Master Sourcing Strategies for AC to DC Power Supply

Introduction: Navigating the Global Market for ac to dc power supply

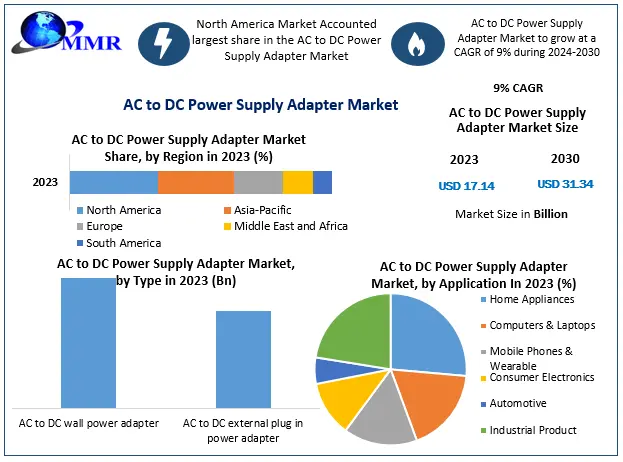

Navigating the complexities of the global market for AC to DC power supplies is essential for B2B buyers who seek to ensure the efficiency, reliability, and safety of their electronic systems. As a fundamental component of modern technology, AC to DC power supplies play a critical role in powering everything from industrial machinery to consumer electronics. Understanding the differences between AC and DC power sources can significantly impact operational performance and innovation across industries in Africa, South America, the Middle East, and Europe.

This comprehensive guide serves as a vital resource for international B2B buyers, providing in-depth insights into various types of AC and DC power supplies, including their materials, manufacturing processes, quality control standards, and supplier landscapes. By exploring cost considerations and market dynamics, buyers will gain the knowledge necessary to make informed sourcing decisions that align with their specific operational needs.

The guide also addresses frequently asked questions, clarifying common concerns and challenges faced by decision-makers. By equipping buyers with actionable insights, this resource aims to enhance competitiveness and drive innovation, ensuring businesses are well-prepared to navigate the ever-evolving global marketplace. In an age where technology continues to advance rapidly, understanding AC to DC power supply solutions is not just beneficial—it is imperative for sustainable growth and success.

Understanding ac to dc power supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Linear Power Supply | Simple design with low noise and stable output | Laboratory equipment, audio devices | Pros: High stability, low ripple. Cons: Less efficient, bulkier. |

| Switching Power Supply | High efficiency and compact size | Industrial machinery, consumer electronics | Pros: Lightweight, energy-efficient. Cons: More complex, potential EMI issues. |

| AC-DC Power Supply | Converts AC to DC for low-voltage devices | Computers, LED lighting, telecommunications | Pros: Versatile for modern electronics. Cons: Voltage drops can occur under load. |

| DC-DC Converter | Adjusts DC voltage levels for various applications | Renewable energy systems, electric vehicles | Pros: Efficient voltage regulation, compact. Cons: Limited by input voltage range. |

| Uninterruptible Power Supply (UPS) | Provides backup power and surge protection | Data centers, hospitals, critical infrastructure | Pros: Ensures continuous operation. Cons: Higher initial investment, maintenance required. |

Linear Power Supply

Linear power supplies are known for their straightforward design and ability to deliver a stable output with minimal noise. They are particularly suitable for applications requiring high precision, such as laboratory equipment and high-fidelity audio systems. When considering a purchase, B2B buyers should weigh the benefits of stability against the drawbacks of lower efficiency and increased size, which may necessitate additional cooling solutions.

Switching Power Supply

Switching power supplies are characterized by their high efficiency and compact form factor, making them ideal for industrial machinery and consumer electronics. Their ability to convert power efficiently can lead to significant energy savings. However, B2B buyers should be mindful of the potential for electromagnetic interference (EMI) and the complexity of these systems, which can complicate installation and maintenance. Evaluating the specific application requirements is crucial for optimal performance.

AC-DC Power Supply

An AC-DC power supply is essential for converting alternating current into direct current, enabling the operation of devices like computers and LED lighting. This type of power supply is widely used in telecommunications and consumer electronics. Buyers should prioritize voltage stability and compatibility with device specifications, as under-load voltage drops can impact performance. Selecting a high-quality AC-DC supply is vital for ensuring reliability in powering electronic devices.

DC-DC Converter

DC-DC converters are specialized devices designed to adjust voltage levels within DC systems, making them particularly useful in renewable energy applications and electric vehicles. Their compact size and efficient voltage regulation capabilities are significant advantages. B2B buyers must consider the input voltage range and output requirements when selecting a DC-DC converter, as these factors can limit performance. Ensuring compatibility with existing systems is essential for maximizing efficiency.

Uninterruptible Power Supply (UPS)

Uninterruptible Power Supplies (UPS) are critical for providing backup power and protecting sensitive equipment from voltage surges. They are commonly used in data centers, hospitals, and other critical infrastructure where continuous operation is paramount. Buyers should evaluate the UPS’s capacity and runtime to ensure it meets their operational needs. While the initial investment may be higher, the protection and reliability offered by a UPS can justify the cost in mission-critical environments.

Related Video: Diode Tutorial & How to build an AC to DC power supply

Key Industrial Applications of ac to dc power supply

| Industry/Sector | Specific Application of ac to dc power supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Powering base stations and network equipment | Ensures reliable operation of critical communication infrastructure | Voltage stability, compact size, and efficiency ratings |

| Renewable Energy | Charging systems for solar inverters | Facilitates energy storage and management in off-grid applications | Compatibility with solar panel output, efficiency under load |

| Industrial Automation | Control systems for machinery | Increases productivity and operational efficiency | Robustness, heat management, and regulatory compliance |

| Healthcare | Medical devices and diagnostic equipment | Enhances patient safety and device reliability | Compliance with medical standards, low electromagnetic interference |

| Consumer Electronics | Power supplies for laptops and home appliances | Supports diverse consumer needs with compact solutions | Voltage compatibility, efficiency, and thermal management |

Telecommunications

In the telecommunications sector, AC to DC power supplies are essential for powering base stations and network equipment. These supplies ensure the reliable operation of critical communication infrastructure, which is vital for connectivity in remote areas, particularly in Africa and South America. Buyers should prioritize voltage stability and compact designs to accommodate space constraints in urban installations. Additionally, efficiency ratings are crucial to minimize operational costs, especially in regions with high energy prices.

Renewable Energy

AC to DC power supplies play a pivotal role in renewable energy applications, specifically in charging systems for solar inverters. These systems convert AC from the grid or generated by solar panels into DC, which is then used for charging batteries or powering DC loads. This is particularly beneficial in off-grid applications common in rural areas of Africa and South America. Buyers should focus on compatibility with solar panel outputs and efficiency under varying load conditions to ensure optimal performance.

Industrial Automation

In industrial automation, AC to DC power supplies are critical for control systems that manage machinery and processes. By providing stable DC power, these supplies enhance productivity and operational efficiency, reducing downtime in manufacturing settings. For B2B buyers in Europe and the Middle East, sourcing robust power supplies that can handle harsh industrial environments is essential. Heat management and compliance with industry regulations are also significant considerations to ensure reliability and safety.

Healthcare

Healthcare facilities rely heavily on AC to DC power supplies for medical devices and diagnostic equipment. These power supplies enhance patient safety by ensuring that critical devices operate reliably without interruptions. B2B buyers in the healthcare sector must consider compliance with medical standards and the potential for low electromagnetic interference, which can affect sensitive equipment. Sourcing high-quality power supplies that meet these stringent requirements is vital for maintaining operational integrity in healthcare environments.

Consumer Electronics

In the consumer electronics industry, AC to DC power supplies are used in laptops, smartphones, and home appliances. They support diverse consumer needs by providing compact and efficient solutions. Buyers should pay attention to voltage compatibility and thermal management to ensure long-term reliability and performance. With the increasing demand for energy-efficient devices, sourcing power supplies that meet these standards can significantly enhance product appeal in competitive markets across Europe and the Middle East.

Related Video: Design Tutorial for 24VAC to DC Power Supply for HVAC Applications Part 1

Strategic Material Selection Guide for ac to dc power supply

When selecting materials for AC to DC power supplies, international B2B buyers must consider various factors that influence performance, durability, and compliance with industry standards. Below is an analysis of four common materials used in the manufacturing of components for AC to DC power supplies, including their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Copper

Key Properties:

Copper is renowned for its excellent electrical conductivity, thermal conductivity, and corrosion resistance. It can withstand high temperatures, making it suitable for various electrical applications.

Pros & Cons:

Copper’s high conductivity ensures minimal energy loss, enhancing the efficiency of power supplies. However, its relatively high cost and susceptibility to oxidation can be drawbacks. Additionally, the manufacturing complexity increases with the need for protective coatings to prevent corrosion.

Impact on Application:

Copper is ideal for wiring and PCB traces in AC to DC power supplies, where efficient current flow is critical. Its compatibility with various media makes it a versatile choice.

Considerations for Buyers:

Buyers should ensure compliance with international standards like ASTM B170 for copper wire and consider local sourcing options to mitigate costs. In regions like Africa and South America, where copper mining is prevalent, local availability can influence pricing.

2. Aluminum

Key Properties:

Aluminum is lightweight, has good electrical conductivity, and is resistant to corrosion. It can operate effectively in a wide range of temperatures.

Pros & Cons:

While aluminum is less expensive than copper and offers a favorable strength-to-weight ratio, its lower conductivity means that larger cross-sections are required for equivalent performance. This can lead to increased manufacturing complexity and space requirements in designs.

Impact on Application:

Aluminum is often used in heat sinks and casings for AC to DC power supplies, where weight reduction is beneficial. Its corrosion resistance makes it suitable for outdoor applications.

Considerations for Buyers:

Buyers should be aware of the relevant standards such as JIS H 4040 for aluminum alloys. In regions with high humidity, additional protective coatings may be necessary to enhance durability.

3. Silicon

Key Properties:

Silicon is a semiconductor material that operates effectively at high temperatures and has good thermal stability. It is essential for rectifiers and voltage regulators in power supplies.

Pros & Cons:

Silicon’s ability to handle high voltages and currents makes it ideal for power conversion applications. However, its brittleness can lead to failures under mechanical stress, and the manufacturing process can be complex and costly.

Impact on Application:

Silicon is critical in the rectification process, converting AC to DC. Its performance directly affects the efficiency and reliability of power supplies.

Considerations for Buyers:

Buyers should ensure that silicon components meet international standards such as IEC 60747 for semiconductor devices. In emerging markets, sourcing from established manufacturers can help ensure quality and compliance.

4. Polycarbonate

Key Properties:

Polycarbonate is a durable thermoplastic with excellent impact resistance and thermal stability. It is often used for enclosures and insulation in power supply applications.

Pros & Cons:

Polycarbonate’s lightweight and robust nature make it suitable for various applications. However, it can be more expensive than other plastics, and its performance can degrade under prolonged UV exposure.

Impact on Application:

Polycarbonate is commonly used for protective casings in AC to DC power supplies, ensuring safety and durability in various environments.

Considerations for Buyers:

Buyers should look for compliance with standards such as UL 94 for flammability. In regions with high UV exposure, selecting UV-stabilized polycarbonate can enhance longevity.

| Material | Typical Use Case for ac to dc power supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and PCB traces | Excellent electrical conductivity | High cost and oxidation susceptibility | High |

| Aluminum | Heat sinks and casings | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Silicon | Rectifiers and voltage regulators | Handles high voltages and currents | Brittle and complex manufacturing | High |

| Polycarbonate | Protective casings | Durable and impact-resistant | Can degrade under UV exposure | Medium |

This strategic material selection guide provides essential insights for B2B buyers, enabling them to make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for ac to dc power supply

Manufacturing Processes for AC to DC Power Supply

The manufacturing process for AC to DC power supplies involves several critical stages, each designed to ensure that the final product meets stringent performance and quality standards. For B2B buyers, understanding these processes can provide insights into product reliability and the potential for customization.

Material Preparation

The first stage of manufacturing involves sourcing high-quality materials, which are fundamental to the efficiency and longevity of the power supply. Key components include:

- Transformers: Made from high-grade silicon steel to minimize energy loss.

- Rectifiers: Typically utilize diodes such as silicon or Schottky for optimal performance.

- Capacitors: Must be selected based on their voltage rating and equivalent series resistance (ESR) to ensure effective filtering.

- Regulators: Often made from robust materials that can handle thermal and electrical stress.

B2B buyers should inquire about the supplier’s material sources, as high-quality raw materials significantly impact the overall performance and durability of the power supply.

Forming

In this stage, the materials are shaped into the necessary components. This includes:

- Winding of Transformers: Conductors are wound to create the primary and secondary coils, a process requiring precision to ensure the correct inductance.

- Diode and Capacitor Housing: Components are housed to prevent environmental damage and ensure safety.

Advanced techniques such as CNC machining and automated winding are commonly employed to improve accuracy and reduce production time. Buyers should seek manufacturers that utilize state-of-the-art forming techniques to enhance product consistency.

Assembly

The assembly stage involves integrating all components into a cohesive unit. This process typically includes:

- Soldering: Components are soldered onto printed circuit boards (PCBs) using automated soldering machines to ensure strong electrical connections.

- Mounting: Components like transformers, capacitors, and regulators are securely mounted on the PCB.

- Wiring: Proper wiring techniques are employed to maintain safety and efficiency, including the use of insulated wires to prevent shorts.

Quality control during assembly is crucial. B2B buyers should verify that suppliers have robust assembly protocols, including the use of skilled technicians and automated systems to minimize human error.

Finishing

Finishing involves final touches that prepare the product for market readiness. This includes:

- Encapsulation: Some power supplies are encapsulated in resin or plastic to protect against moisture and dust.

- Labeling: Important safety and operational information is labeled according to international standards.

- Final Inspection: Each unit undergoes a thorough inspection to ensure compliance with specifications.

Buyers should confirm that manufacturers follow best practices in finishing processes to enhance product durability and compliance with international regulations.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical aspect of the manufacturing process for AC to DC power supplies. It ensures that products meet specified standards and function reliably in their intended applications.

International Standards

Several international standards guide quality assurance in the manufacturing of AC to DC power supplies. Key standards include:

- ISO 9001: This standard outlines criteria for a quality management system, ensuring that organizations consistently provide products that meet customer and regulatory requirements.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- UL Certification: Ensures that the product has been tested for safety and meets specific safety standards in the United States.

B2B buyers should prioritize suppliers who hold these certifications, as they indicate a commitment to quality and safety.

Quality Control Checkpoints

Quality control checkpoints are essential throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Inspects raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors the manufacturing process at various stages to identify and rectify defects early.

- Final Quality Control (FQC): Conducts a comprehensive inspection of the finished product before it is shipped to customers.

B2B buyers should ask suppliers about their specific quality control processes and the frequency of inspections at each stage.

Common Testing Methods

To ensure the reliability of AC to DC power supplies, manufacturers employ various testing methods, including:

- Load Testing: Verifies that the power supply can handle its rated load without failure.

- Thermal Testing: Assesses the heat dissipation capabilities of the unit to prevent overheating.

- Electrical Testing: Includes measurements of output voltage, ripple, and efficiency to ensure compliance with specifications.

Buyers can request test reports to verify that products have undergone these evaluations, providing assurance of their performance.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control measures is essential to ensure product reliability. Here are strategies to consider:

- Audits: Conduct regular audits of the supplier’s manufacturing facilities to assess compliance with quality standards and practices.

- Inspection Reports: Request detailed inspection reports that outline the results of IQC, IPQC, and FQC processes.

- Third-Party Inspections: Engage third-party inspection services to independently verify the quality of products before shipment.

Buyers from regions such as Africa, South America, the Middle East, and Europe should be particularly diligent in supplier verification, as this can mitigate risks associated with product quality and compliance.

Navigating Quality Control Nuances

Different regions may have unique quality control requirements and standards. For instance:

- Africa: Buyers should be aware of regional standards such as SANS (South African National Standards) and ensure suppliers comply with local regulations.

- South America: Suppliers may need to meet certifications like INMETRO for Brazil, which can impact the acceptance of products in the market.

- Middle East: Compliance with Gulf Standards (GSO) is crucial for market entry.

- Europe: Adherence to CE marking and RoHS directives is essential for legal compliance and market access.

B2B buyers should consider these nuances when evaluating suppliers to ensure that products meet both local and international standards.

By understanding the manufacturing processes and quality assurance measures in place for AC to DC power supplies, B2B buyers can make informed decisions that align with their operational requirements and market expectations.

Related Video: How It’s Made Air Conditioner In Factories | Air Conditioner Manufacturing Process @Techmachine_

Comprehensive Cost and Pricing Analysis for ac to dc power supply Sourcing

Understanding the cost structure and pricing dynamics of AC to DC power supply sourcing is crucial for international B2B buyers. This section provides an in-depth analysis of the various cost components involved, the factors influencing prices, and actionable tips for buyers navigating this complex market landscape.

Cost Components

-

Materials: The primary materials for AC to DC power supplies include transformers, rectifiers, capacitors, and protective circuitry. The choice of materials significantly impacts the overall cost. For instance, higher quality capacitors and diodes can enhance performance but may also increase costs.

-

Labor: Labor costs vary by region and manufacturing processes. Skilled labor is required for assembling complex components, and labor costs can be higher in countries with stringent labor laws or higher living standards.

-

Manufacturing Overhead: This includes costs associated with factory operations, equipment maintenance, and utilities. Manufacturing overhead can differ based on location, operational efficiency, and the scale of production.

-

Tooling: Initial tooling costs are significant, especially for custom designs. These costs can be amortized over larger production runs, making it essential to evaluate the minimum order quantities (MOQs) for cost efficiency.

-

Quality Control (QC): Implementing rigorous quality control measures is vital to ensure product reliability and compliance with international standards. These costs can include testing equipment, personnel, and inspection processes.

-

Logistics: Shipping and handling expenses can vary greatly based on the origin of the materials and the destination. Factors such as distance, shipping method, and customs duties can all influence logistics costs.

-

Margin: Suppliers typically mark up prices to cover costs and ensure profitability. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: Pricing often benefits from economies of scale. Higher volumes can lead to lower per-unit costs, while lower MOQs may result in higher prices due to less favorable production efficiencies.

-

Specifications/Customization: Custom designs or specific features can lead to increased costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Materials Quality/Certifications: Higher-quality materials and certifications (such as ISO standards) may lead to increased upfront costs but can significantly reduce total cost of ownership (TCO) over time due to enhanced reliability and performance.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge more but can offer better quality assurance and customer service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can impact pricing by defining responsibilities for shipping, insurance, and tariffs. Understanding these terms is crucial for accurate cost assessment.

Buyer Tips

-

Negotiation: Engage in proactive negotiations with suppliers. Leverage volume commitments and long-term contracts to secure better pricing and terms.

-

Cost Efficiency: Assess the total cost of ownership rather than just the upfront price. Consider factors such as energy efficiency, maintenance costs, and expected lifespan.

-

Pricing Nuances for International Buyers: Understand the unique market conditions in regions such as Africa, South America, the Middle East, and Europe. Local economic conditions, currency fluctuations, and import tariffs can significantly affect pricing strategies.

-

Quality vs. Cost: While it may be tempting to choose lower-cost options, prioritize quality to avoid long-term issues that can arise from subpar products.

-

Stay Informed: Keep abreast of market trends and material costs, as these can fluctuate and influence pricing. Regularly reviewing supplier performance and market conditions can aid in making informed sourcing decisions.

Disclaimer

Prices can vary widely based on numerous factors, and the information provided here is indicative. Buyers should conduct thorough market research and obtain multiple quotes to ensure they are making cost-effective sourcing decisions.

Spotlight on Potential ac to dc power supply Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ac to dc power supply’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ac to dc power supply

Key Technical Properties of AC to DC Power Supplies

Understanding the essential technical properties of AC to DC power supplies is crucial for B2B buyers to ensure they select the right components for their applications. Here are some critical specifications that buyers should consider:

- Output Voltage (Vout)

– Definition: The stable voltage that the power supply delivers to the load.

– Importance: It is vital to match the output voltage with the requirements of the connected devices. An incorrect voltage can lead to device malfunction or damage.

Illustrative Image (Source: Google Search)

-

Output Current (Iout)

– Definition: The maximum current that the power supply can provide to the load.

– Importance: Buyers must ensure that the output current is sufficient to meet the needs of the application. Overloading a power supply can lead to overheating and failure. -

Efficiency Rating

– Definition: The ratio of output power to input power, expressed as a percentage.

– Importance: Higher efficiency reduces energy costs and minimizes heat generation. This is especially crucial for applications in regions where energy costs are high, such as parts of Europe and the Middle East.

Illustrative Image (Source: Google Search)

-

Ripple Voltage

– Definition: The residual periodic variation in DC voltage, typically expressed in millivolts.

– Importance: Low ripple voltage is essential for sensitive electronics to operate correctly. High ripple can cause noise and instability in devices, affecting performance and longevity. -

Temperature Range

– Definition: The operational temperature limits within which the power supply can function reliably.

– Importance: Ensuring the power supply operates within its specified temperature range is critical, especially in harsh environments like those found in many African and South American regions. -

Protection Features

– Definition: Safety mechanisms such as overvoltage, overcurrent, and thermal protection built into the power supply.

– Importance: These features safeguard both the power supply and the connected devices from potential damage, which is crucial for maintaining operational reliability in critical applications.

Common Trade Terminology in AC to DC Power Supply

Familiarizing oneself with industry jargon can significantly streamline procurement processes. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Buyers often source components from OEMs to ensure compatibility and reliability in their final products. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Understanding MOQ is crucial for budget management and inventory planning, especially for companies in emerging markets with limited initial capital. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and availability for specific products or services.

– Importance: An RFQ allows buyers to gather competitive quotes, enabling informed decision-making and negotiation. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, which is vital for international trade, especially for buyers from Africa and South America. -

Lead Time

– Definition: The time it takes from placing an order to receiving the goods.

– Importance: Knowing the lead time is essential for planning and ensures that production schedules are met without delays. -

Certification Standards

– Definition: Compliance with industry standards (e.g., UL, CE) that ensure safety and performance.

– Importance: Certifications validate the quality and reliability of power supplies, which is particularly important for international buyers who must meet local regulations.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing AC to DC power supplies, ultimately leading to improved operational efficiency and product reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ac to dc power supply Sector

Market Overview & Key Trends

The global market for AC to DC power supplies is experiencing significant transformation driven by several factors. Digitalization and the growing reliance on electronics across various sectors, including telecommunications, consumer electronics, and renewable energy, are increasing the demand for reliable power conversion solutions. Additionally, the shift towards renewable energy sources is propelling the need for efficient AC to DC converters, particularly in regions like Africa and South America, where off-grid and hybrid systems are gaining traction.

In terms of sourcing trends, international buyers are focusing on local suppliers to reduce lead times and mitigate risks associated with global supply chain disruptions. This trend is particularly relevant in the Middle East and Africa, where local manufacturing initiatives are being encouraged. Emerging technologies, such as advanced power management ICs and smart power supplies equipped with IoT capabilities, are also becoming pivotal. These innovations not only enhance efficiency but also allow for better monitoring and control of power supply systems.

For B2B buyers, understanding the market dynamics is crucial. Factors like regulatory changes, tariff impacts, and sustainability mandates can influence sourcing decisions. Buyers should also consider the total cost of ownership, which includes not just the initial purchase price but also operational efficiency and maintenance costs over the product’s lifecycle. By aligning procurement strategies with these trends, buyers can enhance their competitiveness in an increasingly complex market.

Sustainability & Ethical Sourcing in B2B

The environmental impact of AC to DC power supplies is an increasingly important consideration for international B2B buyers. The production and disposal of electronic components can lead to significant electronic waste (e-waste) and carbon emissions. Consequently, organizations are urged to adopt sustainable sourcing practices that minimize these impacts. This includes selecting suppliers who prioritize environmentally friendly manufacturing processes and materials.

Ethical supply chains are also gaining prominence as buyers seek to ensure that their sourcing practices align with corporate social responsibility (CSR) goals. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are critical indicators of a supplier’s commitment to sustainability. Additionally, opting for green materials—such as recyclable plastics and low-emission metals—can significantly reduce the environmental footprint of AC to DC power supply systems.

Furthermore, buyers should consider the energy efficiency of power supply units, as more efficient designs not only reduce operational costs but also contribute to lower greenhouse gas emissions. By prioritizing sustainable and ethical sourcing, B2B buyers can not only comply with regulatory requirements but also enhance their brand reputation and customer loyalty.

Brief Evolution/History

The evolution of AC to DC power supplies has been shaped by technological advancements and changing market needs. Initially, linear power supplies dominated the market, offering simplicity and stability but lacking in efficiency. The introduction of switching power supplies in the late 20th century marked a significant shift, allowing for more compact designs and improved efficiency, which became essential as electronic devices became smaller and more power-hungry.

As industries began to prioritize energy efficiency and sustainability, the focus shifted towards developing smart power supplies that integrate advanced control systems and communication capabilities. This evolution continues today, with innovations in materials and design further enhancing the performance and reliability of AC to DC converters. Understanding this historical context is vital for B2B buyers, as it underscores the importance of selecting suppliers that are not only innovative but also aligned with the future direction of the industry.

Related Video: International Trade and Supply Chains

Frequently Asked Questions (FAQs) for B2B Buyers of ac to dc power supply

-

How can I effectively vet suppliers of AC to DC power supplies?

When vetting suppliers, prioritize their industry experience, certifications, and customer reviews. Request detailed product specifications and inquire about their manufacturing processes. It’s beneficial to ask for references from other clients, especially those in your region, to gauge reliability. Additionally, consider suppliers that have a robust quality management system (QMS) in place, such as ISO 9001 certification, which ensures adherence to quality standards. -

Are customization options available for AC to DC power supplies?

Many suppliers offer customization options to meet specific requirements, such as voltage, current ratings, and physical dimensions. Communicate your needs clearly, including any particular features or safety standards you require. Ensure that the supplier has the capability to deliver customized products within your timeline and budget. Always request prototypes or samples for testing before making a large order. -

What are the typical Minimum Order Quantities (MOQs) and lead times for AC to DC power supplies?

MOQs can vary significantly based on the supplier and the complexity of the product. Standard orders might have MOQs ranging from 50 to 500 units, while custom designs may require higher quantities. Lead times also depend on the supplier’s capacity and your order’s complexity, usually ranging from 4 to 12 weeks. Always confirm these details upfront to avoid delays in your supply chain. -

What payment terms are common when sourcing AC to DC power supplies internationally?

Payment terms can vary by supplier but generally include options like advance payments, letters of credit, or payment upon delivery. For new suppliers, it’s prudent to negotiate terms that minimize risk, such as partial payment upfront and the balance upon delivery. Be aware of any currency exchange implications and consider using secure payment platforms that protect your financial transaction. -

What quality assurance measures should I expect from AC to DC power supply suppliers?

Suppliers should have a comprehensive quality assurance plan that includes testing at various production stages, such as incoming material inspection, in-process testing, and final product evaluation. Request to see their quality control certifications and any test reports for the specific products you intend to purchase. Ensure they adhere to international standards relevant to your market, such as CE, UL, or RoHS compliance. -

How can I manage logistics for importing AC to DC power supplies from international suppliers?

Effective logistics management involves selecting reliable freight forwarders and understanding shipping regulations in your country. Discuss shipping options with your supplier, including Incoterms, to clarify responsibilities for shipping costs, insurance, and customs duties. Consider the potential for delays and plan for them by including buffer time in your project schedules, particularly for customs clearance.

-

What steps can I take to resolve disputes with international suppliers?

To manage disputes effectively, establish clear communication channels and document all agreements and expectations in writing. If issues arise, attempt to resolve them through direct negotiation first. If necessary, refer to the dispute resolution clauses in your contract, which may include mediation or arbitration. Engaging a local legal advisor familiar with international trade laws can also be beneficial. -

What certifications should I look for when sourcing AC to DC power supplies?

Key certifications to look for include ISO 9001 for quality management, CE marking for compliance with European safety standards, and UL certification for safety in the United States. Other relevant certifications may include RoHS for hazardous substances and IEC standards for electrical equipment. These certifications not only ensure product safety and reliability but also enhance your company’s credibility in the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ac to dc power supply

In summary, strategic sourcing of AC to DC power supplies is pivotal for international B2B buyers aiming to enhance operational efficiency and reliability in their electronic systems. By understanding the distinctions between various types of power supplies—including linear, switching, and AC-DC converters—buyers can make informed decisions that align with their specific industry needs. Emphasizing factors such as efficiency, voltage stability, and protection features will ensure that the selected power supply meets both performance and safety standards.

Moreover, establishing strong partnerships with reputable suppliers will not only optimize procurement costs but also foster innovation and adaptability in a rapidly evolving marketplace. As businesses in Africa, South America, the Middle East, and Europe navigate the complexities of sourcing power solutions, it is essential to remain proactive in evaluating market trends and technological advancements.

Looking ahead, international B2B buyers are encouraged to embrace a comprehensive sourcing strategy that prioritizes quality and efficiency. By leveraging the insights from this guide, businesses can position themselves to thrive in the competitive landscape of electronic supply chains, ensuring they are equipped to meet the demands of tomorrow’s innovations.