Master Sourcing Strategies for AirPro Fan and Blower

Introduction: Navigating the Global Market for airpro fan and blower

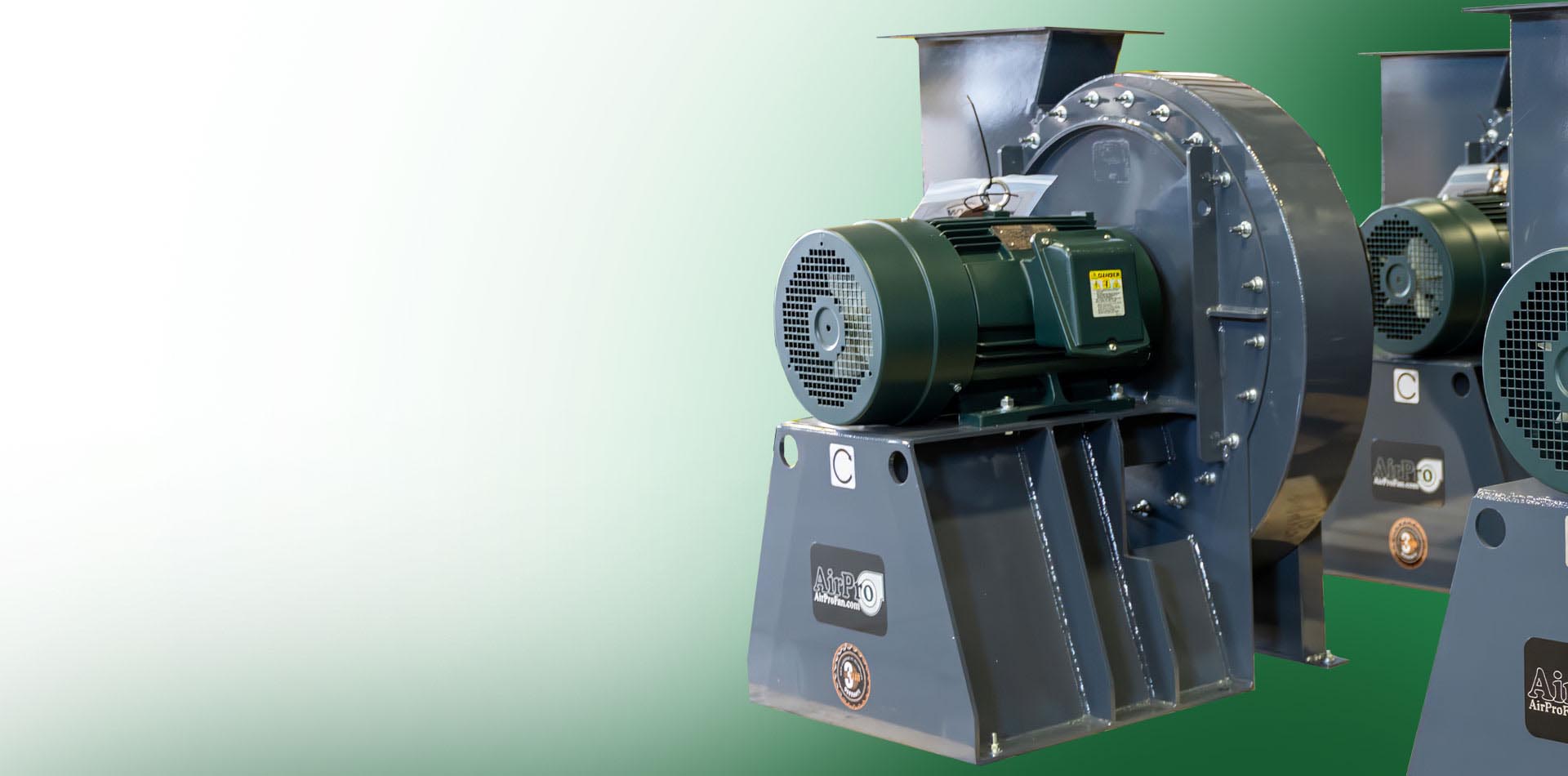

In today’s interconnected global marketplace, AirPro fans and blowers play a pivotal role in various industrial applications, from ventilation systems to dust control and air filtration. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of this equipment is crucial for optimizing operations, ensuring compliance with safety standards, and achieving energy efficiency.

This comprehensive guide is designed to empower you with the knowledge necessary for informed sourcing decisions. It covers a wide array of topics including:

- Types of Fans and Blowers: Explore the different categories such as centrifugal and axial fans, each suited for specific applications.

- Materials and Construction: Gain insights into the materials that enhance durability and performance, including options for high-temperature and corrosive environments.

- Manufacturing and Quality Control: Understand the standards and practices that ensure product reliability and compliance with international regulations.

- Supplier Landscape: Identify reputable suppliers and manufacturers, facilitating connections that can streamline your procurement process.

- Cost Considerations: Analyze pricing structures to make budget-conscious decisions without compromising on quality.

- Market Trends: Stay abreast of evolving trends that could influence your purchasing strategy.

- FAQs: Find answers to common queries that can guide your procurement efforts.

By leveraging the insights offered in this guide, you will be well-equipped to navigate the complexities of sourcing AirPro fans and blowers, ultimately enhancing your operational efficiency and competitive edge in the market.

Understanding airpro fan and blower Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centrifugal Fans | High pressure, radial airflow, and compact design | HVAC systems, dust collection | Pros: Efficient for high static pressure; Cons: Can be noisy and require more space. |

| Axial Fans | Direct airflow, lower pressure, and larger diameter | Ventilation, cooling applications | Pros: Cost-effective; Cons: Less effective in high-pressure scenarios. |

| Blowers | High airflow rates, suitable for material transport | Pneumatic conveying, industrial processes | Pros: Versatile for various materials; Cons: May require additional equipment for filtration. |

| High-Temperature Fans | Designed for extreme heat environments | Foundries, power plants | Pros: Durable under high temperatures; Cons: Higher initial investment. |

| Explosion-Proof Fans | Specialized design to prevent ignition in hazardous areas | Chemical plants, mining | Pros: Safety compliance; Cons: Higher cost and complexity in installation. |

Centrifugal Fans

Centrifugal fans are known for their ability to generate high pressure and are commonly used in applications requiring substantial airflow against resistance. Their radial design allows them to efficiently handle dust and particulate matter, making them ideal for dust collection systems and HVAC applications. When purchasing centrifugal fans, consider the specific pressure requirements, space constraints, and noise levels, as these units can be louder than other types.

Axial Fans

Axial fans provide a direct airflow path, making them suitable for applications where low pressure and high volume are essential. They are typically used in ventilation and cooling systems due to their cost-effectiveness and ease of installation. Buyers should assess the required airflow rates and ensure that the installation environment can accommodate the fan’s size and performance characteristics, as they are less effective in high-pressure applications.

Blowers

Blowers are designed to deliver high airflow rates, making them essential in pneumatic conveying and various industrial processes. They can efficiently transport bulk materials and are often used in applications such as grain handling and material drying. When evaluating blowers, buyers should consider the type of materials being conveyed, the system’s pressure requirements, and the need for additional filtration systems to ensure operational efficiency.

High-Temperature Fans

High-temperature fans are engineered to withstand extreme heat, making them suitable for environments like foundries and power plants. Their robust construction ensures reliable performance in demanding conditions. Buyers should weigh the initial investment against long-term durability and maintenance costs, as these fans often require specialized materials and designs to handle elevated temperatures.

Explosion-Proof Fans

Explosion-proof fans are crucial in industries dealing with flammable gases or dust, such as chemical processing and mining. These fans are designed to prevent ignition, ensuring safety in hazardous environments. When considering explosion-proof fans, it is essential to evaluate compliance with safety regulations, installation complexity, and the potential for higher costs associated with specialized designs.

Related Video: AirPro Fan Wheels: Design Differences & Application Requirements

Key Industrial Applications of airpro fan and blower

| Industry/Sector | Specific Application of airpro fan and blower | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Ventilation systems for production facilities | Improved air quality and worker safety | Durability, energy efficiency, and maintenance support |

| Food Processing | Cooling and drying processes in food production | Enhanced product quality and safety | Compliance with food safety standards and hygiene |

| Mining | Dust control and ventilation in underground mines | Increased worker health and regulatory compliance | Robust design for harsh environments and explosion-proof options |

| Chemical Processing | Exhaust systems for fume and vapor extraction | Protection against harmful emissions and odors | Material compatibility with chemicals and custom solutions |

| Pharmaceuticals | Cleanroom ventilation and air filtration systems | Compliance with stringent industry regulations | High filtration efficiency and low noise levels |

In the manufacturing sector, airpro fans and blowers are crucial for maintaining proper ventilation in production facilities. They help in controlling temperature and humidity levels, which is essential for worker comfort and safety. Additionally, these systems reduce the concentration of airborne particles, thus enhancing air quality. Buyers should prioritize durability and energy efficiency, as these factors contribute to long-term operational cost savings.

In food processing, airpro fans are utilized in cooling and drying processes to ensure that products maintain their quality and safety standards. Effective ventilation prevents moisture buildup, which can lead to spoilage and contamination. For international buyers, it is essential to ensure that the fans comply with local food safety regulations and hygiene standards, as these vary significantly across regions.

The mining industry employs airpro fans for dust control and ventilation, particularly in underground operations. These fans mitigate health risks associated with dust inhalation and help maintain a safe working environment. Buyers in this sector must consider the robustness of the equipment, as it must withstand harsh conditions, and may require explosion-proof designs to comply with safety regulations.

In the chemical processing sector, airpro fans are integral to exhaust systems designed for fume and vapor extraction. This application is vital for protecting workers from harmful emissions and maintaining air quality. Buyers should focus on material compatibility with various chemicals and the availability of custom solutions to meet specific operational needs.

Finally, in the pharmaceutical industry, airpro fans are essential for cleanroom ventilation and air filtration systems. These systems ensure compliance with strict industry regulations by maintaining sterile environments critical for drug production. Buyers should prioritize high filtration efficiency and low noise levels to enhance operational effectiveness while adhering to regulatory requirements.

Related Video: Industrial Fan Types, Energy Consumption, and the Fan Static Efficiency Calculation

Strategic Material Selection Guide for airpro fan and blower

When selecting materials for AirPro fans and blowers, international B2B buyers must consider several factors that influence performance, durability, and compliance with local standards. Below is an analysis of four common materials used in the manufacturing of these products, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions including Africa, South America, the Middle East, and Europe.

1. Carbon Steel

Key Properties:

Carbon steel offers excellent strength and durability, making it suitable for high-pressure applications. It can withstand temperatures up to 400°F (204°C) and is relatively easy to fabricate.

Pros & Cons:

– Pros: High tensile strength, cost-effective, and readily available.

– Cons: Prone to corrosion without adequate protective coatings, which can lead to maintenance issues.

Impact on Application:

Carbon steel is ideal for applications involving air and non-corrosive gases. However, it may not be suitable for environments with high humidity or corrosive media.

Considerations for Buyers:

Buyers should ensure that carbon steel components are treated with protective coatings (e.g., galvanization) to enhance corrosion resistance. Compliance with standards such as ASTM A36 is crucial for quality assurance.

2. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance and can handle temperatures up to 1,800°F (982°C) depending on the grade. It is also non-reactive, making it suitable for various applications.

Pros & Cons:

– Pros: Exceptional durability, aesthetic appeal, and low maintenance.

– Cons: Higher cost compared to carbon steel and more complex manufacturing processes.

Impact on Application:

Stainless steel is ideal for applications in industries such as food processing and pharmaceuticals where hygiene is paramount. Its resistance to corrosion makes it suitable for both indoor and outdoor environments.

Considerations for Buyers:

International buyers should verify compliance with standards like ASTM A240 for stainless steel grades. The cost implications should also be considered, especially for large-scale projects.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good thermal conductivity, with a maximum operating temperature of around 400°F (204°C). It is also resistant to corrosion due to its natural oxide layer.

Pros & Cons:

– Pros: Lightweight, good strength-to-weight ratio, and easy to machine.

– Cons: Lower strength compared to steel, making it less suitable for high-pressure applications.

Impact on Application:

Aluminum is often used in applications requiring lightweight components, such as portable fans and blowers. Its corrosion resistance makes it suitable for humid environments.

Considerations for Buyers:

Buyers should consider the specific alloy of aluminum for their applications, as different alloys have varying properties. Compliance with standards like ASTM B221 is essential for quality assurance.

4. Fiberglass Reinforced Plastic (FRP)

Key Properties:

FRP is lightweight, has excellent chemical resistance, and can withstand temperatures up to 200°F (93°C). It is non-corrosive and offers good insulation properties.

Pros & Cons:

– Pros: Excellent corrosion resistance, lightweight, and customizable.

– Cons: Lower mechanical strength compared to metals and can be more expensive to produce.

Impact on Application:

FRP is ideal for applications in corrosive environments, such as chemical processing plants. It is also used in applications where weight is a critical factor.

Considerations for Buyers:

Buyers should ensure that the FRP used complies with relevant standards, such as ASTM D638 for tensile properties. Cost considerations should also be evaluated, particularly for large-scale applications.

Summary Table

| Material | Typical Use Case for airpro fan and blower | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Industrial ventilation systems | High tensile strength | Prone to corrosion without coatings | Low |

| Stainless Steel | Food processing, pharmaceuticals | Exceptional durability | Higher cost and complex manufacturing | High |

| Aluminum | Portable fans, lightweight applications | Lightweight and easy to machine | Lower strength compared to steel | Medium |

| Fiberglass Reinforced Plastic | Chemical processing, corrosive environments | Excellent corrosion resistance | Lower mechanical strength | Medium |

This strategic material selection guide provides international B2B buyers with critical insights necessary for making informed decisions regarding the materials used in AirPro fans and blowers. By understanding the properties, advantages, and limitations of each material, buyers can select the most suitable options for their specific applications while ensuring compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for airpro fan and blower

The manufacturing processes and quality assurance (QA) practices for AirPro fans and blowers are critical components that international B2B buyers need to understand. This section provides a comprehensive overview of the typical manufacturing stages, key techniques involved, and the quality control measures that ensure the reliability and performance of these products.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing process involves selecting and preparing the raw materials. Common materials used for AirPro fans and blowers include:

- Steel and Aluminum: For durable and lightweight construction.

- Plastic Composites: For specific applications where corrosion resistance is essential.

- Coatings: Such as powder coatings or galvanizing to enhance durability.

Material preparation includes cutting, shearing, and sometimes pre-treatment processes such as cleaning or coating to ensure optimal adhesion and performance.

2. Forming

Once materials are prepared, the next step is forming. This involves shaping the materials into the desired components, typically through methods such as:

- Stamping: For creating metal parts with high precision.

- Casting: Used for complex shapes, especially in aluminum components.

- Machining: To achieve tight tolerances on critical dimensions.

Advanced technologies such as CNC (Computer Numerical Control) machining are often employed to enhance precision and efficiency.

3. Assembly

After forming, the components move to the assembly stage. This process may involve:

- Welding: For joining metal parts, ensuring structural integrity.

- Bolting and Fastening: To allow for easier disassembly and maintenance.

- Electrical Assembly: In fans that require motors or electronic controls, this step integrates wiring and circuitry.

Efficient assembly lines are designed to minimize handling and ensure that each component fits perfectly, which is crucial for performance.

4. Finishing

The final manufacturing stage is finishing, which includes:

- Surface Treatments: Such as painting, anodizing, or powder coating to protect against corrosion and improve aesthetics.

- Final Assembly: Where all components, including motors and controls, are assembled into the final product.

- Quality Checks: Before packaging, products undergo a series of quality checks to ensure they meet specifications.

Quality Assurance

Quality assurance is essential in maintaining the performance and reliability of AirPro fans and blowers. The following outlines the key QA standards, checkpoints, and methods relevant to international B2B buyers.

Relevant International Standards

- ISO 9001: This globally recognized standard outlines the criteria for a quality management system (QMS). Compliance ensures that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Particularly important for European buyers, CE marking indicates that the product meets EU safety, health, and environmental protection standards.

- API Standards: For fans and blowers used in the oil and gas industry, adherence to American Petroleum Institute (API) standards may be required.

Quality Control Checkpoints

Quality control is typically segmented into several checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, checks are performed to monitor quality and adherence to specifications.

- Final Quality Control (FQC): Once the product is completed, it undergoes final inspections and testing to verify performance before shipment.

Common Testing Methods

Manufacturers utilize various testing methods to ensure product reliability, including:

- Performance Testing: Evaluating airflow, pressure, and efficiency.

- Vibration Testing: To assess the operational stability of fans and blowers.

- Noise Level Testing: Ensuring compliance with industry standards for sound emissions.

Verifying Supplier Quality Control

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify supplier quality control:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices.

- Request Quality Reports: Buyers should ask for documentation that outlines quality control measures and testing results.

- Engage Third-party Inspectors: Utilizing independent inspectors can provide an unbiased assessment of the supplier’s capabilities and compliance with international standards.

Quality Control Nuances for International Buyers

Buyers from different regions may encounter unique challenges regarding quality assurance:

- Regulatory Differences: Understanding the regulatory landscape in your region is critical. For instance, CE marking is vital for European buyers but may not be relevant for those in Africa or South America.

- Cultural Factors: Communication styles and business practices can vary significantly. Building strong relationships with suppliers is essential for ensuring compliance with quality standards.

- Logistical Considerations: Importing products may involve additional quality checks at customs. Buyers should be aware of these potential hurdles and plan accordingly.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices for AirPro fans and blowers is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control measures, buyers can ensure that they are sourcing high-quality products that meet their operational needs. Engaging with suppliers through audits and requesting comprehensive quality documentation can further enhance confidence in the purchasing decision.

Comprehensive Cost and Pricing Analysis for airpro fan and blower Sourcing

When sourcing AirPro fans and blowers, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will cover the key components of cost, the influencers on pricing, and provide actionable tips for negotiation and procurement, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary costs stem from the raw materials used in manufacturing fans and blowers, such as metals, plastics, and electrical components. Prices can fluctuate based on market demand and availability, especially for specialized materials.

-

Labor: Labor costs are significant, particularly in regions with varying wage standards. Skilled labor is essential for precision manufacturing, which can add to the overall cost.

-

Manufacturing Overhead: This includes expenses related to utilities, maintenance, and operational costs of the manufacturing facility. Overhead is often a percentage of the total manufacturing cost and can vary significantly by location.

-

Tooling: Initial tooling costs can be substantial, particularly for custom or specialized fan designs. This cost is amortized over the production run, affecting the per-unit price.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to the cost. Certifications such as ISO can influence both the cost structure and the perceived value of the product.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and current freight rates. For international buyers, understanding Incoterms is critical to determining who bears these costs.

-

Margin: Suppliers will typically include a profit margin on top of their costs, which can vary based on competition, demand, and relationship with the buyer.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts. Buyers should consider their long-term needs to negotiate better prices.

-

Specifications and Customization: Custom designs may incur additional costs. Standardized products typically offer more competitive pricing.

-

Materials and Quality: Higher quality materials and additional certifications (like CE or UL) can increase costs but may be necessary for compliance in certain markets.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Established suppliers may command higher prices due to perceived quality.

-

Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential as they determine cost responsibilities and logistics management.

Buyer Tips

-

Negotiation: Always negotiate prices and terms. Suppliers may have flexibility, especially with bulk orders or long-term contracts.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes purchase price, maintenance, energy consumption, and potential downtime. This holistic view can justify higher upfront costs for superior products.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, tariffs or taxes in South America or import duties in Africa can significantly impact total costs.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and priority service, especially in times of high demand.

-

Market Research: Conduct thorough market research to understand prevailing prices and competitor offerings. This knowledge empowers buyers during negotiations.

Disclaimer

Prices can vary significantly based on market conditions, specific requirements, and supplier relationships. It is advisable to obtain multiple quotes and conduct due diligence before making procurement decisions.

Spotlight on Potential airpro fan and blower Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘airpro fan and blower’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for airpro fan and blower

Understanding the essential technical properties and trade terminology related to AirPro fans and blowers is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This knowledge not only facilitates informed purchasing decisions but also enhances communication with suppliers and manufacturers.

Key Technical Properties

-

Material Grade

– Definition: The specific type of material used in the fan or blower construction, typically categorized by its strength, durability, and resistance to corrosion.

– B2B Importance: Selecting the appropriate material grade ensures longevity and reliability, particularly in demanding industrial environments. For instance, stainless steel is often preferred for its corrosion resistance, while aluminum may be chosen for its lightweight properties. -

Airflow Capacity

– Definition: Measured in cubic feet per minute (CFM), this indicates the volume of air a fan or blower can move.

– B2B Importance: Understanding airflow capacity is vital for ensuring that the fan or blower meets the specific requirements of the application, such as ventilation in manufacturing facilities or cooling in data centers. -

Static Pressure

– Definition: The resistance to airflow in a system, measured in inches of water gauge (in. wg). This property reflects the fan’s ability to overcome obstacles like ductwork and filters.

– B2B Importance: A fan’s static pressure capability determines its effectiveness in various applications. For example, higher static pressure fans are necessary in systems with extensive ductwork. -

Tolerance

– Definition: The permissible limit of variation in a physical dimension or measured value, ensuring components fit and function together correctly.

– B2B Importance: Tolerances affect the performance and efficiency of fans and blowers. Tight tolerances are essential for precision applications, while looser tolerances may be acceptable in less critical environments. -

Power Rating

– Definition: The amount of electrical power required for the fan or blower to operate, usually expressed in horsepower (HP) or kilowatts (kW).

– B2B Importance: Knowing the power rating helps buyers assess energy consumption and operational costs, which is crucial for budgeting and sustainability efforts.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships can help buyers identify quality standards and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Recognizing MOQ is essential for budgeting and inventory management, especially for international buyers looking to optimize shipping costs.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a price quote for specific products or services.

– Significance: Issuing RFQs allows buyers to compare prices and terms from multiple suppliers, promoting competitive pricing and informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Significance: Familiarity with Incoterms is crucial for buyers to understand shipping logistics, risk management, and cost responsibilities, ensuring smooth cross-border transactions. -

Lead Time

– Definition: The time taken from the placement of an order to the delivery of goods.

– Significance: Knowing the lead time is vital for planning and inventory management, particularly in industries where timely delivery is critical to operations.

Illustrative Image (Source: Google Search)

By grasping these essential technical properties and trade terms, international B2B buyers can navigate the complexities of purchasing AirPro fans and blowers more effectively, ensuring that their investment aligns with operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the airpro fan and blower Sector

Market Overview & Key Trends

The airpro fan and blower sector is witnessing significant growth driven by various global factors. Increasing industrialization in emerging economies across Africa, South America, and the Middle East is a primary catalyst. These regions are investing heavily in infrastructure, manufacturing, and energy sectors, which directly boosts demand for efficient ventilation and air management solutions. Additionally, the rise of smart manufacturing technologies is paving the way for advanced B2B tech trends such as IoT integration and automation in fan and blower systems, allowing for real-time monitoring and enhanced operational efficiency.

International B2B buyers should also be aware of shifting sourcing trends. There is a marked preference for suppliers who offer customizable solutions that can cater to specific operational needs. This is particularly relevant for industries like pharmaceuticals and food processing, where precise airflow control is crucial. Furthermore, the adoption of e-commerce platforms for B2B transactions is becoming prevalent, enabling buyers to easily compare products, suppliers, and pricing from different regions, including Europe and Latin America.

Market dynamics are also influenced by regulatory changes aimed at reducing energy consumption and emissions. As European markets, in particular, implement stricter environmental regulations, buyers are encouraged to seek out energy-efficient products that comply with these standards. Understanding these dynamics will empower B2B buyers to make informed purchasing decisions that align with both operational requirements and sustainability goals.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a non-negotiable factor in the procurement process for airpro fans and blowers. The environmental impact of these systems, particularly in terms of energy consumption and material waste, has prompted buyers to prioritize solutions that are energy-efficient and designed for longevity. Manufacturers are now focusing on creating products that minimize their carbon footprint throughout the lifecycle, from production to disposal.

Ethical sourcing is also gaining traction. Buyers are urged to ensure that their supply chains are transparent and responsible, adhering to ethical labor practices and environmental standards. This is particularly important in regions like Africa and South America, where supply chain conditions can vary significantly. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming essential benchmarks for evaluating supplier sustainability practices.

Additionally, the use of ‘green’ materials in the production of airpro fans and blowers is on the rise. Buyers should look for products made from recycled or sustainably sourced materials, as well as those that incorporate low-VOC (volatile organic compound) components, to align with global sustainability trends. By prioritizing sustainable and ethical sourcing, B2B buyers can not only enhance their brand reputation but also contribute positively to global environmental efforts.

Brief Evolution/History

The airpro fan and blower sector has evolved significantly over the past few decades. Initially dominated by mechanical designs, advancements in materials science and engineering have led to the development of more efficient, durable, and versatile products. The introduction of digital technologies has further transformed the landscape, enabling features such as remote monitoring and predictive maintenance.

As industries across the globe become more conscious of their environmental impact, the sector has adapted by embracing sustainability, focusing on energy efficiency, and ethical sourcing practices. This evolution not only reflects changing consumer expectations but also the regulatory pressures that shape the industry today. B2B buyers can leverage this historical context to understand the trajectory of product innovation and sustainability in their procurement strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of airpro fan and blower

-

What should I consider when vetting suppliers for AirPro fans and blowers?

When vetting suppliers, prioritize their industry experience and reputation. Check for certifications relevant to your region, such as ISO or CE, which indicate compliance with international standards. Request references from previous clients, particularly those in your region (e.g., Africa or South America), to gauge reliability. Additionally, evaluate their customer service responsiveness and technical support capabilities, as these are critical for resolving issues that may arise post-purchase. -

Can I customize AirPro fans and blowers to meet my specific needs?

Yes, many suppliers offer customization options to tailor AirPro fans and blowers to your specifications. Discuss your requirements in detail, including size, airflow capacity, and material preferences. Ensure that the supplier has the capability and experience to execute such customizations. It’s also advisable to request prototypes or detailed specifications to confirm that the final product will meet your operational requirements before placing a bulk order. -

What are the minimum order quantities (MOQ) and lead times for AirPro products?

Minimum order quantities can vary significantly among suppliers, often ranging from a few units to several dozen. Lead times typically depend on the complexity of your order and the supplier’s production capacity. For standard products, expect lead times of 4-6 weeks, while customized orders may take longer. Always confirm these details with your supplier upfront to avoid delays in your operations. -

What payment options are available, and what should I be aware of regarding international transactions?

Common payment methods include wire transfers, letters of credit, and online payment platforms. For international transactions, consider currency exchange rates and transaction fees, which can impact the final cost. It’s advisable to negotiate favorable payment terms, such as partial payments upfront and the balance upon delivery, to mitigate risk. Ensure that your supplier provides a clear invoice detailing all costs involved to avoid any hidden fees. -

How can I ensure quality assurance and certifications for AirPro fans and blowers?

Request documentation of quality assurance processes from your supplier, including testing protocols and compliance certifications. Look for products that meet international standards such as ISO 9001 or industry-specific certifications relevant to your sector. Additionally, consider third-party inspections or audits to verify that the supplier adheres to these quality standards before shipment, especially if sourcing from regions with varying manufacturing practices. -

What logistics considerations should I keep in mind when importing AirPro fans and blowers?

Logistics involve planning for shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling industrial equipment to navigate the complexities of international shipping. Understand the import regulations in your country, including tariffs and taxes, to avoid unexpected costs. Collaborate closely with your supplier to ensure proper packaging and documentation to facilitate smooth customs processing. -

How can I handle disputes or issues that may arise with my supplier?

Establish clear communication channels and document all agreements in writing to address disputes effectively. If issues arise, try to resolve them through direct communication with the supplier first. If a resolution cannot be reached, consider mediation or arbitration as alternatives to litigation. Understanding the legal frameworks governing international trade in both your country and the supplier’s country can also be beneficial for resolving disputes. -

What are the best practices for maintaining AirPro fans and blowers once they are installed?

Regular maintenance is crucial for the longevity and performance of AirPro fans and blowers. Develop a maintenance schedule that includes inspections, cleaning, and any necessary repairs. Ensure that your team is trained on proper operational procedures and troubleshooting techniques. Keep a record of maintenance activities to identify patterns that may indicate underlying issues, allowing for proactive rather than reactive maintenance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for airpro fan and blower

In conclusion, strategic sourcing of AirPro fans and blowers is not only essential for optimizing operational efficiency but also for enhancing sustainability and cost-effectiveness. By leveraging a diverse supplier network across Africa, South America, the Middle East, and Europe, businesses can ensure access to high-quality products that meet specific industry needs.

Key Takeaways for International B2B Buyers:

- Quality Assurance: Prioritize suppliers with robust quality control processes to ensure reliable performance.

- Cost Management: Analyze total cost of ownership, including maintenance and energy efficiency, to make informed purchasing decisions.

- Local Regulations: Stay informed about local compliance and environmental regulations to avoid costly penalties and ensure smooth operations.

- Supplier Relationships: Foster long-term partnerships with suppliers to benefit from innovation and tailored solutions.

As the demand for efficient and sustainable airflow solutions continues to grow, forward-thinking companies should act now. Engage with reputable suppliers to explore cutting-edge technologies that align with your operational goals. Seize the opportunity to position your organization as a leader in the industry by investing in advanced AirPro solutions that enhance productivity and environmental stewardship.