Master Sourcing Push Button Electrical Switches for Maximum

Introduction: Navigating the Global Market for push button electrical switch

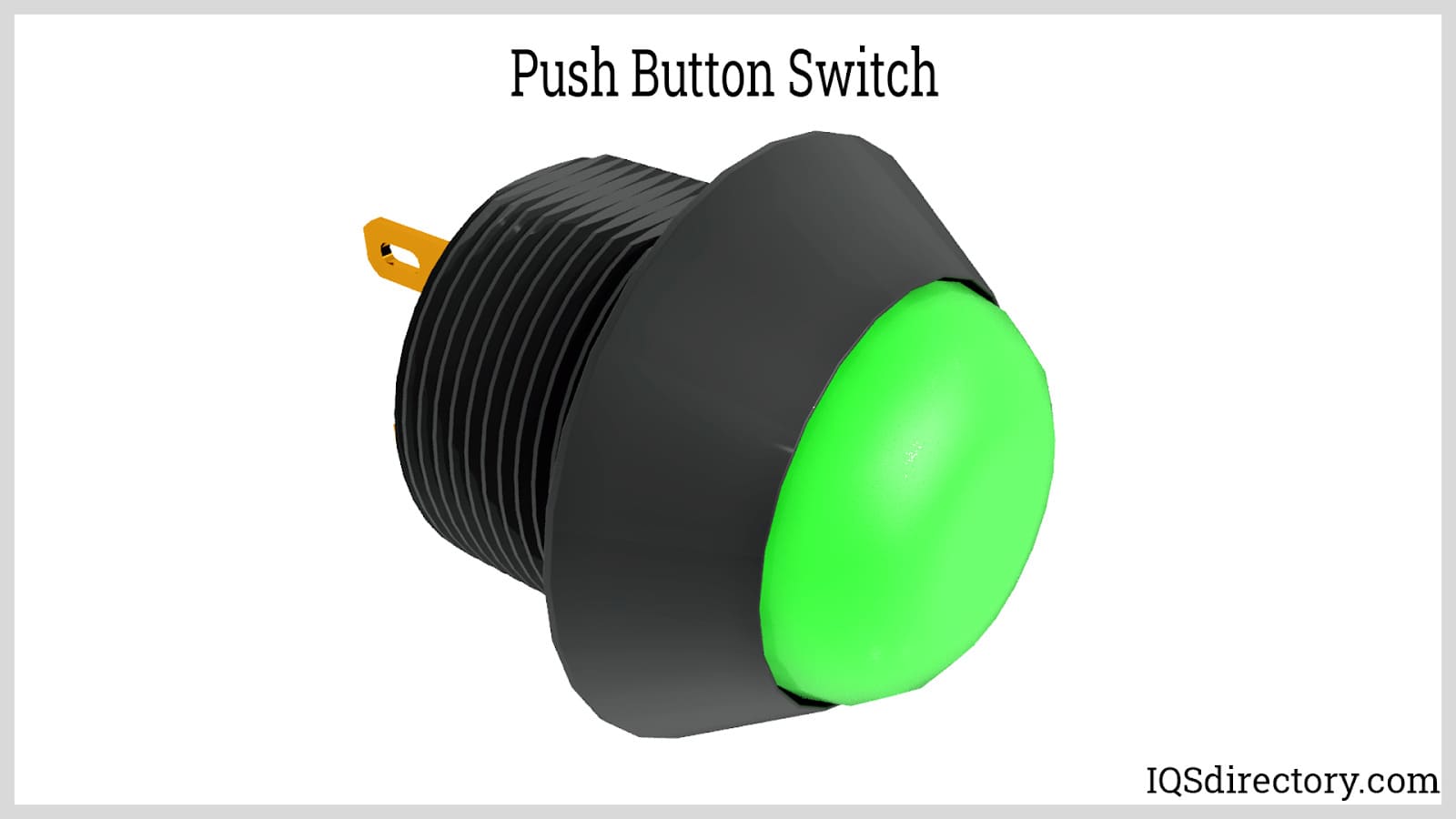

Navigating the complexities of the global market for push button electrical switches is crucial for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. As technology advances and industries evolve, the demand for reliable and innovative push button switches is on the rise. These components are integral to various applications—from automotive systems to industrial machinery—enhancing user experience and ensuring operational safety.

This guide provides a comprehensive overview of push button electrical switches, detailing the various types available, including momentary, latching, waterproof, illuminated, and multi-function switches. Each type is examined in terms of materials, manufacturing processes, and quality control measures, empowering buyers to make informed decisions. Additionally, we highlight reputable suppliers, outline pricing structures, and address common FAQs to clarify any misconceptions that may arise during the sourcing process.

By leveraging the insights within this guide, B2B buyers can enhance their procurement strategies, ensuring they select high-quality products that meet their specific needs and comply with international standards. This approach not only facilitates better product performance but also contributes to increased customer satisfaction in a competitive marketplace. The knowledge gained here is essential for navigating the intricacies of sourcing push button electrical switches, ultimately leading to successful and sustainable business operations.

Understanding push button electrical switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Momentary Push Button | Activates a function only while pressed | Automotive controls, machinery | Pros: Simple operation; Cons: May wear out with frequent use. |

| Latching Push Button | Maintains its position until pressed again | Home automation, industrial machinery | Pros: Reduces accidental activation; Cons: Can be confusing if not labeled properly. |

| Waterproof Push Button | Sealed against moisture and dust | Outdoor applications, marine vehicles | Pros: Durable in harsh environments; Cons: Typically more expensive. |

| Illuminated Push Button | Features an integrated LED for visibility | Dashboard controls, night-time applications | Pros: Enhances user interface; Cons: Can be more complex to install. |

| Multi-Function Push Button | Controls multiple functions with a single switch | Advanced automotive systems, smart devices | Pros: Space-saving design; Cons: Complexity can lead to user errors. |

Momentary Push Button

Momentary push button switches are designed for temporary activation, ideal for applications requiring immediate response, such as automotive controls and machinery. Their simplicity makes them easy to use, but frequent activation can lead to wear and tear. B2B buyers should prioritize durability and tactile feedback when sourcing these switches to ensure they can withstand operational demands.

Latching Push Button

Latching push buttons remain in the last position until pressed again, making them suitable for home automation and industrial machinery. This feature helps prevent accidental activation, enhancing safety. When purchasing, clear labeling and intuitive design are essential to avoid confusion. Buyers should also consider the mechanical reliability of the locking mechanism, which is crucial for maintaining operational integrity.

Waterproof Push Button

Waterproof push button switches are designed to resist moisture and dust, making them ideal for outdoor applications and marine environments. The effectiveness of these switches is often indicated by their IP (Ingress Protection) rating. While they may come at a higher price point, their durability in harsh conditions justifies the investment. Buyers should assess the sealing technology used to ensure long-term reliability.

Illuminated Push Button

Illuminated push button switches incorporate LED lights, enhancing visibility in low-light situations. They are commonly found in dashboard controls and other applications requiring clear signaling. While they improve user interface experience, their installation can be more complex due to electronic components. B2B buyers should evaluate brightness and color options to ensure they meet specific application needs.

Multi-Function Push Button

Multi-function push button switches can control several functions from a single unit, making them efficient for advanced automotive systems and smart devices. Their space-saving design is appealing, but the complexity may lead to user errors if not designed intuitively. When sourcing these switches, buyers should focus on programming capabilities and ensure they can handle the electrical load without compromising performance.

Related Video: Illuminated Push button switch from Easy Harmony | Schneider Electric

Key Industrial Applications of push button electrical switch

| Industry/Sector | Specific Application of push button electrical switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Dashboard controls and user interfaces | Enhances driver safety and user experience | Look for durability, tactile feedback, and compliance with automotive standards. |

| Industrial Automation | Machinery control panels | Streamlines operations and improves safety | Ensure compatibility with existing systems and evaluate IP ratings for environmental resilience. |

| Home Automation | Smart home control systems | Increases convenience and energy efficiency | Focus on multi-function capabilities and user-friendly design to minimize errors. |

| Marine and Outdoor | Control systems for boats and outdoor equipment | Provides reliable operation in harsh environmental conditions | Assess waterproof ratings and durability under extreme conditions. |

| Consumer Electronics | Appliances and devices requiring user interaction | Enhances usability and aesthetic appeal | Consider design, lighting options, and ease of installation to improve consumer satisfaction. |

Automotive Applications

In the automotive industry, push button electrical switches are integral to dashboard controls and user interfaces. These switches facilitate critical functions such as ignition, climate control, and infotainment systems. For international buyers, particularly in regions like Africa and the Middle East, sourcing durable switches that comply with automotive standards is crucial. The switches must provide tactile feedback to ensure safe operation while driving. Additionally, buyers should prioritize suppliers that offer a variety of designs to enhance the user experience and meet diverse consumer preferences.

Industrial Automation

Push button switches are widely used in industrial automation for machinery control panels. They enable operators to start, stop, or adjust machinery settings efficiently. This functionality streamlines operations and significantly enhances workplace safety. For buyers in South America and Europe, it is essential to consider the compatibility of these switches with existing machinery, as well as their Ingress Protection (IP) ratings to ensure resilience against dust and moisture. Sourcing switches from reputable manufacturers can help mitigate operational risks and improve overall productivity.

Home Automation

In the home automation sector, push button switches play a pivotal role in smart home control systems, allowing users to manage lighting, heating, and security from a single interface. This increases convenience and can lead to energy savings. Buyers, especially in technologically advanced markets in Europe and the UAE, should focus on multi-function switches that are intuitive to use. Ensuring that these switches are compatible with various smart home ecosystems is vital for seamless integration and enhanced user satisfaction.

Marine and Outdoor Applications

Marine and outdoor applications demand push button switches that can withstand harsh environmental conditions. These switches are essential for controlling equipment on boats and outdoor machinery, where exposure to moisture and dust is common. For B2B buyers in Africa and the Middle East, assessing the waterproof ratings and overall durability of these switches is critical. Sourcing high-quality switches can reduce maintenance costs and ensure reliable operation in challenging environments, ultimately enhancing operational efficiency.

Consumer Electronics

In consumer electronics, push button switches are used in a wide range of appliances and devices, enhancing usability and aesthetic appeal. They are crucial for user interaction in products such as kitchen appliances, gaming devices, and personal gadgets. Buyers should evaluate design options, including illuminated features, to improve user experience. Additionally, considering the ease of installation and long-term reliability can significantly impact customer satisfaction and brand loyalty in competitive markets across Europe and South America.

Related Video: How the Push Button Works || Electrical Simulation

Strategic Material Selection Guide for push button electrical switch

When selecting materials for push button electrical switches, international B2B buyers must consider a range of factors that influence product performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of push button switches: Plastic, Metal, Rubber, and Composite Materials. Each material has unique properties that affect its suitability for specific applications.

Plastic

Key Properties: Plastics such as polycarbonate and nylon are lightweight, resistant to corrosion, and can withstand a wide range of temperatures. They typically have a temperature rating between -40°C to +85°C and are non-conductive, making them ideal for electrical applications.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, which allows for mass production. However, plastics can be less durable than metals, especially under high mechanical stress or extreme temperatures. They may also degrade over time when exposed to UV light or harsh chemicals.

Impact on Application: Plastic switches are suitable for indoor applications where moisture and heavy mechanical impact are not significant concerns. However, they may not be ideal for environments with high temperatures or exposure to aggressive chemicals.

Considerations for Buyers: Buyers should ensure that the plastics used comply with international standards such as ASTM or DIN, especially regarding flammability and chemical resistance. Understanding local preferences for materials can also guide sourcing decisions.

Metal

Key Properties: Metals like stainless steel and aluminum offer excellent strength, durability, and corrosion resistance. They can withstand high temperatures (up to 200°C) and pressures, making them suitable for heavy-duty applications.

Pros & Cons: The key advantage of metal switches is their robustness and long lifespan, which can reduce replacement costs over time. However, they are generally more expensive to manufacture and can be heavier than plastic options. Additionally, metal switches may require more complex installation due to their weight and electrical conductivity.

Impact on Application: Metal switches are ideal for outdoor applications or environments where they may be exposed to moisture, dust, or chemicals. Their durability makes them a preferred choice in industrial settings.

Considerations for Buyers: International buyers must consider compliance with corrosion resistance standards, especially in humid or saline environments. Understanding the local market’s acceptance of metal components is crucial for successful procurement.

Rubber

Key Properties: Rubber materials, particularly silicone and EPDM, provide excellent flexibility and resistance to extreme temperatures and environmental conditions. They typically function effectively in temperatures ranging from -50°C to +150°C.

Pros & Cons: The main advantage of rubber is its ability to create a watertight seal, making it ideal for waterproof switches. However, rubber can be more expensive than plastic and may degrade over time when exposed to certain chemicals or UV light.

Impact on Application: Rubber switches are particularly suitable for outdoor applications or in environments where moisture and dust are prevalent. They are often used in marine and automotive applications due to their sealing capabilities.

Considerations for Buyers: Buyers should ensure that rubber materials meet international standards for environmental resistance and durability. Understanding the specific requirements for sealing and waterproof ratings can guide material selection.

Composite Materials

Key Properties: Composite materials, often a blend of plastics and metals, offer a balance of strength, weight, and cost. They can be engineered to provide specific properties, such as enhanced electrical insulation and resistance to environmental factors.

Pros & Cons: The advantage of composites is their versatility; they can be tailored for specific applications. However, they can be more complex to manufacture and may not always provide the same level of durability as pure metals.

Impact on Application: Composite switches are suitable for applications that require a combination of lightweight and strength, such as in automotive and aerospace industries.

Considerations for Buyers: Buyers should evaluate the specific properties of composite materials and ensure they meet relevant international standards. Understanding the manufacturing processes and potential supply chain complexities is also essential.

Summary Table

| Material | Typical Use Case for push button electrical switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Indoor applications, consumer electronics | Low cost, easy to manufacture | Less durable under stress | Low |

| Metal | Outdoor, industrial applications | High durability, corrosion resistant | Higher manufacturing cost | High |

| Rubber | Marine, automotive applications | Excellent sealing capabilities | Can degrade with certain exposures | Medium |

| Composite Materials | Automotive, aerospace applications | Versatile, tailored properties | More complex manufacturing | Medium |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for push button electrical switches, ensuring informed sourcing decisions that align with their specific operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for push button electrical switch

The manufacturing of push button electrical switches involves several critical stages, each designed to ensure that the final product meets the functional, aesthetic, and safety requirements of various industries, particularly automotive and industrial applications. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of these processes to make informed sourcing decisions.

Manufacturing Processes

-

Material Preparation

– Selection of Materials: The manufacturing process begins with the careful selection of materials. Common materials include plastics (such as polycarbonate and nylon), metals (like aluminum or stainless steel), and rubber for seals. The choice of material affects durability, functionality, and cost.

– Material Treatment: Before forming, materials may undergo treatments such as molding, extrusion, or machining to achieve the desired properties. For instance, plastics may be treated to enhance their resistance to UV light or chemicals. -

Forming

– Molding: For plastic components, injection molding is a prevalent technique. This process involves injecting molten plastic into a mold to create the switch’s housing. Precision in this step is crucial, as it determines the switch’s final shape and durability.

– Metal Stamping: For metallic parts, stamping processes are used to create the necessary shapes and features. This involves cutting and forming metal sheets into specific designs through dies and presses. -

Assembly

– Component Integration: Once the individual components (housing, button, contacts, etc.) are prepared, they are assembled. This can involve manual assembly or automated processes, depending on the production scale.

– Soldering and Wiring: Electrical connections are established through soldering, where wires are attached to contacts within the switch. This step must be carefully executed to ensure reliable electrical performance. -

Finishing

– Surface Treatment: After assembly, switches often undergo finishing processes such as painting, coating, or plating. These processes not only enhance aesthetic appeal but also improve resistance to environmental factors like moisture and dust.

– Quality Testing: Before packaging, switches are subjected to various tests to ensure they meet performance standards. This includes functional tests and durability assessments.

Quality Assurance (QA)

Quality assurance in the manufacturing of push button electrical switches is vital to guarantee safety and reliability. B2B buyers should be familiar with the key quality standards and checkpoints involved.

- International Standards

– ISO 9001: This standard focuses on quality management systems and is applicable across industries. Manufacturers should adhere to ISO 9001 to ensure consistent quality and customer satisfaction.

– CE Marking: For products marketed in Europe, CE marking signifies conformity with health, safety, and environmental protection standards.

– API Standards: For specific applications, particularly in the oil and gas sector, compliance with American Petroleum Institute (API) standards can be crucial.

Illustrative Image (Source: Google Search)

-

Quality Control Checkpoints

– Incoming Quality Control (IQC): At this stage, raw materials and components are inspected for defects before manufacturing begins. This ensures that only high-quality materials enter the production process.

– In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the production process. This includes verifying dimensions and testing for proper assembly.

– Final Quality Control (FQC): After assembly, each switch undergoes final testing to ensure it meets all specifications. This may involve functional testing, electrical testing, and environmental simulations. -

Testing Methods

– Functional Testing: Ensures that the switch operates correctly under expected conditions. This includes testing the switch’s response time and electrical conductivity.

– Durability Testing: Simulates the expected life cycle of the switch, assessing its performance after repeated use.

– Environmental Testing: Evaluates how well the switch withstands various environmental conditions, such as humidity, temperature extremes, and exposure to dust.

Verifying Supplier Quality Control

For B2B buyers, especially those sourcing internationally, verifying a supplier’s quality control processes is essential:

- Supplier Audits: Conducting audits can provide insights into a manufacturer’s quality management practices. This may include reviewing their processes, facilities, and compliance with international standards.

- Quality Reports: Requesting detailed quality reports can help assess a supplier’s performance over time. This includes data on defect rates, customer complaints, and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of product quality before shipment. This is particularly useful for buyers in regions with less stringent local regulations.

Navigating QC Nuances for International Buyers

International buyers should be aware of the nuances in quality control that may affect sourcing decisions:

- Cultural Differences: Understanding the cultural context of suppliers can influence quality expectations and communication. This is particularly relevant in regions with different manufacturing standards.

- Regulatory Compliance: Different countries may have varying requirements for product safety and environmental impact. Buyers should ensure that suppliers comply with local regulations in their target markets.

- Logistical Challenges: Shipping products internationally can introduce risks related to damage or loss. Buyers should verify that suppliers have robust packaging and shipping practices to mitigate these risks.

By understanding the manufacturing processes and quality assurance measures in place for push button electrical switches, B2B buyers can make informed decisions that enhance their procurement strategies and ensure product reliability.

Related Video: Factory tour – Industrial push button switches | Schneider Electric

Comprehensive Cost and Pricing Analysis for push button electrical switch Sourcing

Understanding the cost structure and pricing landscape for push button electrical switches is crucial for international B2B buyers. This analysis will cover the key cost components, pricing influencers, and practical tips for making informed sourcing decisions, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost of push button switches. Common materials include plastics, metals, and rubber, with high-performance materials for specialized applications costing more. Buyers should consider not only the initial cost but also the durability and long-term performance of these materials.

-

Labor: Labor costs vary by region and manufacturing processes. Countries with lower labor costs may offer competitive pricing, but it’s essential to ensure that quality is not compromised. Skilled labor is particularly important for complex switch designs and quality assurance.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Buyers should inquire about the manufacturer’s production capabilities and efficiencies, as these can influence pricing.

-

Tooling: Custom tooling for specialized designs can be a significant upfront cost. However, for high-volume orders, this cost can be amortized, leading to lower per-unit costs. Buyers should assess whether the tooling costs are included in the quoted price or if they will be billed separately.

-

Quality Control (QC): Effective QC measures ensure product reliability and compliance with international standards. While robust QC processes may increase upfront costs, they can prevent costly failures and recalls in the long run.

-

Logistics: Shipping costs can vary widely based on distance, volume, and chosen Incoterms. It’s crucial to factor in logistics when calculating total costs, particularly for international shipments.

-

Margin: Supplier margins can vary based on market conditions and competition. Understanding the typical margins in the industry can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Pricing often improves with higher volumes. Buyers should negotiate for better pricing based on projected order volumes.

-

Specifications/Customization: Customized switches typically incur additional costs. Buyers must evaluate the necessity of these customizations against their budget.

-

Materials: Premium materials or advanced features (e.g., waterproofing, illumination) can drive up costs. Assessing the specific needs of the application will help in making cost-effective choices.

-

Quality/Certifications: Products with higher quality ratings or certifications (e.g., ISO, CE) may come at a premium. Investing in certified products can enhance safety and reliability.

-

Supplier Factors: Established suppliers with a good reputation may charge more, but they often provide greater reliability and service. Evaluating supplier backgrounds can provide insight into their pricing structure.

-

Incoterms: Understanding Incoterms is essential for determining who bears the costs and risks during shipping. Choosing the right terms can lead to significant cost savings.

Buyer Tips

-

Negotiation: Always negotiate pricing with suppliers. Leverage volume commitments or long-term partnerships to secure better terms.

-

Cost Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the purchase price. Evaluate maintenance, replacement, and operational costs over the product’s lifespan.

-

Pricing Nuances: Be aware of regional pricing variations. For example, suppliers in Europe may have higher costs due to labor and regulatory standards compared to those in Asia. Buyers from Africa and South America should compare local suppliers to those abroad for potential savings.

Disclaimer

Prices for push button electrical switches can vary widely based on the factors discussed above. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential push button electrical switch Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘push button electrical switch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for push button electrical switch

Understanding the technical specifications and terminology associated with push button electrical switches is crucial for B2B buyers. This knowledge not only aids in making informed purchasing decisions but also ensures compliance with industry standards and customer requirements.

Key Technical Properties

-

Material Grade

– Definition: The type of material used in the construction of the switch, commonly plastics (like polycarbonate) or metals (like stainless steel).

– Importance: Material choice affects durability, resistance to environmental conditions, and overall performance. For instance, high-grade materials provide better resistance to wear and corrosion, which is essential for outdoor or industrial applications. -

Electrical Rating

– Definition: The maximum voltage and current that a switch can handle safely, typically expressed in volts (V) and amperes (A).

– Importance: Selecting a switch with the appropriate electrical rating is critical to prevent failures or safety hazards. B2B buyers must ensure that the switches meet the specifications of their application to maintain system integrity. -

Tolerance

– Definition: The permissible limit of variation in the switch’s dimensions and performance characteristics.

– Importance: Tolerance impacts the fit and functionality of the switch within a system. Tight tolerances are crucial in precision applications, while looser tolerances may suffice for less critical uses. Buyers should understand the tolerances to ensure compatibility with their systems. -

IP Rating (Ingress Protection)

– Definition: A classification that indicates the level of protection a switch has against dust and moisture, denoted by two digits (e.g., IP67).

– Importance: For applications in harsh environments, knowing the IP rating helps buyers choose suitable switches that will withstand exposure to elements, enhancing reliability and reducing maintenance costs. -

Actuation Force

– Definition: The amount of force required to activate the switch, typically measured in grams.

– Importance: The actuation force affects user experience. A switch that requires too much force can lead to user fatigue, while one that is too sensitive may result in accidental activations. Understanding this property helps in selecting switches that align with user needs. -

Lifecycle Rating

– Definition: The expected number of operations a switch can perform before failure.

– Importance: This rating is vital for understanding the longevity of the switch in high-use environments. B2B buyers should evaluate lifecycle ratings to ensure they are investing in durable products that minimize the need for replacements.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is essential for buyers looking to source switches that meet specific quality and performance standards set by established brands. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their inventory and budget. It can also affect pricing; larger orders often lead to better pricing per unit. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and availability for specific products.

– Importance: An RFQ is a crucial step in the procurement process, allowing buyers to compare offers and negotiate terms effectively. -

Incoterms (International Commercial Terms)

– Definition: A series of international standards for shipping and freight that define the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risk management, and the logistics involved in international transactions, ensuring smoother procurement processes. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Importance: Understanding lead times is vital for supply chain management. Buyers need to factor this into their project timelines to avoid delays in production or delivery. -

Certification Standards

– Definition: Industry-specific standards that products must meet to ensure safety and performance, such as ISO, CE, or UL.

– Importance: Compliance with certification standards is critical for market acceptance and legal compliance. B2B buyers should verify that the switches they intend to purchase adhere to relevant standards for their region and application.

By grasping these technical properties and trade terms, B2B buyers can enhance their sourcing strategies, ensuring they select high-quality push button electrical switches that meet their operational needs and compliance requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the push button electrical switch Sector

Market Overview & Key Trends

The global push button electrical switch market is witnessing significant transformation, driven by technological advancements and evolving consumer expectations. Key drivers include the increasing demand for automation in industrial applications, the rise of electric and smart vehicles, and the growing focus on user experience in consumer electronics. In regions such as Africa, South America, the Middle East, and Europe, B2B buyers must adapt to these market dynamics by understanding the local demands and leveraging innovative sourcing strategies.

Emerging trends indicate a shift toward multifunctional switches that integrate various functionalities into a single unit, catering to space-saving needs in modern designs. Additionally, the use of smart technologies, such as IoT connectivity, is gaining traction, enabling enhanced control and monitoring capabilities. Buyers should be vigilant in sourcing suppliers that offer these advanced solutions, as they can provide a competitive edge in the marketplace.

Furthermore, the market is becoming increasingly competitive, with a diverse range of suppliers emerging globally. Buyers are encouraged to evaluate suppliers based on their technological capabilities, quality assurance processes, and responsiveness to market changes. Understanding regional preferences and compliance requirements is crucial, especially for buyers in Africa and South America, where market maturity may vary significantly.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical concern in the push button electrical switch sector. The environmental impact of manufacturing processes and materials used in these components can be significant. As a result, B2B buyers must prioritize ethical sourcing practices and seek suppliers committed to sustainability. This includes evaluating the lifecycle of products, from raw material extraction to end-of-life disposal.

Adopting ‘green’ certifications and utilizing sustainable materials are vital for enhancing brand reputation and meeting consumer demand for environmentally friendly products. Buyers should look for suppliers that offer products made from recyclable materials or those that have implemented energy-efficient manufacturing processes. Additionally, certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) can serve as indicators of a supplier’s commitment to sustainability.

Moreover, fostering transparent supply chains is essential for building trust with customers and stakeholders. By collaborating with suppliers who share a commitment to ethical practices, B2B buyers can contribute to a more sustainable industry while mitigating risks associated with unethical sourcing.

Brief Evolution/History

The evolution of push button electrical switches dates back to the early 20th century, when simple mechanical designs were first introduced. These early switches were primarily used in industrial settings. Over the decades, advancements in materials and technology led to the development of more sophisticated designs, including illuminated and waterproof switches, catering to various applications from automotive to home automation.

In recent years, the integration of smart technology has redefined the functionality of push button switches, allowing them to support advanced features such as remote access and automation. This evolution reflects the broader trends in technology and consumer preferences, highlighting the importance of innovation in meeting the demands of modern markets. For international B2B buyers, understanding this historical context can provide valuable insights into selecting the right products for their specific applications.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of push button electrical switch

-

How can I effectively vet suppliers for push button electrical switches?

Vetting suppliers is crucial for ensuring quality and reliability. Start by researching the supplier’s background, including years in business, customer reviews, and industry certifications. Request references from previous clients and assess their responsiveness to inquiries. Additionally, consider visiting their manufacturing facilities if feasible, or leverage third-party audits to verify compliance with international standards. Finally, ensure they can provide product samples to evaluate quality firsthand. -

Are customization options available for push button electrical switches?

Many suppliers offer customization options for push button switches, including size, color, functionality, and labeling. When seeking customized solutions, clearly communicate your specifications and desired features. Ensure the supplier has a robust design and prototyping process to accommodate your needs. It’s also advisable to confirm any additional costs associated with customization, as these can impact your overall budget. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary significantly among suppliers, typically ranging from 100 to 1,000 units. For small-scale projects, look for suppliers who offer flexible MOQs or sample orders. Lead times for production can also vary, generally ranging from 2 to 8 weeks, depending on the complexity of the order and the supplier’s capacity. Always discuss these factors upfront to align expectations and avoid delays in your procurement process.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when sourcing push button switches internationally?

Payment terms can vary based on the supplier’s policies and your negotiation skills. Common methods include wire transfers, letters of credit, or payment upon delivery. It’s important to clarify terms such as deposit amounts, balance payments, and acceptable currencies. Always ensure that payment terms are documented in the purchase agreement to avoid misunderstandings and protect your investment. -

What quality assurance measures should suppliers provide?

Suppliers should have robust quality assurance processes, including ISO certifications, to ensure product reliability. Request documentation for quality control measures such as inspection reports and test results for push button switches. It’s also beneficial to establish a clear return policy for defective products and consider including quality clauses in your contracts to safeguard your interests. -

How can I ensure compliance with international standards and certifications?

Verify that your suppliers comply with relevant international standards, such as IEC, UL, or RoHS, based on your target market’s regulations. Request certification documentation to confirm compliance, and inquire about their testing processes. Additionally, consider suppliers who have experience exporting to your region, as they will be more familiar with local regulations and compliance requirements. -

What are the best practices for logistics and shipping when sourcing internationally?

Work closely with your supplier to determine the most efficient shipping methods based on your budget and delivery timelines. Options may include air freight for faster delivery or sea freight for cost savings. Ensure that the supplier provides all necessary shipping documents, including invoices and certificates of origin. It’s also prudent to engage a reliable logistics partner familiar with customs procedures to facilitate smooth importation. -

How should disputes be handled in international transactions?

Dispute resolution can be complex in international trade. Establish clear terms in your contracts regarding dispute resolution methods, such as arbitration or mediation, and specify the governing law. Maintain open communication with the supplier to address issues promptly. Document all interactions and agreements to provide a clear record in case of disputes. Consider consulting legal experts with experience in international trade to guide you through potential conflicts effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for push button electrical switch

As the demand for push button electrical switches continues to rise across various industries, strategic sourcing becomes increasingly vital for international B2B buyers. Understanding the diverse types of switches—ranging from momentary to illuminated and multi-function—enables businesses to select components that best fit their specific applications. Buyers should prioritize suppliers who offer not only quality products but also transparency in pricing and robust customer support.

Key Takeaways for Buyers:

- Evaluate Supplier Reliability: Choose suppliers with proven track records and certifications that align with international standards to ensure product quality and compliance.

- Consider Technological Advancements: With the push towards electric and smart vehicles, investing in innovative switch designs can enhance user experience and operational efficiency.

- Assess Total Cost of Ownership: Look beyond initial purchase prices to consider factors such as durability, maintenance, and potential downtime costs.

Looking ahead, the landscape for push button electrical switches will continue to evolve. By embracing strategic sourcing practices, B2B buyers from Africa, South America, the Middle East, and Europe can position themselves for success in a competitive market. Engage with your suppliers, stay informed about industry trends, and leverage this knowledge to optimize your procurement strategies. The future is bright for those who prioritize informed decision-making in sourcing.