Master Sourcing Small Spring Hinges: A Comprehensive Guide

Introduction: Navigating the Global Market for small spring hinge

Navigating the global market for small spring hinges is essential for B2B buyers looking to enhance the functionality and aesthetic appeal of their products. These compact and versatile components are critical in a variety of applications, including fine woodworking, electronics, and custom furniture design. Their ability to deliver reliable pivoting action in constrained spaces makes them indispensable in both industrial and consumer sectors.

This comprehensive guide aims to empower international B2B buyers—especially those from Africa, South America, the Middle East, and Europe (including key markets like France and Spain)—with the knowledge needed to make informed sourcing decisions. It covers a wide array of topics, including the different types of small spring hinges, their materials and finishes, manufacturing processes, quality control standards, and supplier recommendations. Additionally, we delve into cost considerations and market trends, providing insights that are crucial for effective procurement strategies.

By equipping buyers with actionable insights and practical advice, this guide facilitates smarter purchasing decisions, ensuring that companies can select the right small spring hinges to meet their specific project needs. As the demand for precision hardware continues to grow globally, understanding the nuances of this market will be vital for sustaining competitive advantage and driving innovation in product design.

Understanding small spring hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Spring Hinge | Simple design, integrated spring mechanism for automatic closing | Cabinet doors, small access panels | Pros: Cost-effective, easy installation. Cons: Limited adjustability. |

| Self-Closing Spring Hinge | Automatically closes doors after opening, adjustable tension | Commercial doors, restroom stalls | Pros: Enhances security, reduces wear on doors. Cons: May require periodic tension adjustment. |

| Heavy-Duty Spring Hinge | Robust construction, designed for high-frequency use | Industrial machinery, heavy doors | Pros: Excellent durability, withstands heavy use. Cons: Higher cost, may require specialized installation. |

| Concealed Spring Hinge | Hidden when the door is closed, aesthetic appeal | High-end cabinetry, luxury furniture | Pros: Sleek design, enhances appearance. Cons: More expensive, complex installation. |

| Adjustable Spring Hinge | Allows for tension adjustment post-installation | Custom projects, varying door weights | Pros: Versatile, accommodates different applications. Cons: Can be more complicated to install. |

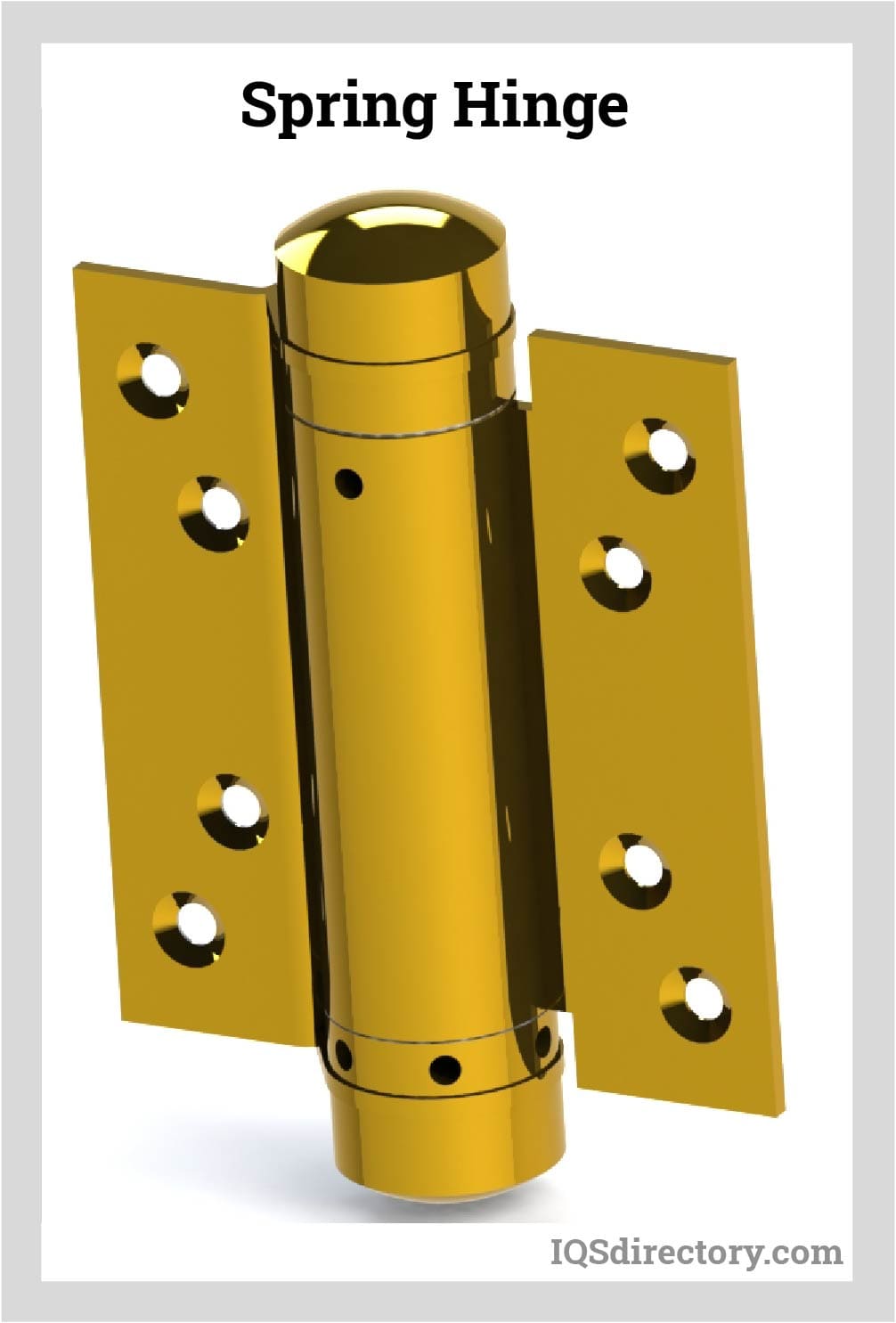

Standard Spring Hinge

Standard spring hinges are characterized by their straightforward design and integrated spring mechanism, which allows for the automatic closing of doors. They are commonly used in applications like cabinet doors and small access panels. For B2B buyers, the primary considerations include cost-effectiveness and ease of installation. However, they may lack adjustability and are best suited for lighter-duty applications.

Self-Closing Spring Hinge

Self-closing spring hinges are engineered to automatically close doors after they have been opened. This feature is particularly beneficial in commercial settings, such as restroom stalls and office doors, where maintaining privacy and security is essential. Buyers should consider the adjustable tension feature, which allows for customization based on door weight. While they enhance security, they do require periodic adjustments to maintain optimal performance.

Heavy-Duty Spring Hinge

Heavy-duty spring hinges are constructed for durability and designed to handle high-frequency usage. They are ideal for industrial machinery and heavy doors, where robustness is critical. B2B buyers should focus on their long lifespan and ability to withstand significant wear and tear. The downside is their higher cost and potential need for specialized installation, which could affect overall project budgets.

Concealed Spring Hinge

Concealed spring hinges offer an aesthetic advantage as they are hidden from view when the door is closed, making them a popular choice for high-end cabinetry and luxury furniture. Their sleek design enhances the overall appearance of a project. However, buyers should be aware of their higher price point and the complexity involved in installation. These hinges are best for projects where aesthetics are a top priority.

Adjustable Spring Hinge

Adjustable spring hinges provide the flexibility to adjust the tension after installation, making them suitable for custom projects with varying door weights. They are ideal for applications where doors may require different closing forces. Buyers should consider their versatility but also note that they can be more complicated to install compared to standard options. This added complexity can affect project timelines and labor costs.

Related Video: Justor Double Action Spring Hinge Installation

Key Industrial Applications of small spring hinge

| Industry/Sector | Specific Application of small spring hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | Laptop and tablet enclosures | Ensures durability and smooth operation of screens | Look for hinges that can withstand frequent use and provide reliable pivoting. |

| Medical Devices | Access doors for medical equipment | Facilitates easy access while maintaining hygiene | Sourcing from manufacturers with certifications for medical-grade materials is essential. |

| Furniture Manufacturing | Cabinet doors and custom furniture pieces | Enhances aesthetic appeal while providing functionality | Consider materials that match the furniture design and offer corrosion resistance. |

| Automotive | Small compartments in vehicles | Improves user experience by providing secure access | Ensure hinges meet automotive standards for durability and safety. |

| Aerospace | Instrument panels and access doors | Critical for operational efficiency and safety | Source from suppliers who specialize in aerospace-grade components for reliability. |

In the electronics industry, small spring hinges are essential for laptop and tablet enclosures. These hinges allow for smooth opening and closing of screens, which is vital for user experience. Buyers should prioritize hinges that are durable and can withstand repeated use, ensuring that they maintain alignment and structural integrity over time. Additionally, sourcing from reputable manufacturers can help ensure compliance with international quality standards.

In medical devices, small spring hinges are commonly used for access doors in equipment such as diagnostic machines and surgical instruments. These hinges allow for easy access to internal components for maintenance and cleaning, which is crucial in maintaining hygiene standards. Buyers should focus on sourcing hinges made from medical-grade materials and that have the necessary certifications to ensure safety and reliability in medical environments.

Within the furniture manufacturing sector, small spring hinges are often used in cabinet doors and custom furniture designs. These hinges not only provide functionality but also enhance the overall aesthetic of the furniture. Buyers should consider materials that complement their designs, such as brass or stainless steel, which offer both beauty and durability. Additionally, finishes that resist corrosion and wear can help maintain the furniture’s appearance over time.

In the automotive industry, small spring hinges are utilized in small compartments and access panels within vehicles. They improve the user experience by providing secure and easy access to storage areas. When sourcing these hinges, it is essential to ensure they meet automotive standards for durability and safety, as automotive components are subject to rigorous testing and usage conditions.

Lastly, in the aerospace sector, small spring hinges are critical for instrument panels and access doors in aircraft. These hinges must provide reliable operation under extreme conditions and contribute to the overall safety of the aircraft. Buyers should look for suppliers that specialize in aerospace-grade components, as these products need to meet strict regulatory standards and undergo thorough testing for reliability and performance.

Strategic Material Selection Guide for small spring hinge

When selecting materials for small spring hinges, international B2B buyers must consider various factors that influence performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of small spring hinges: brass, stainless steel, zinc alloy, and plastic.

Brass

Key Properties: Brass is an alloy primarily composed of copper and zinc. It exhibits excellent corrosion resistance, particularly in moist environments. It also has good thermal and electrical conductivity, making it suitable for applications involving electrical components.

Pros & Cons: Brass hinges are known for their aesthetic appeal, often used in decorative applications due to their warm, golden hue. They are relatively easy to machine, which simplifies manufacturing. However, brass can be more expensive than other materials, and its softness may lead to wear over time, especially in high-traffic applications.

Impact on Application: Brass is ideal for applications where appearance is essential, such as in furniture and cabinetry. However, its lower strength compared to steel may limit its use in heavy-duty applications.

Considerations for International Buyers: Brass hinges must comply with standards like ASTM B36 and EN 12163. Buyers in Europe, especially in countries like France and Spain, often prefer brass for its aesthetic qualities, while buyers in Africa and South America might consider cost implications.

Stainless Steel

Key Properties: Stainless steel is renowned for its exceptional strength and corrosion resistance, particularly in harsh environments. It can withstand high temperatures and pressures, making it suitable for industrial applications.

Pros & Cons: The durability of stainless steel hinges makes them ideal for high-use environments, such as in machinery and electronic devices. However, they can be more expensive than brass and harder to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel is suitable for applications exposed to moisture, chemicals, or high temperatures, such as in medical devices or outdoor equipment. Its strength ensures longevity, even in demanding conditions.

Considerations for International Buyers: Compliance with standards such as ASTM A276 and DIN 1.4301 is essential. Buyers from the Middle East and Europe often prefer stainless steel for its durability, while those from Africa and South America may weigh cost against performance.

Zinc Alloy

Key Properties: Zinc alloy is a cost-effective material known for its good strength-to-weight ratio and corrosion resistance. It can be easily cast into complex shapes, making it suitable for intricate designs.

Pros & Cons: Zinc alloy hinges are generally less expensive than brass and stainless steel, making them appealing for mass production. However, they may not perform as well under extreme conditions, such as high temperatures or heavy loads.

Impact on Application: These hinges are often used in consumer products, such as toys and small appliances, where cost efficiency is critical. However, their limited durability may restrict their use in more demanding applications.

Considerations for International Buyers: Compliance with standards like ASTM B240 is important. Buyers in South America may find zinc alloy hinges appealing due to their lower cost, while those in Europe may prioritize durability over price.

Plastic

Key Properties: Plastic hinges are lightweight and resistant to corrosion and moisture, making them ideal for specific applications. They can be manufactured in various colors and styles, providing aesthetic versatility.

Pros & Cons: Plastic hinges are often the most cost-effective option and are easy to install. However, they typically have lower strength and durability compared to metal options, which may limit their use in high-stress applications.

Impact on Application: Plastic hinges are commonly used in applications like electronics and lightweight furniture. Their resistance to corrosion makes them suitable for humid environments, but they may not withstand heavy loads.

Considerations for International Buyers: Compliance with standards such as ISO 9001 is crucial. Buyers in Africa and South America may prefer plastic hinges for their affordability, while European buyers may focus on performance and aesthetic compatibility.

Summary Table

| Material | Typical Use Case for small spring hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Decorative furniture and cabinetry | Aesthetic appeal | Softness leads to wear | Medium |

| Stainless Steel | Industrial and electronic devices | Exceptional strength and durability | Higher cost and machining complexity | High |

| Zinc Alloy | Consumer products like toys | Cost-effective and lightweight | Limited performance under stress | Low |

| Plastic | Electronics and lightweight furniture | Lightweight and corrosion-resistant | Lower strength compared to metals | Low |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions tailored to their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for small spring hinge

When considering the procurement of small spring hinges, it is essential for international B2B buyers to understand the manufacturing processes and quality assurance protocols involved. This knowledge not only aids in making informed purchasing decisions but also ensures that the products meet specific application requirements.

Manufacturing Process of Small Spring Hinges

The manufacturing of small spring hinges typically involves several key stages, each critical to the final product’s quality and functionality. Understanding these stages can help buyers evaluate suppliers more effectively.

1. Material Preparation

The first stage involves selecting and preparing the raw materials. Common materials for small spring hinges include stainless steel, brass, and zinc alloys, each chosen for its unique properties such as corrosion resistance or strength.

- Material Selection: Buyers should specify the desired material based on the hinge’s end use—stainless steel for outdoor applications or brass for aesthetic projects.

- Preparation: Materials are cut to size and may undergo treatments to enhance properties, such as annealing for flexibility.

2. Forming

In this stage, the raw materials are shaped into the hinge components.

- Techniques Used: Common forming techniques include stamping, forging, and CNC machining. Stamping is particularly prevalent for producing high volumes of uniform parts quickly and efficiently.

- Precision Engineering: For small spring hinges, precision is crucial. Buyers should look for manufacturers that utilize advanced machinery capable of achieving tight tolerances.

3. Assembly

After forming, the hinge components are assembled.

- Spring Integration: In small spring hinges, the spring mechanism is integrated during assembly, requiring careful alignment to ensure proper function.

- Automation vs. Manual Assembly: While automation speeds up production, manual assembly might be necessary for more complex designs. Buyers should inquire about the assembly process to understand how it affects quality and consistency.

4. Finishing

The final stage involves applying surface treatments to enhance appearance and durability.

- Coating Options: Finishing processes may include plating, painting, or anodizing, depending on the material and intended use. For example, nickel plating can improve corrosion resistance, while powder coating can provide aesthetic appeal.

- Quality of Finish: A good finish not only enhances visual appeal but also protects against wear and tear, a key consideration for longevity.

Quality Assurance Protocols

Quality assurance (QA) is vital in ensuring that small spring hinges meet international standards and customer specifications.

Relevant International Standards

International standards such as ISO 9001 are critical for ensuring quality management systems are in place. Other relevant certifications may include:

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

- API Certification: Important for hinges used in the oil and gas industry, ensuring they meet specific operational standards.

Quality Control Checkpoints

Quality control is typically conducted at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch defects early and maintain standards.

- Final Quality Control (FQC): A thorough examination of the finished product before shipment, ensuring it meets all specifications and standards.

Common Testing Methods

To verify the quality and performance of small spring hinges, various testing methods may be employed:

- Functional Testing: Ensures the hinge operates as intended under specified loads and conditions.

- Corrosion Resistance Testing: Assesses how well the hinge can withstand environmental factors.

- Fatigue Testing: Determines the durability of the hinge under repeated stress, simulating long-term use.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control measures is crucial to ensure product reliability and compliance with standards.

Audits and Reports

Buyers should request:

- Quality Management System Audits: Evaluating the supplier’s adherence to established quality standards.

- Production Reports: Detailed documentation of the manufacturing process and quality checks can provide insights into the supplier’s practices.

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. This is particularly important for buyers in regions like Africa and South America, where local regulations and standards may vary significantly.

Considerations for International Buyers

When sourcing small spring hinges, particularly from regions such as Europe, the Middle East, and South America, consider the following:

- Cultural Differences: Be aware of different business practices and communication styles. Understanding these can facilitate smoother negotiations and partnerships.

- Regulatory Compliance: Ensure that the hinges comply with local regulations and standards in your region. This is especially important when importing products.

- Shipping and Logistics: Consider the logistics of transporting hinges, including shipping times and costs, as well as potential customs duties.

By thoroughly understanding the manufacturing processes and quality assurance measures associated with small spring hinges, B2B buyers can make more informed purchasing decisions, ensuring they receive high-quality products tailored to their specific needs.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for small spring hinge Sourcing

The cost structure of small spring hinges involves multiple components that contribute to the final pricing. Understanding these elements is crucial for international B2B buyers to make informed sourcing decisions.

Cost Components

-

Materials: The choice of materials significantly affects the cost. Common materials for small spring hinges include brass, stainless steel, and zinc alloys. Brass is often more expensive due to its durability and aesthetic appeal, while zinc alloys can provide a cost-effective alternative without compromising strength.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs, such as those in parts of Asia or Eastern Europe, may offer cheaper pricing. However, the trade-off may be in quality or consistency.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and salaries for non-direct labor. Higher overhead can lead to increased prices, particularly in regions with elevated living costs.

-

Tooling: The initial investment in tooling for production can impact pricing, especially for customized hinges. If a buyer requests a unique design or specific dimensions, the tooling costs may be passed on in the form of higher prices.

-

Quality Control (QC): Rigorous quality control processes add to the manufacturing costs. Certifications such as ISO or industry-specific standards can further increase expenses but may be essential for specific markets, particularly in Europe.

-

Logistics: Shipping costs are a critical factor in the total cost of acquisition. Variables include distance, mode of transport, and any tariffs or duties applicable in the buyer’s country. Choosing the right Incoterms can also affect overall logistics costs.

-

Margin: Suppliers typically apply a margin on top of their costs to ensure profitability. This margin can vary based on market competition, supplier reputation, and the buyer’s negotiation skills.

Price Influencers

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should inquire about minimum order quantities (MOQs) and negotiate based on their purchasing power.

-

Specifications/Customization: Customized or highly specified hinges typically incur additional costs. Buyers should weigh the necessity of custom features against their budget.

-

Quality/Certifications: Premium quality hinges with certifications will command higher prices. Buyers should evaluate their quality requirements and the importance of certifications in their industry.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is essential for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost.

Buyer Tips

-

Negotiation: Engage in negotiations with suppliers to secure the best possible pricing. Highlighting long-term business potential can motivate suppliers to offer better terms.

-

Cost-Efficiency: Consider total cost of ownership (TCO) rather than just the purchase price. Include factors like durability, maintenance, and lifecycle costs in your analysis.

-

Pricing Nuances: International buyers should be aware of regional pricing differences and currency fluctuations that could impact costs. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to identify competitive pricing and viable suppliers.

Disclaimer

Prices for small spring hinges can vary widely based on the factors mentioned above. Buyers should conduct their due diligence and obtain multiple quotes to ensure they are getting a fair deal.

Illustrative Image (Source: Google Search)

Spotlight on Potential small spring hinge Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘small spring hinge’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for small spring hinge

Small spring hinges are essential components in various applications, combining functionality with aesthetic considerations. Understanding their technical properties and the terminology used in trade can significantly enhance the purchasing process for B2B buyers. Here’s a breakdown of the critical specifications and common terms associated with small spring hinges.

Key Technical Properties

-

Material Grade

– The material used in small spring hinges significantly affects durability, corrosion resistance, and overall functionality. Common materials include stainless steel, brass, and zinc alloy. For instance, stainless steel is ideal for outdoor applications due to its superior rust resistance, while brass is favored for decorative purposes. -

Load Capacity

– This specification indicates the maximum weight the hinge can support while maintaining its functionality. Knowing the load capacity is crucial for buyers, especially in industries like electronics and furniture, where the integrity of the hinge affects the performance of the entire assembly. -

Spring Tension

– The tension of the spring within the hinge determines how forcefully the hinge returns to its closed position. This property is critical in applications requiring automatic closing, such as cabinet doors or access panels. Buyers should assess the required tension to ensure the hinge meets the functional needs of their project. -

Tolerance Levels

– Tolerance refers to the allowable deviation in measurements during manufacturing. High tolerance levels ensure that the hinge fits perfectly in its intended application, reducing the risk of malfunction or damage over time. This is particularly important for precision industries, such as automotive or aerospace. -

Finish and Coating

– The finish applied to a small spring hinge affects its aesthetic appeal and resistance to environmental factors. Options may include polished brass, matte black, or powder coating. Buyers should consider the intended use and environmental conditions when selecting a finish to ensure longevity and visual compatibility. -

Size and Dimensions

– The dimensions of a small spring hinge, including its width, height, and thickness, are vital for fit and function. Buyers must accurately measure the installation space to select a hinge that will operate effectively without obstruction.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality sources for small spring hinges that meet specific project standards. -

MOQ (Minimum Order Quantity)

– MOQ defines the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and planning inventory levels, especially in regions like Africa and South America, where bulk purchasing may provide cost advantages. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. Including detailed specifications for small spring hinges in an RFQ can lead to more accurate quotes and better purchasing decisions. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to navigate shipping and delivery logistics effectively. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times for small spring hinges can help buyers plan their production schedules and ensure timely project completion. -

Certification Standards

– This refers to the compliance of small spring hinges with industry standards, such as ISO or ASTM. Certifications ensure quality and safety, making it easier for buyers to trust their suppliers and products.

By grasping these essential properties and terms, international B2B buyers can make informed decisions that align with their project requirements and operational goals, enhancing both efficiency and effectiveness in procurement processes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the small spring hinge Sector

Market Overview & Key Trends

The small spring hinge sector is experiencing significant growth driven by increasing demand across various industries, including furniture manufacturing, electronics, and precision instruments. This surge is primarily fueled by the rise of custom and bespoke furniture, where aesthetic appeal and functional performance are paramount. B2B buyers from Africa, South America, the Middle East, and Europe (notably France and Spain) are particularly seeking innovative solutions that blend design with functionality.

Emerging trends indicate a shift towards smart hinges that integrate technology for enhanced functionality, such as self-closing mechanisms or remote control capabilities. Additionally, buyers are increasingly favoring lightweight materials that do not compromise strength, aligning with global trends toward more sustainable and efficient manufacturing processes. Digital transformation in sourcing is also gaining traction, with platforms enabling real-time procurement and supplier evaluations, streamlining the buying process for international B2B customers.

Market dynamics are evolving, with suppliers focusing on customization and short lead times to meet the demands of diverse applications. International buyers are advised to stay abreast of regional manufacturing capabilities and logistics solutions to optimize sourcing strategies. As competition intensifies, leveraging data analytics for informed purchasing decisions will be crucial in navigating this dynamic landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central theme in the small spring hinge sector, as environmental concerns shape buyer preferences and regulatory frameworks. The production of small hinges can have a considerable environmental impact, particularly in terms of resource consumption and waste generation. Therefore, buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices.

Ethical sourcing is vital, with an emphasis on transparent supply chains. Buyers should seek manufacturers who adhere to recognized standards and certifications, such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) certification for wood-based products. Utilizing materials that are recycled or sustainably sourced not only minimizes ecological footprints but also enhances brand reputation among environmentally conscious consumers.

Incorporating green materials in hinge production, such as eco-friendly coatings and non-toxic finishes, is also gaining traction. This shift not only aligns with sustainability goals but can also lead to cost savings through improved efficiency and reduced waste. By prioritizing suppliers that align with these values, international B2B buyers can contribute to a more sustainable future while meeting their operational needs.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The small spring hinge has evolved significantly over the years, with its origins tracing back to traditional woodworking practices. Initially crafted from simple materials, advancements in metallurgy and engineering have led to the development of more sophisticated designs. The introduction of spring mechanisms has enhanced functionality, allowing for smoother operation and greater durability.

Historically, small hinges were primarily utilized in furniture and cabinetry. However, as industries have diversified, these components have found applications in electronics and precision instruments, reflecting the ongoing demand for compact and reliable hardware solutions. This evolution has positioned small spring hinges as essential elements in both aesthetic and functional applications, highlighting their importance in contemporary manufacturing and design.

International buyers should recognize this historical context to better appreciate the innovations and standards that continue to shape the small spring hinge market today.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of small spring hinge

-

What should I consider when vetting suppliers for small spring hinges?

When vetting suppliers, prioritize their experience and reputation in the industry. Look for certifications such as ISO 9001, which indicate adherence to quality management standards. Check reviews and testimonials from other B2B buyers, particularly those from your region (Africa, South America, the Middle East, or Europe). Additionally, assess their production capabilities, technology used, and whether they can provide samples to evaluate hinge quality before committing to a larger order. -

Can I customize small spring hinges to meet specific requirements?

Many manufacturers offer customization options for small spring hinges. You can request specific dimensions, materials, finishes, and even functional features such as tension strength or color. Ensure you communicate your requirements clearly and ask for prototypes or samples to validate the design before proceeding with bulk orders. Customization may also affect lead times and costs, so discuss these aspects upfront. -

What are the typical minimum order quantities (MOQ) and lead times for small spring hinges?

Minimum order quantities for small spring hinges can vary significantly based on the supplier and the complexity of the order. Generally, MOQs can range from 100 to 1,000 units. Lead times also depend on production schedules and customization; standard orders may take 2-4 weeks, while customized products could take longer. Always confirm these details during negotiations to align your procurement timelines with project deadlines. -

What payment methods are commonly accepted by suppliers, and how can I ensure security?

Common payment methods include wire transfers, letters of credit, and online payment platforms. For international transactions, letters of credit are often preferred as they provide security for both parties. To ensure transaction safety, conduct payments through reputable channels, and consider using escrow services for large orders. It’s also wise to negotiate terms that allow partial payments upfront and the remainder upon delivery. -

How can I ensure quality assurance and certification of the small spring hinges I purchase?

Request documentation of quality assurance processes from your suppliers, including test reports and certifications relevant to your industry. Certifications such as CE (European Conformity) for the EU market or RoHS (Restriction of Hazardous Substances) can be critical, depending on your application. Conducting an on-site audit or third-party inspection can further assure compliance with your quality standards, especially for large shipments. -

What logistics considerations should I keep in mind when importing small spring hinges?

Logistics considerations include shipping methods, costs, and customs clearance procedures. Assess whether air or sea freight is more suitable based on your timeline and budget. Understand the import regulations in your country, including tariffs and taxes applicable to small hardware items. Collaborating with a reliable freight forwarder can streamline the logistics process and help you navigate international shipping complexities. -

How can disputes over quality or delivery be effectively managed with suppliers?

To manage disputes effectively, establish clear terms and conditions in your purchase agreement, detailing expectations regarding quality standards, delivery timelines, and return policies. Maintain open lines of communication with your supplier throughout the process to address issues promptly. If disputes arise, refer to your contract and engage in constructive dialogue to seek resolution; mediation or arbitration may be necessary if direct negotiations fail. -

What are the best practices for maintaining a long-term relationship with small spring hinge suppliers?

Building a long-term relationship with suppliers involves consistent communication and feedback on product quality and service. Regularly review performance metrics, such as delivery times and responsiveness, to foster transparency. Consider placing repeat orders or exploring additional product lines to demonstrate loyalty. Engaging suppliers in joint development initiatives can also strengthen partnerships and encourage mutual growth in the competitive B2B landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for small spring hinge

In summary, the strategic sourcing of small spring hinges is vital for international B2B buyers looking to enhance their product offerings across diverse industries. By understanding the various types, materials, and applications of small hinges, businesses can make informed decisions that optimize functionality and aesthetic appeal.

Key takeaways include the importance of selecting the right hinge type for specific applications, considering materials that align with environmental conditions, and choosing finishes that enhance product value. Furthermore, leveraging the right suppliers can ensure high-quality standards, timely delivery, and competitive pricing, which are crucial for maintaining operational efficiency.

As we look to the future, the global demand for customized and high-performance small spring hinges is expected to grow, driven by advancements in technology and design. International buyers from Africa, South America, the Middle East, and Europe should actively engage with manufacturers and suppliers who can provide innovative solutions tailored to their unique needs.

Take action now by exploring strategic partnerships and investing in high-quality small spring hinges to stay ahead in a competitive market. Embrace the opportunities that come with informed sourcing decisions and watch your business thrive.