Master Sourcing Linear Rails: Key Insights for Global B2B

Introduction: Navigating the Global Market for linear rails

In today’s rapidly evolving industrial landscape, linear rails play a pivotal role in enhancing automation, precision, and efficiency across various manufacturing processes. As a crucial component in machinery and equipment, linear rails facilitate smooth linear motion, making them indispensable for sectors ranging from automotive to aerospace. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the intricacies of linear rails is vital for making informed sourcing decisions that can significantly impact productivity and operational costs.

This comprehensive guide delves into the diverse types of linear rails, including round and profile rails, and explores the various materials utilized in their manufacturing. It also emphasizes the importance of manufacturing quality control and offers insights into selecting reliable suppliers. Cost considerations are addressed, providing a clear picture of the investment required for different rail types and applications. Additionally, this guide features a market overview that highlights trends and opportunities, alongside a dedicated FAQs section to answer common queries.

By equipping B2B buyers with knowledge and actionable insights, this guide empowers them to navigate the global market for linear rails confidently. In doing so, buyers can streamline their procurement processes, mitigate risks, and enhance their competitive advantage in an increasingly interconnected world.

Understanding linear rails Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Round Rails | Self-aligning, allows for slight misalignment | Robotics, conveyor systems | Pros: Forgiving of installation errors; Cons: Lower precision compared to profile rails. |

| Profile Rails | High rigidity, precision positioning capabilities | CNC machines, automated assembly | Pros: Superior accuracy; Cons: Requires precise installation and alignment. |

| Double-Backed Rails | Back-to-back bearing arrangement for rigidity | Heavy machinery, industrial automation | Pros: Enhanced load capacity; Cons: More complex installation process. |

| Double-Faced Rails | Two parallel surfaces for bearing contact | Precision machinery, medical devices | Pros: Balanced load distribution; Cons: Higher cost than round rails. |

| Linear Guides | Fixed and moving components for guided motion | Packaging, printing machinery | Pros: Versatile applications; Cons: Varies widely in quality and price. |

Round Rails

Round rails are characterized by their self-aligning capabilities, allowing them to accommodate slight misalignment during installation. This feature makes them particularly suitable for applications in robotics and conveyor systems, where quick assembly and flexibility are essential. When purchasing round rails, buyers should consider their lower precision compared to profile rails, which may impact applications requiring exact positioning. However, their forgiving nature can lead to reduced installation headaches, making them an appealing choice for many automation projects.

Profile Rails

Profile rails are designed for high rigidity and precision, making them ideal for applications such as CNC machines and automated assembly lines. They offer superior positioning accuracy and load capacity, ensuring that machinery operates smoothly under varying conditions. However, buyers must be aware that profile rails require precise installation and alignment to function optimally. This may necessitate additional expertise during setup, which can be a consideration for companies looking to minimize labor costs in their operations.

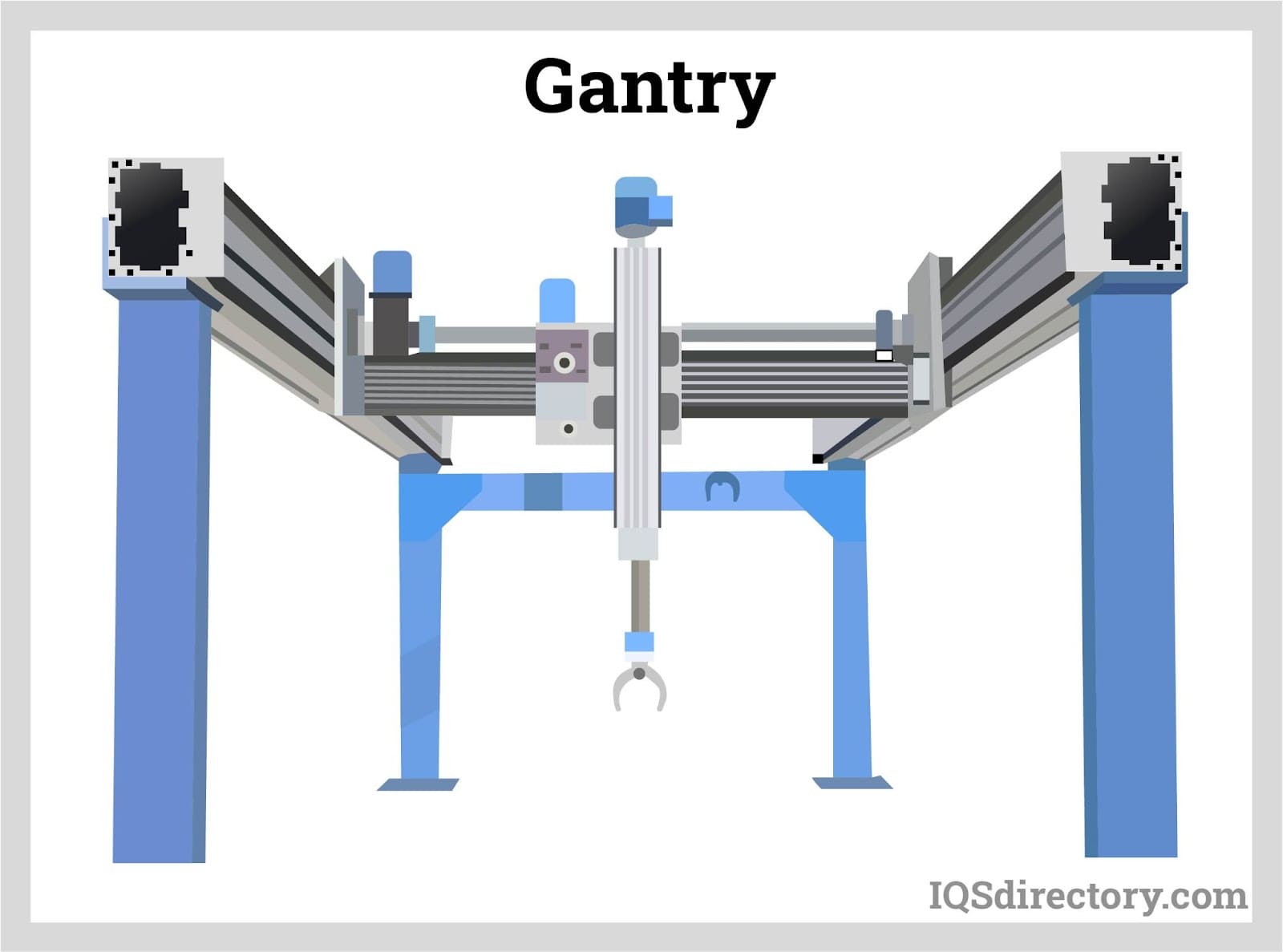

Illustrative Image (Source: Google Search)

Double-Backed Rails

Double-backed rails utilize a back-to-back bearing arrangement, providing enhanced rigidity and load capacity, making them suitable for heavy machinery and industrial automation applications. While they offer significant advantages in terms of stability, their installation process can be more complex than other types of linear rails. Buyers must weigh the benefits of increased load capacity against the potential for higher installation costs and the need for specialized knowledge during setup.

Double-Faced Rails

Double-faced rails feature two parallel surfaces for bearing contact, which aids in balanced load distribution and stability. This design is particularly beneficial in precision machinery and medical devices, where accuracy and reliability are paramount. However, buyers should consider the higher costs associated with double-faced rails compared to round rails. The investment may be justified for applications requiring stringent performance standards, but cost-conscious buyers might look for alternatives depending on their specific needs.

Linear Guides

Linear guides consist of fixed and moving components that facilitate guided motion across various applications, including packaging and printing machinery. Their versatility makes them a valuable choice for businesses seeking adaptable solutions. However, the quality and price of linear guides can vary significantly, so buyers need to conduct thorough research to ensure they select a product that meets their operational requirements. Understanding the specific characteristics of the linear guide can lead to better purchasing decisions and improved operational efficiency.

Related Video: All Machine Learning Models Clearly Explained!

Key Industrial Applications of linear rails

| Industry/Sector | Specific Application of Linear Rails | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machining Centers | Enhanced precision and repeatability in machining | Tolerance levels, load capacity, and rail length |

| Automotive | Automated Assembly Lines | Increased efficiency and reduced assembly time | Compatibility with existing systems and automation |

| Packaging | Robotic Packaging Systems | Improved speed and accuracy in packaging processes | Durability and resistance to environmental factors |

| Aerospace | Flight Simulation Equipment | High precision and reliability in simulations | Certifications and compliance with aerospace standards |

| Medical Devices | Automated Testing Equipment | Ensured accuracy in testing and quality control | Cleanroom compatibility and material specifications |

Manufacturing

In the manufacturing sector, linear rails are integral to CNC machining centers, where they facilitate precise linear motion. By providing a stable and accurate guide for cutting tools, linear rails help reduce machining errors, thereby enhancing product quality and consistency. Buyers should consider the tolerance levels and load capacities of linear rails to ensure they meet the specific requirements of their machining processes. Additionally, compatibility with existing machinery is crucial, especially for international buyers who may be sourcing from diverse manufacturers.

Automotive

In the automotive industry, linear rails are employed in automated assembly lines to streamline production processes. They allow for the smooth movement of robotic arms and other machinery, significantly increasing efficiency and reducing cycle times. For buyers, it is essential to evaluate the compatibility of linear rails with existing automation systems and consider the specific load requirements for the assembly tasks. This is particularly important for companies in regions like South America and Africa, where local supply chains may vary.

Packaging

Linear rails play a vital role in robotic packaging systems, where they enhance the speed and accuracy of packaging processes. By enabling precise movement, they help reduce product damage and improve overall throughput. Businesses should prioritize sourcing rails that offer durability and resistance to environmental factors, as packaging environments can vary widely. Buyers in the Middle East, for instance, should also consider the impact of temperature and humidity on rail performance.

Aerospace

In the aerospace sector, linear rails are crucial for flight simulation equipment, where high precision and reliability are paramount. These systems require components that can maintain strict tolerances to ensure accurate simulations. When sourcing linear rails, aerospace companies must ensure compliance with industry standards and certifications, which can differ significantly across regions such as Europe and Africa. This attention to detail is essential for maintaining safety and operational integrity.

Medical Devices

For automated testing equipment in the medical devices industry, linear rails provide the necessary precision for accurate testing and quality control. The ability to maintain strict alignment and smooth movement is vital for ensuring the reliability of medical devices. Buyers must consider sourcing rails that are compatible with cleanroom environments, as well as materials that meet stringent health and safety regulations. This is particularly critical for international buyers who must navigate varying regulatory landscapes across different regions.

Related Video: Linear rails guide and test on Ender 3 and Ender 5

Strategic Material Selection Guide for linear rails

When selecting materials for linear rails, B2B buyers must consider various factors such as performance characteristics, manufacturing complexities, and cost implications. Below is an analysis of four common materials used in linear rail systems, along with their respective advantages and limitations.

1. Steel

Key Properties:

Steel is known for its high strength and rigidity, making it suitable for high-load applications. It typically has a high temperature and pressure rating, and can withstand significant mechanical stress. However, it is susceptible to corrosion if not properly treated.

Pros & Cons:

Steel’s durability and load-bearing capacity are significant advantages. It is relatively cost-effective compared to other materials. However, its weight can be a disadvantage in applications where weight reduction is critical. Additionally, the need for surface treatments to enhance corrosion resistance can complicate manufacturing processes.

Impact on Application:

Steel linear rails are ideal for heavy machinery and industrial applications where high loads and rigidity are required. However, in environments with high humidity or exposure to corrosive substances, additional protective coatings may be necessary.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM or DIN for steel grades. In regions like Africa and South America, sourcing quality steel may vary, so verifying supplier certifications is crucial.

2. Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance. It offers good thermal conductivity and can operate effectively in a range of temperatures. However, it has lower strength compared to steel.

Pros & Cons:

Aluminum’s lightweight nature makes it suitable for applications requiring mobility and ease of installation. Its corrosion resistance is advantageous in outdoor or humid environments. On the downside, aluminum can be more expensive than steel and may not support as heavy loads.

Impact on Application:

Aluminum linear rails are often used in applications like robotics and automation systems where weight and mobility are critical. They are also suitable for environments where corrosion is a concern.

Considerations for International Buyers:

Buyers should look for suppliers who adhere to international standards such as JIS for aluminum alloys. In regions like Europe, the availability of high-quality aluminum can be more consistent compared to other regions.

3. Stainless Steel

Key Properties:

Stainless steel combines the strength of steel with excellent corrosion resistance. It can withstand high temperatures and is often used in environments where hygiene is paramount, such as food processing.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to corrosion, making it suitable for harsh environments. However, it is generally more expensive than both aluminum and standard steel, which can impact budget considerations.

Impact on Application:

Stainless steel linear rails are ideal for applications in food processing, pharmaceuticals, and other industries where cleanliness and corrosion resistance are critical.

Considerations for International Buyers:

Buyers must ensure that the stainless steel grades meet local and international standards, such as ASTM A276 or AISI. In regions like the Middle East, sourcing high-quality stainless steel can be challenging, so verifying supplier capabilities is essential.

4. Composite Materials

Key Properties:

Composite materials, often made from a combination of polymers and reinforcements, offer unique properties such as reduced weight and excellent corrosion resistance. They can operate effectively in a variety of temperatures but may not handle heavy loads as well as metals.

Pros & Cons:

The lightweight nature of composites makes them ideal for applications requiring reduced weight. They also provide excellent resistance to chemicals and moisture. However, they typically have lower load-bearing capabilities and can be more expensive to manufacture.

Impact on Application:

Composite linear rails are suitable for applications in the aerospace and automotive industries, where weight savings are critical. They are also beneficial in chemical processing environments due to their corrosion resistance.

Considerations for International Buyers:

Buyers should ensure that composite materials meet relevant industry standards and certifications. In regions like South America, the availability of advanced composite materials may be limited, necessitating careful supplier evaluation.

Summary Table

| Material | Typical Use Case for linear rails | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery and industrial applications | High strength and load capacity | Susceptible to corrosion | Medium |

| Aluminum | Robotics and automation systems | Lightweight and corrosion-resistant | Lower load capacity than steel | Medium to High |

| Stainless Steel | Food processing and pharmaceuticals | Excellent corrosion resistance | Higher cost compared to steel and aluminum | High |

| Composite Materials | Aerospace and chemical processing | Reduced weight and chemical resistance | Lower load-bearing capacity | Medium to High |

This guide provides a comprehensive overview of the materials used in linear rails, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for linear rails

The manufacturing of linear rails involves a series of intricate processes that are crucial for ensuring precision and reliability. Understanding these processes and the quality assurance measures in place can empower B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Manufacturing Processes

-

Material Preparation

– The first stage involves selecting high-quality materials, typically steel or aluminum alloys, known for their strength and durability. Materials are often sourced from certified suppliers to ensure consistency and reliability.

– The raw materials undergo rigorous inspections to verify their chemical composition and mechanical properties. This initial quality check is crucial for preventing defects in the final product. -

Forming

– Machining: The selected materials are cut and machined to form the basic rail shapes. Techniques such as CNC (Computer Numerical Control) machining are commonly used to achieve high precision.

– Heat Treatment: Post-machining, the rails may undergo heat treatment processes such as quenching and tempering. This enhances their hardness and wear resistance, which are vital for performance under load.

– Surface Treatment: The rails are often subjected to surface treatments such as anodizing or coating to improve corrosion resistance and reduce friction. These treatments can also enhance aesthetic appeal. -

Assembly

– Assembly involves the integration of various components, including the rail itself and the bearings or carriages. This step is critical, as proper alignment and fitting ensure optimal performance.

– Alignment Techniques: Specialized tools and fixtures are employed during assembly to maintain precise alignment. This is crucial, as misalignment can lead to premature wear or failure of the linear motion system. -

Finishing

– The final stage of manufacturing includes polishing and additional surface treatments to ensure a smooth finish. This is essential for reducing friction and wear during operation.

– Final inspections are conducted to verify dimensions and tolerances, ensuring compliance with specifications.

Quality Assurance

Quality assurance in the manufacturing of linear rails is paramount, as it directly impacts the product’s performance and longevity. Here are key aspects of the quality assurance process:

-

International Standards

– Compliance with international standards such as ISO 9001 is crucial for manufacturers. This standard focuses on quality management systems, ensuring that processes meet customer and regulatory requirements.

– Specific industry standards, such as CE marking in Europe, indicate that products meet health, safety, and environmental protection standards. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This involves inspecting materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are made to monitor dimensions, alignment, and other critical parameters.

– Final Quality Control (FQC): A comprehensive review occurs after production, where finished products undergo rigorous testing and inspections. -

Common Testing Methods

– Dimensional Inspection: This includes measuring critical dimensions using precision tools such as calipers and micrometers to ensure they meet design specifications.

– Load Testing: Rails are subjected to load tests to simulate operational conditions, checking for deflection and overall performance under stress.

– Surface Roughness Testing: This assesses the smoothness of the rail surfaces, which is vital for minimizing friction and wear. -

Verification of Supplier QC

– B2B buyers can verify a supplier’s quality control measures through several methods:- Audits: Conducting on-site audits of the manufacturing facilities can provide insights into the production processes and quality control measures in place.

- Quality Reports: Requesting detailed quality reports and certifications can help verify adherence to international standards and internal quality protocols.

- Third-Party Inspections: Engaging independent third-party inspection agencies can provide unbiased evaluations of the manufacturer’s quality assurance practices.

-

QC and Certification Nuances for International Buyers

– B2B buyers from different regions should be aware of the specific certifications that may be required in their markets. For example, products sold in the European market need CE marking, while buyers in the Middle East may require compliance with local standards.

– Understanding these nuances can help buyers navigate import regulations and ensure that the products they source meet local compliance requirements.

Conclusion

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, a thorough understanding of the manufacturing processes and quality assurance measures for linear rails is essential. By focusing on these aspects, buyers can make informed decisions, ensuring that the linear rails they procure will meet their operational needs and standards. The emphasis on quality not only enhances performance but also contributes to the long-term reliability and efficiency of automation systems.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for linear rails Sourcing

Understanding Cost Components in Linear Rails Sourcing

When sourcing linear rails, it is crucial for B2B buyers to understand the detailed cost structure involved. The primary components include:

-

Materials: The type of material used significantly affects cost. Common materials include aluminum, steel, and high-performance alloys. Steel tends to be more expensive but offers superior strength and durability.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing, but this could come at the expense of quality control.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, making it essential to choose suppliers with optimized operations.

-

Tooling: The cost of specialized tools necessary for producing linear rails can be substantial. Custom tooling for unique specifications can increase initial costs but may be justified by improved product performance.

-

Quality Control (QC): Investing in rigorous QC processes ensures that the linear rails meet industry standards, especially for high-precision applications. This can add to the overall cost but is crucial for long-term reliability.

-

Logistics: Transportation costs can vary significantly based on the supplier’s location and the shipping method chosen. Incoterms play a vital role in determining who bears these costs.

-

Margin: Suppliers will typically add a margin to their costs, which can vary based on market conditions and competition. Understanding this can aid in effective negotiation.

Factors Influencing Pricing

Several factors can influence the final pricing of linear rails:

-

Volume/MOQ: Higher order volumes generally lead to lower per-unit costs. Establishing a long-term relationship with suppliers can also provide leverage for better pricing.

-

Specifications/Customization: Custom designs or specific tolerances can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Material Quality/Certifications: Higher quality materials and certifications (like ISO) can raise costs but are often necessary for applications requiring high reliability.

-

Supplier Factors: The reputation, location, and manufacturing capabilities of suppliers can impact pricing. Suppliers with advanced technologies may command higher prices due to their ability to deliver superior products.

-

Incoterms: Understanding shipping terms is essential for calculating total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who pays for shipping and insurance, affecting overall expenditure.

Strategic Buyer Tips

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, the following tips can help optimize costs:

-

Negotiate Effectively: Don’t hesitate to negotiate pricing based on volume, loyalty, or competitive offers. Building rapport with suppliers can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also maintenance, durability, and potential downtime costs associated with the linear rails. Cheaper options may incur higher long-term costs.

-

Understand Pricing Nuances: Be aware of currency fluctuations, tariffs, and trade agreements that may affect pricing when sourcing from international suppliers.

-

Research Local Suppliers: In regions like Poland and Colombia, local suppliers may offer competitive pricing and reduced shipping costs, making them viable options.

-

Request Prototypes: Before placing large orders, request prototypes to assess quality and fit for your application. This can prevent costly mistakes later in the sourcing process.

Disclaimer on Indicative Prices

Prices for linear rails can vary widely based on the aforementioned factors and market conditions. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always consider the specific requirements of your application when assessing pricing.

Spotlight on Potential linear rails Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘linear rails’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for linear rails

When evaluating linear rails for international B2B applications, it is vital to understand both the technical properties that define their performance and the specific trade terminology that facilitates smooth transactions. Here’s a detailed overview tailored for decision-makers in Africa, South America, the Middle East, and Europe.

Key Technical Properties of Linear Rails

-

Material Grade

– Linear rails are commonly made from materials like stainless steel or aluminum. The choice of material affects corrosion resistance, load capacity, and overall durability. For instance, stainless steel rails are ideal for environments prone to moisture or chemical exposure, while aluminum offers a lightweight solution for applications where weight reduction is crucial. -

Load Capacity

– This specification indicates the maximum load a linear rail can safely support without failure. It is critical for buyers to match the load capacity to their specific application needs. Overloading a rail can lead to premature wear or catastrophic failure, impacting productivity and safety. -

Tolerance

– Tolerance refers to the allowable deviation from a specified dimension. In linear rails, tighter tolerances generally result in better accuracy and performance. For precision applications, such as in CNC machinery, a tolerance of ±0.01 mm may be necessary, while less demanding applications may accept wider tolerances.

-

Linear Motion Accuracy

– This property defines how precisely the linear rail can guide the motion of attached components. High accuracy is essential for applications that require exact positioning, such as robotics and automation systems. Specifications often indicate accuracy in terms of repeatability and positional accuracy. -

Surface Finish

– The surface finish of a linear rail affects friction, wear resistance, and overall performance. Smooth finishes reduce friction and wear, enhancing the longevity of the rail and associated bearings. Buyers should consider the surface treatment options available, such as hard anodizing for aluminum rails or polished finishes for stainless steel. -

Profile Type

– Linear rails come in various profiles, including round and profile rails. Each type has distinct advantages depending on the application. Profile rails offer higher rigidity and load capacity, while round rails provide self-alignment capabilities, accommodating installation errors. Understanding the requirements of your system will guide the choice of rail profile.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of linear rails, working with OEMs can ensure high-quality components tailored to specific industry needs. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and budget constraints effectively. A higher MOQ may require a more significant upfront investment but could lead to lower per-unit costs. -

RFQ (Request for Quotation)

– An RFQ is a standard business process where a buyer solicits price quotes from suppliers for specific products or services. Issuing an RFQ for linear rails allows buyers to compare pricing, terms, and delivery timelines from multiple vendors. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding Incoterms is crucial for international transactions, as they clarify who bears the costs and risks at various stages of shipping and delivery.

-

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the product. This metric is vital for planning production schedules and ensuring timely project completion. Buyers should always inquire about lead times to avoid delays in their operations. -

Warranty

– Warranty refers to the guarantee provided by the manufacturer regarding the performance and longevity of the linear rail. A robust warranty can provide buyers with peace of mind and financial protection against defects or failures.

By familiarizing yourself with these essential properties and terms, you can make informed purchasing decisions that align with your operational needs and strategic objectives.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the linear rails Sector

Market Overview & Key Trends

The linear rails market is experiencing significant growth, driven by advancements in automation, robotics, and manufacturing technologies. As industries across Africa, South America, the Middle East, and Europe (notably Poland and Colombia) invest in modernization, the demand for precision components like linear rails is surging. Key trends include the increasing adoption of smart manufacturing practices and Industry 4.0 technologies, which emphasize connectivity and real-time data processing.

Additionally, there is a notable shift towards customization and flexibility in linear rail systems. Buyers are increasingly seeking solutions that can be tailored to specific applications, enhancing efficiency and performance. This trend is complemented by a growing focus on integration capabilities, where linear rails are being designed to work seamlessly with other automated systems, ensuring smooth operations and reduced downtime.

Emerging technologies such as additive manufacturing (3D printing) are also influencing the sourcing landscape. Buyers can now source custom linear rail components at lower costs and shorter lead times, which is particularly advantageous for small to medium-sized enterprises looking to scale operations without substantial upfront investments. Furthermore, the rise of digital platforms for procurement is streamlining sourcing processes, making it easier for international buyers to connect with suppliers globally.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of business operations in the linear rails sector. The environmental impact of manufacturing processes and materials is under scrutiny, compelling companies to adopt greener practices. For international B2B buyers, this shift necessitates a thorough evaluation of supply chains to ensure that suppliers prioritize sustainable practices.

Ethical sourcing is equally critical, as buyers increasingly demand transparency regarding the origins of materials used in linear rail production. This includes verifying that suppliers comply with environmental regulations and labor standards. Certifications such as ISO 14001 for environmental management and sustainable materials certification can serve as benchmarks for responsible sourcing.

Moreover, the use of recyclable materials and eco-friendly manufacturing processes is on the rise. Buyers should actively seek out suppliers who utilize ‘green’ materials in their linear rail systems, reducing the overall carbon footprint. Embracing sustainability not only meets regulatory requirements but also enhances brand reputation and appeal in a market that increasingly values corporate social responsibility.

Brief Evolution/History

The evolution of linear rails can be traced back to the early 20th century, initially serving basic industrial needs. Over the decades, technological advancements have transformed linear rails into precision-engineered components critical for modern automation and robotics. The introduction of profile rails in the 1960s marked a significant milestone, allowing for higher load capacities and precision compared to traditional round rails.

As industries continue to evolve, the demand for more sophisticated linear rail systems has led to ongoing innovations, such as self-aligning designs and enhanced materials that improve durability and performance. This historical context is essential for B2B buyers who must understand the lineage and technological advancements in linear rails to make informed sourcing decisions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of linear rails

-

What factors should I consider when vetting suppliers of linear rails?

When vetting suppliers, consider their industry experience, production capacity, and quality control measures. Look for certifications such as ISO 9001 that demonstrate a commitment to quality. It’s also vital to assess their reputation through reviews or testimonials from other B2B buyers, particularly in your region. Request samples to evaluate product quality firsthand. Finally, inquire about their supply chain reliability to ensure timely deliveries. -

Can I customize linear rails to meet specific application requirements?

Yes, many suppliers offer customization options for linear rails, including length, width, material, and load capacity. Discuss your specific application requirements with potential suppliers to determine what customization options they provide. Ensure you communicate your technical specifications clearly, and ask for design prototypes or CAD models to visualize the final product. This will help prevent any misunderstandings and ensure the rails meet your operational needs. -

What are the typical minimum order quantities (MOQs) and lead times for linear rails?

Minimum order quantities can vary widely among suppliers, typically ranging from 50 to 100 units for standard products. Custom orders may have higher MOQs depending on the complexity of the specifications. Lead times also vary, generally ranging from 2 to 8 weeks. It’s crucial to discuss these factors upfront and factor them into your project timelines to avoid delays. -

What payment terms should I expect when sourcing linear rails internationally?

Payment terms can vary by supplier and region, but common practices include upfront payments, deposits, and net payment terms (e.g., net 30 or net 60 days). For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms and conditions before placing an order to avoid any financial misunderstandings. -

How do I ensure quality assurance and certifications for linear rails?

To ensure quality, request documentation of certifications such as ISO, CE, or other relevant industry standards from suppliers. Ask for detailed quality assurance processes they follow, including material testing, dimensional checks, and performance testing of the rails. Regular audits and inspections of production facilities can also provide insights into their adherence to quality standards. -

What logistics considerations should I keep in mind when importing linear rails?

Logistics is crucial in international sourcing. Consider shipping methods (air vs. sea), transit times, and costs associated with freight forwarding. Research potential customs duties and regulations in your country to avoid unexpected fees. Collaborate with logistics providers experienced in handling industrial components to streamline the shipping process and ensure timely delivery. -

How can I resolve disputes with suppliers over linear rail orders?

To handle disputes effectively, first, maintain clear communication with your supplier. Document all agreements, specifications, and correspondence to establish a clear record. If a dispute arises, attempt to resolve it amicably through negotiation. Should that fail, refer to the dispute resolution clauses in your contract, which may include arbitration or mediation as alternatives to litigation. -

What are the best practices for maintaining linear rails once sourced?

Regular maintenance is key to extending the lifespan of linear rails. Implement a routine inspection schedule to check for wear, misalignment, and lubrication levels. Use appropriate lubricants as recommended by the manufacturer to minimize friction and wear. Additionally, ensure that the installation environment is clean and free from contaminants that could affect performance. Providing training for your staff on proper handling and maintenance can further enhance reliability and performance.

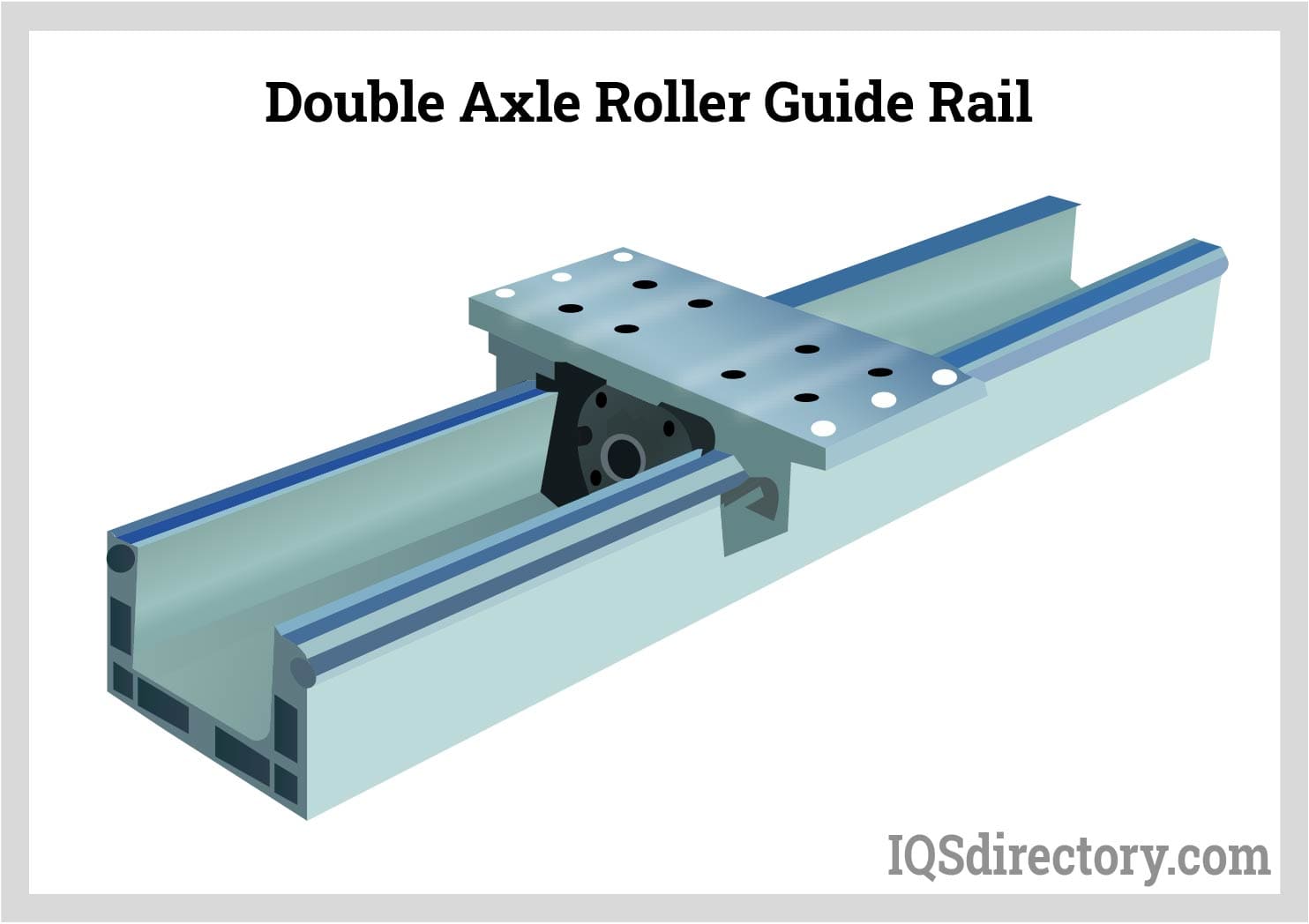

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for linear rails

In conclusion, the strategic sourcing of linear rails is crucial for optimizing operational efficiency and ensuring the longevity of machinery across diverse applications. International buyers must prioritize understanding the specific requirements of their projects, including load capacity, alignment tolerances, and environmental conditions. By choosing the right type of linear rail—be it round or profile rails—buyers can significantly enhance performance and reduce maintenance costs.

Key Takeaways:

– Prioritize Alignment: Misalignment can lead to catastrophic failures; investing in self-aligning systems can mitigate risks.

– Evaluate Load Requirements: Understand the load capacities of different rail types to ensure optimal performance.

– Consider Local Suppliers: Engaging with local manufacturers in regions like Africa, South America, the Middle East, and Europe can reduce lead times and shipping costs.

As the market for linear rails evolves, staying informed about emerging technologies and supplier capabilities will be essential. Buyers are encouraged to actively engage with suppliers to explore innovative solutions tailored to their needs. By doing so, they can position themselves advantageously in a competitive landscape, ensuring both operational excellence and sustainable growth.