Master Sourcing Strategies for 316 Stainless Steel: A B2B

Introduction: Navigating the Global Market for 316 stainless steel

Stainless steel 316 stands out as a pivotal material for global industries, renowned for its exceptional resistance to corrosion, strength, and versatility in demanding environments. For international B2B buyers across Africa, South America, the Middle East, and Europe—including key markets like France and Italy—understanding the properties and applications of 316 stainless steel is essential for effective procurement. Whether your needs span marine applications, chemical processing, or advanced manufacturing, the right choice in stainless steel can significantly influence operational efficiency and project success.

This comprehensive guide delves into the multifaceted world of 316 stainless steel, covering various types and sub-grades, detailed material compositions, and essential manufacturing and quality control processes. Additionally, it offers insights into identifying reputable suppliers and navigating the complexities of global pricing trends. By addressing critical factors such as regional market dynamics and certification standards, this guide equips you with actionable strategies to enhance sourcing decisions.

With its robust framework, this resource empowers you to confidently assess suppliers, optimize costs, and ensure compliance with performance specifications. As the demand for high-quality materials continues to rise, leveraging the insights provided here will enable you to make informed, strategic decisions that drive value and sustain your competitive edge in the international market.

Understanding 316 stainless steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 316 (Standard) | Contains 2–3% Mo for enhanced corrosion resistance | Marine, chemical processing, construction | Excellent corrosion resistance; higher cost than 304 |

| 316L | Low carbon variant (<0.03% C) for better weldability | Pharmaceutical, food, welded structures | Superior weld performance; slightly lower strength |

| 316Ti | Stabilized with titanium for high-temperature stability | Heat exchangers, building facades, piping | Improved intergranular corrosion resistance; limited sources |

| 316H | Higher carbon content (>0.04% C) for high strength | Pressure vessels, boilers, power industries | Better strength at high temp; more prone to carbide formation |

| 316LN | Low carbon with extra nitrogen to boost strength | Aerospace, medical implants, cryogenics | Increased strength and toughness; higher cost, niche supply |

316 (Standard)

The standard 316 stainless steel is renowned for its robust corrosion resistance and mechanical strength, making it suitable for a variety of applications, including marine hardware and industrial piping. It contains 2-3% molybdenum, enhancing its performance in chloride-rich environments. For B2B buyers, the standard grade offers reliable availability and compliance with international standards. However, its higher cost compared to 304 stainless steel should be considered in budget planning.

316L

The 316L variant features a lower carbon content, which significantly reduces the risk of carbide precipitation during welding. This makes it particularly advantageous for industries like pharmaceuticals and food processing, where weld integrity is critical. Buyers should prioritize 316L when extensive welding is involved, as it maintains corrosion resistance in welded areas. It’s essential to verify the actual carbon content and consider its slightly lower tensile strength in high-stress applications.

316Ti

316Ti is a titanium-stabilized version of 316, designed to withstand high temperatures without losing corrosion resistance. It is ideal for applications in heat exchangers and environments subjected to thermal cycling. While 316Ti offers improved performance in high-temperature settings, its niche availability can pose challenges for procurement. Buyers should assess local sourcing options and ensure that suppliers are well-versed in relevant manufacturing standards.

316H

This high-carbon variant of 316 is engineered for enhanced strength at elevated temperatures, making it suitable for demanding applications in the petrochemical and power generation industries. While 316H provides superior creep resistance, its higher carbon content can lead to greater susceptibility to carbide formation, particularly during welding. Buyers must carefully evaluate the specific temperature and corrosive conditions of their applications to ensure compatibility.

316LN

316LN incorporates nitrogen to enhance strength and pitting resistance, making it particularly suitable for high-performance applications in aerospace and medical fields. This variant offers increased toughness but may come at a higher procurement cost and less standardization in the marketplace. Buyers should consider both the technical requirements and the potential for limited availability when sourcing 316LN, ensuring they partner with suppliers who can meet these specialized needs.

Key Industrial Applications of 316 stainless steel

| Industry/Sector | Specific Application of 316 stainless steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine | Boat fittings, hardware, and railings | Excellent corrosion resistance in saltwater environments | Verify compliance with marine standards (e.g., ASTM, ISO) |

| Chemical Processing | Storage tanks and piping systems | Durable against aggressive chemicals, enhancing safety | Ensure material certifications and compatibility with chemicals used |

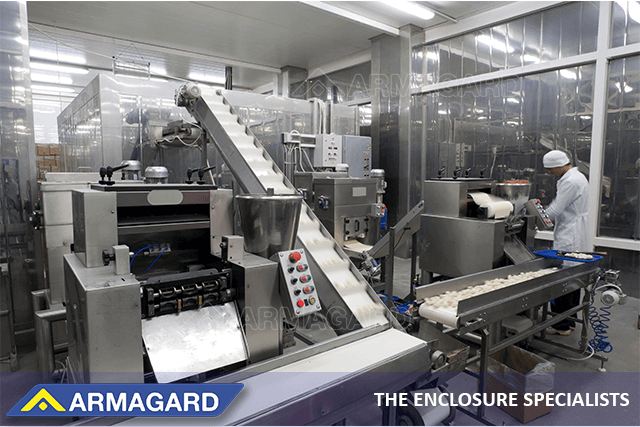

| Food Processing | Equipment for hygiene-sensitive production | Maintains cleanliness and prevents contamination | Look for suppliers with certifications in food-grade materials |

| Pharmaceutical | Bioreactors and pharmaceutical production equipment | Essential for maintaining product purity and safety | Confirm low carbon content for welding applications (316L) |

| Oil & Gas | Offshore platforms and pipelines | High strength and corrosion resistance in harsh environments | Assess local suppliers’ capabilities and compliance with industry standards |

Marine Applications

In the marine sector, 316 stainless steel is extensively used for boat fittings, hardware, and railings. Its superior corrosion resistance in saltwater environments significantly reduces maintenance costs and extends the lifespan of marine vessels. For international buyers, especially in coastal regions of Africa and South America, sourcing 316 stainless steel that complies with marine standards is crucial to ensure durability and safety in harsh conditions.

Chemical Processing

In chemical processing, 316 stainless steel is utilized for storage tanks and piping systems due to its ability to withstand aggressive chemicals without degrading. This durability enhances safety and operational efficiency, reducing the likelihood of leaks or failures. Buyers in the Middle East, where petrochemical industries are prevalent, should prioritize suppliers who provide material certifications and can demonstrate compatibility with specific chemicals used in their processes.

Food Processing

The food processing industry leverages 316 stainless steel for equipment used in hygiene-sensitive production environments, such as food processing lines and storage containers. This material helps maintain cleanliness and prevents contamination, which is vital for compliance with health regulations. B2B buyers in Europe, particularly in countries like France and Italy, should seek suppliers with certifications in food-grade materials to ensure that their purchases meet stringent safety standards.

Pharmaceutical Applications

In the pharmaceutical sector, 316 stainless steel is critical for constructing bioreactors and other production equipment where maintaining product purity is essential. Its low carbon content variant, 316L, is particularly favored for its superior weldability, which minimizes the risk of contamination during manufacturing. International buyers must verify that suppliers can provide materials that meet regulatory requirements for pharmaceutical applications, ensuring both safety and efficacy in production.

Oil & Gas Applications

The oil and gas industry employs 316 stainless steel for offshore platforms and pipelines, where high strength and corrosion resistance are paramount. This material can withstand the harsh conditions typical of offshore environments, thus ensuring operational integrity. Buyers from regions with active oil exploration, such as parts of Africa and the Middle East, should assess local suppliers for their capabilities and compliance with industry standards to mitigate risks associated with sourcing.

Related Video: Steel Types – Stainless Steel Vs Carbon Steel Explained.

Strategic Material Selection Guide for 316 stainless steel

When considering the procurement of 316 stainless steel, international B2B buyers must evaluate various material types based on specific application needs, environmental conditions, and regulatory compliance. Below is a detailed analysis of key variations of 316 stainless steel, focusing on their properties, advantages, disadvantages, and implications for buyers from Africa, South America, the Middle East, and Europe.

316 Stainless Steel

Key Properties:

Standard 316 stainless steel contains 2-3% molybdenum, enhancing its resistance to pitting and crevice corrosion, particularly in chloride-rich environments. It has a temperature rating of up to 870°C (1,600°F) for intermittent service and up to 925°C (1,700°F) for continuous service.

Pros & Cons:

The primary advantage of 316 stainless steel is its excellent corrosion resistance, making it suitable for marine and chemical processing applications. However, it is more expensive than 304 stainless steel due to the higher nickel and molybdenum content, which can affect overall project costs.

Impact on Application:

316 stainless steel is widely used in marine environments, chemical processing, and food manufacturing due to its ability to withstand harsh conditions. Buyers must consider the specific media involved, as certain chemicals can still pose risks even to 316.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 and EN 10088. Understanding local market dynamics and supplier capabilities is crucial, especially in regions with varying levels of material quality assurance.

316L Stainless Steel

Key Properties:

316L is a low-carbon variant of 316, with carbon content capped at 0.03%. This composition minimizes the risk of carbide precipitation during welding, enhancing its corrosion resistance in welded areas.

Pros & Cons:

The main advantage of 316L is its superior weldability, making it ideal for applications requiring extensive welding, such as in the pharmaceutical and food industries. However, its lower tensile strength compared to standard 316 may limit its use in high-stress applications.

Impact on Application:

316L is particularly effective in environments where corrosion resistance is critical post-welding, such as in sanitary applications. Buyers must assess whether the lower strength meets the engineering requirements of their projects.

Considerations for International Buyers:

Buyers should confirm dual certification for 316L to ensure compliance with both ASTM and EN standards. Additionally, sourcing from reputable suppliers who can provide verified mill certifications is essential to avoid quality discrepancies.

316Ti Stainless Steel

Key Properties:

316Ti is stabilized with titanium, which prevents sensitization and intergranular corrosion. It maintains its properties at elevated temperatures, making it suitable for applications involving thermal cycling.

Pros & Cons:

The key advantage of 316Ti is its ability to withstand high temperatures and corrosive environments, making it ideal for heat exchangers and exhaust systems. However, it may be less commonly available, particularly outside Europe, leading to potential supply chain challenges.

Impact on Application:

316Ti is particularly beneficial in industries where equipment is subjected to prolonged exposure to high temperatures, such as petrochemical processing. Buyers should evaluate whether their applications will require this level of thermal stability.

Considerations for International Buyers:

Buyers should ensure that suppliers are familiar with EN/DIN equivalents and can provide documentation supporting the material’s performance under specified conditions. Understanding regional supply channels is vital for timely procurement.

316H Stainless Steel

Key Properties:

316H has a higher carbon content (greater than 0.04%), which enhances its strength at elevated temperatures, making it suitable for high-stress applications.

Pros & Cons:

The primary advantage of 316H is its improved creep resistance, making it ideal for use in power generation and petrochemical applications. However, its higher carbon content can lead to increased susceptibility to corrosion in certain environments.

Impact on Application:

316H is best suited for applications involving high temperatures and pressures, such as pressure vessels and boilers. Buyers must consider the specific operating conditions to ensure compatibility.

Considerations for International Buyers:

Buyers should verify compliance with industry standards such as ASME for pressure equipment. Understanding local regulations regarding material specifications is also crucial for successful procurement.

| Material | Typical Use Case for 316 stainless steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 316 | Marine hardware, industrial piping | Excellent corrosion resistance | Higher cost than 304 | High |

| 316L | Pharmaceutical, food processing | Superior weldability | Lower tensile strength | Medium |

| 316Ti | Heat exchangers, exhaust systems | High-temperature stability | Limited availability | High |

| 316H | Pressure vessels, petrochemical | Improved creep resistance | More prone to corrosion | Medium |

This analysis equips international B2B buyers with the necessary insights to make informed decisions regarding the selection of 316 stainless steel variants, ensuring that their procurement aligns with both project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 316 stainless steel

The manufacturing processes and quality assurance protocols for 316 stainless steel are critical components that influence the material’s performance and reliability in various applications. For international B2B buyers, understanding these processes can significantly impact procurement decisions and project outcomes. Here’s a detailed overview of the key manufacturing stages, quality control measures, and actionable insights for buyers.

Manufacturing Processes

The manufacturing of 316 stainless steel involves several critical stages, each designed to ensure the material meets the stringent requirements of various industries. Here are the main stages of the manufacturing process:

1. Material Preparation

The first step in producing 316 stainless steel involves sourcing high-quality raw materials. This typically includes:

– Iron ore and nickel as primary components.

– Molybdenum, which is crucial for enhancing corrosion resistance.

– Alloying elements such as chromium and carbon.

Once sourced, these materials are melted together in an electric arc furnace (EAF) or a basic oxygen furnace (BOF) under controlled conditions to achieve the desired chemical composition.

2. Forming

After melting, the molten steel is cast into slabs, billets, or blooms. This is often followed by processes such as:

– Hot rolling, where the steel is passed through rollers at high temperatures to achieve the desired thickness and shape.

– Cold rolling, which further refines the steel at room temperature, enhancing its surface finish and mechanical properties.

These forming techniques are vital for achieving the specific dimensions and tolerances required in various applications, from piping to structural components.

3. Assembly

For products that require welding or assembling, such as tanks or frameworks, specific techniques are employed:

– Welding processes, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas), are commonly used for joining components.

– Fabrication may involve cutting, bending, and shaping the stainless steel into final forms.

The choice of technique often depends on the application and the specific grade of 316 stainless steel being used.

4. Finishing

The final stage involves surface treatments to enhance corrosion resistance and aesthetic appeal. Common finishing processes include:

– Pickling and passivation, which remove impurities and enhance the passive layer on the surface.

– Polishing to achieve a smooth finish, particularly important in food processing and pharmaceutical applications.

Each of these finishing techniques contributes to the overall durability and longevity of the material, making it suitable for harsh environments.

Quality Assurance

Quality assurance is a critical aspect of the manufacturing process, ensuring that the 316 stainless steel produced meets international standards and customer specifications. Here are key components of the quality assurance framework:

International Standards

To ensure consistent quality, many manufacturers adhere to recognized international standards, such as:

– ISO 9001: This standard outlines the criteria for a quality management system (QMS) and is widely adopted across industries.

– ASTM (American Society for Testing and Materials): Specific ASTM standards apply to the chemical and mechanical properties of stainless steel.

In Europe, compliance with CE marking requirements is also essential, particularly for products used in construction and infrastructure.

Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages to ensure processes are within set parameters.

- Final Quality Control (FQC): Comprehensive testing of finished products against established standards before dispatch.

Common Testing Methods

Several testing methods are employed to verify the quality of 316 stainless steel:

– Chemical analysis to ensure proper alloy composition.

– Mechanical testing (tensile, impact, hardness tests) to assess physical properties.

– Non-destructive testing (NDT) methods, such as ultrasonic testing or dye penetrant inspection, to detect internal flaws without damaging the material.

Verifying Supplier Quality Control

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are actionable steps to ensure quality assurance:

-

Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes and quality control systems. This helps verify compliance with international standards and ensure that the supplier can consistently meet your requirements.

-

Request Quality Reports: Ask suppliers for detailed quality assurance reports, including results from IQC, IPQC, and FQC processes. These documents should provide insight into the testing methods used and the outcomes of those tests.

-

Third-Party Inspections: Engage third-party inspection agencies to perform independent assessments of the supplier’s products. This adds an extra layer of assurance and credibility.

-

Certifications: Ensure that suppliers provide relevant certifications, such as ISO 9001, CE marking, and any industry-specific certifications applicable to your project. This documentation is critical for compliance, particularly in sectors like construction and petrochemicals.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for 316 stainless steel is crucial for B2B buyers navigating the global market. By focusing on material preparation, forming, assembly, and finishing stages, as well as rigorous quality control measures, buyers can make informed decisions that align with their operational needs and project specifications. Ensuring supplier compliance with international standards and conducting thorough audits and inspections will help mitigate risks and enhance procurement outcomes across diverse industries and regions.

Related Video: Top 3 Incredible Mass Production Factory Manufacturing Process Videos

Comprehensive Cost and Pricing Analysis for 316 stainless steel Sourcing

Understanding the cost structure and pricing dynamics of 316 stainless steel is crucial for international B2B buyers. This material is highly sought after across various industries due to its exceptional corrosion resistance and mechanical properties. However, the overall cost involves multiple components and factors that can significantly influence pricing.

Cost Components

-

Materials: The primary cost driver in sourcing 316 stainless steel is the raw materials, particularly nickel and molybdenum. Fluctuations in the global market for these metals can lead to price volatility. Buyers should stay informed about market trends to anticipate changes in material costs.

-

Labor: Labor costs can vary significantly depending on the region of sourcing. Countries with higher wage standards may incur increased labor costs, impacting the final price of the product. This is particularly relevant for countries in Europe compared to emerging markets in Africa or South America.

-

Manufacturing Overhead: This includes expenses related to equipment, utilities, and facility maintenance. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers in the form of lower prices.

-

Tooling: Custom tooling can be necessary for specific projects, particularly when unique specifications or shapes are required. This one-time investment can add to initial costs but may lead to long-term savings if bulk orders are placed.

-

Quality Control (QC): Ensuring compliance with international standards and certifications (such as ASTM or EN) requires rigorous QC processes. The costs associated with quality assurance can vary, impacting the overall price of the steel. Buyers should consider the implications of lower-quality materials versus the potential costs of failure or non-compliance.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, freight mode, and local customs duties can add significant expenses. Understanding Incoterms is essential for managing these costs effectively.

-

Margin: Suppliers typically build in a margin based on their operational costs and market conditions. This margin can vary widely, depending on the supplier’s positioning in the market and the level of competition.

Price Influencers

Several factors influence the pricing of 316 stainless steel:

-

Volume/MOQ (Minimum Order Quantity): Larger orders can lead to discounts, as suppliers often reduce prices for bulk purchases. Buyers should assess their needs carefully to maximize cost-efficiency.

-

Specifications/Customization: Custom specifications can drive up costs. Buyers should evaluate whether standard grades meet their requirements before opting for specialized products.

-

Quality/Certifications: Higher quality and certified materials typically come at a premium. However, investing in quality can reduce the Total Cost of Ownership (TCO) by minimizing maintenance and replacement costs over time.

-

Supplier Factors: The reputation and reliability of suppliers play a vital role. Established suppliers with a history of delivering quality products may charge higher prices but can offer better assurance of material performance.

-

Incoterms: Understanding the terms of shipping is crucial for cost management. Different Incoterms can significantly affect the final price, as they dictate who is responsible for shipping costs, insurance, and tariffs.

Buyer Tips

To navigate the complexities of sourcing 316 stainless steel, consider the following strategies:

-

Negotiate: Engage in discussions with suppliers to explore pricing flexibility, particularly for large orders or long-term contracts. Building relationships can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price. Consider maintenance, operational efficiency, and potential downtime costs when assessing overall value.

-

Be Aware of Pricing Nuances: International buyers should be conscious of regional pricing variations and market dynamics. For example, prices in Europe may differ significantly from those in Africa or South America due to local supply and demand conditions.

-

Monitor Market Trends: Stay updated on global commodity prices and economic indicators affecting the steel market. This knowledge can inform better purchasing decisions and timing.

By understanding these components and influencers, international B2B buyers can optimize their sourcing strategies for 316 stainless steel, ensuring they achieve the best value while meeting their project’s specific requirements.

Disclaimer: Prices for 316 stainless steel can fluctuate based on market conditions and supplier pricing strategies. The insights provided here are indicative and should be verified with suppliers for accurate quotes.

Spotlight on Potential 316 stainless steel Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘316 stainless steel’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 316 stainless steel

Understanding the critical technical properties and trade terminology of 316 stainless steel is essential for international B2B buyers, especially when navigating diverse markets across Africa, South America, the Middle East, and Europe. This section outlines key specifications that impact procurement decisions and common industry jargon that buyers should be familiar with.

Illustrative Image (Source: Google Search)

Critical Specifications for 316 Stainless Steel

- Material Grade

The most recognized grades of stainless steel include 316, 316L, 316H, and 316Ti. Each grade offers distinct advantages based on its chemical composition, which affects properties such as corrosion resistance and weldability. For instance, 316L is preferred for its low carbon content, making it suitable for welded applications in the pharmaceutical and food industries. Buyers must select the appropriate grade to ensure compliance with industry standards and project requirements.

Illustrative Image (Source: Google Search)

-

Chemical Composition

The typical composition of 316 stainless steel includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum enhances resistance to pitting corrosion, particularly in chloride environments. Understanding the chemical makeup is crucial for buyers as it directly influences the material’s performance in specific applications, particularly in harsh or corrosive settings. -

Mechanical Properties

Key mechanical properties include yield strength, tensile strength, and elongation. For 316 stainless steel, the yield strength typically ranges from 290 to 310 MPa, and tensile strength from 580 to 620 MPa. These properties are vital for ensuring that the material can withstand the operational stresses of various applications, such as in construction or chemical processing. Buyers should verify that these properties meet the requirements of their specific projects. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of the material. For stainless steel, tolerances can affect fit and performance in assemblies. Understanding tolerance levels is essential for procurement, as variations can lead to compatibility issues, increased costs, and project delays. Buyers should ensure that suppliers adhere to relevant standards (e.g., ASTM) to guarantee the quality and performance of the materials. -

Surface Finish

The surface finish of 316 stainless steel can significantly impact its corrosion resistance and aesthetic appeal. Common finishes include mill finish, polished, or passivated surfaces. Buyers should consider the required finish based on the application, especially in environments where cleanliness and corrosion resistance are paramount, such as food processing or medical equipment.

Common Trade Terms in Stainless Steel Sourcing

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is crucial for buyers looking to source stainless steel components that meet specific quality and compatibility standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to consider when budgeting for purchases, as higher MOQs may lead to increased upfront costs. Buyers should negotiate MOQs based on their project needs and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit pricing and terms from suppliers for specific products or services. For international buyers, issuing an RFQ can help ensure competitive pricing and facilitate comparisons among different suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for buyers to understand shipping responsibilities, insurance, and risk management during transport. -

Certification

Certification refers to the documentation that verifies a material’s compliance with specific standards, such as ASTM, EN, or ISO. For B2B buyers, obtaining certifications ensures that the materials sourced meet regulatory and performance requirements, which is critical for project success and safety.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance procurement efficiency and project outcomes in their respective regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 316 stainless steel Sector

Market Overview & Key Trends

The 316 stainless steel market is currently shaped by several global drivers influencing B2B procurement strategies. The rising demand for corrosion-resistant materials in industries such as marine, food processing, and pharmaceuticals is at the forefront. As countries in Africa, South America, the Middle East, and Europe ramp up infrastructure development and industrial projects, the need for durable materials like 316 stainless steel becomes increasingly critical.

Emerging technologies are also reshaping sourcing trends, with digital platforms enhancing transparency and efficiency in supply chains. B2B buyers are leveraging data analytics to make informed decisions about pricing, supplier reliability, and material availability. Additionally, automation in manufacturing processes is expected to lower costs and improve quality consistency, which is particularly beneficial for international buyers navigating diverse regulatory landscapes.

Market dynamics are further influenced by geopolitical factors and trade policies, which can impact the availability and pricing of raw materials like nickel and molybdenum, essential for 316 stainless steel production. Buyers must stay vigilant about market fluctuations and develop robust supplier relationships to mitigate risks associated with supply chain disruptions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a focal point in the procurement of 316 stainless steel, reflecting a growing awareness of environmental impacts. The production of stainless steel, particularly through traditional methods, can be resource-intensive and generate significant carbon emissions. As a result, international buyers are increasingly prioritizing suppliers who adopt eco-friendly practices and materials.

Ethical sourcing is paramount for B2B buyers, particularly those operating in regions with stringent environmental regulations. Engaging with suppliers who hold certifications such as ISO 14001 (Environmental Management) or those utilizing recycled materials can enhance a company’s reputation and compliance status. Moreover, buyers should consider the life cycle of the material, ensuring that their sourcing decisions contribute to a circular economy.

The demand for “green” certifications is also on the rise, with many buyers seeking materials produced with minimal environmental impact. Understanding the sustainability credentials of suppliers not only aligns with corporate social responsibility goals but also addresses consumer expectations for environmentally responsible products.

Brief Evolution/History

The development of stainless steel, particularly the 316 grade, can be traced back to the early 20th century, marking a significant innovation in material science. Originally developed in the 1920s, the introduction of molybdenum into the alloy composition of 316 stainless steel allowed for enhanced corrosion resistance, particularly in chloride environments. Over the decades, 316 stainless steel has evolved through various sub-grades—such as 316L and 316Ti—tailored to specific industry needs, emphasizing improved weldability and high-temperature performance. As global industries continue to innovate, 316 stainless steel remains a vital material, integral to advancements in technology and infrastructure across diverse sectors.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of 316 stainless steel

-

What criteria should I use to vet suppliers of 316 stainless steel?

When vetting suppliers, prioritize their industry experience, certifications (such as ISO 9001), and compliance with international standards (ASTM, EN). Request references from previous clients and assess their ability to provide technical documentation, including mill test reports and material safety data sheets. Engage in direct communication to understand their quality control processes and lead times. Additionally, consider suppliers’ geographical proximity to reduce logistics costs and time, especially when sourcing from regions like Africa or South America. -

Can I customize my order for 316 stainless steel?

Yes, many suppliers offer customization options for 316 stainless steel products. Customization may include specific dimensions, finishes, or even chemical composition adjustments to meet particular application requirements. When discussing customization, clearly articulate your needs and request prototypes or samples to ensure the final product aligns with your specifications. Be mindful that custom orders may come with longer lead times and higher costs, so factor these into your procurement timeline. -

What are the typical minimum order quantities (MOQ) and lead times for 316 stainless steel?

Minimum order quantities for 316 stainless steel can vary significantly by supplier and product type, generally ranging from 1 ton to several tons. Lead times can also fluctuate based on order size, complexity, and supplier location, typically spanning from 2 to 12 weeks. For urgent projects, it’s advisable to discuss your timeline with suppliers upfront and explore options for expedited manufacturing or partial shipments to meet critical deadlines. -

How can I ensure the quality of the 316 stainless steel I purchase?

To ensure quality, always request relevant certifications and compliance documents from suppliers. Key certifications include ASTM A240 for sheet products and ASTM A312 for pipes. Additionally, consider third-party inspections or audits as part of your procurement strategy. These measures can verify that the material meets specified standards and is free from defects. Establishing a clear quality assurance agreement before procurement can also help mitigate risks and ensure accountability. -

What payment terms are common in international transactions for 316 stainless steel?

Payment terms can vary widely, but common practices include upfront payment, letters of credit, or payment upon delivery. For larger orders, negotiating favorable terms such as 30% upfront and 70% upon delivery is beneficial. Consider using escrow services for added security, particularly when dealing with new suppliers. Understanding local banking practices and currency fluctuations is crucial, especially when sourcing from diverse regions like Africa or the Middle East. -

What logistical considerations should I keep in mind when sourcing 316 stainless steel?

Logistics play a vital role in the procurement process. Assess shipping methods, customs regulations, and potential tariffs that may apply when importing 316 stainless steel. Ensure that your supplier has experience handling international shipments and can provide reliable shipping documentation. Additionally, factor in delivery times and costs when selecting a supplier, as these can significantly affect your overall project budget and timeline. -

How should I handle disputes with suppliers over 316 stainless steel quality or delivery issues?

To manage disputes effectively, maintain clear and documented communication with your suppliers throughout the procurement process. Establish a formal complaint resolution process and define terms for product returns or replacements in your contract. If a dispute arises, gather all relevant documentation, including contracts, correspondence, and quality reports, to support your case. If necessary, consider mediation or arbitration as a means to resolve conflicts amicably and avoid lengthy legal processes. -

What are the best practices for maintaining a long-term relationship with suppliers of 316 stainless steel?

To foster long-term supplier relationships, maintain open lines of communication and provide constructive feedback on their products and services. Regularly review performance metrics, including delivery times and product quality, to identify areas for improvement. Additionally, consider collaborative projects or joint ventures that can benefit both parties. Building trust through consistent orders and timely payments can enhance your supplier’s commitment to your business, ultimately leading to better pricing and service.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 316 stainless steel

In conclusion, strategic sourcing of 316 stainless steel is pivotal for international B2B buyers aiming to enhance operational efficiency and ensure long-term project success. The material’s exceptional corrosion resistance, mechanical strength, and adaptability make it a preferred choice across various industries, including marine, chemical processing, and advanced manufacturing. As you navigate the complexities of the global market, prioritize understanding the differences between the various grades—such as 316, 316L, and 316Ti—and their specific applications to align with your project requirements.

Key Takeaways:

– Evaluate suppliers based on their compliance with international standards to mitigate risks associated with quality inconsistencies.

– Be aware of regional supply dynamics, as local availability can significantly impact procurement costs and timelines.

– Leverage supplier relationships for better negotiation outcomes, especially in regions with competitive markets.

Looking ahead, as industries evolve and regulations tighten, the demand for high-quality materials like 316 stainless steel will only grow. By adopting a proactive sourcing strategy and remaining informed about market trends, B2B buyers from Africa, South America, the Middle East, and Europe can not only secure the best materials but also drive innovation and sustainability in their operations. Engage with trusted suppliers today to position your business for future success.