Master Sourcing Plastic Sheet with Holes for Optimal B2B

Introduction: Navigating the Global Market for plastic sheet with holes

In today’s competitive global marketplace, plastic sheets with holes have become indispensable components across a myriad of industries, including packaging, construction, and automotive. These versatile materials are engineered to enhance airflow, light diffusion, and aesthetic appeal while maintaining durability and resistance to environmental factors. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to optimize their sourcing strategies, understanding the intricacies of perforated plastic sheets is crucial for making informed decisions.

This comprehensive guide delves into the diverse types of perforated plastic sheets, covering their unique properties and applications. It provides in-depth insights into the manufacturing processes and quality control measures that ensure product reliability, allowing buyers to assess supplier capabilities effectively. Additionally, the guide addresses cost considerations and current market trends, equipping buyers with the knowledge needed for effective negotiation and budgeting.

Furthermore, a dedicated FAQ section tackles common queries, clarifying complexities in sourcing and logistics. By empowering B2B buyers with actionable insights and a thorough understanding of the market landscape, this guide serves as an essential resource for fostering collaboration with suppliers and driving business growth in a rapidly evolving global economy.

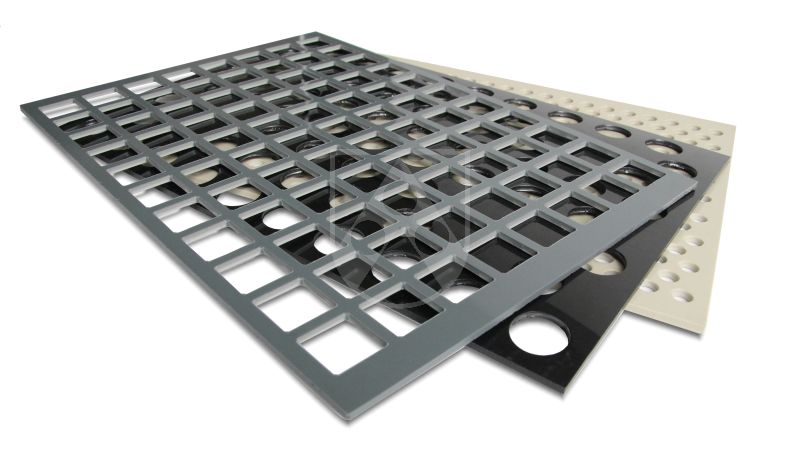

Understanding plastic sheet with holes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Perforated Polyethylene | Lightweight, moisture-resistant, customizable hole patterns | Agriculture, packaging, filtration | Pros: Cost-effective, versatile; Cons: Limited UV resistance |

| Perforated Polycarbonate | High impact resistance, excellent thermal stability | Safety equipment, automotive parts | Pros: Durable, suitable for harsh environments; Cons: Higher cost |

| Perforated PVC | Rigid, available in various colors, good chemical resistance | Construction, signage, HVAC | Pros: Affordable, easy to work with; Cons: Less durable under stress |

| Micro-perforated Films | Extremely fine holes, maintains material integrity | Food packaging, breathable films | Pros: Enhanced breathability, moisture control; Cons: Limited mechanical strength |

| Perforated Acrylic | High clarity, UV resistant, aesthetic appeal | Displays, decorative panels | Pros: Excellent light transmission; Cons: Prone to scratching |

Perforated Polyethylene

Perforated polyethylene sheets are known for their lightweight and moisture-resistant properties, making them ideal for agricultural applications such as crop covers and drainage systems. They can be customized with various hole patterns to suit specific ventilation or filtration needs. When sourcing, buyers should consider the thickness and UV resistance, especially for outdoor applications, as prolonged exposure may affect durability.

Perforated Polycarbonate

These sheets are highly valued in industries requiring durability and impact resistance, such as safety equipment and automotive applications. Their excellent thermal stability allows them to perform well in extreme conditions. Buyers should weigh the higher costs against the long-term benefits of enhanced safety and longevity, particularly in high-risk environments where material failure is not an option.

Perforated PVC

Perforated PVC sheets offer a cost-effective solution for construction, signage, and HVAC systems. They are available in various colors and thicknesses, allowing for versatile design applications. Buyers must consider the specific environmental conditions, as while PVC is affordable and easy to work with, it may not withstand high-stress scenarios as effectively as other materials.

Micro-perforated Films

Micro-perforated films feature extremely fine holes that allow for breathability while maintaining the integrity of the material. This makes them particularly suitable for food packaging, where moisture control is essential. Buyers should evaluate the balance between breathability and mechanical strength, as these films may not be suitable for applications requiring robust structural support.

Perforated Acrylic

Perforated acrylic sheets are prized for their high clarity and aesthetic appeal, making them ideal for displays and decorative panels. Their UV resistance ensures longevity in outdoor applications. However, buyers should be mindful of their susceptibility to scratching, which can detract from their visual quality. When sourcing, consider the thickness and specific application requirements to ensure optimal performance.

Related Video: Understanding Plastic Deformation Mechanisms | Skill-Lync

Key Industrial Applications of plastic sheet with holes

| Industry/Sector | Specific Application of plastic sheet with holes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Ventilated greenhouse covers | Enhances airflow and temperature regulation | Look for UV-resistant materials; consider local climate impacts. |

| Construction | Sound attenuation panels | Reduces noise pollution in urban areas | Ensure compliance with building codes; assess material durability. |

| Packaging | Breathable packaging films | Extends shelf life of perishable goods | Evaluate perforation size for specific product needs; check for food safety compliance. |

| Automotive | Interior paneling for ventilation | Improves air circulation and reduces weight | Confirm material compatibility with vehicle standards; focus on impact resistance. |

| Medical | Air filtration membranes | Maintains sterile environments in healthcare | Verify regulatory compliance; assess filtration efficiency and durability. |

Agriculture

In the agriculture sector, perforated plastic sheets are commonly used as ventilated greenhouse covers. These sheets facilitate airflow and temperature regulation, crucial for optimizing plant growth. International buyers should prioritize UV-resistant materials to ensure longevity and performance in varying climates. Additionally, understanding local agricultural practices and climate conditions can guide the selection of appropriate sheet thickness and hole size for maximum efficiency.

Construction

In construction, plastic sheets with holes serve as sound attenuation panels, significantly reducing noise pollution in urban environments. These panels can be integrated into building facades or used as internal partitions. Buyers must ensure that the materials comply with local building codes and standards, particularly regarding fire resistance and structural integrity. Additionally, evaluating the durability of the sheets against environmental factors is essential for long-term performance.

Illustrative Image (Source: Google Search)

Packaging

Breathable packaging films made from perforated plastic sheets are vital in the food packaging industry. These films allow for gas exchange, extending the shelf life of perishable goods like fruits and vegetables. For B2B buyers, evaluating the perforation size is critical to meet specific product needs, such as moisture control and respiration rates. Furthermore, ensuring compliance with food safety regulations is paramount to avoid contamination and maintain product quality.

Automotive

In the automotive industry, perforated plastic sheets are utilized for interior paneling, enhancing ventilation while reducing overall vehicle weight. This application supports better air circulation within the vehicle, contributing to passenger comfort. Buyers should confirm material compatibility with industry standards, particularly regarding impact resistance and fire safety. Additionally, understanding the specific requirements of different vehicle models can aid in sourcing the right materials.

Medical

Perforated plastic sheets find application in air filtration membranes in healthcare settings. These membranes are crucial for maintaining sterile environments, particularly in operating rooms and laboratories. Buyers in this sector must verify that the materials meet stringent regulatory compliance standards. Assessing the filtration efficiency and durability of the sheets is also essential to ensure they perform effectively under varying conditions, thus safeguarding public health.

Related Video: Manual Acrylic Bending Machine for PP, Plexiglass, Plastic sheet, organic glass

Strategic Material Selection Guide for plastic sheet with holes

When selecting materials for perforated plastic sheets, it is essential to consider the unique properties and applications of various plastics. This guide analyzes four common materials—Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), and Polycarbonate (PC)—focusing on their performance characteristics, advantages, disadvantages, and specific considerations for international B2B buyers.

Polyethylene (PE)

Key Properties:

Polyethylene is known for its excellent chemical resistance and low-temperature flexibility. It can withstand temperatures up to 80°C (176°F) and has good impact resistance.

Pros & Cons:

PE is lightweight and cost-effective, making it a popular choice for various applications. However, it has limited UV resistance, which can lead to degradation when exposed to sunlight over time.

Impact on Application:

PE is compatible with a wide range of media, including water and various chemicals, making it suitable for applications like drainage and filtration systems.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding plastic materials, especially in food-related applications. Familiarity with standards such as ASTM D1248 or EN 13501 can aid in sourcing the right products.

Polypropylene (PP)

Key Properties:

Polypropylene boasts higher temperature resistance than PE, withstanding temperatures up to 100°C (212°F). It also exhibits excellent fatigue resistance and chemical stability.

Pros & Cons:

PP is durable and has a good strength-to-weight ratio, making it ideal for applications requiring rigidity. However, it can be more expensive than PE and may require more complex manufacturing processes.

Impact on Application:

PP is particularly suitable for applications involving exposure to solvents and chemicals, such as in the automotive and medical sectors.

Considerations for International Buyers:

Buyers in regions with stringent safety regulations should ensure that the PP sheets meet relevant standards like ISO 105-B02 for color fastness and ASTM D638 for tensile strength.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a versatile material with good chemical resistance and can endure temperatures up to 60°C (140°F). It is also known for its rigidity and durability.

Pros & Cons:

PVC sheets are cost-effective and available in various colors, making them suitable for decorative applications. However, they can be less durable under high-stress conditions and may release harmful chemicals when burned.

Impact on Application:

PVC is widely used in construction and signage due to its rigidity and aesthetic options. It is also suitable for applications where moisture resistance is essential.

Considerations for International Buyers:

Buyers should be aware of regional regulations concerning the use of PVC, especially in the EU, where compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is critical.

Polycarbonate (PC)

Key Properties:

Polycarbonate is known for its exceptional impact resistance and can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F). It also offers high clarity and UV resistance.

Pros & Cons:

While PC is more expensive than other plastics, its durability and safety features justify the cost in high-risk applications. However, it can be prone to scratching if not treated properly.

Impact on Application:

PC is ideal for applications requiring transparency and strength, such as safety barriers and glazing.

Considerations for International Buyers:

Buyers should verify that the polycarbonate sheets meet international standards such as ASTM D5767 for optical clarity and impact resistance, particularly for safety applications.

Summary Table

| Material | Typical Use Case for plastic sheet with holes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Drainage and filtration systems | Excellent chemical resistance | Limited UV resistance | Low |

| Polypropylene | Automotive and medical applications | High temperature resistance | More expensive than PE | Medium |

| Polyvinyl Chloride | Construction and signage | Cost-effective and versatile | Less durable under stress | Low |

| Polycarbonate | Safety barriers and glazing | Exceptional impact resistance | Prone to scratching | High |

This guide aims to equip international B2B buyers with the knowledge necessary to make informed decisions regarding the selection of perforated plastic sheets, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic sheet with holes

In the competitive landscape of B2B sourcing for perforated plastic sheets, understanding the manufacturing processes and quality assurance practices is essential for international buyers. This section provides a detailed overview of the typical manufacturing stages, key techniques employed, and the critical quality control (QC) measures that ensure product reliability and compliance with international standards.

Manufacturing Processes for Perforated Plastic Sheets

The production of perforated plastic sheets involves several key stages that collectively ensure the final product meets the specific needs of various industries.

1. Material Preparation

The first step in the manufacturing process is selecting the appropriate plastic material. Commonly used materials include polyethylene (PE), polypropylene (PP), PVC, and high-density polyethylene (HDPE). Each type of plastic offers distinct properties such as chemical resistance, durability, and flexibility, which influence the final application of the perforated sheets. Once the material is chosen, it undergoes preparation, which may include:

- Pelletizing: Transforming raw plastic into pellets for easy handling and feeding into the production line.

- Melting: Heating the plastic to a specific temperature to achieve a workable state.

2. Forming

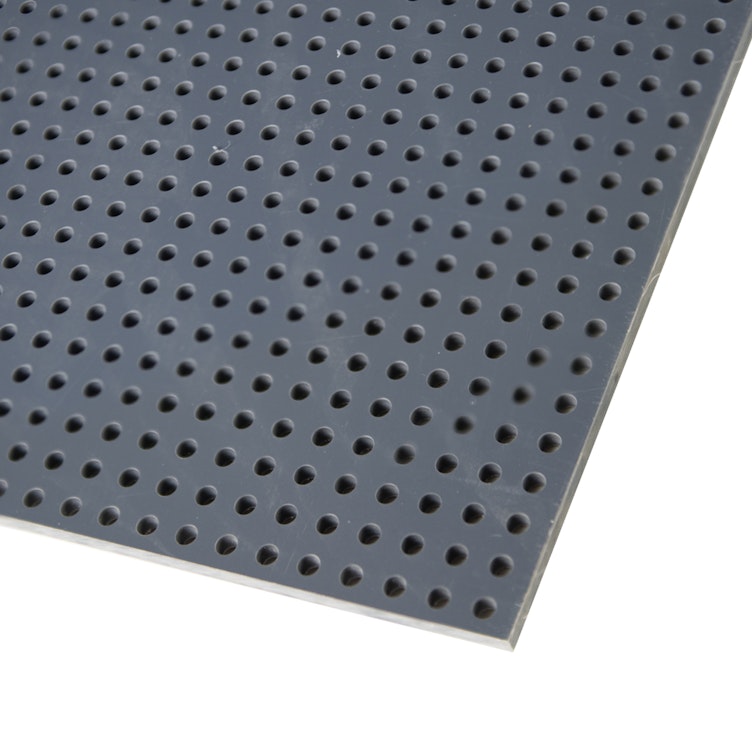

During the forming stage, the prepared plastic is processed using specialized perforating machinery. Key techniques include:

- Hot and Cold Pin Rotary Perforation: This method utilizes rotating pins to create holes. The hot pin method cauterizes edges to prevent fraying, while the cold pin method produces clean holes without heat.

- Laser Perforation: A high-precision technique that uses lasers to create micro-perforations, ideal for applications requiring minimal hole size and clean edges.

- Die Punching: A traditional method where a die is used to punch holes in the plastic sheet, suitable for lower production volumes.

Each of these techniques allows for custom hole patterns and sizes, accommodating specific client requirements.

3. Assembly

While perforated sheets are often used as standalone products, they may sometimes require assembly with other components. This could involve:

- Laminating: Bonding multiple layers of plastic for enhanced strength and insulation.

- Trimming and Cutting: Ensuring the sheets are cut to the precise dimensions required by the buyer.

4. Finishing

The finishing stage involves surface treatments that enhance the properties of the perforated sheets. Processes may include:

- Coating: Applying a protective layer to improve UV resistance or chemical stability.

- Polishing: Enhancing the aesthetic appeal and surface smoothness.

Quality Assurance Practices

Quality assurance is crucial in ensuring that perforated plastic sheets meet both functional and safety standards. International B2B buyers should be aware of the following quality control measures and standards.

Relevant International Standards

Several international standards guide the quality assurance processes for plastic manufacturing. Key standards include:

- ISO 9001: Focuses on quality management systems and ensures consistent quality in products and services.

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: Applicable for products used in the oil and gas industry, ensuring that materials meet specific performance criteria.

QC Checkpoints

Quality control is typically structured around several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet the specified requirements before production begins.

- In-Process Quality Control (IPQC): Regular checks during production to monitor processes and identify any deviations from standards.

- Final Quality Control (FQC): Comprehensive testing of the finished products to ensure they meet all specifications before shipping.

Common Testing Methods

B2B buyers should be familiar with common testing methods used to verify product quality, including:

- Dimensional Inspection: Measuring thickness, width, and length to ensure compliance with specifications.

- Mechanical Testing: Evaluating tensile strength, flexibility, and impact resistance.

- Chemical Resistance Testing: Assessing how the material withstands exposure to various chemicals, particularly for applications in sensitive environments.

Verifying Supplier Quality Control

To ensure that suppliers meet quality standards, B2B buyers should implement the following verification strategies:

- Audits: Conduct regular audits of suppliers’ manufacturing facilities to assess compliance with quality standards and practices.

- Quality Reports: Request detailed quality assurance reports that outline testing methods, results, and any corrective actions taken.

- Third-Party Inspection: Engage independent third-party inspectors to conduct comprehensive evaluations of the supplier’s processes and products.

Quality Control Nuances for International Buyers

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several nuances in quality control:

- Cultural and Regulatory Differences: Be aware of varying regulatory requirements across regions. What is acceptable in one market may not be in another.

- Logistical Challenges: Understand the implications of shipping and handling on product quality. Ensure suppliers have robust logistics systems in place to minimize damage during transit.

- Long-Term Relationships: Building strong relationships with suppliers can enhance communication regarding quality issues and foster a culture of continuous improvement.

By comprehensively understanding the manufacturing processes and quality assurance measures for perforated plastic sheets, B2B buyers can make informed purchasing decisions that align with their operational needs and industry standards. This knowledge will ultimately facilitate smoother transactions and enhance collaboration with suppliers, driving business success in a competitive market.

Related Video: PET Plastic Bottle Manufacturing Process Step-by-Step Introduction

Comprehensive Cost and Pricing Analysis for plastic sheet with holes Sourcing

Understanding the cost structure and pricing for perforated plastic sheets is crucial for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. This analysis will provide insights into the various cost components involved, factors influencing pricing, and strategic tips for effective sourcing.

Cost Components

-

Materials: The choice of plastic (e.g., polyethylene, polypropylene, PVC) significantly impacts the overall cost. Higher quality materials that offer better durability and resistance to environmental factors usually come at a premium.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and the complexity of the manufacturing process. Regions with lower labor costs may provide a competitive advantage, but this must be weighed against quality and reliability.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, maintenance, and equipment depreciation. Efficient production processes can help minimize these costs.

-

Tooling: Custom tooling for specific perforation patterns can be a significant upfront investment. The complexity of the design will affect the cost, with more intricate patterns requiring advanced machinery.

-

Quality Control (QC): Implementing rigorous quality control measures is essential to ensure product consistency and compliance with international standards. This can add to the overall production cost but is critical for maintaining customer trust.

-

Logistics: Shipping costs are often a major component in the total cost structure. Factors such as distance, mode of transport, and customs duties will affect logistics expenses. Understanding Incoterms is vital to clarify who bears these costs.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary widely based on market conditions, competition, and perceived value of the product.

Price Influencers

-

Volume/MOQ: Larger order volumes often lead to lower per-unit prices due to economies of scale. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

-

Specifications/Customization: Custom perforation patterns and specific material types can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Quality/Certifications: Products that meet international quality standards or certifications (e.g., ISO, FDA) may command higher prices but provide assurance regarding product reliability and safety.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer higher prices but provide better service and quality assurance.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial. These terms dictate the responsibilities of buyers and sellers regarding shipping costs and risks, which can significantly affect overall pricing.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing, especially when placing bulk orders. Highlighting long-term partnerships can also lead to better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, installation, and potential maintenance costs over the product’s lifecycle.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local market conditions that may affect pricing. Buyers in regions like Africa and South America should factor in these variables when budgeting for imports.

-

Supplier Comparison: Don’t hesitate to compare multiple suppliers to find the best combination of price, quality, and service. Utilize platforms that provide reviews and ratings to make informed decisions.

Disclaimer

The prices mentioned in this analysis are indicative and can fluctuate based on market dynamics, supplier negotiations, and changes in raw material costs. Buyers are encouraged to conduct thorough market research and engage directly with suppliers for the most accurate and current pricing information.

Spotlight on Potential plastic sheet with holes Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘plastic sheet with holes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for plastic sheet with holes

Key Technical Properties of Plastic Sheets with Holes

When sourcing plastic sheets with holes, several technical properties are critical to ensure the product meets specific application requirements. Understanding these properties can help B2B buyers make informed decisions.

-

Material Grade: The choice of material affects durability, flexibility, and resistance to environmental factors. Common materials include Polyethylene (PE), Polypropylene (PP), and Polyvinyl Chloride (PVC). Each material has unique properties suitable for different applications, such as chemical resistance or lightweight characteristics. Selecting the right grade is vital for achieving the desired performance in specific environments.

-

Hole Size and Shape: The dimensions and geometry of the holes directly influence airflow, drainage, and aesthetic appeal. Common shapes include round, square, and custom designs. Buyers must specify hole size to ensure compatibility with their application, such as filtration or sound attenuation, thereby optimizing functionality.

-

Thickness: The thickness of the plastic sheet can affect its strength and application suitability. Thicker sheets tend to provide greater durability and resistance to impact, making them ideal for demanding environments. Buyers should assess the required thickness based on the intended use, ensuring that the sheet can withstand expected stresses.

-

Tolerance Levels: Tolerance refers to the allowable deviation from specified dimensions. Tight tolerances are essential for applications requiring precision, such as in manufacturing or construction. Understanding tolerance levels helps buyers ensure that the perforated sheets will fit seamlessly into their operational processes, reducing the risk of errors and increasing efficiency.

-

Chemical Resistance: This property is particularly important for applications in industries like agriculture, food processing, or chemical handling. Buyers should evaluate the chemical resistance of the material to ensure it can withstand exposure to specific substances without degrading or losing functionality.

Common Trade Terminology

Familiarity with industry jargon can facilitate smoother negotiations and procurement processes. Here are several key terms relevant to B2B transactions involving plastic sheets with holes:

-

OEM (Original Equipment Manufacturer): Refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of plastic sheets, understanding OEM relationships can help buyers identify reliable suppliers who can provide consistent quality.

-

MOQ (Minimum Order Quantity): The smallest number of units that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to ensure that their purchasing volume aligns with supplier capabilities, thereby avoiding excess inventory or stock shortages.

-

RFQ (Request for Quotation): A document sent to suppliers requesting pricing and other details for specific products. An RFQ helps buyers compare offers and negotiate better terms, making it a vital tool in the procurement process.

-

Incoterms: Short for International Commercial Terms, these are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for buyers to clarify shipping responsibilities, insurance, and risk during transport, thus preventing misunderstandings.

-

Lead Time: The time it takes from placing an order until the product is delivered. Knowing lead times is critical for supply chain management, as it affects project timelines and inventory levels.

-

Customization Options: Refers to the ability to tailor the product specifications, such as hole pattern, size, and material type, to meet specific needs. Buyers should inquire about customization capabilities to ensure the product aligns perfectly with their applications.

By grasping these technical properties and terms, international B2B buyers can navigate the procurement process more effectively, ensuring they select the right products to meet their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the plastic sheet with holes Sector

Market Overview & Key Trends

The global market for perforated plastic sheets is experiencing robust growth, driven by increasing demand across various sectors such as construction, automotive, and packaging. Key factors influencing this growth include the rising need for lightweight materials that offer durability and versatility, along with a shift towards more sustainable building practices. In regions like Africa and South America, infrastructure development projects are fueling demand, while in Europe and the Middle East, regulatory frameworks are promoting the use of eco-friendly materials.

Emerging B2B technologies, such as advanced manufacturing processes and digital supply chain management, are reshaping sourcing strategies. Automation and precision engineering are enhancing production efficiency, allowing manufacturers to meet custom specifications at scale. For international buyers, particularly those in developing markets, leveraging digital platforms to connect with suppliers can streamline procurement processes and facilitate better negotiation terms. Additionally, trends towards customization are gaining traction, with buyers increasingly seeking tailored solutions that align with specific project requirements.

Understanding local market dynamics is crucial for buyers. For instance, the increased focus on energy efficiency and reduced environmental impact is influencing purchasing decisions. Buyers should stay informed about regional regulations and standards that may affect sourcing, ensuring compliance while optimizing their supply chains.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration in the sourcing of perforated plastic sheets. The environmental impact of plastic production is significant, and international buyers are increasingly prioritizing suppliers who adhere to sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and responsible waste management.

Ethical supply chains are essential for maintaining brand reputation and customer trust. Buyers should look for suppliers with certifications such as ISO 14001 for environmental management and other recognized ‘green’ certifications. These credentials signal a commitment to sustainability and ethical sourcing practices. Furthermore, the adoption of biodegradable or compostable alternatives to traditional plastics is gaining momentum, providing buyers with options that align with their sustainability goals.

Engaging with suppliers who prioritize transparency in their sourcing practices can also mitigate risks associated with unethical labor practices and environmental degradation. By fostering partnerships with responsible manufacturers, international buyers can contribute to a more sustainable future while enhancing their competitive advantage in the marketplace.

Brief Evolution/History

The development of perforated plastic sheets can be traced back to the mid-20th century when advancements in plastic manufacturing technology began to emerge. Initially used for basic applications in packaging and construction, the versatility of perforated plastics quickly gained recognition in diverse sectors. As industries evolved, so did the manufacturing processes, leading to the adoption of more sophisticated techniques such as laser perforation and CNC machining.

In recent years, the focus has shifted towards sustainability and customization, reflecting broader societal trends. Innovations in materials science have enabled the production of eco-friendly alternatives, while digital design tools allow for precise customization of perforation patterns. This evolution not only meets the increasing demand for functional and aesthetically pleasing products but also aligns with the global push for sustainable practices in manufacturing and sourcing.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of plastic sheet with holes

-

How can I effectively vet suppliers for perforated plastic sheets?

When vetting suppliers, prioritize their experience in manufacturing perforated plastic sheets. Look for companies with certifications such as ISO 9001, which indicates a commitment to quality management. Request samples to evaluate product quality and assess their production capabilities. Additionally, check references and reviews from other international buyers, particularly those from your region, to gauge reliability and service quality. Engaging with suppliers through video calls can also provide insights into their operations and professionalism. -

Can I customize the design and specifications of perforated plastic sheets?

Yes, most reputable manufacturers offer customization options. When discussing your requirements, provide detailed specifications, including hole size, pattern, thickness, and material type. Utilize CAD designs to communicate your vision accurately. Ensure that the supplier has the capability to produce your desired customizations and ask for prototypes to confirm that the final product meets your expectations before committing to a larger order. -

What are the typical minimum order quantities (MOQ) and lead times for perforated plastic sheets?

MOQs can vary significantly between suppliers, often influenced by the complexity of the customization and the production process. Generally, expect MOQs ranging from 100 to 1,000 units. Lead times typically range from 2 to 6 weeks, depending on the supplier’s production capacity and your order’s complexity. Always confirm these details upfront to plan your inventory and avoid disruptions in your supply chain. -

What payment options are commonly available for international B2B transactions?

Payment options for international transactions usually include wire transfers, letters of credit, and PayPal. Wire transfers are the most common, but they may lack buyer protection. Letters of credit provide more security as they involve banks that guarantee payment upon meeting specific conditions. Discuss with your supplier which payment methods they accept and consider using escrow services for high-value transactions to safeguard your investment. -

How can I ensure quality assurance and certification compliance?

To ensure quality assurance, request documentation of the supplier’s quality control processes, including any relevant certifications like ISO or ASTM. Ask for test results from third-party laboratories that verify material specifications and performance characteristics. Establish clear quality expectations in your purchase agreement, and consider incorporating a quality inspection prior to shipment to confirm that the products meet your standards. -

What logistics considerations should I keep in mind when importing perforated plastic sheets?

Logistics is crucial in international trade. Confirm shipping methods with your supplier—air freight is faster but more expensive, while sea freight is cost-effective for larger volumes but takes longer. Understand the customs regulations in your country to avoid delays, and ensure all necessary documentation (e.g., commercial invoice, bill of lading) is prepared. Consider working with a freight forwarder who can navigate these complexities and provide guidance on duties and taxes. -

What should I do if I encounter a dispute with my supplier?

In the event of a dispute, first attempt to resolve the issue directly with the supplier through open communication. Document all correspondence and agreements to support your case. If resolution fails, consider mediation or arbitration as a more amicable approach than litigation. Review your contract for dispute resolution clauses and involve legal counsel if necessary. Establishing a good relationship with your supplier from the outset can help prevent disputes and facilitate resolution. -

Are there specific industry standards or regulations I should be aware of when sourcing perforated plastic sheets?

Yes, industry standards vary by application and region. For instance, if the sheets are intended for food packaging, ensure compliance with food safety regulations, such as FDA standards in the U.S. or EFSA in Europe. Additionally, check for environmental regulations regarding plastic use and recycling in your region. Understanding these regulations not only ensures compliance but also enhances your brand’s reputation by demonstrating commitment to safety and sustainability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for plastic sheet with holes

In summary, strategic sourcing of perforated plastic sheets is essential for international B2B buyers seeking to enhance their supply chains and meet diverse application needs across various industries. Understanding the manufacturing processes and the unique properties of different plastic types, such as polyethylene and polycarbonate, allows buyers to make informed decisions that align with their operational requirements.

Buyers from Africa, South America, the Middle East, and Europe should prioritize establishing strong relationships with reputable suppliers who can offer customized solutions and maintain high-quality standards. Leveraging the insights provided in this guide will empower businesses to negotiate better pricing, ensure timely delivery, and achieve optimal performance in their applications.

As the global market continues to evolve, staying ahead of industry trends and technological advancements in perforated plastic sheets will be crucial. Engaging with suppliers and participating in industry discussions can provide valuable knowledge and foster innovation. Take the next step in your strategic sourcing journey—evaluate your current suppliers, explore new partnerships, and invest in the future of your business with perforated plastic sheets that meet your specific needs.