Master Sourcing Linear Motion Bearings: A Complete B2B

Introduction: Navigating the Global Market for linear motion bearing

In today’s global market, linear motion bearings play a pivotal role in enhancing the efficiency and precision of various industrial applications. These components are essential for minimizing friction in moving parts, thereby improving the performance and longevity of machinery across sectors such as manufacturing, automation, and robotics. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of linear motion bearings is crucial for making informed sourcing decisions.

This comprehensive guide delves into the diverse landscape of linear motion bearings, covering critical aspects such as types, materials, manufacturing quality control, reputable suppliers, and cost considerations. By addressing these elements, the guide aims to empower buyers with the knowledge needed to navigate supplier networks and evaluate product quality effectively.

Additionally, it provides insights into market trends and regional dynamics, ensuring that buyers are equipped to respond to specific challenges and opportunities in their respective markets. The FAQ section further clarifies common queries, facilitating a smoother purchasing process.

With this resource, B2B buyers can confidently approach sourcing linear motion bearings, optimizing their supply chain strategies and enhancing operational efficiency in their enterprises.

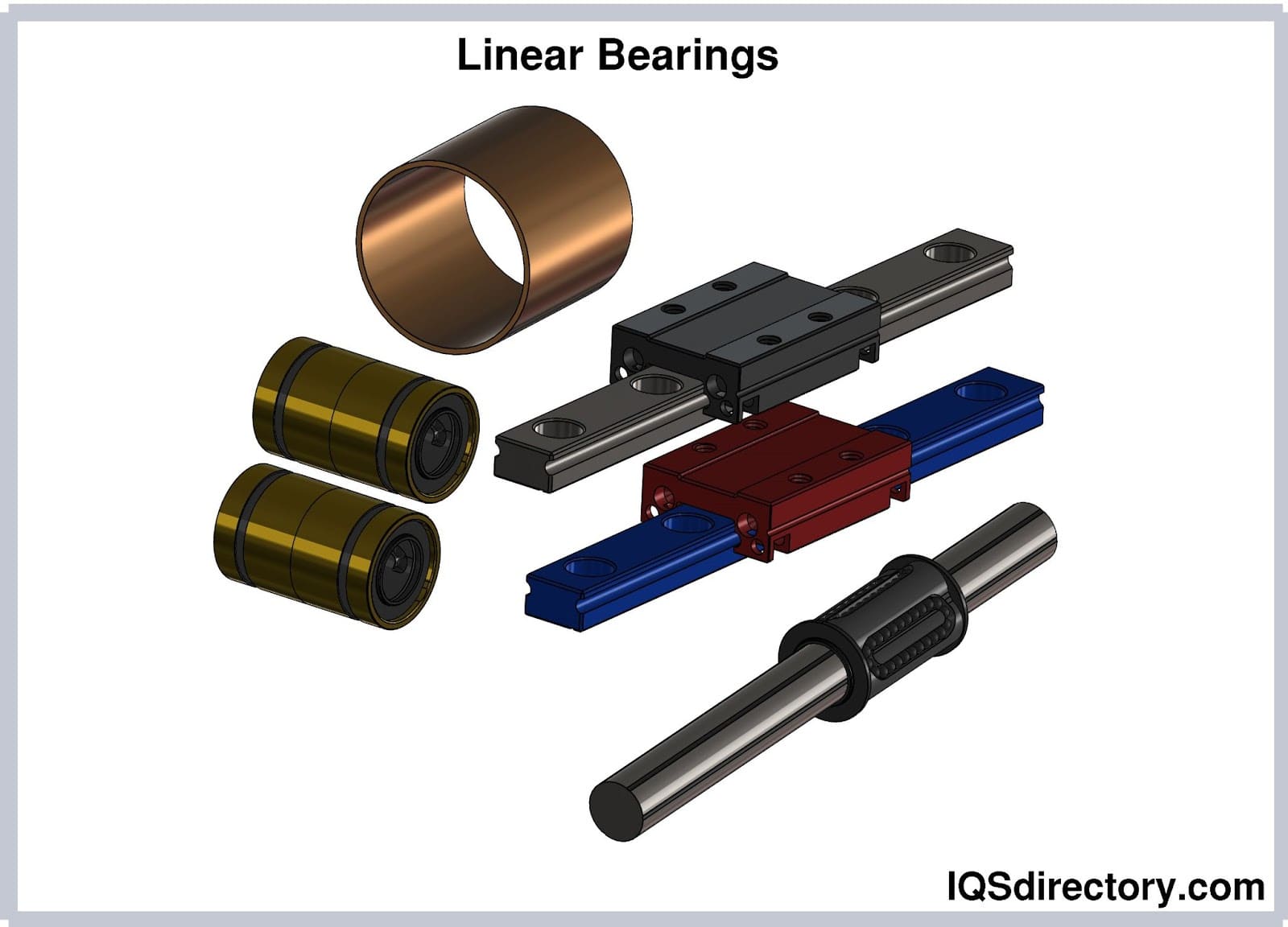

Understanding linear motion bearing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ball Bearings | Spherical balls provide low friction and smooth motion. | Robotics, CNC machines, automation systems. | Pros: High speed, low friction. Cons: Sensitive to contamination. |

| Roller Bearings | Cylindrical rollers support heavier loads and provide stability. | Construction equipment, heavy machinery. | Pros: Higher load capacity. Cons: More friction than ball bearings. |

| Linear Guides | Provide precise linear motion with high rigidity. | Precision machinery, medical devices. | Pros: Excellent accuracy, durability. Cons: Higher cost. |

| Magnetic Bearings | Use magnetic fields to support loads without contact. | Aerospace, high-speed machinery. | Pros: Minimal wear, high-speed capability. Cons: Complex installation. |

| Plastic Bearings | Lightweight and corrosion-resistant, suitable for harsh environments. | Food processing, pharmaceuticals. | Pros: Cost-effective, resistant to chemicals. Cons: Limited load capacity. |

Ball Bearings

Ball bearings are widely recognized for their ability to reduce friction between moving parts, making them ideal for applications requiring high speed and efficiency. They consist of spherical balls that roll between inner and outer races, facilitating smooth linear motion. B2B buyers should consider their application environment, as ball bearings can be sensitive to contaminants, which may affect their performance and longevity.

Roller Bearings

Roller bearings utilize cylindrical rollers instead of balls, allowing them to support heavier loads while providing stability. This makes them particularly suitable for applications in construction equipment and heavy machinery, where load capacity is critical. Buyers should weigh the benefits of higher load ratings against the increased friction, which may necessitate more frequent maintenance.

Linear Guides

Linear guides are designed for applications that require precise linear motion and high rigidity. They are commonly used in precision machinery and medical devices, where accuracy is paramount. While they offer exceptional durability and performance, their higher cost may be a consideration for budget-conscious buyers. It’s essential to assess the long-term benefits of investing in quality linear guides.

Magnetic Bearings

Magnetic bearings provide a unique solution by using magnetic fields to levitate loads, eliminating contact and wear. This technology is particularly advantageous in aerospace and high-speed machinery applications where minimizing friction is crucial. However, buyers must be prepared for the complexities involved in installation and maintenance, which can be more demanding compared to traditional bearings.

Plastic Bearings

Plastic bearings are an economical choice for industries such as food processing and pharmaceuticals, where corrosion resistance and lightweight properties are essential. These bearings can withstand harsh environments and are often less expensive than their metal counterparts. However, buyers should consider their limited load capacity, ensuring that the chosen bearing meets the specific requirements of their application.

Key Industrial Applications of linear motion bearing

| Industry/Sector | Specific Application of Linear Motion Bearing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machines | Enhances precision and speed in machining processes | Ensure compatibility with existing machinery and load capacity. |

| Robotics | Automated Guided Vehicles (AGVs) | Improves reliability and efficiency in material handling | Look for bearings with high durability and low maintenance needs. |

| Packaging | High-speed Packaging Machines | Increases throughput and reduces downtime | Consider the operating environment and resistance to wear. |

| Medical Devices | Surgical Robots | Provides precise movement for minimally invasive surgeries | Focus on biocompatibility and regulatory compliance. |

| Construction | Elevators and Lifts | Ensures smooth and safe vertical transportation | Assess load ratings and environmental resistance. |

Detailed Applications

Manufacturing: CNC Machines

Linear motion bearings are critical in CNC (Computer Numerical Control) machines, which require high precision and repeatability in movement. These bearings help reduce friction and wear, allowing for smoother operation and extended equipment life. For international buyers, especially in Africa and South America, sourcing bearings that meet global quality standards is essential to avoid costly downtimes and ensure compatibility with local manufacturing processes.

Robotics: Automated Guided Vehicles (AGVs)

In robotics, linear motion bearings are integral to the functionality of AGVs, which are used for transporting materials within manufacturing and warehouse environments. These bearings facilitate smooth movement across various surfaces, enhancing the reliability and efficiency of the AGVs. Buyers in the Middle East and Europe should prioritize sourcing bearings that offer high durability and low maintenance to minimize operational interruptions.

Packaging: High-speed Packaging Machines

Linear motion bearings play a vital role in high-speed packaging machines by enabling rapid and accurate movement of components. This efficiency translates to increased throughput and reduced operational downtime, which is critical in competitive markets. For buyers in South Africa and Nigeria, understanding the specific environmental conditions—such as humidity and temperature—can guide the selection of the right bearing materials to ensure optimal performance.

Medical Devices: Surgical Robots

In the medical field, linear motion bearings are essential for surgical robots that require precise and controlled movements during procedures. These bearings must meet strict biocompatibility standards and regulatory requirements. International buyers, particularly from Europe, should focus on sourcing bearings that are certified and designed for sterile environments to ensure patient safety and compliance with health regulations.

Construction: Elevators and Lifts

In the construction industry, linear motion bearings are crucial for the smooth operation of elevators and lifts. They ensure safe and efficient vertical transportation in buildings. Buyers from the Middle East and Africa need to consider load ratings and environmental factors, such as dust and moisture, when sourcing these bearings to guarantee reliability and longevity in various construction settings.

Related Video: What are Linear Motion Bearings?

Strategic Material Selection Guide for linear motion bearing

When selecting materials for linear motion bearings, it is essential to consider the specific requirements of the application, including environmental conditions, load capacities, and operational longevity. Below is an analysis of four common materials used in linear motion bearings, highlighting their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Steel

Key Properties: Steel bearings typically offer high strength and excellent load-bearing capacity. They can withstand high temperatures (up to 300°C) and pressures, making them suitable for demanding applications. Steel also provides good wear resistance and can be treated for enhanced corrosion resistance.

Pros & Cons: The primary advantage of steel is its durability and strength, which translates to a longer lifespan under heavy loads. However, steel bearings can be susceptible to rust and corrosion, particularly in humid or corrosive environments unless properly treated. Manufacturing complexity is moderate, as steel can be machined and heat-treated easily.

Impact on Application: Steel bearings are compatible with a variety of media, including oils and greases. They are often used in industrial machinery, automotive applications, and heavy equipment.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for quality assurance. In regions like Africa and South America, where humidity can be high, selecting stainless steel or coated options may be beneficial.

2. Plastic

Key Properties: Plastic bearings, often made from materials like POM (Polyoxymethylene) or PTFE (Polytetrafluoroethylene), are lightweight and offer excellent corrosion resistance. They can operate effectively in temperatures ranging from -40°C to 100°C.

Pros & Cons: The key advantage of plastic bearings is their resistance to corrosion and low friction properties, which can lead to reduced energy consumption. However, they generally have lower load capacities compared to metal bearings and may wear out faster under heavy loads. Manufacturing is simpler and often less expensive than metal options.

Impact on Application: Plastic bearings are ideal for applications in food processing, pharmaceuticals, and environments where moisture is prevalent. They are also suitable for applications requiring non-magnetic materials.

Considerations for International Buyers: Buyers in Europe may prefer plastic bearings due to stringent hygiene regulations in food and medical industries. It’s crucial to verify that the materials meet local compliance standards.

3. Ceramic

Key Properties: Ceramic bearings are known for their exceptional hardness and wear resistance, capable of withstanding high temperatures (up to 1000°C) and corrosive environments. They are also non-conductive, making them suitable for electrical applications.

Pros & Cons: The primary advantage of ceramic bearings is their high performance in extreme conditions, offering longevity and reduced maintenance. However, they are brittle and can be prone to cracking under shock loads. The manufacturing process is complex, often leading to higher costs.

Impact on Application: Ceramic bearings are commonly used in aerospace, medical devices, and applications requiring high precision and low friction.

Considerations for International Buyers: Buyers should consider the higher initial investment in ceramic bearings against their longer lifespan and reduced maintenance needs. Compliance with international quality standards is essential, especially in high-tech industries.

4. Composite Materials

Key Properties: Composite bearings combine materials like polymers with reinforcing fibers (e.g., glass or carbon) to enhance strength and wear resistance. They can operate effectively in a temperature range of -40°C to 120°C.

Pros & Cons: The key advantage of composite bearings is their lightweight nature and excellent resistance to wear and corrosion. They are also less expensive than ceramics. However, their load capacity may be lower than that of steel, and they can be more complex to manufacture.

Impact on Application: Composite bearings are suitable for applications in the automotive and aerospace industries, where weight savings are critical.

Considerations for International Buyers: Buyers should assess the specific application requirements and ensure that composite materials meet the necessary performance standards. This is particularly relevant in regions with varying industrial standards.

Summary Table

| Material | Typical Use Case for linear motion bearing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial machinery, automotive | High strength and durability | Susceptible to corrosion | Medium |

| Plastic | Food processing, pharmaceuticals | Corrosion resistance, lightweight | Lower load capacity | Low |

| Ceramic | Aerospace, medical devices | High performance in extreme conditions | Brittle, higher cost | High |

| Composite | Automotive, aerospace | Lightweight, good wear resistance | Lower load capacity | Medium |

This guide provides a comprehensive overview of material options for linear motion bearings, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for linear motion bearing

Manufacturing Processes for Linear Motion Bearings

The manufacturing of linear motion bearings involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these processes helps B2B buyers from Africa, South America, the Middle East, and Europe make informed decisions about their suppliers.

1. Material Preparation

The first step in manufacturing linear motion bearings is the selection and preparation of materials. Common materials include:

- Steel Alloys: High-carbon steel is often used for its strength and durability.

- Plastics: Engineering plastics like POM (polyoxymethylene) are also popular for their low friction properties.

Material preparation involves cutting raw materials into the required dimensions, followed by processes like heat treatment to enhance hardness and wear resistance. Ensuring the quality of materials is crucial, as it directly impacts the performance and longevity of the bearings.

2. Forming

Once the materials are prepared, they undergo various forming techniques, including:

- Machining: CNC (Computer Numerical Control) machining is commonly used to achieve precise dimensions and tolerances. This includes turning, milling, and drilling.

- Forging: Some components may be forged to improve grain structure and strength. This process is particularly beneficial for high-load applications.

Each method requires skilled operators and advanced machinery to ensure accuracy and repeatability, which are essential for the performance of linear motion bearings.

3. Assembly

After forming, the components are assembled into the final bearing structure. This stage may involve:

- Ball and Race Assembly: In ball bearings, balls are placed between inner and outer races. The assembly must be done carefully to avoid damage and ensure smooth operation.

- Lubrication: Applying the correct type of lubricant is crucial to reduce friction and wear. Lubrication systems may vary based on the application.

Assembly quality is monitored closely, as any defects can lead to performance issues in the final product.

4. Finishing

The finishing stage enhances the surface quality and performance characteristics of the bearings. Key processes include:

- Grinding: Precision grinding is performed to achieve the final dimensions and surface finish. This ensures optimal contact surfaces for reduced friction.

- Coating: Protective coatings may be applied to enhance corrosion resistance and wear properties.

Finishing processes are critical to achieving the desired performance metrics, such as load capacity and service life.

Quality Assurance in Manufacturing

Quality assurance (QA) is a fundamental aspect of manufacturing linear motion bearings. It involves several international and industry-specific standards, checkpoints, and testing methods to ensure that products meet the required specifications.

International Standards

B2B buyers should be familiar with relevant international quality standards, such as:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable across various industries, including manufacturing.

- CE Marking: In Europe, products must meet certain safety and environmental requirements to be sold, which includes compliance with directives related to machinery and equipment.

In addition to these, industry-specific certifications may be relevant, such as API (American Petroleum Institute) for bearings used in the oil and gas sector.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify defects early in the process, reducing waste and rework.

- Final Quality Control (FQC): The final product is thoroughly tested before shipment to ensure it meets all specifications.

By implementing these checkpoints, manufacturers can maintain high-quality standards and minimize defects.

Common Testing Methods

Several testing methods are commonly used to verify the quality of linear motion bearings, including:

- Dimensional Inspection: Using tools like calipers and micrometers to ensure parts meet specified dimensions.

- Performance Testing: Conducting load and speed tests to evaluate the bearing’s performance under operational conditions.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle inspection are used to detect internal flaws without damaging the component.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

-

Supplier Audits: Conduct on-site audits of potential suppliers to evaluate their manufacturing processes, quality management systems, and adherence to international standards.

-

Request Documentation: Ask for quality assurance documents, including ISO certifications, quality control reports, and inspection records. This information can provide insights into their quality practices.

-

Third-Party Inspections: Engage third-party inspection services to verify the quality of products before shipment. This is particularly useful for large orders or when sourcing from new suppliers.

-

Understand Regional Nuances: Be aware of specific quality assurance challenges in different regions. For example, certain markets may have less stringent regulations, making it essential to conduct thorough due diligence.

Conclusion

Understanding the manufacturing processes and quality assurance measures for linear motion bearings is vital for B2B buyers aiming to source high-quality products. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control, buyers can ensure they partner with reliable suppliers that meet their operational needs.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for linear motion bearing Sourcing

When sourcing linear motion bearings, understanding the comprehensive cost structure and pricing analysis is crucial for international B2B buyers. Below, we dissect the various cost components, price influencers, and provide actionable tips for buyers, particularly those from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly impacts the cost of linear motion bearings. Common materials include stainless steel, aluminum, and specialized polymers. Higher-grade materials often yield better performance and durability but come at a premium.

-

Labor: Labor costs vary significantly by region and can influence the final pricing. In regions like South Africa and Nigeria, labor may be less expensive compared to Europe, potentially lowering overall manufacturing costs.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production. Efficient manufacturers may minimize overhead costs, allowing for competitive pricing.

-

Tooling: The initial investment in tooling for custom or specialized bearings can be substantial. This cost is often amortized over the production run, making it critical to consider expected order volumes when evaluating overall costs.

-

Quality Control (QC): Implementing stringent QC processes ensures that bearings meet required specifications and certifications. This can add to manufacturing costs but is essential for maintaining quality, especially in critical applications.

-

Logistics: Shipping and handling costs are vital, especially for international transactions. Factors such as distance, mode of transport, and import/export tariffs can significantly influence total costs.

-

Margin: Suppliers typically add a markup to cover their risks and profits. Understanding the average margin in the industry can help buyers gauge whether pricing is competitive.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes generally lead to lower per-unit costs. Buyers should negotiate for better pricing based on their purchasing forecasts.

-

Specifications/Customization: Custom designs or specific performance requirements can lead to increased costs. Buyers should clearly define their needs to avoid unexpected charges.

-

Materials Quality/Certifications: Bearings that meet international quality standards or specific certifications may command higher prices. Buyers should assess whether the added cost aligns with their application requirements.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers with a track record of quality may charge more but provide peace of mind.

-

Incoterms: The agreed Incoterms can significantly affect the total cost, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for budgeting.

Buyer Tips

-

Negotiation: Always negotiate pricing, especially for bulk orders. Suppliers are often willing to adjust prices based on commitment levels.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the initial purchase price. Factors like longevity, maintenance, and energy efficiency can contribute to overall savings.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import duties that can affect costs. Buyers from regions like Africa and South America should factor in these variables when budgeting.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, more favorable terms, and improved service.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends. Utilize platforms like DirectIndustry to compare supplier offerings and prices.

Disclaimer

Prices for linear motion bearings can vary widely based on the aforementioned factors. The insights provided here are indicative and should be used as a guideline rather than definitive pricing. Always consult multiple suppliers and gather detailed quotes to ensure a comprehensive understanding of the market landscape.

Spotlight on Potential linear motion bearing Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘linear motion bearing’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for linear motion bearing

Essential Technical Properties of Linear Motion Bearings

Understanding the technical specifications of linear motion bearings is crucial for making informed purchasing decisions. Here are key properties to consider:

-

Material Grade

– Definition: The type of material used in the bearing, commonly stainless steel, plastic, or bronze.

– Importance: Material grade affects durability, load capacity, and resistance to environmental factors such as corrosion. For instance, stainless steel is preferred in humid conditions, while plastic may be suitable for lightweight applications. -

Load Rating

– Definition: The maximum load a bearing can support while maintaining performance.

– Importance: Load ratings are critical for ensuring that the bearing can handle the intended operational loads without failure. Buyers must match the load rating to their application’s requirements to avoid premature wear or catastrophic failure. -

Tolerance

– Definition: The permissible limit of variation in the dimensions of the bearing.

– Importance: High tolerance levels ensure precise movement and alignment. This is particularly important in applications requiring high accuracy, such as in robotics or CNC machinery. A tighter tolerance often results in better performance but may also increase costs. -

Speed Rating

– Definition: The maximum rotational or linear speed at which the bearing can operate effectively.

– Importance: Understanding the speed rating is essential for applications that involve rapid movement. Exceeding this rating can lead to overheating and failure, hence proper matching with application speed is necessary. -

Lubrication Type

– Definition: The method used to reduce friction between moving parts, including grease or oil.

– Importance: The choice of lubrication affects the lifespan and efficiency of the bearing. Some applications may require sealed bearings that do not require additional lubrication, while others may benefit from regular maintenance. -

Operating Temperature Range

– Definition: The range of temperatures within which the bearing can operate effectively.

– Importance: Different applications may expose bearings to varying temperatures. Knowing the operating temperature range ensures that the bearing can perform optimally without degradation of materials.

Common Trade Terminology in Linear Motion Bearings

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: When sourcing linear motion bearings, understanding whether a supplier is an OEM can help assess the quality and reliability of the product. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchases according to budget and storage capabilities. It is particularly relevant for small businesses or startups. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a price quote for specific products or services.

– Importance: An RFQ is a critical step in the procurement process, enabling buyers to compare prices and terms from multiple suppliers, ensuring competitive pricing. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international sales terms published by the International Chamber of Commerce.

– Importance: Understanding Incoterms is vital for international transactions, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

Illustrative Image (Source: Google Search)

-

Lead Time

– Definition: The time taken from placing an order to delivery.

– Importance: Lead time is a key factor in project planning and inventory management. Buyers must consider lead times when scheduling production or project timelines. -

Customization

– Definition: Modifications made to a product to meet specific requirements.

– Importance: Many applications may require bespoke solutions. Understanding the extent of customization available can help buyers choose the right supplier who can meet their unique specifications.

By comprehending these technical properties and trade terminologies, international B2B buyers can make more informed decisions regarding linear motion bearings, optimizing their procurement processes and enhancing operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the linear motion bearing Sector

Market Overview & Key Trends

The linear motion bearing sector is experiencing significant transformation driven by global industrialization, technological advancements, and the increasing demand for automation. In recent years, the rise of Industry 4.0 has prompted businesses to adopt smart manufacturing practices, leading to heightened interest in precision-engineered components like linear motion bearings. Key trends include the integration of IoT technologies, which enhance monitoring capabilities and predictive maintenance, ultimately reducing operational costs.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of emerging sourcing strategies. The shift towards localized supply chains has gained momentum, as companies seek to mitigate risks associated with global disruptions. As a result, sourcing from regional manufacturers can offer advantages in lead times and responsiveness. Additionally, buyers should consider the growing trend of custom solutions tailored to specific application needs, which can provide a competitive edge in their respective markets.

Another notable trend is the increasing focus on energy efficiency and reduced friction in linear motion systems. As industries strive for sustainability, manufacturers are investing in innovative designs that minimize energy consumption while maximizing performance. B2B buyers should prioritize suppliers who can demonstrate advancements in energy-efficient technologies, as this can lead to significant cost savings and improved environmental outcomes.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the linear motion bearing sector. The environmental impact of manufacturing processes, including resource depletion and waste generation, necessitates a shift towards more sustainable practices. B2B buyers must evaluate their supply chains and seek partners who prioritize sustainable manufacturing methods.

Ethical sourcing is equally important, as companies face increasing scrutiny regarding their supply chain practices. Buyers should look for suppliers who adhere to recognized standards, such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety. Additionally, certifications like EcoLabel or Green Seal can indicate a commitment to sustainable materials and processes.

Illustrative Image (Source: Google Search)

Incorporating ‘green’ materials into linear motion bearing products is also gaining traction. Manufacturers are exploring alternatives such as bioplastics or recycled materials, which can help reduce the carbon footprint of their products. B2B buyers should engage with suppliers who are transparent about their sourcing practices and can provide documentation on the sustainability of their materials.

Brief Evolution/History

The development of linear motion bearings has evolved significantly since their inception in the early 20th century. Initially, these components were designed for basic applications, but advancements in materials and engineering have led to high-performance solutions that cater to a wide range of industries, including automotive, aerospace, and manufacturing.

The introduction of new technologies, such as computer-aided design (CAD) and advanced manufacturing techniques, has further refined the production of linear motion bearings. Today, these bearings are characterized by their precision, reliability, and ability to operate in extreme conditions, marking a shift from traditional mechanical systems to more sophisticated solutions that align with modern industrial demands. For international B2B buyers, understanding this evolution is crucial, as it informs sourcing decisions and helps identify suppliers who are at the forefront of innovation in the sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of linear motion bearing

-

What criteria should I use to vet suppliers of linear motion bearings?

When sourcing linear motion bearings, it’s crucial to assess suppliers based on their industry reputation, experience, and certifications. Look for suppliers with ISO certifications, which indicate adherence to international quality standards. Additionally, request references from other clients to gauge their reliability and customer service. Review their product catalog for range and customization options, and consider their production capacity to ensure they can meet your demands. -

Can I customize linear motion bearings to fit my specific needs?

Yes, many suppliers offer customization options for linear motion bearings to meet specific application requirements. This can include adjustments in size, materials, and load capacities. When discussing customization, provide detailed specifications of your application, including the operational environment and load requirements. Collaborate closely with the supplier’s engineering team to ensure the design meets your needs while adhering to quality standards. -

What are the typical minimum order quantities (MOQ) and lead times for linear motion bearings?

Minimum order quantities for linear motion bearings can vary significantly by supplier and product type, ranging from a few pieces to several hundred. Lead times also depend on factors such as customization, supplier location, and current production schedules. Generally, expect lead times of 2-6 weeks for standard products, while customized orders may take longer. Always clarify these details upfront to avoid delays in your supply chain. -

What payment terms are commonly offered by suppliers?

Payment terms for linear motion bearings can differ widely among suppliers. Common arrangements include advance payments, letters of credit, or net 30 to net 90 days after delivery. It’s advisable to negotiate terms that align with your cash flow and financial policies. Ensure that the payment method provides adequate protection against fraud, especially when dealing with international transactions. -

How can I ensure quality assurance and certification for the bearings I purchase?

To ensure quality assurance, request documentation that verifies compliance with international standards, such as ISO 9001. Suppliers should provide certificates of conformity and test reports for their products. Implementing a quality control process on your end, including inspections upon receipt and regular audits of the supplier, can further safeguard against quality issues. Establish clear communication regarding expectations for quality and performance. -

What logistics considerations should I be aware of when importing linear motion bearings?

Logistics for importing linear motion bearings involve several factors, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with your destination country’s regulations to streamline the process. Be aware of potential duties and tariffs that may apply. Planning for lead times and potential delays in customs is essential to ensure timely delivery and minimize disruptions to your operations. -

How should I handle disputes with suppliers?

Handling disputes with suppliers requires a clear strategy. Start by documenting all communications and agreements related to the order. Address issues directly with the supplier through a formal discussion to seek resolution. If necessary, refer to the terms outlined in your contract, including any arbitration clauses. Maintaining a professional tone and focusing on resolution rather than blame can help facilitate a constructive dialogue. -

What are the best practices for maintaining a long-term relationship with suppliers?

Building a strong, long-term relationship with your suppliers involves regular communication, transparency, and mutual respect. Provide feedback on product performance and service quality to help them understand your needs better. Schedule regular check-ins to discuss any upcoming projects or changes in demand. Consider collaborating on innovations that could benefit both parties, such as developing new products or improving existing ones. This proactive approach fosters loyalty and ensures better service.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for linear motion bearing

The effective strategic sourcing of linear motion bearings is essential for optimizing operational efficiency and enhancing product performance across various industries. Key takeaways for international B2B buyers include the importance of evaluating suppliers based on quality, reliability, and cost-effectiveness. Engaging with established manufacturers and leveraging platforms such as DirectIndustry can facilitate access to a diverse range of products tailored to specific industrial needs.

Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize building long-term relationships with suppliers who understand local market dynamics and can provide customized solutions. Additionally, considering the integration of advanced technologies, such as IoT and automation, can significantly improve the performance and longevity of linear motion systems.

As the market evolves, staying abreast of trends and innovations will be crucial. Now is the time for B2B buyers to refine their sourcing strategies, capitalize on emerging opportunities, and invest in high-quality linear motion bearings that meet their operational requirements. By doing so, they can drive significant value for their businesses in a competitive global landscape.