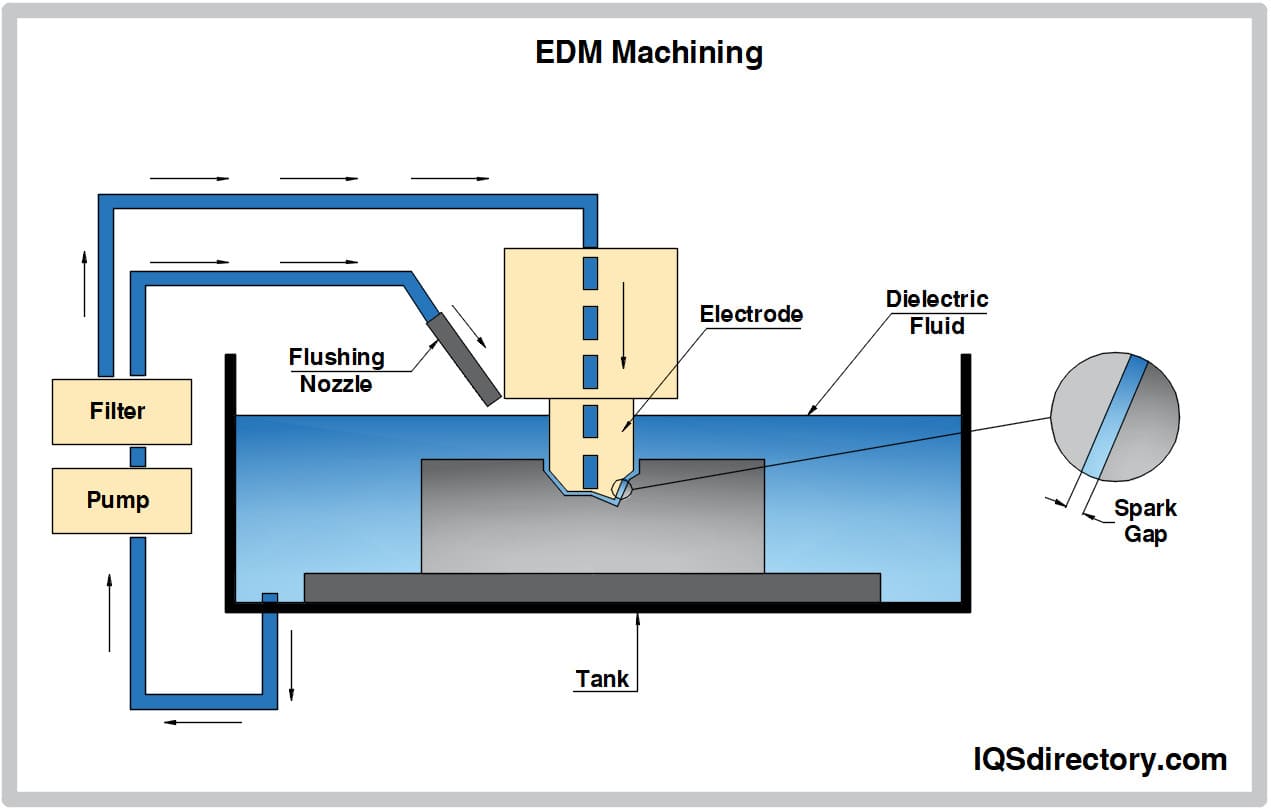

This stage is where the actual EDM process takes place. There are two primary types of EDM: Sinker EDM and Wire EDM. Each method has distinct applications and benefits.

- Sinker EDM: Utilizes a pre-shaped electrode that erodes the workpiece to create complex shapes. This method is ideal for creating molds and cavities.

- Wire EDM: Employs a thin wire as the electrode, which moves through the workpiece to cut it into desired shapes. This method is particularly effective for intricate designs and tight tolerances.

3. Assembly

Post-EDM, components may require assembly, especially if they are part of a larger mechanism or machine.

- Precision Alignment: Ensuring that all parts fit together seamlessly is vital. This may involve additional machining processes to achieve the necessary tolerances.

- Fixture and Support Design: Proper fixtures must be designed to hold components securely during the assembly process.

4. Finishing

Finishing processes enhance the surface quality and functionality of EDM parts.

- Surface Treatments: Techniques such as polishing, coating, or heat treatment may be applied to improve wear resistance and corrosion protection.

- Dimensional Verification: Measurements are taken to ensure that the final product meets the specified tolerances, which can be critical in industries like aerospace and medical.

Quality Assurance for EDM Machine Parts

Quality assurance in the manufacturing of EDM machine parts is paramount, especially for international buyers who must navigate varying standards and regulations.

International Standards

Adhering to international standards is crucial for ensuring quality and reliability. Key standards include:

- ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization. Compliance ensures that suppliers maintain consistent quality in their processes.

- CE Marking: For products sold in the European Economic Area, CE marking signifies conformity with health, safety, and environmental protection standards.

- API Standards: For parts used in the oil and gas industry, the American Petroleum Institute (API) has specific standards that must be met.

QC Checkpoints

Implementing multiple checkpoints throughout the manufacturing process helps maintain quality.

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process allow for real-time adjustments and corrections, minimizing defects.

- Final Quality Control (FQC): The final inspection ensures that the finished product meets all specifications and standards before shipment.

Common Testing Methods

Various testing methods are used to verify the quality of EDM machine parts:

- Dimensional Inspection: Using precision measuring tools to ensure parts meet exact specifications.

- Non-Destructive Testing (NDT): Methods such as ultrasonic testing or magnetic particle inspection can identify internal defects without damaging the part.

- Functional Testing: Verifying that the parts perform as intended in their application.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is essential.

- Audits: Conducting regular audits of suppliers can provide insights into their manufacturing practices and adherence to quality standards. Buyers should request to see audit reports and certifications.

- Reports and Documentation: Suppliers should provide detailed QC reports that outline the testing methods used and the results obtained. This transparency builds trust and confidence.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of product quality and compliance with standards.

QC and Certification Nuances for International Buyers

When sourcing EDM machine parts from international suppliers, buyers must be aware of regional nuances in quality control and certification processes.

- Cultural Differences: Understanding the local manufacturing culture can help buyers navigate potential challenges. For example, suppliers in some regions may prioritize cost over quality, while others may adhere strictly to international standards.

- Regulatory Compliance: Buyers should ensure that suppliers are compliant with both local and international regulations, particularly in industries with stringent requirements like aerospace and medical devices.

- Language Barriers: Clear communication is essential. Buyers may need to consider language differences when discussing quality standards and specifications.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing EDM machine parts, ensuring they receive high-quality products that meet their specific needs.

Related Video: Mercedes C-Class CAR FACTORY – HOW IT’S MADE Assembly Production Line Manufacturing Making of

Comprehensive Cost and Pricing Analysis for edm machine parts Sourcing

Understanding the Cost Structure for EDM Machine Parts

When sourcing EDM machine parts, international B2B buyers must navigate a complex cost structure that can significantly affect the final price. Key components of this structure include:

-

Materials: The choice of materials directly impacts cost. High-performance materials like tungsten carbide or titanium are more expensive than standard alloys. It is essential to evaluate whether the material properties align with your application needs to avoid unnecessary expenditures.

-

Labor: Skilled labor is required for both manufacturing and quality control processes. Regions with lower labor costs may offer competitive pricing, but ensure that quality is not compromised.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities and maintenance. A supplier’s production capacity and technology can influence this overhead, thereby affecting overall pricing.

-

Tooling: Custom tooling can be a significant upfront cost. If your project requires specialized tools, negotiate these costs upfront, as they can vary widely between suppliers.

-

Quality Control (QC): Rigorous QC processes add to costs but are vital for ensuring product reliability. Look for suppliers that offer certifications like ISO 9001, which can enhance credibility and justify higher prices.

-

Logistics: Shipping costs can vary based on distance, weight, and chosen Incoterms. Understand the full logistics cost, including duties and taxes, to avoid surprises.

-

Margin: Suppliers will typically add a profit margin to their costs. This can vary based on market demand, competition, and the supplier’s business model.

Price Influencers to Consider

Several factors can influence the pricing of EDM machine parts:

-

Volume/MOQ: Higher order volumes often lead to reduced unit prices. If possible, consolidate orders to leverage volume discounts.

-

Specifications and Customization: Custom parts or those requiring specific tolerances may incur higher costs. Clearly define your specifications to avoid scope creep during production.

-

Material Quality and Certifications: Premium materials and certifications can lead to increased costs but may enhance performance and longevity.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities play a critical role in pricing. Establishing long-term relationships with reliable suppliers can lead to better pricing and terms.

-

Incoterms: Different Incoterms can significantly impact total costs. Understanding the implications of terms like FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) is crucial for accurate budgeting.

Buyer Tips for Cost-Efficiency

To maximize value when sourcing EDM machine parts, consider the following strategies:

-

Negotiate: Always negotiate on price and terms. Suppliers may be willing to adjust pricing based on your order volume or long-term commitment.

-

Total Cost of Ownership (TCO): Evaluate the TCO, including maintenance, potential downtime, and performance longevity. A higher initial cost may be justified if the part has a longer lifespan or requires less frequent replacement.

-

Be Aware of Pricing Nuances: Understand regional pricing dynamics, especially when sourcing from Africa, South America, the Middle East, or Europe. Currency fluctuations and local market conditions can affect pricing.

-

Request Quotes from Multiple Suppliers: This not only provides a benchmark for pricing but also reveals the range of services and quality available.

-

Stay Informed on Market Trends: Keep an eye on industry trends that may affect material costs, such as supply chain disruptions or changes in trade regulations.

Disclaimer

Prices for EDM machine parts can vary widely based on the factors discussed above. Always conduct thorough market research and supplier evaluations to obtain indicative pricing tailored to your specific needs and circumstances.

Spotlight on Potential edm machine parts Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘edm machine parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for edm machine parts

Key Technical Properties of EDM Machine Parts

When sourcing EDM machine parts, understanding critical specifications is essential for ensuring compatibility and performance in manufacturing processes. Here are several key properties to consider:

-

Material Grade

– Definition: Material grade indicates the specific type of material used for the machine part, such as copper, graphite, or tungsten.

– B2B Importance: Choosing the appropriate material grade is vital for optimizing the EDM process. For instance, copper is known for its excellent conductivity, while graphite offers good wear resistance. The right material can enhance machining efficiency and part longevity. -

Tolerance

– Definition: Tolerance refers to the allowable deviation from a specified dimension, typically measured in millimeters (mm).

– B2B Importance: In industries requiring high precision, such as aerospace or medical device manufacturing, tighter tolerances (e.g., ±0.005 mm) are crucial. Understanding tolerance requirements helps buyers ensure that the EDM parts will meet their specific operational standards and reduce the risk of costly rework. -

Surface Finish

– Definition: Surface finish describes the texture of the part’s surface after machining, often measured in microinches or micrometers.

– B2B Importance: A smooth surface finish is essential for parts that will undergo further assembly or those that must minimize friction. Buyers should specify the required surface finish to ensure the final product meets operational and aesthetic standards. -

Electrode Wear Rate

– Definition: This measures how quickly the tool electrode wears down during the machining process, expressed in millimeters per hour.

– B2B Importance: A lower wear rate indicates a more efficient machining process, which can lead to cost savings and increased productivity. Buyers should consider this metric when selecting electrode materials and designs. -

Spark Gap

– Definition: The spark gap is the distance between the electrode and the workpiece during machining, typically between 0.01 mm to 0.5 mm.

– B2B Importance: Maintaining an optimal spark gap is crucial for effective material removal and precision. Buyers should inquire about the machine’s ability to maintain this gap under varying conditions to ensure consistent performance.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the EDM parts market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is crucial for buyers looking to source parts that fit specific equipment requirements or maintain brand standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ can help buyers plan their inventory and budget effectively. Suppliers may offer better pricing for larger orders, which can be advantageous for companies with high-volume needs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a quote on specific products or services.

– Importance: Utilizing RFQs helps buyers compare pricing and terms across multiple suppliers, ensuring they get the best deal for their EDM machine parts. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international trade.

– Importance: Understanding Incoterms is essential for managing shipping costs, insurance, and risk during transportation. They help clarify who is responsible for shipping, duties, and insurance, which can significantly affect total procurement costs. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the goods.

– Importance: Knowing lead times is critical for planning production schedules and ensuring timely delivery of EDM parts. Buyers should factor lead times into their project timelines to avoid delays.

By grasping these essential technical properties and trade terminologies, international B2B buyers can navigate the EDM machine parts market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the edm machine parts Sector

Market Overview & Key Trends

The EDM machine parts sector is experiencing significant growth driven by a surge in demand across various industries such as aerospace, automotive, and medical devices. As global manufacturing continues to evolve, the need for precision components that can be produced efficiently and cost-effectively is paramount. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly focusing on suppliers who can provide advanced EDM solutions that meet stringent quality standards.

Emerging technologies such as automation and Industry 4.0 are reshaping the landscape of EDM manufacturing. Automation not only enhances operational efficiency but also reduces lead times, making it essential for buyers to seek suppliers who are investing in these technologies. Additionally, the integration of Artificial Intelligence (AI) in EDM processes is gaining traction, allowing for predictive maintenance and improved quality control, which can significantly lower operational costs and downtime.

Another key trend is the rise of digital platforms for sourcing EDM parts. These platforms enable buyers to compare suppliers, review product specifications, and streamline procurement processes. With a focus on transparency and accessibility, B2B buyers are empowered to make informed decisions, ensuring they select the right partners to meet their machining needs. As competition intensifies, suppliers that demonstrate agility and responsiveness to market demands will stand out.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial consideration for B2B buyers in the EDM machine parts sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who implement sustainable practices in their operations, such as using energy-efficient machines and minimizing waste through recycling and reusing materials.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are not only efficient but also socially responsible. This includes transparency regarding labor practices and adherence to environmental regulations. Suppliers that hold certifications such as ISO 14001 for environmental management or ISO 45001 for occupational health and safety demonstrate a commitment to sustainability and ethical standards, which can enhance their appeal to international buyers.

The use of ‘green’ materials in EDM, such as biodegradable dielectrics or recycled metals, is gaining popularity. Buyers should look for suppliers who offer these options, as they not only reduce environmental impact but also meet the increasing demand from end-users for sustainable products. By aligning procurement strategies with sustainability goals, B2B buyers can contribute to a greener economy while enhancing their brand reputation.

Brief Evolution/History

Electrical Discharge Machining (EDM) has its roots in the late 1940s when it was first developed as a method to machine hard materials that were difficult to process using conventional techniques. Initially, EDM was employed primarily in the aerospace and tool-making industries, where precision was paramount. Over the decades, advancements in technology have transformed EDM into a highly versatile machining method. Today, it is widely used across various sectors, including automotive, electronics, and medical devices, thanks to its ability to produce intricate shapes and fine details with minimal material waste. As the demand for precision components continues to grow, EDM remains a vital technology in modern manufacturing, adapting to the needs of global markets and driving innovation in machining processes.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of edm machine parts

-

What key factors should I consider when vetting EDM machine parts suppliers?

When vetting EDM machine parts suppliers, prioritize their experience in the industry, reputation, and certifications. Check for ISO certifications or industry-specific qualifications that indicate adherence to quality standards. Request references or case studies from previous clients, especially those in your region or industry. Additionally, assess their production capabilities, technology used, and the range of materials they can work with to ensure they meet your specific needs. -

Can EDM machine parts be customized to fit my specific requirements?

Yes, many suppliers offer customization options for EDM machine parts. You should discuss your specific requirements, including dimensions, materials, and tolerances, with potential suppliers. Be clear about your expectations and ask for prototypes or samples before placing larger orders. Some suppliers may have design capabilities, allowing them to assist with engineering the parts to meet your unique specifications. -

What are the typical minimum order quantities (MOQ) and lead times for EDM machine parts?

MOQs and lead times can vary significantly among suppliers. Generally, MOQs for EDM machine parts can range from a few pieces to several hundred, depending on the supplier’s production setup and your specific requirements. Lead times typically range from a few weeks to a couple of months. Always clarify these details upfront and consider suppliers that offer flexible options for smaller orders if necessary.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when sourcing EDM machine parts internationally?

Payment terms for international orders can vary by supplier and region. Common practices include upfront payment, partial payment with the balance due on delivery, or payment upon receipt of goods. It’s advisable to discuss and agree on payment methods (e.g., wire transfer, letters of credit) that protect both parties. Ensure that the terms are clearly documented in a contract to avoid misunderstandings later. -

How can I ensure the quality of EDM machine parts before they are shipped?

To ensure quality, request detailed quality assurance (QA) protocols from your supplier. This should include inspections, testing procedures, and certifications that the parts meet industry standards. You may also consider third-party inspections before shipment, especially for high-value or critical components. Establishing clear specifications and acceptance criteria will help maintain quality throughout the production process. -

What certifications should I look for in EDM machine parts suppliers?

Look for suppliers that hold relevant certifications such as ISO 9001 for quality management systems or industry-specific certifications relevant to your sector (e.g., aerospace, medical). Certifications ensure that the supplier adheres to international quality standards and practices. Additionally, inquire about specific certifications related to materials used, especially if your application requires strict compliance. -

What logistics considerations should I keep in mind when sourcing EDM machine parts?

Logistics play a crucial role in international sourcing. Consider factors such as shipping methods, costs, and estimated delivery times. Discuss with suppliers whether they handle shipping or if you need to arrange it. Ensure that you understand customs regulations in your country to avoid delays. It’s also wise to have a plan for handling any potential damage or loss during transportation. -

How should I handle disputes or quality issues with suppliers?

Establish clear communication channels and protocols for addressing disputes when entering a supplier relationship. Document all agreements, including quality expectations and delivery schedules. If issues arise, address them promptly and professionally, providing evidence of the problem. Many suppliers are willing to negotiate solutions, such as refunds or replacements, but having a written contract can facilitate smoother dispute resolution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for edm machine parts

In conclusion, the strategic sourcing of EDM machine parts is essential for international B2B buyers looking to enhance their manufacturing capabilities. By prioritizing precision, reliability, and quality, organizations can optimize their production processes and achieve superior outcomes. Key takeaways include the importance of understanding the specific requirements of EDM applications, selecting reputable suppliers with a proven track record, and leveraging technological advancements to improve machining efficiency.

As the demand for high-precision components continues to grow across industries such as aerospace, automotive, and medical, international buyers from regions like Africa, South America, the Middle East, and Europe should adopt a proactive sourcing strategy. This involves not only evaluating potential suppliers based on their product offerings but also considering their ability to provide ongoing support and innovation.

Illustrative Image (Source: Google Search)

Looking ahead, the EDM landscape is poised for further advancements, driven by the integration of smart technologies and sustainable practices. Therefore, it is crucial for B2B buyers to stay informed about market trends and emerging technologies. Embrace strategic sourcing today to secure a competitive edge in the evolving EDM market.