Master Sourcing Plastic L Channels: Key Strategies for B2B

Introduction: Navigating the Global Market for plastic l channel

Navigating the complexities of the global market for plastic L channels is essential for international B2B buyers seeking to enhance their supply chain efficiency and product offerings. These versatile components, integral to various industries such as construction, automotive, and manufacturing, serve critical roles in organization and protection of wiring, piping, and other materials. Understanding the unique attributes and sourcing strategies related to plastic L channels can significantly impact operational success.

This comprehensive guide delves into the myriad aspects of plastic L channels, offering insights into types, materials, manufacturing and quality control processes, supplier evaluations, cost considerations, and market dynamics. Each section is designed to equip buyers from diverse regions—including Africa, South America, the Middle East, and Europe—with the knowledge necessary to make informed procurement decisions.

By addressing frequently asked questions and providing actionable strategies, this guide empowers B2B buyers to navigate the intricacies of sourcing plastic L channels. In an era where efficient supply chain management and sustainable sourcing are paramount, having access to authoritative information can lead to enhanced competitiveness and reduced operational risks. Whether you’re a buyer in Nigeria or Saudi Arabia, understanding the global landscape of plastic L channels is crucial for optimizing your procurement strategy and ensuring long-term business success.

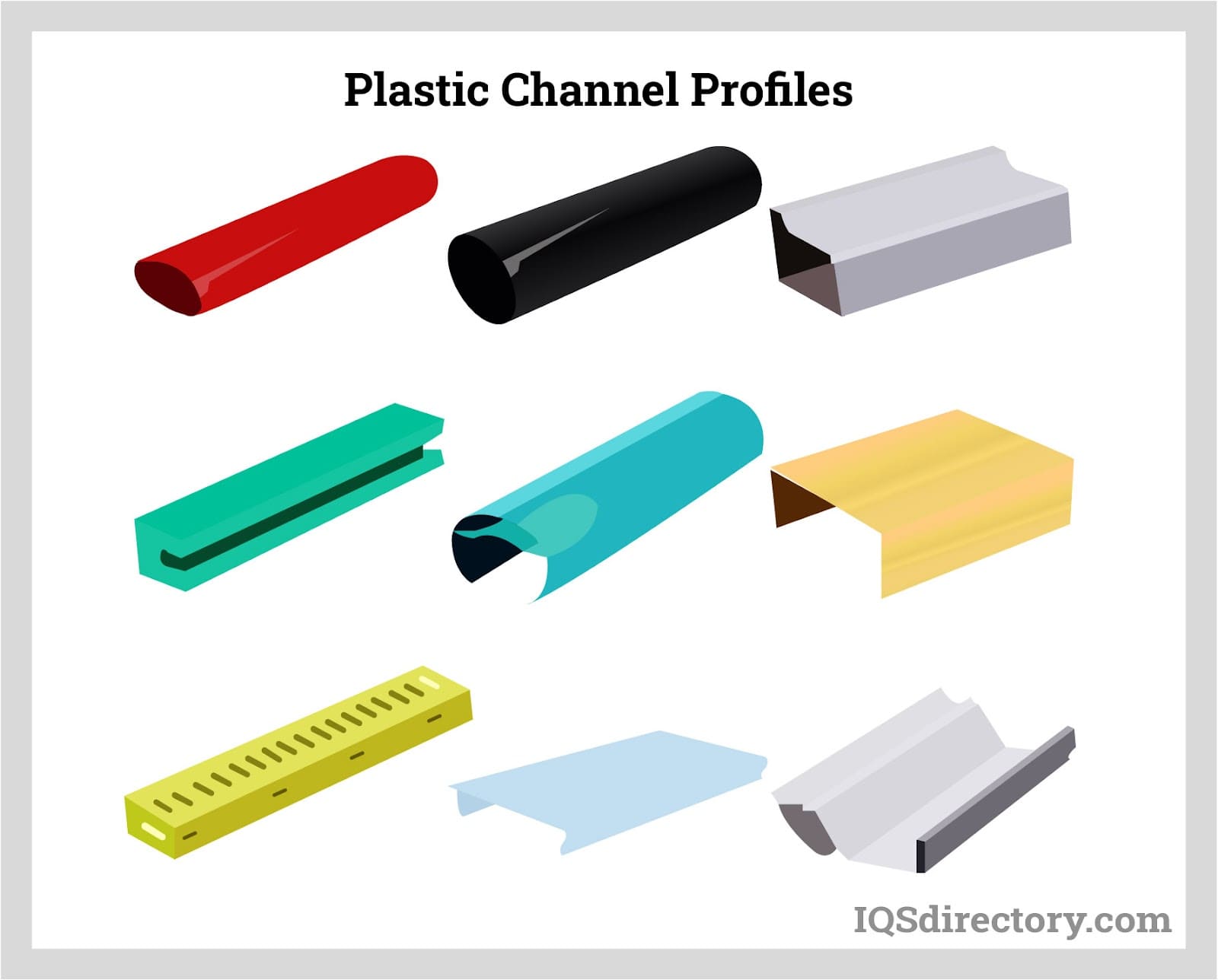

Understanding plastic l channel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Plastic L Channel | Commonly used, available in various sizes and colors | Construction, signage, framing | Pros: Versatile, cost-effective. Cons: May lack durability under extreme conditions. |

| Heavy-Duty Plastic L Channel | Thicker gauge, enhanced load-bearing capacity | Industrial applications, storage | Pros: High strength, long-lasting. Cons: Higher cost, limited color options. |

| Flexible Plastic L Channel | Made from softer materials, can bend without breaking | Custom installations, displays | Pros: Adaptable to various shapes, easy to install. Cons: Lower load capacity, may wear faster. |

| UV-Resistant Plastic L Channel | Treated to withstand UV exposure, retains color | Outdoor applications, signage | Pros: Durable in sunlight, maintains appearance. Cons: Typically more expensive than standard options. |

| Decorative Plastic L Channel | Available in various designs and finishes | Retail displays, interior design | Pros: Aesthetic appeal, enhances branding. Cons: May not be as strong as standard options. |

Standard Plastic L Channel

The Standard Plastic L Channel is widely recognized for its versatility and cost-effectiveness. Typically available in a range of sizes and colors, it is ideal for applications in construction, signage, and framing. B2B buyers should consider its suitability for general-purpose use, but be cautious of its limitations in extreme environments where durability may be compromised.

Heavy-Duty Plastic L Channel

Designed for industrial applications, the Heavy-Duty Plastic L Channel boasts a thicker gauge and enhanced load-bearing capacity. This type is perfect for use in storage solutions and other demanding environments. While it provides exceptional strength and longevity, buyers should weigh the higher cost against their specific needs, particularly if aesthetics are less of a priority.

Flexible Plastic L Channel

The Flexible Plastic L Channel is crafted from softer materials, allowing it to bend without breaking, making it suitable for custom installations and displays. Its adaptability is a significant advantage for projects that require unique shapes. However, B2B buyers should note that while it is easy to install, its lower load capacity and potential for quicker wear may limit its use in more robust applications.

UV-Resistant Plastic L Channel

For outdoor applications, the UV-Resistant Plastic L Channel is treated to withstand prolonged exposure to sunlight, ensuring it retains its color and structural integrity. This makes it an excellent choice for signage and other outdoor installations. Buyers should expect a higher price point, but the investment is often justified by its durability and low maintenance requirements.

Decorative Plastic L Channel

The Decorative Plastic L Channel is designed with aesthetics in mind, offering various designs and finishes that enhance retail displays and interior design projects. While it adds significant value in terms of branding and visual appeal, buyers must consider that it may not provide the same level of strength as standard options, making it essential to evaluate its application carefully.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of plastic l channel

| Industry/Sector | Specific Application of plastic l channel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural support in modular construction systems | Lightweight, corrosion-resistant alternative to metal | Ensure compliance with local building codes and standards. |

| Automotive | Cable management systems in vehicle interiors | Enhances organization and safety of electrical systems | Assess durability and temperature resistance for automotive use. |

| Electronics | Housing for circuit boards and electronic components | Provides protection and insulation for sensitive parts | Look for materials that meet specific electrical standards. |

| Agriculture | Framing for greenhouse structures | Increases longevity and reduces maintenance costs | Evaluate UV resistance and flexibility for different climates. |

| Retail | Display fixtures and shelving units | Improves aesthetic appeal and product visibility | Consider customization options and weight-bearing capacities. |

Construction

In the construction industry, plastic L channels are commonly used as structural supports in modular construction systems. Their lightweight nature makes them easy to handle and install, while their corrosion resistance ensures durability over time. For international buyers, especially in regions like Africa and South America, it is crucial to ensure that these materials comply with local building codes and standards to avoid potential legal and safety issues.

Automotive

In the automotive sector, plastic L channels serve as effective cable management systems within vehicle interiors. By organizing and securing electrical wiring, these channels enhance safety and reduce the risk of electrical failures. Buyers from Europe and the Middle East should prioritize sourcing materials that exhibit high durability and temperature resistance to meet the demanding conditions of automotive environments.

Electronics

Plastic L channels are utilized in the electronics industry as housing for circuit boards and various electronic components. They provide essential protection and insulation for sensitive parts, ensuring optimal performance and longevity. When sourcing these materials, international buyers must ensure compliance with specific electrical standards, particularly in regions with stringent regulations regarding electronic safety and quality.

Agriculture

In agricultural applications, plastic L channels are often employed as framing elements for greenhouse structures. Their resistance to weathering and corrosion extends the lifespan of these installations, reducing maintenance costs significantly. Buyers from diverse climates, particularly in Africa and the Middle East, should evaluate the UV resistance and flexibility of these materials to ensure they can withstand local environmental conditions.

Retail

In the retail sector, plastic L channels are frequently used for display fixtures and shelving units. They enhance the aesthetic appeal of product displays while ensuring stability and visibility for merchandise. When sourcing for retail applications, businesses should consider customization options to fit specific design requirements and assess the weight-bearing capacities to ensure safety and functionality.

Related Video: Plastic Processing Overview

Strategic Material Selection Guide for plastic l channel

When selecting materials for plastic L channels, it’s essential to consider the properties, advantages, disadvantages, and specific application impacts of each material. Below are analyses of four common materials used in the production of plastic L channels, tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties: PVC is known for its excellent chemical resistance and durability. It can withstand temperatures up to 60°C (140°F) and has good tensile strength, making it suitable for various applications.

Pros & Cons: PVC is relatively inexpensive and easy to manufacture, allowing for cost-effective production. However, it can become brittle over time when exposed to UV light unless treated. Its rigidity may limit its use in applications requiring flexibility.

Impact on Application: PVC is compatible with a wide range of media, including water and chemicals, making it ideal for plumbing and electrical applications. However, it is not suitable for high-temperature applications due to its lower thermal stability.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding PVC use, as some regions have restrictions due to environmental concerns. Standards such as ASTM D1784 are relevant for assessing the quality of PVC products.

Polypropylene (PP)

Key Properties: Polypropylene boasts a high melting point (up to 160°C or 320°F) and excellent chemical resistance. It is lightweight yet strong, making it a versatile choice for many applications.

Pros & Cons: The primary advantage of PP is its resistance to fatigue, making it ideal for applications that require repeated bending or flexing. However, it can be more expensive than PVC and may require more complex manufacturing processes.

Impact on Application: PP is suitable for applications involving hot liquids and chemicals, providing a reliable option for industries such as food processing and pharmaceuticals. Its low moisture absorption rate enhances its performance in humid environments.

Considerations for International Buyers: When sourcing PP, buyers should verify compliance with food safety standards (like FDA regulations) if applicable. Familiarity with standards such as ISO 105-A02 for color fastness may also be necessary.

Acrylonitrile Butadiene Styrene (ABS)

Key Properties: ABS is known for its toughness and impact resistance, with a temperature range of -20°C to 80°C (-4°F to 176°F). It offers good dimensional stability and is relatively easy to machine.

Pros & Cons: The durability of ABS makes it suitable for high-impact applications, but it can be more expensive than other plastics. Additionally, it has lower chemical resistance compared to PVC and PP, which may limit its use in certain environments.

Impact on Application: ABS is often used in electronic housings and automotive components due to its strength and aesthetic appeal. However, it may not be suitable for applications involving strong solvents.

Considerations for International Buyers: Buyers should consider compliance with electrical standards (such as UL 94 for flammability) when using ABS in electronic applications. Understanding local regulations regarding plastic waste management is also crucial.

High-Density Polyethylene (HDPE)

Key Properties: HDPE is characterized by its high tensile strength and resistance to impact and chemicals. It can withstand temperatures up to 120°C (248°F) and is known for its durability.

Pros & Cons: The primary advantage of HDPE is its excellent resistance to environmental stress cracking, making it ideal for outdoor applications. However, it can be more challenging to bond and may require specialized adhesives.

Impact on Application: HDPE is widely used in applications such as piping and storage tanks due to its chemical resistance and strength. Its flexibility also makes it suitable for various industrial applications.

Considerations for International Buyers: Buyers should ensure that HDPE products meet local environmental regulations and standards such as ASTM D3350 for polyethylene. Understanding the implications of recycling and sustainability in their region is also important.

Summary Table

| Material | Typical Use Case for plastic l channel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Plumbing and electrical applications | Cost-effective and durable | Becomes brittle with UV exposure | Low |

| Polypropylene (PP) | Food processing and pharmaceuticals | High melting point and lightweight | More expensive and complex to manufacture | Med |

| Acrylonitrile Butadiene Styrene (ABS) | Electronic housings and automotive components | Tough and impact-resistant | Lower chemical resistance | Med |

| High-Density Polyethylene (HDPE) | Piping and storage tanks | Excellent environmental stress resistance | Difficult to bond | Med |

This guide provides a comprehensive overview of the materials used in plastic L channels, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic l channel

The manufacturing process for plastic L channels involves several critical stages, each designed to ensure efficiency, quality, and compliance with international standards. For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding these processes is essential for making informed purchasing decisions.

Manufacturing Process

1. Material Preparation

The first step in manufacturing plastic L channels is material preparation. This typically involves selecting high-quality raw materials, such as polypropylene or PVC, which are known for their durability and resistance to environmental factors.

- Material Selection: B2B buyers should ensure that suppliers use materials compliant with relevant industry standards, such as those established by ASTM or ISO.

- Preprocessing: The selected materials may undergo preprocessing steps like drying and milling to achieve the desired consistency and remove moisture, which could affect the final product’s integrity.

2. Forming

Once the materials are prepared, the next stage is forming. This is where the actual shape of the L channel is created.

- Extrusion: The most common technique for producing plastic L channels is extrusion. In this process, raw plastic is melted and forced through a die to create a continuous shape, which is then cut to length.

- Injection Molding: For more complex designs, injection molding may be used, where molten plastic is injected into a mold. This technique allows for intricate shapes and tight tolerances, which may be beneficial for specific applications.

3. Assembly

After forming, the components may require assembly, especially for L channels that are part of larger systems or applications.

- Joining Techniques: Depending on the application, various joining techniques, such as welding or adhesive bonding, may be employed to ensure a strong and durable connection between different parts.

- Customization: B2B buyers should inquire about customization options, as manufacturers may offer tailored solutions based on specific project requirements.

4. Finishing

The final stage in the manufacturing process involves finishing, which enhances the product’s appearance and performance.

- Surface Treatment: This may include processes such as sanding, polishing, or coating to improve aesthetics and protect against corrosion.

- Quality Control: Throughout this stage, manufacturers should implement quality control measures to ensure that finished products meet the specified standards.

Quality Assurance

Quality assurance is paramount in the manufacturing of plastic L channels, ensuring that products meet both international and industry-specific standards.

Relevant International Standards

B2B buyers should be aware of the following standards that govern the quality of plastic products:

- ISO 9001: This is a globally recognized standard that focuses on quality management systems. Manufacturers certified under ISO 9001 demonstrate their commitment to quality through systematic processes.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. Buyers should verify that their suppliers have CE certification where applicable.

Industry-Specific Standards

Depending on the application, additional certifications may be necessary:

- API Standards: For plastic L channels used in the oil and gas industry, compliance with API standards is critical. These standards ensure that materials can withstand harsh environments.

- ASTM Standards: Various ASTM standards pertain to specific plastic materials and their applications, providing guidelines for performance and safety.

Quality Control Checkpoints

Quality control should be integrated throughout the manufacturing process, with several key checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During production, ongoing inspections ensure that the manufacturing process adheres to quality standards.

- Final Quality Control (FQC): After production, finished products are subjected to rigorous testing to confirm they meet all specified requirements.

Common Testing Methods

B2B buyers should familiarize themselves with common testing methods used to evaluate plastic L channels:

- Mechanical Testing: This includes tensile strength, impact resistance, and flexural testing to ensure durability.

- Thermal Testing: Assessing heat resistance and thermal stability is vital, especially for applications exposed to high temperatures.

- Chemical Resistance Testing: This evaluates how well the material withstands various chemicals, which is crucial for industrial applications.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps:

- Supplier Audits: Conducting regular audits of suppliers can help verify compliance with quality standards and production processes. This includes reviewing their quality management systems and production facilities.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including test results and compliance with standards.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality assurance processes and the final product quality.

QC/Cert Nuances for International Buyers

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of several nuances when it comes to quality certification and assurance:

- Regulatory Differences: Different regions may have varying regulations regarding plastic products. Buyers should understand local compliance requirements to ensure that products meet the necessary legal standards.

- Cultural Considerations: Communication and expectations around quality may differ across regions. Establishing clear quality expectations and maintaining open lines of communication with suppliers can help mitigate misunderstandings.

- Documentation: Ensure that all certifications and quality assurance documentation are translated and readily available. This is particularly important for buyers in multilingual regions.

By thoroughly understanding the manufacturing processes and quality assurance protocols for plastic L channels, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This knowledge not only enhances procurement strategies but also fosters stronger relationships with suppliers.

Related Video: Most Amazing Factory Manufacturing Process Videos | Factory Mass Production

Comprehensive Cost and Pricing Analysis for plastic l channel Sourcing

Understanding the cost structure and pricing dynamics of plastic L channels is crucial for international B2B buyers. This analysis focuses on the various components that contribute to the overall cost, the key factors influencing pricing, and actionable tips for making informed purchasing decisions.

Cost Components

-

Materials: The primary raw materials used in manufacturing plastic L channels typically include PVC, ABS, or other thermoplastics. The choice of material impacts both the cost and the quality of the final product. Prices can fluctuate based on global supply and demand, so it is advisable to monitor market trends.

-

Labor: Labor costs are significant in the manufacturing process. These costs vary by region, with labor-intensive countries potentially offering lower costs. However, consider the trade-off between cost and quality, as cheaper labor may lead to inferior manufacturing practices.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Overhead can significantly affect pricing, especially if the manufacturer operates in a high-cost area. Buyers should inquire about the manufacturer’s operational efficiencies to gauge potential cost savings.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are often amortized over the production run, so larger orders can lead to lower per-unit costs. It’s essential to discuss tooling costs upfront when considering custom specifications.

-

Quality Control (QC): Implementing stringent quality control measures adds to the manufacturing cost but is vital for ensuring product reliability. Buyers should ask about the QC processes in place and whether certifications (e.g., ISO) are adhered to, as these can justify higher prices.

-

Logistics: Shipping costs play a significant role in the overall price, particularly for international buyers. Factors such as distance, mode of transport, and Incoterms can influence logistics costs. Buyers should consider local regulations, tariffs, and potential delays in their sourcing strategy.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainability. Understanding the average margins in the industry can provide buyers with leverage during negotiations.

Price Influencers

-

Volume/MOQ: Manufacturers often have a minimum order quantity (MOQ) that can affect pricing. Larger orders usually benefit from volume discounts. Buyers should assess their needs carefully and consider pooling orders with other businesses to meet MOQs.

-

Specifications/Customization: Custom designs and specifications can increase costs. Buyers should weigh the necessity of customization against potential cost increases and explore standard options when possible.

-

Quality/Certifications: Higher quality products and certifications often come at a premium. However, investing in quality can lead to long-term savings through reduced failure rates and warranty claims.

-

Supplier Factors: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers may charge more but often provide better service and reliability.

-

Incoterms: Understanding Incoterms is critical for international transactions. They dictate who is responsible for shipping, insurance, and tariffs, which can dramatically affect the total cost of ownership.

Buyer Tips

-

Negotiate: Always approach negotiations with a clear understanding of your budget and the market landscape. Leverage your purchasing power by discussing volume discounts and payment terms.

-

Focus on Cost-Efficiency: Conduct a thorough analysis of the Total Cost of Ownership (TCO), which includes purchase price, maintenance costs, and logistics expenses. This holistic view can lead to better long-term decisions.

-

Stay Informed: Keep abreast of global market trends and regional economic factors that may impact pricing. This knowledge can provide leverage during negotiations and help in forecasting future costs.

-

Evaluate Multiple Suppliers: Compare quotes from multiple suppliers to ensure competitive pricing. Look beyond the price tag to assess quality and service standards.

-

Understand Pricing Nuances: Be aware of regional differences in pricing strategies. For instance, suppliers in Africa may have different pricing structures compared to those in Europe or the Middle East due to varying market dynamics.

Disclaimer

Prices for plastic L channels can vary widely based on the factors discussed above. This analysis provides indicative insights but should not be construed as definitive pricing. Buyers are encouraged to conduct their own due diligence and obtain specific quotes tailored to their requirements.

Spotlight on Potential plastic l channel Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘plastic l channel’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for plastic l channel

Understanding the essential technical properties and terminology associated with plastic L channels is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This knowledge facilitates informed decision-making and enhances procurement strategies.

Key Technical Properties of Plastic L Channels

-

Material Grade

The material grade indicates the type of plastic used, such as PVC, ABS, or polypropylene. Each grade offers different levels of durability, chemical resistance, and temperature tolerance. For B2B buyers, selecting the appropriate material grade is vital for ensuring that the L channel meets specific application requirements and environmental conditions. -

Dimensional Tolerance

This specification refers to the allowable variation in the dimensions of the plastic L channel. A tighter tolerance ensures a better fit during installation, which is crucial in applications requiring precision. For buyers, understanding tolerance levels can prevent costly rework and ensure compatibility with existing systems. -

Load Capacity

Load capacity defines the maximum weight or pressure that the plastic L channel can withstand without deforming. This property is particularly important in construction and manufacturing applications where structural integrity is essential. B2B buyers must evaluate load capacity to ensure that the channels will support their intended use without failure. -

UV Resistance

UV resistance indicates the material’s ability to withstand degradation from exposure to ultraviolet light. This property is particularly relevant for outdoor applications or in regions with high sun exposure. Buyers should prioritize UV resistance to ensure the longevity of the product and reduce replacement costs over time. -

Color and Finish Options

While often overlooked, the color and finish of plastic L channels can affect aesthetic appeal and visibility in certain applications. Various options allow buyers to choose products that align with branding or safety standards. Understanding available finishes helps buyers meet both functional and aesthetic requirements.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of plastic L channels, knowing whether a supplier is an OEM can affect pricing, quality assurance, and delivery timelines. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory levels and budgeting effectively. It may also influence sourcing decisions, especially for smaller businesses or those with limited storage capacity. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price and delivery information for specific products. For buyers, issuing an RFQ allows for comparative analysis of suppliers, ensuring they receive competitive pricing and favorable terms. -

Incoterms

International Commercial Terms (Incoterms) are a series of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand shipping costs and risk management during transportation. -

Lead Time

Lead time refers to the period from placing an order until the product is delivered. For B2B buyers, understanding lead times is crucial for project planning and inventory management. Longer lead times may necessitate adjustments in production schedules or sourcing strategies. -

Certification Standards

Certification standards are qualifications that a product meets specific industry or safety regulations. For plastic L channels, certifications can include environmental impact standards or structural integrity tests. Buyers should verify certifications to ensure compliance with local regulations and enhance product credibility.

By grasping these technical properties and terminology, B2B buyers can make informed decisions, streamline procurement processes, and foster successful supplier relationships in the competitive landscape of plastic L channels.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the plastic l channel Sector

Market Overview & Key Trends

The plastic l channel sector is experiencing significant transformation driven by several global factors. A notable surge in demand for lightweight, durable materials in various industries, including construction and automotive, is propelling growth. The rise of B2B e-commerce is also reshaping how businesses source materials, with projections indicating continued annual growth in online transactions. International buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly leveraging digital platforms to streamline procurement processes, enhance supplier visibility, and reduce costs.

Emerging technologies, such as AI-driven procurement tools and blockchain for supply chain transparency, are becoming essential for B2B buyers. These innovations not only improve efficiency but also enable better tracking of supplier performance and compliance with industry standards. Furthermore, the ongoing digital transformation in B2B transactions is pushing suppliers to adopt more agile and responsive business models, which is particularly beneficial for buyers looking to optimize their supply chains.

Market dynamics are also influenced by geopolitical factors and trade agreements, which can affect pricing and availability of materials. Buyers must stay informed about regional developments that could impact sourcing strategies, including tariffs and import regulations, especially when dealing with suppliers from diverse regions like Nigeria and Saudi Arabia.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a priority for businesses in the plastic l channel sector. The environmental impact of plastic production and waste is significant, prompting buyers to seek ethical sourcing practices that minimize harm to the planet. Companies are now expected to adopt sustainable materials, such as recycled plastics and biodegradable alternatives, which align with global efforts to reduce carbon footprints.

Incorporating green certifications into procurement processes is also gaining traction. Certifications such as ISO 14001 (Environmental Management) and the Global Recycle Standard (GRS) help buyers identify suppliers committed to sustainable practices. These certifications not only enhance brand reputation but also fulfill regulatory requirements and consumer expectations for environmentally responsible products.

Moreover, fostering ethical supply chains that prioritize fair labor practices and transparency is crucial. Buyers from regions with varying regulatory environments must ensure that their sourcing strategies align with international standards, thereby mitigating risks related to labor exploitation and environmental degradation.

Brief Evolution/History

The plastic l channel has evolved significantly over the last few decades, transitioning from traditional, localized sourcing methods to a more globalized and digitized landscape. Initially dominated by regional suppliers, the sector has expanded due to technological advancements and the globalization of trade. The introduction of B2B e-commerce platforms has revolutionized how businesses interact with suppliers, enabling easier access to a wider array of products and competitive pricing.

As environmental concerns gained prominence in the late 20th century, the industry began to shift towards more sustainable practices. This evolution continues today, with increasing pressure from consumers and regulatory bodies for businesses to adopt environmentally friendly practices. The drive towards sustainability is reshaping not only sourcing strategies but also product development within the plastic l channel sector.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of plastic l channel

-

What should I consider when vetting suppliers for plastic l channels?

When vetting suppliers, prioritize their experience in the industry and customer reviews. Verify their manufacturing capabilities, quality control processes, and compliance with international standards. Request documentation such as ISO certifications and product specifications. Additionally, consider their financial stability, production capacity, and ability to meet your specific needs, including customization options. Engaging with suppliers through video calls can also help assess their facilities and operations. -

Can plastic l channels be customized to meet specific requirements?

Yes, many suppliers offer customization options for plastic l channels. This can include variations in size, color, material, and design to fit your project specifications. When discussing customization, clearly communicate your requirements and request samples to ensure the final product meets your expectations. Be mindful that customization may affect minimum order quantities (MOQs) and lead times, so factor this into your procurement planning. -

What are typical minimum order quantities (MOQs) and lead times for plastic l channels?

MOQs can vary significantly among suppliers, often ranging from 500 to 5,000 units, depending on the material and complexity of the product. Lead times typically span from 2 to 6 weeks, influenced by factors such as order size, supplier location, and production schedules. Always confirm these details upfront to avoid unexpected delays and to ensure that your project timelines align with the supplier’s capabilities. -

What payment options are available for international purchases of plastic l channels?

International suppliers commonly accept various payment methods, including wire transfers, letters of credit, and online payment platforms. Each method has its pros and cons; for instance, letters of credit provide security for both parties but may involve higher fees. Always clarify payment terms, including deposits and final payment schedules, and consider negotiating favorable terms based on your purchasing volume or relationship with the supplier.

Illustrative Image (Source: Google Search)

-

How do I ensure quality assurance and certification for plastic l channels?

To ensure quality, request certifications such as ISO 9001 or product-specific compliance documents. It’s essential to establish a quality assurance process, which may include third-party inspections or audits of the supplier’s manufacturing practices. Additionally, consider implementing a quality control plan that outlines testing procedures, acceptance criteria, and remedies for any non-conformance issues, ensuring that the products meet your standards before shipment. -

What logistics considerations should I keep in mind when sourcing plastic l channels?

Logistics play a crucial role in international sourcing. Ensure you understand the shipping options available, including air freight for speed or sea freight for cost-effectiveness. Evaluate the supplier’s shipping capabilities, including packaging and labeling compliance with your country’s import regulations. Additionally, consider customs duties, taxes, and potential delays at borders. Collaborating with a logistics partner can streamline this process and help manage any complexities. -

How can I resolve disputes with suppliers effectively?

To resolve disputes, start by reviewing the contractual agreements and terms of service to understand your rights and obligations. Open communication is key; discuss the issue directly with the supplier to seek a mutual resolution. If necessary, escalate the matter to a higher management level. If disputes persist, consider mediation or arbitration as outlined in your contract. Maintaining a professional relationship throughout the process can often lead to more satisfactory outcomes. -

What should I do if I receive defective plastic l channels?

If you receive defective products, document the issues with photos and detailed descriptions, then contact the supplier immediately. Follow the established return and warranty policies outlined in your agreement. Be prepared to negotiate a solution, which may include replacements, repairs, or refunds. If the supplier is unresponsive, consider escalating the issue through formal channels, such as trade associations or legal avenues, depending on the severity of the defect and the terms of your contract.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for plastic l channel

The landscape of strategic sourcing for plastic L channels presents a wealth of opportunities for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. Key takeaways from this guide emphasize the importance of embracing digital transformation, leveraging B2B eCommerce platforms, and prioritizing sustainable sourcing practices. By implementing a robust procurement strategy, organizations can streamline their supply chain, reduce costs, and enhance product quality.

Strategic sourcing not only fosters better supplier relationships but also equips businesses with the agility to respond to market changes. As demand for plastic L channels continues to grow, companies that adopt a data-driven approach to sourcing will position themselves advantageously. This includes analyzing market trends, understanding supplier capabilities, and continuously optimizing procurement processes.

Looking ahead, international B2B buyers are encouraged to seize these opportunities by investing in innovative technologies and strategic partnerships. Engaging with local suppliers while exploring global markets will be crucial for sustained growth. By taking proactive steps today, businesses can ensure they remain competitive and responsive to the evolving demands of their industries.

Illustrative Image (Source: Google Search)