Master Sourcing PVC Extrusion Suppliers for Optimal

Introduction: Navigating the Global Market for pvc extrusion suppliers

In the dynamic realm of international trade, PVC extrusion suppliers play a pivotal role in providing essential materials that cater to a multitude of industries. From construction to automotive manufacturing, PVC extrusions are integral to creating durable, versatile products that withstand various environmental challenges. As global demand for these materials continues to rise, understanding the sourcing landscape becomes crucial for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe.

This guide offers a comprehensive overview of the PVC extrusion market, detailing the various types and materials available, the manufacturing processes, and quality control standards that ensure product reliability. Buyers will find valuable insights into potential suppliers, cost considerations, and prevailing market trends that influence purchasing decisions. By addressing frequently asked questions, the guide demystifies the complexities associated with sourcing PVC extrusions, empowering buyers to engage confidently with suppliers.

Armed with this knowledge, international B2B buyers can navigate the global market more effectively, negotiate favorable terms, and secure high-quality products tailored to their specific needs. Whether you are based in bustling cities like Lagos or Madrid, this guide is designed to enhance your sourcing strategy, ultimately driving successful procurement outcomes in your business endeavors.

Understanding pvc extrusion suppliers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid PVC Extrusions | Strong, lightweight, and dimensionally stable; ideal for structural applications. | Construction, automotive, marine, and plumbing. | Pros: High durability and chemical resistance. Cons: Limited flexibility. |

| Flexible PVC Extrusions | Soft and pliable due to added plasticizers; easily bendable. | Electrical insulation, flooring, and seals. | Pros: Versatile and easy to handle. Cons: Lower chemical resistance. |

| PVC Duct Profiles | Designed for HVAC systems; smooth interior for optimal airflow. | Ventilation and air conditioning systems. | Pros: Efficient airflow and lightweight. Cons: Not suitable for high-pressure environments. |

| PVC Tubing | Highly resistant to chemicals and available in various shapes. | Fluid transport, medical applications, and food processing. | Pros: Customizable and robust. Cons: May require specific fittings for connections. |

| Custom PVC Extrusions | Tailored shapes and sizes for specific applications; high adaptability. | Specialized industrial applications. | Pros: Meets unique project requirements. Cons: Potentially longer lead times and higher costs. |

Rigid PVC Extrusions

Rigid PVC, often referred to as unplasticized PVC (uPVC), is a foundational material in various industries. It is characterized by its strength, lightweight nature, and dimensional stability, making it suitable for applications in construction, automotive, and plumbing sectors. B2B buyers should consider its high durability and chemical resistance, which ensure a long service life. However, the lack of flexibility may limit its use in applications requiring bending or shaping.

Flexible PVC Extrusions

Flexible PVC is formulated with plasticizers that enhance its pliability, making it ideal for applications such as electrical insulation and flooring. This type of extrusion is widely utilized in sectors requiring soft, bendable materials, including weatherstripping and protective edge trims. While flexible PVC offers versatility and ease of handling, buyers must be aware that it generally has lower chemical resistance than its rigid counterpart, which may affect its suitability in certain environments.

PVC Duct Profiles

PVC duct profiles are specifically designed for HVAC applications, featuring a smooth interior that promotes efficient airflow. These extrusions are lightweight and easy to install, making them a popular choice for ventilation and air conditioning systems. B2B buyers should note that while they excel in airflow efficiency, these ducts are not suitable for high-pressure environments, which could limit their application in some industrial settings.

PVC Tubing

PVC tubing is a versatile product that is highly resistant to chemicals, making it ideal for fluid transport in various industries, including medical and food processing. Available in multiple shapes, such as round and square, this type of extrusion can be tailored for specific performance needs. Buyers should consider the need for specialized fittings to ensure secure connections, as this may impact installation and operational efficiency.

Custom PVC Extrusions

Custom PVC extrusions allow for tailored shapes and sizes, addressing specific project requirements across diverse industries. These extrusions can be designed for unique applications, enhancing their adaptability in specialized settings. While they provide significant benefits in terms of meeting precise specifications, B2B buyers should be mindful of potentially longer lead times and higher costs associated with custom manufacturing, which may affect budgeting and project timelines.

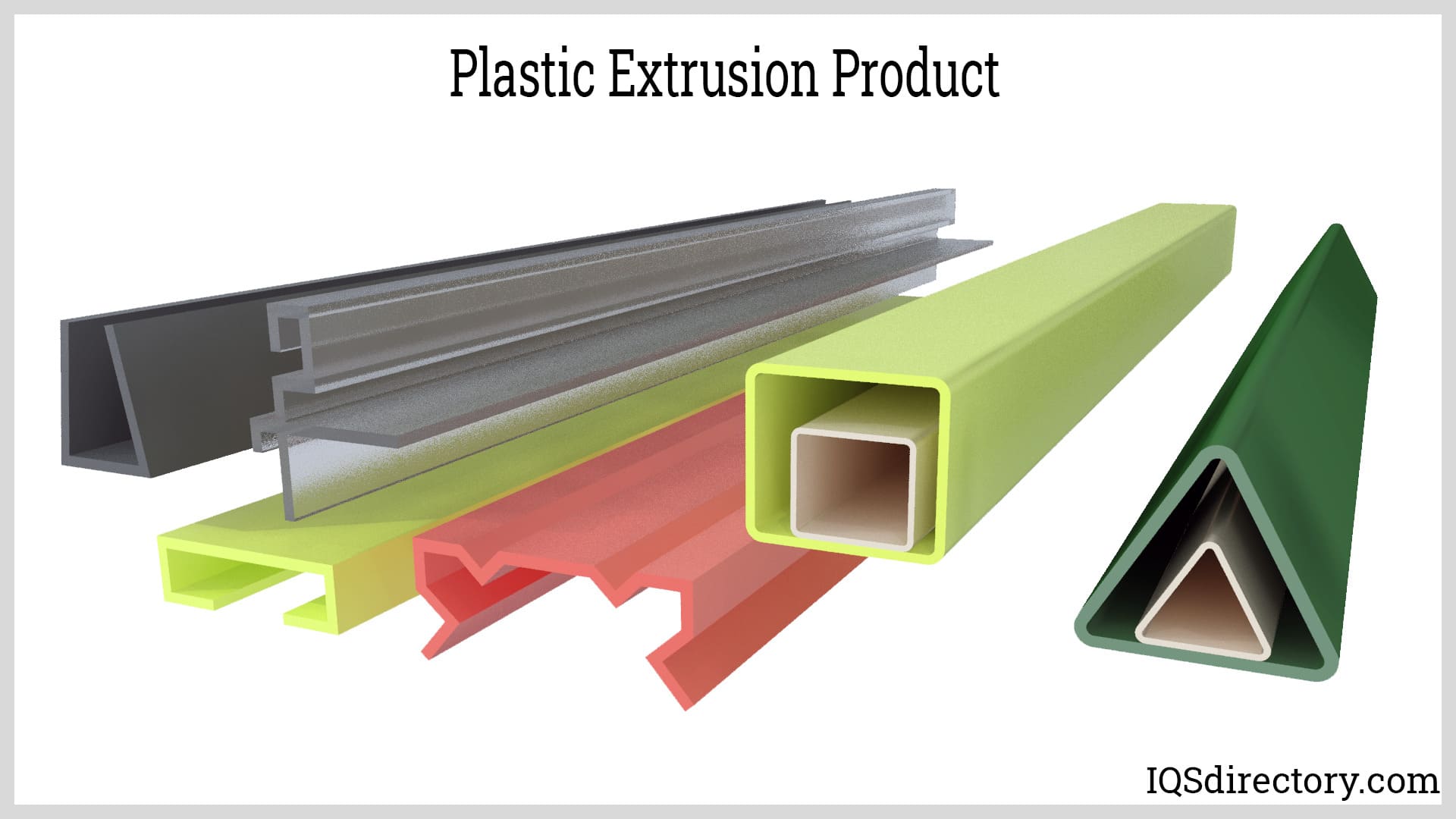

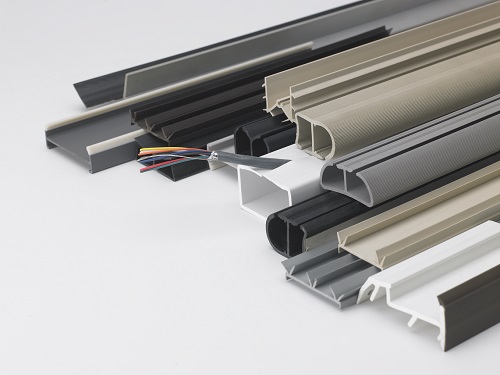

Related Video: Plastic Extrusion

Key Industrial Applications of pvc extrusion suppliers

| Industry/Sector | Specific Application of PVC Extrusion Suppliers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Water and drainage pipes, cladding, window frames | Durable, cost-effective solutions with low maintenance | Ensure compliance with local building codes and standards |

| Transportation | Dashboard profiles, body trims, protective components | Lightweight, corrosion-resistant parts improving vehicle longevity | Seek suppliers with experience in automotive-grade materials |

| Agriculture | Irrigation systems, drainage solutions | Efficient water management and reduced environmental impact | Look for UV-resistant options for outdoor durability |

| Electrical | Cable management systems, protective conduits | Enhanced safety and organization for electrical installations | Verify electrical insulation properties and certifications |

| Retail & Display | Custom display structures, signage supports | Attractive, lightweight solutions that enhance product visibility | Prioritize suppliers with capabilities for custom designs |

Construction

PVC extrusion suppliers play a pivotal role in the construction industry by providing essential components like water and drainage pipes, cladding, and window frames. These products are valued for their durability and resistance to environmental factors, making them ideal for both indoor and outdoor applications. For international buyers, particularly in regions with varying climates such as Africa and the Middle East, sourcing PVC that meets local building codes and standards is crucial to ensure compliance and performance.

Transportation

In the transportation sector, PVC extrusions are utilized in manufacturing dashboard profiles, body trims, and protective components for vehicles. The lightweight nature of PVC, combined with its corrosion resistance, contributes to improved vehicle longevity and efficiency. B2B buyers should seek suppliers experienced in automotive-grade materials to ensure that the products meet stringent industry standards for safety and performance, particularly in regions like Europe where regulations are strict.

Agriculture

PVC extrusions are increasingly important in agriculture, specifically for irrigation systems and drainage solutions. These applications help in efficient water management, which is essential for sustainable farming practices. For buyers in South America and Africa, selecting UV-resistant PVC options is critical, as these materials can withstand harsh outdoor conditions, ensuring long-term reliability and reduced environmental impact.

Electrical

In the electrical sector, PVC extrusion suppliers provide cable management systems and protective conduits that enhance safety and organization in installations. The excellent electrical insulation properties of PVC make it a preferred choice for low-voltage applications. International B2B buyers must verify that the products sourced meet relevant electrical safety standards and certifications, particularly in regions like Europe where compliance is heavily regulated.

Retail & Display

In retail and display applications, PVC extrusions are used to create custom display structures and signage supports. These solutions are lightweight and visually appealing, enhancing product visibility and customer engagement. When sourcing from suppliers, buyers should prioritize those capable of providing custom designs to meet specific marketing needs, ensuring that the final product aligns with brand identity and attracts customers effectively.

Related Video: The Extrusion Process of Making PVC Profiles

Strategic Material Selection Guide for pvc extrusion suppliers

When selecting materials for PVC extrusion, international B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. Below is an analysis of four common materials used in PVC extrusion, focusing on their key properties, advantages, disadvantages, and implications for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

Rigid PVC (uPVC)

Key Properties:

Rigid PVC, also known as unplasticized polyvinyl chloride (uPVC), is known for its high strength, dimensional stability, and low weight. It has a temperature rating of up to 60°C (140°F) and exhibits excellent chemical resistance, making it suitable for various applications.

Pros & Cons:

The primary advantage of rigid PVC is its durability and long service life, which reduces the need for frequent replacements. It is also cost-effective compared to other materials. However, its rigidity can limit its applications in environments requiring flexibility, and it may become brittle over time when exposed to UV light without proper additives.

Impact on Application:

Rigid PVC is ideal for applications such as piping, window frames, and cladding. Its chemical resistance makes it suitable for transporting water and various chemicals, but it may not be compatible with high-temperature fluids.

Considerations for International Buyers:

Buyers must ensure compliance with local standards such as ASTM or DIN. In regions with high UV exposure, selecting UV-stabilized variants is crucial to enhance longevity.

Flexible PVC

Key Properties:

Flexible PVC is formulated with plasticizers that enhance its pliability. It can withstand temperatures ranging from -10°C to 60°C (14°F to 140°F) and offers good resistance to chemicals and abrasion.

Pros & Cons:

The flexibility of this material makes it ideal for applications requiring bending, such as electrical insulation and tubing. However, the inclusion of plasticizers can lead to lower overall durability compared to rigid PVC, and it may have a higher manufacturing complexity.

Impact on Application:

Flexible PVC is commonly used in electrical applications, gaskets, and flooring. Its ability to resist chemicals makes it suitable for food processing and medical applications, but it may not be ideal for high-pressure systems.

Considerations for International Buyers:

Buyers should verify that flexible PVC products meet relevant safety standards, especially in food and medical applications. Understanding the local regulations regarding plasticizers is also essential, as some regions may have restrictions.

CPVC (Chlorinated PVC)

Key Properties:

Chlorinated PVC (CPVC) is a modified version of PVC with enhanced temperature and pressure ratings, allowing it to handle temperatures up to 93°C (200°F). It also exhibits excellent chemical resistance.

Pros & Cons:

CPVC is advantageous for hot water systems and industrial applications due to its higher temperature tolerance. However, it is generally more expensive than standard PVC and may require specialized installation techniques.

Impact on Application:

CPVC is particularly suitable for plumbing and industrial applications where hot water transport is necessary. Its chemical resistance makes it a preferred choice for corrosive environments.

Considerations for International Buyers:

When sourcing CPVC, buyers should ensure compliance with local plumbing codes and standards. Understanding the specific requirements for installation and maintenance is also crucial, especially in regions with varying climatic conditions.

PVC Alloy

Key Properties:

PVC alloys combine PVC with other polymers to enhance flexibility and impact resistance. They maintain a temperature rating similar to rigid PVC but offer improved performance in dynamic applications.

Pros & Cons:

The major advantage of PVC alloys is their enhanced durability and flexibility, making them suitable for applications requiring resilience. However, they can be more expensive to produce and may complicate recycling processes.

Impact on Application:

PVC alloys are ideal for applications in automotive and marine industries, where impact resistance is critical. They are also used in outdoor settings due to their weather resistance.

Considerations for International Buyers:

Buyers should consider the environmental impact of PVC alloys and ensure that suppliers adhere to sustainability practices. Understanding the recyclability of these materials is also important, particularly in regions with strict waste management regulations.

Summary Table

| Material | Typical Use Case for pvc extrusion suppliers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rigid PVC | Piping, window frames, cladding | Durable and cost-effective | Limited flexibility, UV sensitivity | Low |

| Flexible PVC | Electrical insulation, tubing | High flexibility | Lower durability, manufacturing complexity | Medium |

| CPVC | Hot water plumbing, industrial applications | High temperature and pressure tolerance | Higher cost, specialized installation | High |

| PVC Alloy | Automotive parts, marine applications | Enhanced flexibility and impact resistance | Higher production cost, recycling challenges | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing PVC extrusion products tailored to their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc extrusion suppliers

The manufacturing of PVC extrusions is a complex process that requires careful planning and execution to ensure the final product meets the required specifications and standards. For international B2B buyers, understanding these processes and quality assurance measures is crucial for making informed sourcing decisions.

Manufacturing Process of PVC Extrusions

The manufacturing process for PVC extrusions can be broken down into four main stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in determining the quality and performance of the final product.

1. Material Preparation

The process begins with the careful selection and preparation of PVC raw materials. PVC pellets or powder are typically used, sometimes combined with additives like stabilizers, impact modifiers, and plasticizers to enhance properties such as flexibility, UV resistance, and durability. Proper material preparation is essential as it directly influences the extrusion quality.

2. Forming

In this stage, the prepared PVC material is fed into a twin-screw extruder. The twin-screw design promotes thorough mixing and uniform melting of the PVC. The extruder operates at controlled temperatures across various zones to achieve optimal viscosity. Once the material is sufficiently melted, it is forced through a shaped die that determines the cross-sectional profile of the extrusion. This could be anything from pipes and tubes to custom profiles required for specific applications.

3. Assembly

Post-extrusion, the newly formed PVC profile enters a cooling system, where it is cooled using water baths or air cooling to solidify its shape. For applications that require joining multiple pieces, assembly techniques such as welding, gluing, or mechanical fastening may be employed. Understanding the assembly methods used is crucial for buyers, especially if the final product needs to meet specific performance criteria.

4. Finishing

The final stage involves finishing processes that may include cutting the extruded profiles to length, surface treatments, or additional coatings. Finishing is important for enhancing the aesthetic appeal and functional properties of the product. Buyers should inquire about the finishing techniques used, as these can affect the durability and usability of the final product in their applications.

Quality Assurance Practices

Quality assurance is critical in the PVC extrusion industry to ensure that products meet international standards and customer expectations. For B2B buyers, familiarity with these practices can help in evaluating potential suppliers.

Illustrative Image (Source: Google Search)

International Standards

Several international standards govern the manufacturing and quality assurance of PVC extrusions. Notably:

- ISO 9001: This standard focuses on quality management systems and is applicable to all organizations. It ensures that suppliers maintain consistent quality in their processes.

- CE Marking: In Europe, products must meet specific safety, health, and environmental protection standards to bear the CE mark, which is crucial for market access.

- API Standards: For suppliers dealing with piping systems in the oil and gas industry, adherence to API standards is essential for ensuring product reliability.

Quality Control Checkpoints

Quality control typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is essential for maintaining quality. This includes checking the extrusion parameters and the physical properties of the extruded products.

- Final Quality Control (FQC): After production, finished products are tested for compliance with specifications. This might involve dimensional checks, visual inspections, and performance testing.

Common Testing Methods

B2B buyers should be aware of the various testing methods used to verify product quality, including:

- Tensile Strength Testing: Measures the material’s resistance to being pulled apart, ensuring it can withstand operational stresses.

- Impact Resistance Testing: Assesses the material’s durability against sudden shocks.

- Thermal Stability Testing: Evaluates how well the PVC can withstand temperature variations without deforming or losing integrity.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control measures is critical to ensuring product reliability. Here are several ways to do so:

- Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing processes, quality control systems, and compliance with international standards directly.

- Quality Assurance Reports: Requesting documentation that details quality control measures, testing results, and compliance with industry standards can provide insight into a supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent third-party organizations to inspect products can offer an unbiased assessment of quality and compliance.

Quality Control Nuances for International Buyers

When sourcing from suppliers in diverse regions such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific quality control nuances:

- Regional Standards: Different regions may have varying regulatory requirements and standards. Understanding these can help buyers ensure compliance and avoid potential import issues.

- Cultural Practices: Quality assurance practices may differ based on cultural attitudes toward quality and production. Establishing clear communication and expectations with suppliers can mitigate misunderstandings.

- Logistical Considerations: International shipping can impact product integrity. Buyers should inquire about how suppliers package and ship their products to prevent damage during transit.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for international B2B buyers looking to source PVC extrusions. By focusing on these aspects, buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their specific needs and standards.

Related Video: Cable extrusion production process – TANO

Comprehensive Cost and Pricing Analysis for pvc extrusion suppliers Sourcing

When sourcing PVC extrusions, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. Here’s a breakdown of the primary cost components, price influencers, and actionable tips for negotiating favorable terms.

Cost Components

-

Materials: The cost of PVC resin is the largest single expense in the production of extrusions. The price can fluctuate based on global oil prices and supply chain factors. Buyers should consider sourcing from suppliers who use high-quality materials that comply with international standards.

-

Labor: Labor costs can vary significantly between regions. In countries with lower labor costs, like some parts of Africa and South America, suppliers may offer more competitive pricing. However, this can sometimes affect the quality of craftsmanship, so it’s essential to balance cost with quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient suppliers often pass on savings to buyers, so look for manufacturers with streamlined operations.

-

Tooling: Custom molds and dies are necessary for producing specific profiles. The initial investment in tooling can be substantial, but suppliers may amortize these costs over larger orders, reducing the per-unit price.

-

Quality Control (QC): Effective QC practices ensure product reliability but can add to the overall cost. Suppliers with rigorous quality standards may charge more, but the investment often pays off in reduced returns and warranty claims.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping costs can significantly impact pricing, especially for international transactions. Factors such as distance, shipping method, and Incoterms (International Commercial Terms) play a vital role. For example, DAP (Delivered At Place) pricing may be higher due to added logistics management.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary based on market competition and the supplier’s reputation. Established suppliers with a strong track record may command higher margins.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk often leads to significant discounts. Buyers should assess their needs and negotiate favorable terms for larger quantities.

-

Specifications/Customization: Custom profiles or unique specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality/Certifications: Certifications (such as ISO) and material quality impact pricing. Suppliers who provide certified materials may charge more, but this can enhance product reliability and safety.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Consider working with suppliers that have a proven track record in your specific industry.

-

Incoterms: Understanding the terms of delivery can help buyers manage costs effectively. Different Incoterms can shift liability and costs, impacting the overall price.

Buyer Tips

-

Negotiate: Leverage your purchasing power by negotiating terms. Suppliers are often willing to adjust pricing based on volume, payment terms, or long-term commitments.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), not just the initial purchase price. Consider factors such as shipping, installation, and maintenance costs.

-

Pricing Nuances: Be aware of currency fluctuations, tariffs, and trade agreements that may affect international sourcing. Buyers from Africa, South America, the Middle East, and Europe should stay informed about regional trade dynamics that could influence costs.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and improved quality assurance. Regular communication and feedback can enhance collaboration.

Disclaimer

Prices for PVC extrusions can vary widely based on the factors outlined above. This analysis provides indicative insights; actual prices may differ based on market conditions, specific supplier offerings, and regional factors. Always consult multiple suppliers to benchmark pricing and terms.

Spotlight on Potential pvc extrusion suppliers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘pvc extrusion suppliers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for pvc extrusion suppliers

Key Technical Properties for PVC Extrusion Suppliers

Understanding the technical properties of PVC extrusions is crucial for B2B buyers in making informed purchasing decisions. Here are some essential specifications to consider:

-

Material Grade: This refers to the quality and type of PVC used in the extrusion process. Common grades include uPVC (unplasticized PVC) and CPVC (chlorinated PVC). The material grade affects the product’s durability, flexibility, and suitability for specific applications, such as plumbing or electrical insulation. Buyers must ensure the material grade aligns with their project requirements to avoid costly failures.

-

Wall Thickness: This specification denotes the thickness of the PVC material in the extrusion. It directly impacts the strength, weight, and pressure capacity of the product. A thicker wall generally provides greater durability and resistance to pressure and impact, making it essential for applications in high-stress environments. B2B buyers should assess the required wall thickness to ensure compliance with industry standards and operational needs.

-

Tolerance: Tolerance indicates the allowable deviation from specified dimensions in the extrusion process. It is critical for ensuring that the parts fit together correctly in assembly. Tighter tolerances may increase manufacturing costs but are necessary for high-precision applications. Buyers should discuss tolerance requirements with suppliers to ensure product compatibility and reduce assembly issues.

-

UV Resistance: For applications exposed to sunlight, UV resistance is a vital property that prevents degradation and discoloration of the PVC material. This feature is particularly important for outdoor applications, such as irrigation systems and building exteriors. Buyers should confirm the UV stability of the products they intend to source, especially in regions with intense sun exposure.

-

Impact Resistance: This property measures the ability of PVC extrusions to withstand sudden force or shock without breaking. Enhanced impact resistance is crucial for applications in construction and transportation where materials are subject to physical stresses. Buyers should evaluate the impact resistance of products to ensure longevity and reliability in demanding environments.

Common Trade Terminology in PVC Extrusion

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the PVC extrusion market, OEMs often supply components that are integrated into larger systems. Buyers should consider partnering with reputable OEMs for quality assurance.

-

MOQ (Minimum Order Quantity): This represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for budgeting and inventory management, as exceeding or falling short of the MOQ can lead to higher costs or missed opportunities. Buyers should negotiate MOQs that align with their project needs to ensure cost-effectiveness.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery timelines. For B2B buyers, submitting a clear and detailed RFQ can lead to more accurate quotes and better supplier responses.

-

Incoterms (International Commercial Terms): These are standardized international trade terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery obligations, which is critical in international procurement.

-

Lead Time: This term refers to the time taken from placing an order to the delivery of the product. Understanding lead times is vital for project planning and inventory management. Buyers should communicate their timelines clearly to suppliers to avoid delays that could impact project schedules.

By grasping these technical properties and trade terms, B2B buyers can enhance their sourcing strategies, optimize procurement processes, and foster better relationships with PVC extrusion suppliers.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pvc extrusion suppliers Sector

Market Overview & Key Trends

The PVC extrusion market is experiencing significant growth, driven by increasing demand across various sectors such as construction, automotive, and packaging. Key factors fueling this growth include urbanization and infrastructural development in emerging economies, particularly in Africa and South America. The construction industry’s shift towards lightweight and durable materials enhances the appeal of rigid PVC extrusions, which are favored for their chemical resistance and low maintenance requirements.

Technological advancements are reshaping the sourcing landscape. Automation in manufacturing processes, such as the use of twin-screw extruders, improves efficiency and product quality. Additionally, the rise of digital platforms for supplier discovery and procurement is streamlining the sourcing process for B2B buyers. Companies are increasingly adopting e-procurement tools to enhance transparency and reduce costs, making it easier to compare suppliers and negotiate better terms.

Furthermore, the market is witnessing a trend towards customization, with suppliers offering tailored solutions to meet specific industry needs. For international buyers, particularly in the Middle East and Europe, understanding these dynamics is crucial. They must stay informed about regional regulations and quality standards, ensuring compliance to avoid costly delays and penalties. As competition intensifies, establishing long-term relationships with reliable suppliers will be key to securing advantageous terms and maintaining a steady supply chain.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central concern for B2B buyers in the PVC extrusion sector. The environmental impact of PVC production, including carbon emissions and plastic waste, necessitates a shift towards more sustainable practices. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental footprint. This includes adopting cleaner manufacturing processes, reducing waste, and utilizing recycled materials in their products.

Ethical sourcing is equally important, as buyers seek to ensure that their suppliers adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and Cradle to Cradle (C2C) provide assurance of a supplier’s commitment to sustainability. Additionally, the use of ‘green’ PVC—produced from renewable resources—can enhance a company’s reputation while meeting regulatory standards.

For buyers in regions like Africa and South America, where environmental regulations may be evolving, aligning sourcing strategies with sustainable practices can provide a competitive advantage. By prioritizing suppliers with strong sustainability credentials, businesses can not only mitigate risks but also appeal to environmentally conscious consumers and stakeholders.

Brief Evolution/History

The history of PVC extrusion dates back to the mid-20th century, when the material gained popularity due to its versatility and durability. Initially, PVC was primarily used in plumbing and electrical applications. Over the decades, advancements in extrusion technology enabled the production of a broader range of products, including profiles for construction, automotive components, and consumer goods.

As global awareness of environmental issues grew, the industry began addressing sustainability concerns by developing more eco-friendly production methods and exploring recyclable alternatives. Today, PVC extrusion is a dynamic sector, with ongoing innovations aimed at enhancing performance while minimizing environmental impact. For B2B buyers, understanding this evolution is essential for making informed sourcing decisions that align with current market demands and sustainability goals.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of pvc extrusion suppliers

-

How can I effectively vet PVC extrusion suppliers?

Vetting suppliers is crucial to ensure quality and reliability. Start by assessing their certifications, such as ISO 9001, which indicates a commitment to quality management. Request references from previous clients and check online reviews or ratings. Additionally, consider visiting their facilities if possible or using third-party inspection services. Understand their production capacity and technological capabilities to ensure they can meet your specific needs. Engaging with local trade associations can also provide insights into reputable suppliers in your region. -

Can PVC extrusions be customized to meet specific project requirements?

Yes, many PVC extrusion suppliers offer customization options. You can specify dimensions, colors, and material formulations to suit your project’s unique needs. When discussing customization, provide detailed specifications and any relevant drawings or prototypes. Ensure the supplier has experience with similar custom projects and inquire about their design and prototyping processes. This will help you gauge their capability to deliver the required products within the desired timeframe. -

What are typical minimum order quantities (MOQs) and lead times for PVC extrusions?

MOQs and lead times vary significantly among suppliers and depend on the complexity of the order. Generally, MOQs can range from a few hundred to several thousand units. Lead times for standard products typically range from 2 to 6 weeks, while custom extrusions may take longer, sometimes up to 12 weeks. Always confirm these details upfront to align your purchasing strategy with production schedules, particularly if you are managing tight project timelines. -

What payment terms should I expect when dealing with PVC extrusion suppliers?

Payment terms can vary widely, but common practices include a deposit upfront (20-50%) with the balance due upon delivery or net 30-60 days. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Discuss and negotiate payment terms before finalizing contracts to avoid misunderstandings. Additionally, ensure that payment terms are documented in the purchase agreement for clarity. -

What quality assurance measures should I look for in PVC extrusion suppliers?

Quality assurance is vital in ensuring the products meet industry standards and your specifications. Look for suppliers who implement robust quality control processes, including material inspections, in-process testing, and final product evaluations. Request documentation of their quality assurance practices, including test reports and compliance certifications. A supplier with a transparent QA process will likely maintain consistent product quality, reducing the risk of defects and rework. -

How do logistics and shipping impact the sourcing of PVC extrusions?

Logistics play a crucial role in sourcing, especially for international buyers. Understand the shipping options available, including air freight for urgent needs and sea freight for cost-effective bulk orders. Assess the supplier’s experience with international shipping, customs clearance, and delivery timelines. Additionally, consider the total landed cost, including shipping, duties, and taxes, to ensure your budget aligns with the final costs. Establish clear communication regarding logistics to avoid delays. -

What should I do if a dispute arises with a PVC extrusion supplier?

In the event of a dispute, begin by reviewing the terms outlined in your contract, including warranties and dispute resolution procedures. Open a dialogue with the supplier to discuss the issue and seek a mutually acceptable resolution. If direct communication fails, consider mediation or arbitration as alternative dispute resolution methods. Keeping detailed records of all communications and transactions can support your case. Establishing a good relationship with suppliers upfront can often prevent disputes from escalating. -

What certifications should I request from PVC extrusion suppliers?

When sourcing PVC extrusions, request certifications that demonstrate the supplier’s compliance with industry standards. Key certifications include ISO 9001 for quality management, ISO 14001 for environmental management, and ASTM standards that relate to material properties and safety. Additionally, if your applications require specific approvals (such as for food contact), verify that the supplier can provide relevant certifications. Ensuring these certifications are in place can safeguard your business against liability and quality issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pvc extrusion suppliers

In the competitive landscape of PVC extrusion sourcing, international B2B buyers must prioritize strategic sourcing to ensure they procure high-quality products that meet their specific needs. Understanding the diverse applications of rigid and flexible PVC, alongside the associated manufacturing processes, empowers buyers to make informed decisions. Buyers in regions such as Africa, South America, the Middle East, and Europe should leverage local supplier networks while also exploring global options to enhance their procurement strategies.

Key takeaways include the importance of assessing supplier reliability, product specifications, and compliance with international standards. Establishing strong relationships with suppliers can lead to better pricing, improved service, and access to innovative products that align with evolving market demands.

As we look ahead, the growth of the PVC extrusion market is expected to continue, driven by advancements in manufacturing technologies and increasing applications across various industries. Buyers are encouraged to remain proactive in their sourcing efforts, exploring new suppliers and technologies that can enhance their operational efficiency. By doing so, they can secure a competitive edge in their respective markets and contribute to sustainable growth in their industries.