Master Sourcing Steel Brackets: Your Comprehensive Guide

Introduction: Navigating the Global Market for steel brackets

Navigating the complex landscape of the global market for steel brackets is critical for B2B buyers looking to optimize their procurement strategies. Steel brackets are fundamental components in various industries, providing essential support and stability in applications ranging from construction and manufacturing to electronics and automotive sectors. Their durability and strength make them indispensable for ensuring structural integrity and longevity.

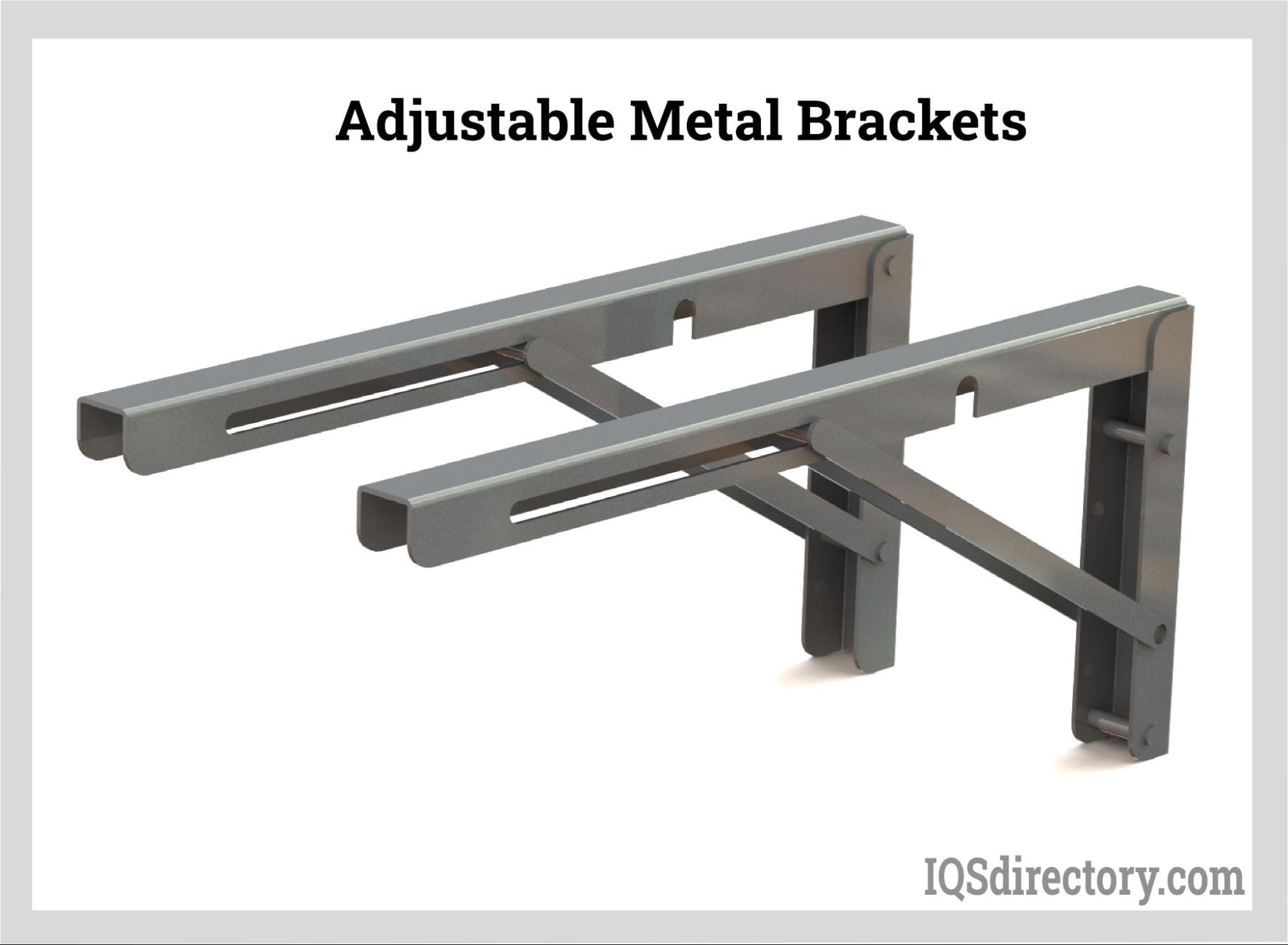

This comprehensive guide will delve into the myriad types of steel brackets available, including L, U, Z, and custom designs tailored to specific needs. We will explore various materials, focusing on the benefits of different grades of steel and coatings that enhance performance in diverse environments. Additionally, the guide will cover manufacturing processes, quality control measures, and the importance of sourcing from reliable suppliers to ensure product consistency and compliance with international standards.

Understanding cost factors, market trends, and regional dynamics is crucial for informed decision-making. This guide empowers international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, by equipping them with actionable insights and practical knowledge. By addressing frequently asked questions and providing a clear pathway for sourcing steel brackets, we aim to enhance your procurement efficiency and drive value in your operations. Whether you’re in Nigeria, South Africa, or beyond, this resource is designed to facilitate your success in the global marketplace.

Understanding steel brackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| L-Brackets | Right-angle shape, simple design | Furniture assembly, shelving | Pros: Cost-effective, easy to install. Cons: Limited load-bearing capacity. |

| U-Brackets | U-shaped design, supports cylindrical objects | Pipe supports, cable management | Pros: Versatile, accommodates various sizes. Cons: Requires precise alignment for optimal support. |

| T-Brackets | T-shape, connects three surfaces | Frame structures, heavy-duty equipment | Pros: Strong support for complex assemblies. Cons: More expensive than simpler types. |

| Z-Brackets | Z-shape, multi-directional support | Wall mounting, furniture support | Pros: Flexible application across angles. Cons: Can be bulky, requiring more space. |

| H-Brackets | H-shape, designed for larger structures | Heavy machinery, structural support | Pros: High load capacity, robust design. Cons: Heavier and more expensive than standard brackets. |

L-Brackets

L-brackets are characterized by their right-angle shape, making them a fundamental choice for various applications. They are commonly used in furniture assembly and shelving, providing a straightforward solution for corner joints. When purchasing L-brackets, buyers should consider the load-bearing capacity and material quality, as these factors significantly influence performance. Their cost-effectiveness and ease of installation make them a popular choice, though their limited load capacity may not suit heavy-duty applications.

U-Brackets

U-brackets feature an upward bend on both sides, allowing them to support cylindrical objects such as pipes or cables. They are widely utilized in pipe supports and cable management systems, where stability is crucial. For B2B buyers, the versatility of U-brackets is a key advantage, as they can accommodate various sizes and shapes. However, precise alignment during installation is critical to ensure optimal support, which can be a challenge in certain setups.

T-Brackets

T-brackets are designed to connect three surfaces at right angles, resembling the letter “T.” They are ideal for complex frame structures and heavy-duty equipment, providing strong support where multiple components meet. Buyers should focus on the material strength and design specifications when selecting T-brackets, as these factors will determine their suitability for specific applications. While they offer robust support, their higher cost compared to simpler brackets may be a consideration for budget-conscious buyers.

Z-Brackets

Z-brackets are uniquely shaped to offer multi-directional support, making them versatile for various mounting applications. They are particularly useful in wall mounting and supporting furniture, where different angles are needed. For international B2B buyers, the flexibility of Z-brackets can enhance project adaptability. However, their bulkier design may require more installation space, which could be a drawback in compact environments.

H-Brackets

H-brackets are engineered to support larger structures and heavy machinery, characterized by their robust H-shape. They provide exceptional load capacity and stability, making them suitable for critical applications in construction and industrial settings. When sourcing H-brackets, buyers should evaluate the weight specifications and material durability to ensure they meet project requirements. While they offer significant strength, their weight and cost may be higher than standard brackets, necessitating a careful cost-benefit analysis.

Key Industrial Applications of steel brackets

| Industry/Sector | Specific Application of Steel Brackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural support in buildings and bridges | Ensures safety and stability of structures | Compliance with local building codes and standards; material grade specifications. |

| Manufacturing | Equipment mounting and assembly | Facilitates efficient production line setups | Precision in dimensions; ability to withstand heavy loads and vibrations. |

| Automotive | Chassis reinforcement and component support | Enhances vehicle safety and performance | Durability against environmental factors; compatibility with existing designs. |

| Energy | Support for solar panels and wind turbines | Maximizes energy efficiency and production | Resistance to corrosion; adaptability to various installation environments. |

| Electronics | Mounting for circuit boards and enclosures | Provides secure housing for sensitive components | Precision manufacturing; thermal conductivity considerations. |

Key Industrial Applications of Steel Brackets

Construction

In the construction industry, steel brackets are vital for providing structural support in buildings and bridges. They are used to secure beams, columns, and other structural elements, ensuring safety and stability. International buyers, particularly in regions like Africa and South America, must ensure that the brackets comply with local building codes and standards. Additionally, the specifications for material grade are crucial to withstand local environmental conditions, such as humidity and temperature fluctuations.

Manufacturing

Steel brackets play a critical role in the manufacturing sector, especially for equipment mounting and assembly. These brackets facilitate the efficient setup of production lines by securing machinery and components in place. For B2B buyers, it is essential to source brackets that are precisely dimensioned to fit specific machinery. Additionally, the ability of these brackets to withstand heavy loads and vibrations is a key consideration, particularly in high-output manufacturing environments.

Automotive

In the automotive industry, steel brackets are used for chassis reinforcement and component support, contributing to vehicle safety and performance. They help secure various parts of the vehicle, including engines and suspension systems. Buyers in this sector should focus on sourcing durable brackets that can resist environmental factors such as corrosion and extreme temperatures. Compatibility with existing vehicle designs is also crucial, ensuring seamless integration during assembly.

Energy

Steel brackets are increasingly used in the energy sector, particularly for supporting solar panels and wind turbines. They provide the necessary stability and strength to withstand wind loads and other environmental stresses, maximizing energy efficiency and production. International buyers should prioritize sourcing brackets that are resistant to corrosion, especially in coastal regions, and that can adapt to various installation environments, from rooftops to open fields.

Electronics

In the electronics industry, steel brackets are essential for mounting circuit boards and enclosures. They provide secure housing for sensitive components, preventing damage during operation. Buyers must consider precision manufacturing to ensure that the brackets fit perfectly and do not interfere with thermal management. Additionally, thermal conductivity is a vital factor, as it can impact the performance and longevity of electronic devices.

Related Video: Steel Construction: Foundations

Strategic Material Selection Guide for steel brackets

When selecting materials for steel brackets, international B2B buyers must consider various factors that influence performance, cost, and suitability for specific applications. Here, we analyze four common materials used in the production of steel brackets: Carbon Steel, Stainless Steel, Galvanized Steel, and Alloy Steel.

Carbon Steel

Key Properties: Carbon steel is known for its high tensile strength and ability to withstand heavy loads. It typically has a temperature rating up to 400°F (204°C) and offers moderate corrosion resistance.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength, making it suitable for applications requiring high durability. However, its susceptibility to rust and corrosion in humid or wet environments can limit its use without protective coatings.

Impact on Application: Carbon steel brackets are ideal for indoor applications where exposure to moisture is minimal. They are commonly used in furniture assembly and structural supports.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM A36 for structural steel. Understanding the environmental conditions is crucial to prevent premature failure due to corrosion.

Stainless Steel

Key Properties: Stainless steel is highly resistant to corrosion and oxidation, with temperature ratings often exceeding 800°F (427°C). It contains chromium, which forms a protective layer on the surface.

Pros & Cons: The main advantage of stainless steel is its durability and aesthetic appeal, making it suitable for both functional and decorative applications. However, it is more expensive than carbon steel and can be challenging to machine due to its hardness.

Impact on Application: Stainless steel brackets are preferred in environments exposed to moisture, such as coastal areas or food processing facilities. They are ideal for applications requiring hygiene and cleanliness.

Considerations for International Buyers: Buyers in the Middle East and Europe should verify compliance with standards like ASTM A240. They should also consider the cost implications, as stainless steel may significantly increase overall project budgets.

Galvanized Steel

Key Properties: Galvanized steel is carbon steel that has been coated with zinc to enhance corrosion resistance. It typically withstands temperatures up to 400°F (204°C) and provides a protective barrier against rust.

Pros & Cons: The key advantage of galvanized steel is its affordability combined with corrosion resistance, making it suitable for outdoor applications. However, the zinc coating can wear off over time, especially in harsh environments, leading to potential rust issues.

Impact on Application: Galvanized steel brackets are widely used in construction and outdoor applications, such as supporting signage or fencing. They are effective in environments with moderate exposure to moisture.

Considerations for International Buyers: Compliance with standards like ASTM A123 for hot-dip galvanizing is essential for buyers in regions like Africa and South America. Buyers should also assess local environmental factors that could impact the longevity of the zinc coating.

Alloy Steel

Key Properties: Alloy steel contains additional elements like chromium, nickel, or molybdenum, enhancing its mechanical properties and temperature ratings up to 1,200°F (649°C). It offers superior strength and toughness.

Pros & Cons: The primary advantage of alloy steel is its versatility and ability to withstand extreme conditions, making it suitable for heavy-duty applications. However, it is generally more expensive and may require specialized manufacturing processes.

Impact on Application: Alloy steel brackets are often used in high-stress applications, such as automotive and aerospace industries, where strength and reliability are critical.

Considerations for International Buyers: Buyers from Europe and the Middle East should ensure compliance with relevant standards, such as ASTM A387 for pressure vessels. Understanding the specific application requirements is crucial for selecting the right alloy composition.

Summary Table

| Material | Typical Use Case for steel brackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Indoor furniture assembly | Cost-effective and strong | Susceptible to rust | Low |

| Stainless Steel | Food processing and coastal applications | Excellent corrosion resistance | Higher cost and machining difficulty | High |

| Galvanized Steel | Outdoor construction and signage supports | Affordable with good corrosion resistance | Zinc coating can wear off over time | Medium |

| Alloy Steel | Heavy-duty automotive and aerospace | Superior strength and toughness | Higher cost and complex manufacturing | High |

This guide provides essential insights into material selection for steel brackets, enabling international B2B buyers to make informed decisions that align with their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for steel brackets

When it comes to the manufacturing of steel brackets, understanding the processes and quality assurance practices is crucial for B2B buyers. This knowledge not only helps in selecting the right suppliers but also ensures the components meet the necessary standards for performance and durability. Below is an in-depth look at the typical manufacturing processes and quality assurance measures employed in the production of steel brackets.

Manufacturing Processes

Material Preparation

The first step in manufacturing steel brackets involves selecting the appropriate raw materials. High-strength steel is typically chosen for its durability and resistance to deformation. The materials are then cut into manageable sizes for processing. Common techniques for this include:

- Sheet Metal Cutting: This can be achieved through methods such as laser cutting, water jet cutting, or mechanical shearing. Each method has its advantages, with laser cutting providing high precision, while water jet cutting avoids heat distortion.

- Material Inspection: Before moving to the next stage, it is essential to conduct an incoming quality check (IQC) to ensure that the materials meet specified standards. This inspection often includes checking for chemical composition, mechanical properties, and surface defects.

Forming

Once the materials are prepared, the next stage is forming. This process shapes the steel into the desired bracket configuration. Key techniques include:

- CNC Machining: Computer Numerical Control (CNC) machining allows for precise shaping and cutting of brackets, accommodating complex designs.

- Bending and Stamping: A press brake is commonly used to bend the steel into specific angles (such as L or U shapes). Stamping presses are used for mass production, allowing for rapid formation of uniform brackets.

- Welding: For brackets requiring multiple components, welding is used to assemble parts. This process must be executed with care to maintain structural integrity.

Assembly

In the assembly stage, the formed components are put together to create the final product. This may involve:

- Joining Techniques: Besides welding, other methods like riveting or bolting may be employed, depending on the application and design requirements.

- Quality Checks: During assembly, in-process quality control (IPQC) is conducted to monitor the assembly integrity, ensuring that all components are correctly aligned and securely fastened.

Finishing

The final stage in the manufacturing process involves finishing treatments, which enhance the steel brackets’ durability and appearance. Common finishing processes include:

- Surface Treatment: Techniques such as powder coating, galvanization, or anodizing are employed to prevent corrosion and improve aesthetic appeal.

- Final Inspection: Before shipping, a final quality check (FQC) is conducted to verify that the brackets meet all specifications and standards.

Quality Assurance

Quality assurance in steel bracket manufacturing is vital for ensuring product reliability. Here are key aspects of the QA process that B2B buyers should consider:

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is essential for manufacturers aiming to ensure consistent quality and customer satisfaction.

- CE Marking: For products sold within the European Economic Area, CE marking signifies compliance with health, safety, and environmental protection standards.

- API Standards: For brackets used in the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial for ensuring safety and quality.

Quality Checkpoints

B2B buyers should be aware of the various quality checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival ensures they meet specified standards.

- In-Process Quality Control (IPQC): Regular checks during the forming and assembly processes help identify defects early.

- Final Quality Control (FQC): A comprehensive inspection before shipment ensures that the final product meets all requirements.

Common Testing Methods

Quality testing methods commonly used in steel bracket manufacturing include:

- Tensile Testing: Measures the strength of the material and ensures it can withstand required loads.

- Impact Testing: Assesses the material’s toughness, particularly important for brackets used in high-stress applications.

- Dimensional Inspection: Verifies that the finished brackets conform to specified dimensions and tolerances.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, ensuring supplier quality is paramount. Here are actionable strategies:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Look for certifications such as ISO 9001.

- Requesting Quality Reports: Suppliers should provide documentation that details their quality control processes, inspection results, and compliance with relevant standards.

- Third-Party Inspections: Engaging independent third-party inspectors can add an additional layer of verification, ensuring that the products meet international standards before they reach your facility.

Quality Control and Certification Nuances for International Buyers

B2B buyers from diverse regions need to be aware of specific quality control nuances:

- Cultural Differences: Understand the cultural context of suppliers, as quality perceptions may vary.

- Regulatory Compliance: Be aware of regional regulations that may affect product quality and certification requirements.

- Language Barriers: Ensure clear communication regarding quality expectations and standards to mitigate misunderstandings.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing steel brackets, ensuring they receive high-quality products that meet their specifications and regulatory requirements.

Related Video: Complete Steel Making Process in easy steps ll. TATA VOCATIONAL TRAINING

Comprehensive Cost and Pricing Analysis for steel brackets Sourcing

Understanding the Cost Structure of Steel Brackets

When sourcing steel brackets, international B2B buyers must navigate a complex cost structure. The primary components influencing the pricing of steel brackets include:

-

Materials: The type of steel used significantly impacts costs. High-strength steel alloys may be more expensive but offer better performance and longevity. Additionally, fluctuations in global steel prices can affect overall expenses.

-

Labor: Labor costs vary by region and manufacturing process. Countries with lower labor costs may provide a competitive advantage, but it’s essential to ensure that quality is not compromised.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, rent, and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: Custom brackets may require specialized tooling, which can be a significant initial investment. Buyers should consider whether the tooling costs can be amortized over a large volume of orders.

-

Quality Control (QC): Stringent quality control measures ensure the reliability of the brackets. While QC adds to costs, it can prevent future expenses related to product failures or recalls.

-

Logistics: Shipping costs, including freight and insurance, can vary widely based on destination and mode of transport. Incoterms will dictate who bears these costs and can influence overall pricing.

-

Margin: Suppliers will add a profit margin based on their operational costs and market conditions. Understanding typical margins in your industry can aid in negotiations.

Key Influencers on Pricing

Several factors can influence the pricing of steel brackets, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Buyers should assess their needs to find a balance between inventory costs and order sizes.

-

Specifications and Customization: Custom designs or specific tolerances can increase costs. Clear communication of requirements is crucial to avoid unexpected expenses.

-

Materials and Certifications: Specific material grades and certifications (e.g., ISO, CE) can affect pricing. Buyers should determine the necessary quality standards for their application.

-

Supplier Factors: Supplier reputation, location, and production capabilities can impact costs. Establishing a long-term relationship with reliable suppliers can lead to better pricing over time.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) will clarify cost responsibilities and can significantly affect the total landed cost of the brackets.

Practical Buyer Tips

-

Negotiate Wisely: Always be prepared to negotiate. Understanding the supplier’s cost structure can provide leverage in discussions. Aim for a win-win scenario to foster long-term relationships.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes initial purchase price, maintenance, and potential disposal costs. A cheaper bracket may lead to higher long-term expenses if it fails prematurely.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local taxes that can affect the final price. Working with suppliers who understand these nuances can simplify the process.

-

Quality Assurance: Prioritize suppliers with robust quality assurance processes. Investing in higher-quality brackets may save money in the long run by reducing failures and maintenance needs.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide insights into market rates and help identify the best value proposition.

Disclaimer

The pricing information provided in this analysis is indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult multiple sources to ensure accurate pricing for your specific needs.

Spotlight on Potential steel brackets Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘steel brackets’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for steel brackets

When sourcing steel brackets for industrial applications, understanding their essential technical properties and the relevant trade terminology is crucial. This knowledge enables B2B buyers to make informed purchasing decisions that align with their project requirements. Below are key properties and terms to consider.

Key Technical Properties of Steel Brackets

-

Material Grade

– The material grade of steel brackets indicates the type and quality of steel used, often specified by standards such as ASTM (American Society for Testing and Materials). Common grades include ASTM A36 (mild steel) and ASTM A572 (high-strength low-alloy steel). Understanding the material grade is critical as it directly affects the bracket’s strength, durability, and resistance to corrosion, ensuring it meets the specific demands of the application. -

Load Capacity

– This refers to the maximum weight a bracket can support without failure. Load capacity is crucial in applications where structural integrity is paramount, such as in construction or heavy machinery. Buyers should assess their requirements based on the intended use and select brackets with appropriate load ratings to prevent potential hazards. -

Tolerance

– Tolerance defines the permissible limits of variation in a bracket’s dimensions. It is vital for ensuring proper fit and function in assemblies. Inaccurate tolerances can lead to assembly issues, increased wear, and reduced performance. Understanding tolerance specifications helps buyers ensure compatibility with other components in their systems. -

Finish

– The surface finish of steel brackets can influence aesthetics, corrosion resistance, and wear properties. Common finishes include powder coating, galvanization, and painting. Selecting the right finish is important for applications exposed to harsh environments, as it can enhance longevity and reduce maintenance costs. -

Thickness

– The thickness of the steel used in brackets affects both strength and weight. Thicker materials typically provide higher strength but may add unnecessary weight for lighter applications. Buyers should balance these factors based on the specific application requirements to optimize performance and cost. -

Welding and Assembly Features

– Many steel brackets are designed with specific features for welding or assembly, such as pre-drilled holes or notches. Understanding these features is important for ensuring ease of installation and compatibility with other components, particularly in custom projects.

Common Trade Terms in Steel Bracket Sourcing

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is important for buyers looking for specific components or custom solutions, as they may need to engage directly with OEMs for tailored products. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand their purchasing options, especially for custom brackets where suppliers may have set minimums that can impact budget and inventory management. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Buyers should prepare detailed RFQs to ensure they receive accurate and competitive pricing from vendors. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, insurance, and risk transfer, particularly for international buyers from regions like Africa and South America. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the product. It is a critical consideration in project planning, as longer lead times can affect project schedules and timelines. Buyers should communicate lead time expectations with suppliers to ensure timely delivery. -

Certification Standards

– Certification standards indicate compliance with industry regulations and quality benchmarks (e.g., ISO, CE). Understanding these standards helps buyers ensure that the steel brackets meet necessary safety and performance criteria, which is particularly important for regulated industries.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies for steel brackets, ensuring they select the right components for their projects while navigating the complexities of international sourcing.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the steel brackets Sector

Market Overview & Key Trends

The global market for steel brackets is primarily driven by the increasing demand for durable and versatile construction materials across various industries, including construction, automotive, and manufacturing. As urbanization progresses in regions like Africa and South America, the need for structural integrity in buildings and infrastructure projects has surged. This demand is further amplified by the trend of modular and prefabricated construction, where steel brackets play a critical role in assembly and support.

Emerging technologies in the B2B sourcing landscape are revolutionizing how international buyers procure steel brackets. The integration of digital platforms, such as e-commerce and online marketplaces, allows for streamlined procurement processes, enabling buyers from regions like Nigeria and South Africa to access a broader range of suppliers. Additionally, advancements in manufacturing technologies, such as CNC machining and automation, enhance precision and reduce lead times, making it easier for buyers to meet tight project deadlines.

Market dynamics are also influenced by fluctuating raw material prices and trade policies. Buyers must stay informed about tariff regulations and trade agreements that may impact costs. Furthermore, the shift towards sustainable practices is prompting suppliers to innovate, offering eco-friendly materials and production methods. This trend is particularly significant for international buyers who are increasingly prioritizing sustainability in their sourcing strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is a crucial consideration for international B2B buyers in the steel brackets sector. The environmental impact of steel production is significant, with high energy consumption and greenhouse gas emissions. As a result, buyers are urged to seek suppliers committed to reducing their carbon footprint through energy-efficient manufacturing processes and recycling initiatives.

The importance of ethical supply chains cannot be overstated. Buyers should prioritize partnerships with suppliers who adhere to ethical labor practices and have transparent sourcing strategies. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for sustainably sourced materials can help buyers identify responsible suppliers. Furthermore, the adoption of recycled steel in manufacturing brackets not only reduces environmental impact but also enhances the circular economy.

Investing in ‘green’ materials and processes not only fulfills corporate social responsibility but can also be a market differentiator. As consumers increasingly demand sustainability, B2B buyers who prioritize eco-friendly products may find themselves ahead of the competition.

Brief Evolution/History

The use of metal brackets can be traced back to ancient civilizations, where they were utilized in various structural applications. The evolution of steel as a primary material in construction during the 19th century marked a significant turning point. Steel brackets became essential components in modern architecture and engineering, providing unparalleled strength and stability.

In recent decades, advancements in manufacturing techniques, such as laser cutting and CNC machining, have transformed the production of steel brackets, allowing for more complex designs and improved durability. As the industry continues to evolve, the focus on sustainability and ethical sourcing is shaping the future of steel brackets, making them not just functional components but also integral parts of responsible construction practices.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of steel brackets

-

What should I look for when vetting suppliers of steel brackets?

When vetting suppliers, prioritize their industry experience, production capabilities, and quality assurance processes. Review customer testimonials and case studies to gauge reliability. Ensure they have certifications relevant to your region, such as ISO 9001, which reflects a commitment to quality management. Additionally, assess their communication responsiveness and ability to meet your specific needs, including customization options and lead times. -

Can I customize steel brackets to fit my specific applications?

Yes, most suppliers offer customization services for steel brackets. You can specify dimensions, material grades, and finishes based on your project requirements. It’s advisable to provide detailed drawings or prototypes to ensure accuracy. Discuss your needs during the initial consultation, and confirm that the supplier has the necessary equipment and expertise to fulfill your customization requests. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary widely by supplier and the complexity of the brackets. Generally, for standard designs, MOQs may range from 100 to 1,000 units, while custom designs might require higher quantities. Lead times typically range from 2 to 12 weeks, depending on the supplier’s capacity and order complexity. Always confirm these details before placing an order to avoid unexpected delays. -

What payment terms should I expect when sourcing steel brackets internationally?

Payment terms vary by supplier but typically include options such as upfront deposits (20-30%) with the balance due upon shipment or delivery. Some suppliers may offer net terms based on your creditworthiness. For international transactions, consider secure payment methods like letters of credit or PayPal to protect against fraud. Always clarify payment terms in the contract to avoid misunderstandings. -

How can I ensure quality and compliance with industry standards?

To ensure quality, request certifications from your supplier that demonstrate compliance with relevant standards, such as ASTM or EN specifications for steel products. Ask for test reports and quality assurance processes, including inspections during production. Consider conducting on-site audits or hiring third-party inspection services to verify that the supplier adheres to quality and safety standards before shipment. -

What logistics considerations should I keep in mind when sourcing steel brackets?

Logistics is crucial in international sourcing. Discuss shipping methods with your supplier, considering options like sea freight for cost-effectiveness or air freight for speed. Understand the customs regulations in your country, including tariffs and import duties, to avoid unexpected costs. Ensure that your supplier provides clear labeling and documentation to facilitate smooth customs clearance. -

How can disputes regarding product quality or delivery be resolved?

To resolve disputes effectively, establish clear terms in your contract regarding quality standards, delivery timelines, and return policies. Maintain open communication with your supplier throughout the process. If a dispute arises, document all communications and evidence related to the issue. Many suppliers will have a formal dispute resolution process in place, which may include mediation or arbitration to reach a satisfactory resolution.

Illustrative Image (Source: Google Search)

- What are the common shipping methods for international delivery of steel brackets?

Common shipping methods for international delivery include sea freight, air freight, and courier services. Sea freight is generally the most economical for large shipments, while air freight is faster but more expensive. For smaller orders or urgent deliveries, consider using express courier services. Discuss with your supplier to determine the best shipping method based on your budget, timeline, and destination.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for steel brackets

In conclusion, strategic sourcing of steel brackets is essential for international B2B buyers seeking to enhance their operational efficiency and product quality. By understanding the diverse types of metal brackets and their applications, businesses can make informed procurement decisions that align with their specific needs. Emphasizing quality, customization, and supplier reliability can lead to significant cost savings and improved product performance.

Moreover, as the global market continues to evolve, buyers from Africa, South America, the Middle East, and Europe should leverage technological advancements in manufacturing processes, such as CNC machining and laser cutting, to access high-quality products tailored to their requirements. Engaging with suppliers who prioritize sustainability and ethical production practices can also enhance brand reputation and customer trust.

Illustrative Image (Source: Google Search)

Looking ahead, the demand for innovative and durable steel brackets will only increase as industries expand and modernize. Now is the time for international B2B buyers to take proactive steps in refining their sourcing strategies, fostering partnerships that will drive growth and resilience in an increasingly competitive landscape. Embrace the future of sourcing—connect with reliable suppliers and unlock new opportunities for success.