Master Sourcing of Latch Mechanism: Key Insights for B2B

Introduction: Navigating the Global Market for latch mechanism

In today’s global market, the significance of latch mechanisms cannot be overstated. These essential components serve as the backbone of security and accessibility in various applications, from industrial machinery to consumer appliances. Understanding the diverse types of latches—ranging from compression and draw latches to more specialized options like slide-to-open mechanisms—enables B2B buyers to make informed sourcing decisions that enhance both functionality and safety in their operations.

This comprehensive guide delves into the intricate world of latch mechanisms, providing insights into the various types and materials available, as well as manufacturing and quality control standards. It also explores the landscape of suppliers and cost considerations, ensuring that buyers are well-equipped to navigate procurement processes effectively. Additionally, the guide addresses frequently asked questions to clarify common uncertainties and assist in decision-making.

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe—regions characterized by diverse industrial needs—this resource is invaluable. By empowering buyers with the knowledge to select the right latch mechanisms for their specific applications, this guide facilitates not only better purchasing choices but also fosters innovation and growth in their respective markets. Embrace the opportunity to enhance your supply chain efficiency and operational security through a thorough understanding of latch mechanisms.

Understanding latch mechanism Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Slide-to-open | Simple sliding mechanism; quick access | Machinery enclosures, drawers, electrical cabinets | Pros: Fast operation; minimal complexity. Cons: May wear out with heavy use. |

| Draw Latch | Over-center locking mechanism; creates tension | Cargo containers, HVAC systems, toolboxes | Pros: Strong closure; resistant to vibrations. Cons: More complex installation. |

| Compression Latch | Provides a sealed closure through compressive force | Electrical housings, HVAC systems, transportation | Pros: Excellent sealing; protects sensitive components. Cons: Higher cost; requires precise installation. |

| Cam Latch | Rotational locking mechanism; simple design | Access panels, storage units, automotive parts | Pros: Economical; easy to install. Cons: Less secure than compression latches. |

| Push-to-open | Mechanism allows opening with a simple push | Cabinets, furniture, appliances | Pros: User-friendly; modern aesthetic. Cons: May not provide strong security. |

Slide-to-open Latches

Slide-to-open latches feature a straightforward sliding mechanism that allows for quick and efficient access to enclosed spaces. They are particularly suited for applications where frequent access is necessary, such as in machinery enclosures and electrical cabinets. When purchasing, consider the latch’s material and durability, especially if it will be subjected to frequent use or harsh environments. The simplicity of the design can lead to faster installation and lower maintenance, making it a cost-effective option for many B2B applications.

Draw Latches

Draw latches utilize an over-center locking action to pull surfaces tightly together, providing a robust and secure closure. They are ideal for environments that require resistance to vibrations and impacts, making them suitable for cargo containers and HVAC systems. Buyers should evaluate the latch’s material strength and corrosion resistance, especially in outdoor or industrial settings. While they offer enhanced security, the installation process may be more complex, requiring careful consideration during procurement.

Illustrative Image (Source: Google Search)

Compression Latches

Compression latches are designed to create a sealed closure by applying compressive force between two surfaces, making them essential for applications where protection from dust, moisture, and electromagnetic interference is critical. Commonly used in electrical housings and HVAC systems, these latches ensure that sensitive components remain secure. When considering a compression latch, assess the sealing capability, ease of operation, and the latch’s compatibility with existing equipment. Though they may come at a higher price point, their protective features can justify the investment for many businesses.

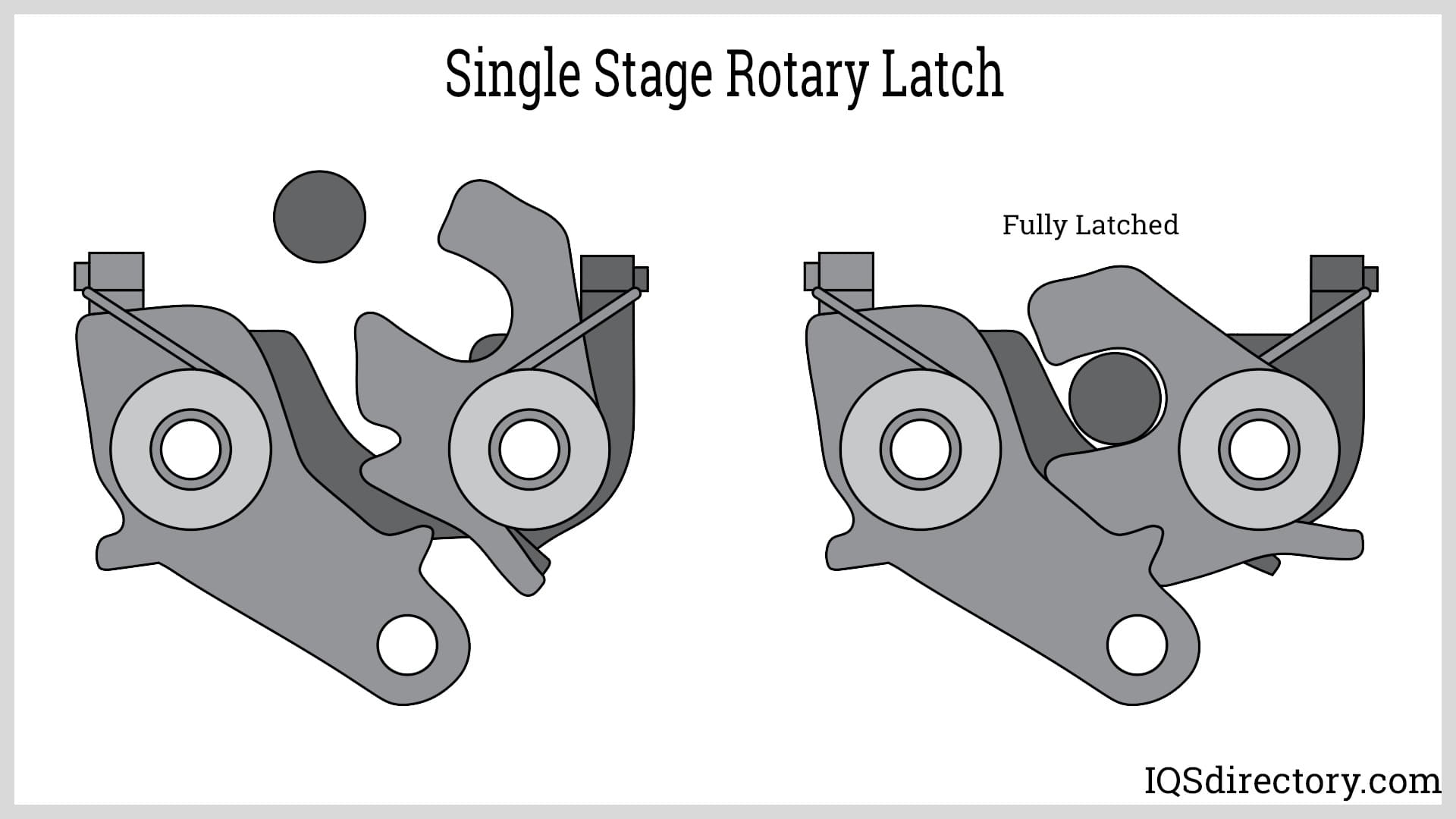

Cam Latches

Cam latches operate through a simple rotational locking mechanism, making them a popular choice for access panels and storage units. Their straightforward design often results in lower manufacturing costs and easier installation, appealing to budget-conscious buyers. However, while they are economical, they may not provide the same level of security as more complex latch types, such as compression latches. Buyers should weigh the trade-off between cost and security needs when selecting cam latches for their applications.

Push-to-open Latches

Push-to-open latches allow users to open doors or panels with a simple push, making them a user-friendly choice for cabinets and modern furniture. Their design provides a sleek aesthetic, appealing to contemporary applications. However, while they enhance convenience, these latches may not offer strong security features, which could be a concern for certain B2B environments. When selecting push-to-open latches, consider the balance between design appeal and functional security to meet your business needs effectively.

Related Video: Andersen door Latch Mechanism

Key Industrial Applications of latch mechanism

| Industry/Sector | Specific Application of latch mechanism | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Cargo and trailer door latches | Enhances safety and security of transported goods | Durability, resistance to vibrations, and ease of use |

| HVAC Systems | Access panels for maintenance | Provides easy access while ensuring airtight seals | Sealing capability, weather resistance, and material strength |

| Industrial Machinery | Enclosures for machinery components | Protects sensitive parts from dust and damage | Compliance with industrial standards and customization options |

| Electronics | Cabinets and enclosures for electronic devices | Prevents dust and moisture ingress, ensuring longevity | Compatibility with existing designs and security features |

| Construction | Gates and access points in construction sites | Enhances site security while allowing controlled access | Weather resistance, ease of installation, and robustness |

Automotive Applications

In the automotive industry, latch mechanisms are crucial for securing cargo and trailer doors. These latches not only enhance safety during transport but also prevent unauthorized access to valuable goods. Buyers should consider sourcing latches that are highly durable and resistant to vibrations, as these features significantly reduce maintenance needs and ensure long-term reliability. Additionally, ease of use is essential for quick access, particularly for businesses operating in regions where efficiency is paramount.

HVAC Systems

Latch mechanisms are integral to access panels in HVAC systems, providing maintenance personnel with easy access while ensuring that units remain airtight. This is vital for the efficient operation of heating and cooling systems, particularly in regions with extreme climates. Buyers must prioritize latches that offer strong sealing capabilities and are resistant to environmental factors such as moisture and dust. Sourcing latches that meet specific industry standards can also enhance operational efficiency and reduce energy costs.

Industrial Machinery

In industrial machinery, latch mechanisms secure enclosures that protect sensitive components from dust and physical damage. This application is particularly relevant for manufacturers focused on maintaining equipment performance and longevity. Buyers should seek latches that comply with rigorous industrial standards and offer customization options to fit various machinery designs. Emphasizing durability and ease of operation can lead to significant reductions in downtime and maintenance costs.

Electronics Sector

Latch mechanisms play a critical role in securing cabinets and enclosures for electronic devices. These latches prevent dust and moisture from compromising sensitive equipment, thus extending their lifespan. For international buyers, especially in regions with varying environmental conditions, it is essential to source latches that are compatible with existing designs and offer robust security features. Additionally, understanding local regulations regarding electronic equipment can guide the selection of suitable latch mechanisms.

Construction Industry

In the construction sector, latch mechanisms are vital for securing gates and access points on job sites. They enhance security and ensure that only authorized personnel can access specific areas. Buyers in this sector should focus on latches that are weather-resistant and easy to install, as construction sites often face harsh environmental conditions. Robustness is also a key consideration, as latches must withstand frequent use and potential impacts during construction activities.

Strategic Material Selection Guide for latch mechanism

When selecting materials for latch mechanisms, international B2B buyers must consider various factors that influence the performance, durability, and cost-effectiveness of their products. Below is an analysis of four common materials used in latch mechanisms, detailing their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it suitable for applications requiring robust performance. It typically has a temperature rating of up to 300°C and excellent resistance to mechanical stress.

Pros & Cons:

Steel latches are highly durable and can withstand harsh conditions, making them ideal for industrial applications. However, they are prone to corrosion unless treated or coated, which can increase manufacturing complexity and costs.

Impact on Application:

Steel is compatible with a wide range of media, including gases and liquids. However, its susceptibility to rust can be a concern in humid environments.

Considerations for International Buyers:

Compliance with standards such as ASTM A36 or DIN 17100 is crucial. Buyers should also consider the availability of corrosion-resistant coatings, particularly in regions with high humidity or saline environments.

Stainless Steel

Key Properties:

Stainless steel boasts excellent corrosion resistance, making it suitable for applications exposed to moisture and chemicals. It can withstand temperatures up to 800°C, depending on the grade.

Pros & Cons:

The primary advantage of stainless steel is its resistance to rust and staining, which enhances the longevity of latch mechanisms. However, it is generally more expensive than regular steel, and its manufacturing processes can be more complex.

Impact on Application:

Stainless steel latches are ideal for outdoor applications and environments where hygiene is essential, such as in food processing or medical equipment.

Considerations for International Buyers:

Buyers should verify compliance with international standards like ASTM A240 or JIS G4303. In addition, understanding local preferences for specific stainless steel grades (e.g., 304 vs. 316) can be beneficial.

Plastic

Key Properties:

Plastic latches are lightweight and can be designed to withstand moderate temperatures, typically up to 80°C. They offer good chemical resistance depending on the type of plastic used.

Pros & Cons:

Plastic is cost-effective and allows for complex shapes and designs, which can simplify manufacturing. However, its mechanical strength is lower than that of metals, making it less suitable for high-stress applications.

Impact on Application:

Plastic latches are often used in consumer goods and applications where weight reduction is essential. They may not perform well under extreme temperatures or heavy loads.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM D638 for tensile properties. Additionally, understanding the local market’s acceptance of plastic components is vital, especially in regions with a strong preference for traditional materials.

Aluminum

Key Properties:

Aluminum is lightweight yet strong, with a temperature rating of up to 150°C. It has good corrosion resistance, especially when anodized.

Pros & Cons:

The main advantage of aluminum is its favorable strength-to-weight ratio, making it ideal for applications where weight is a concern. However, it is softer than steel and can be prone to dents and scratches.

Impact on Application:

Aluminum latches are suitable for aerospace, automotive, and portable equipment applications. They perform well in environments where weight savings are critical.

Considerations for International Buyers:

Buyers should consider compliance with standards such as ASTM B221 or EN 573. Additionally, understanding regional preferences for aluminum alloys can help in selecting the right material for specific applications.

Summary Table

| Material | Typical Use Case for latch mechanism | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial machinery enclosures | High durability | Prone to corrosion | Medium |

| Stainless Steel | Food processing equipment | Excellent corrosion resistance | Higher cost and complexity | High |

| Plastic | Consumer goods | Lightweight and cost-effective | Lower mechanical strength | Low |

| Aluminum | Aerospace and automotive applications | Favorable strength-to-weight ratio | Softer and prone to dents | Medium |

This strategic material selection guide provides essential insights for international B2B buyers. Understanding the properties, advantages, and limitations of each material will facilitate informed decision-making, ensuring the selection of the most suitable latch mechanism for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for latch mechanism

The manufacturing of latch mechanisms involves several key processes, each critical to ensuring the quality and functionality of the final product. B2B buyers, especially those from diverse markets such as Africa, South America, the Middle East, and Europe, should understand these stages and the associated quality assurance measures to make informed purchasing decisions.

Manufacturing Processes

Material Preparation

The manufacturing process begins with material selection, which is fundamental to the latch mechanism’s performance and durability. Common materials include stainless steel, zinc alloys, and high-strength plastics, each chosen based on the intended application—ranging from industrial machinery to consumer products.

- Material Testing: Before production, materials undergo testing for tensile strength, corrosion resistance, and fatigue. This ensures they meet the specific requirements of the latch application.

- Cutting and Shaping: Raw materials are cut to size using techniques such as laser cutting or stamping, which provide precision and reduce waste.

Forming

Forming is the process where the material is shaped into the desired latch configuration. This can involve several techniques:

- Stamping and Pressing: These methods are commonly used to create the basic shapes of latch components. High-speed presses can achieve high-volume production with consistent quality.

- Injection Molding: For plastic latches, injection molding is a popular technique that allows for complex shapes and high levels of detail. This method is particularly useful for producing parts that require intricate designs or features.

Assembly

After forming, the individual components of the latch mechanism are assembled. This stage can vary significantly based on the latch type:

- Manual Assembly: For high-end or custom latches, skilled workers may assemble components manually, allowing for quality checks at every step.

- Automated Assembly Lines: In mass production settings, automated machinery is used to assemble components quickly and efficiently. This can include robotic arms for precision assembly.

Finishing

The final stage in manufacturing involves surface finishing processes that enhance the latch’s durability and aesthetic appeal:

- Coating: Techniques such as powder coating or plating (e.g., zinc plating) are applied to improve corrosion resistance and provide a desirable finish.

- Quality Inspection: Each batch of finished latches undergoes a thorough inspection to ensure they meet the specified standards.

Quality Assurance

Quality assurance (QA) is crucial in the latch manufacturing process, ensuring that products meet international and industry-specific standards. B2B buyers should be aware of the following key aspects of QA:

International Standards

Adherence to international standards such as ISO 9001 is essential for manufacturers. ISO 9001 focuses on quality management systems and helps organizations ensure consistent quality in their products and services.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. This is particularly relevant for latches used in consumer products and industrial applications.

- API Standards: In industries such as oil and gas, compliance with American Petroleum Institute (API) standards may be necessary, especially for latches used in critical applications.

Quality Control Checkpoints

A robust quality control system includes several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during production is essential. This may include regular checks for dimensional accuracy and functionality.

- Final Quality Control (FQC): Finished products undergo rigorous testing, including functional tests and environmental simulations to assess performance under various conditions.

Common Testing Methods

Testing methods for latch mechanisms can include:

- Functional Testing: Ensures that the latch operates correctly under specified conditions.

- Durability Testing: Measures how well the latch withstands repeated use and environmental stresses.

- Corrosion Testing: Evaluates resistance to rust and other forms of degradation.

Verifying Supplier Quality Control

B2B buyers can adopt several strategies to verify the quality control processes of their suppliers:

- Audits: Regular audits of manufacturing facilities can provide insights into the operational practices and quality management systems in place. Buyers should request audit reports from potential suppliers.

- Documentation: Suppliers should provide documentation of their quality assurance processes, including certificates of compliance with relevant standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an independent assessment of the supplier’s quality practices and product reliability.

QC and Certification Nuances for International Buyers

International B2B buyers, particularly from regions like Africa and South America, should consider several nuances in quality control and certification:

- Regional Compliance: Understanding local regulations and compliance requirements is critical. For example, certain countries may have specific safety standards that differ from international norms.

- Supply Chain Transparency: Buyers should seek suppliers who provide transparency regarding their sourcing, manufacturing, and quality control processes. This can help mitigate risks associated with substandard products.

- Cultural Considerations: Different regions may have varying approaches to quality assurance. Engaging with suppliers who understand these cultural differences can facilitate smoother transactions and enhance product quality.

By understanding the manufacturing processes and quality assurance measures in latch mechanism production, international B2B buyers can make more informed decisions, ensuring they procure reliable and high-quality products tailored to their specific needs.

Related Video: Lean Manufacturing – Pull Systems

Comprehensive Cost and Pricing Analysis for latch mechanism Sourcing

When sourcing latch mechanisms, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This section outlines the key components of costs, influential pricing factors, and strategic tips for negotiating better deals.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include stainless steel, aluminum, and plastic, each varying in price based on quality and availability. High-grade materials may enhance durability but also increase costs.

-

Labor: Labor costs vary by region and manufacturing practices. In countries with higher labor costs, such as Germany, the overall expense may be elevated compared to regions with lower labor rates, like parts of Africa or South America.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial tooling costs can be significant, especially for custom latches. Investment in high-quality tooling can lead to better production efficiency and product quality, impacting long-term costs.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to the cost but is essential for minimizing defects and returns. Certification standards (e.g., ISO) can also influence QC costs.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, mode of transport, and customs duties should be factored into the total cost.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the typical margins in your region can help in evaluating supplier quotes.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Higher volumes often lead to lower unit costs, making bulk purchasing advantageous.

-

Specifications/Customization: Custom latches tailored to specific applications may incur additional costs. Buyers should weigh the need for customization against the potential benefits.

-

Materials and Quality/Certifications: The quality of materials used and any certifications required can influence pricing. Premium materials and certifications usually come at a higher price but may be necessary for certain applications.

-

Supplier Factors: Different suppliers have varying pricing strategies based on their market position, production capabilities, and customer service levels. Building relationships with suppliers can sometimes yield better pricing.

-

Incoterms: The terms of shipping and delivery (Incoterms) will affect the final cost. Understanding these terms can help buyers negotiate better shipping costs and clarify responsibilities.

Buyer Tips

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility, especially for larger orders or long-term contracts.

-

Cost-Efficiency: Evaluate not just the purchase price but the Total Cost of Ownership (TCO), including maintenance, operational costs, and longevity of the latch mechanisms.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, regional tariffs, and shipping costs. These factors can significantly influence the final pricing.

-

Research: Conduct thorough market research to understand average prices and supplier offerings in your region. This knowledge empowers buyers during negotiations.

-

Quality Assurance: Prioritize suppliers who demonstrate a commitment to quality. Investing in quality upfront can save costs related to defects and replacements later on.

In conclusion, navigating the costs and pricing of latch mechanisms requires a comprehensive understanding of various influencing factors. By leveraging this knowledge, international B2B buyers can make informed decisions, optimize their procurement strategies, and ultimately achieve better value from their sourcing efforts.

- Disclaimer: Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements.*

Spotlight on Potential latch mechanism Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘latch mechanism’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for latch mechanism

When considering latch mechanisms for international B2B transactions, understanding the essential technical properties and common trade terminology is crucial for informed decision-making. Below is a detailed overview that highlights critical specifications and relevant jargon in the industry.

Key Technical Properties of Latch Mechanisms

-

Material Grade

– Definition: This refers to the type and quality of material used in the latch, such as stainless steel, aluminum, or plastic composites.

– Importance: The material directly affects durability, resistance to corrosion, and overall strength. For industries operating in harsh environments, like construction or mining, selecting the appropriate material is vital for ensuring longevity and performance. -

Load Capacity

– Definition: This specification indicates the maximum weight or force a latch can securely hold without failure.

– Importance: Understanding load capacity is essential for applications involving heavy doors or panels, as it ensures safety and functionality. Buyers must match the latch’s load capacity to their specific use case to prevent operational failures. -

Tolerance

– Definition: Tolerance refers to the permissible limits of variation in the dimensions of the latch components.

– Importance: Proper tolerances are critical for ensuring that latches fit accurately with their corresponding hardware. In manufacturing and assembly, even slight deviations can lead to performance issues or compromised security. -

Operating Temperature Range

– Definition: This property specifies the temperature limits within which the latch can operate effectively.

– Importance: For applications in extreme climates, such as those found in the Middle East or South America, selecting a latch that can withstand high or low temperatures is essential to maintain functionality and prevent material degradation. -

Finish Type

– Definition: The finish type refers to the surface treatment of the latch, such as powder coating, plating, or anodizing.

– Importance: The finish not only enhances aesthetic appeal but also provides additional resistance to environmental factors like moisture and UV light. This is particularly important for outdoor applications. -

Actuation Mechanism

– Definition: This defines how the latch is engaged or disengaged, which can include manual, key-operated, or electronic mechanisms.

– Importance: The choice of actuation affects user convenience and security levels. Buyers must evaluate the ease of use versus security needs based on their operational requirements.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM specifications is critical for buyers looking to source latches that meet specific design and performance standards required for their applications. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers assess their purchasing power and budget. It is particularly relevant for smaller companies or startups that may not require large quantities.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price offers from suppliers for specified goods or services.

– Relevance: RFQs are crucial for buyers to compare pricing, terms, and conditions from different suppliers, enabling better negotiation and procurement strategies. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost implications, facilitating smoother international trade. -

Lead Time

– Definition: The time taken from the placement of an order until its delivery.

– Relevance: Understanding lead times is essential for project planning and inventory management, especially in industries where timely delivery is critical. -

Certification Standards

– Definition: Industry standards that products must meet to ensure safety, performance, and quality.

– Relevance: Buyers should be aware of relevant certification standards (like ISO or CE) that may affect compliance and marketability in their regions, influencing purchasing decisions.

By grasping these properties and terminologies, B2B buyers can make informed decisions that enhance their procurement processes and ensure the suitability of latch mechanisms for their specific applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the latch mechanism Sector

Market Overview & Key Trends

The latch mechanism sector is experiencing notable growth, driven by a surge in demand across various industries, including automotive, construction, and electronics. Globalization has expanded market access for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Key trends influencing this market include the increasing emphasis on automation and smart technology, where latches are integrated into electronic locking systems and smart devices, enhancing security and user convenience.

Moreover, the rise of Industry 4.0 is reshaping manufacturing processes, making them more efficient and precise. Buyers should look for suppliers that leverage advanced manufacturing techniques such as 3D printing and automation, which can lower production costs and improve product customization. Additionally, the shift towards modular designs is gaining traction, allowing for easy integration and replacement of latch components in various applications.

Emerging markets are also becoming significant players in the latch mechanism sector. For example, manufacturers in Turkey and South Africa are ramping up production capabilities, offering competitive pricing and localized solutions that appeal to regional buyers. Understanding these dynamics is essential for international buyers to make informed sourcing decisions that align with their operational requirements and budget constraints.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a priority in global supply chains, the latch mechanism industry is not left behind. International B2B buyers are increasingly seeking products that minimize environmental impact, prompting manufacturers to adopt eco-friendly practices. This includes the use of recyclable materials and energy-efficient production processes.

Buyers should prioritize suppliers that hold certifications such as ISO 14001, which indicates a commitment to environmental management systems. Additionally, sourcing from manufacturers that utilize recycled metals or sustainable plastics can significantly reduce the carbon footprint associated with latch production.

Ethical sourcing is equally critical; businesses must ensure that their supply chains are free from exploitative labor practices. Verifying that suppliers adhere to fair labor standards and sustainability guidelines is essential for maintaining corporate responsibility. Implementing a robust supplier assessment process can help buyers identify and partner with manufacturers that align with their ethical values and sustainability goals.

Brief Evolution/History

The latch mechanism has evolved significantly since its inception in ancient civilizations, where simple wooden latches were used to secure doors and gates. Over the centuries, advancements in materials and manufacturing techniques have transformed latches into sophisticated mechanical devices. The introduction of metalworking during the Middle Ages allowed for the creation of stronger and more reliable latches, paving the way for their widespread use in various applications.

In recent decades, the latch mechanism sector has witnessed a shift towards automation and electronic solutions, driven by technological advancements and changing consumer expectations. Today’s latches are not only functional but also integral to security systems in residential and commercial settings. This evolution underscores the importance for B2B buyers to stay informed about current technologies and market trends to make effective purchasing decisions.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of latch mechanism

-

What criteria should I consider when vetting suppliers for latch mechanisms?

When vetting suppliers, prioritize their experience and reputation in the industry. Request references or case studies from previous clients, and check online reviews. Evaluate their production capabilities, quality control processes, and certifications (ISO, CE, etc.). Additionally, consider their geographical location for logistics efficiency and potential tariffs. Understanding their customer service responsiveness is crucial, as it reflects their commitment to support and resolve issues post-purchase. -

Can I customize latch mechanisms to suit my specific needs?

Yes, many manufacturers offer customization options for latch mechanisms. When discussing customization, clearly define your requirements regarding size, material, finish, and functionality. Request samples or prototypes to ensure the product meets your expectations. Be aware that customized solutions may have longer lead times and higher costs, so budget accordingly and confirm the supplier’s capabilities in handling custom orders. -

What are the typical minimum order quantities (MOQs) and lead times for latch mechanisms?

MOQs can vary significantly depending on the supplier and the complexity of the latch mechanism. Generally, MOQs may range from 100 to several thousand units. Lead times also vary based on the order size and customization requirements, typically ranging from 4 to 12 weeks. It’s advisable to discuss these factors upfront with your supplier to align expectations and plan your inventory management effectively. -

What payment terms are commonly offered by latch mechanism suppliers?

Payment terms vary, but many suppliers offer options such as upfront payment, partial payment before shipment, or net terms (e.g., net 30 or net 60 days). Consider using secure payment methods like letters of credit, especially for larger orders or first-time transactions. Always clarify payment terms in the contract to avoid misunderstandings and ensure that both parties agree on the timeline and method of payment. -

How can I ensure quality assurance and necessary certifications for latch mechanisms?

To ensure quality, request certifications such as ISO 9001 for quality management systems or specific industry-related certifications. Review the supplier’s quality assurance processes, including testing protocols and inspection procedures. Consider conducting factory audits if feasible, or request third-party inspection services to verify compliance with your quality standards. Documenting these certifications can also be beneficial for future audits or regulatory requirements. -

What logistics considerations should I keep in mind when sourcing latch mechanisms internationally?

Logistics are critical in international sourcing. Assess shipping options, costs, and delivery times based on your location and the supplier’s shipping capabilities. Be aware of customs regulations and duties that may apply when importing latch mechanisms. Establish clear communication with your logistics provider to track shipments and handle any potential delays. Consider insurance options for high-value shipments to mitigate risks. -

How should I handle disputes with suppliers regarding latch mechanism orders?

To minimize disputes, establish clear contracts detailing product specifications, delivery timelines, and payment terms. In case of disputes, start with open communication to resolve the issue amicably. If necessary, refer to the contract for resolution procedures, including mediation or arbitration clauses. Maintaining a professional relationship is crucial, so document all communications and resolutions for future reference. -

What are the best practices for maintaining a long-term relationship with latch mechanism suppliers?

Building a long-term relationship with suppliers involves consistent communication, timely payments, and constructive feedback. Regularly review performance metrics such as quality, delivery times, and responsiveness. Establishing joint development projects can foster collaboration and innovation. Additionally, consider sharing your business forecasts to help suppliers plan their production schedules, which can lead to better pricing and service levels over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for latch mechanism

In conclusion, effective strategic sourcing of latch mechanisms is pivotal for international B2B buyers seeking reliability, security, and efficiency in their operations. Key takeaways include the importance of selecting the right type of latch—be it compression, draw, or slide-to-open—based on specific application needs, as well as the necessity for robust supplier partnerships that ensure quality and timely delivery.

Investing in high-performance latches not only enhances product durability but also optimizes operational processes, thereby reducing long-term costs. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers that demonstrate innovation, sustainability, and responsiveness to market demands, as these factors will significantly influence competitive advantage.

Looking ahead, as industries continue to evolve, embracing new technologies and materials in latch mechanisms will be crucial. International B2B buyers are encouraged to stay informed about emerging trends and to actively engage with suppliers who can provide tailored solutions to meet their evolving needs. By doing so, they can secure not only their assets but also drive their business growth in a rapidly changing global market.