Master Sourcing Strategies for Beveled Gear: A B2B Buyer’s

Introduction: Navigating the Global Market for beveled gear

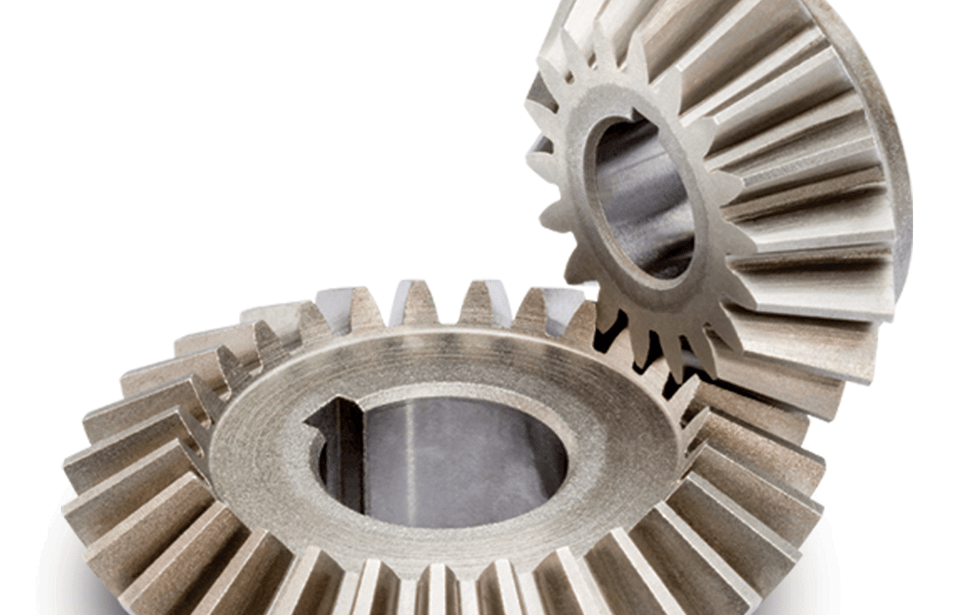

In the dynamic landscape of global manufacturing, beveled gears stand out as critical components that facilitate efficient power transmission across various industries, including automotive, aerospace, and industrial machinery. Their unique design, featuring intersecting axes and conically shaped teeth, enables these gears to handle significant loads while maintaining precise motion. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe (including key markets like Poland and France), understanding the intricacies of beveled gear procurement is essential for ensuring operational efficiency and product reliability.

This comprehensive guide delves into the multifaceted world of beveled gears, covering essential topics such as types of bevel gears, material specifications, and manufacturing processes. We will also explore critical aspects of quality control, supplier selection, and cost considerations to equip buyers with the knowledge necessary for informed sourcing decisions. Additionally, we address frequently asked questions to clarify common uncertainties in the purchasing process.

By empowering buyers with actionable insights and detailed information, this guide serves as a vital resource for navigating the complexities of the global beveled gear market. Whether you are looking to optimize your supply chain or enhance product performance, understanding the nuances of bevel gear selection will position your business for success in a competitive environment.

Illustrative Image (Source: Google Search)

Understanding beveled gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Bevel Gears | Teeth are straight and cut along the gear axis. | Automotive transmissions, industrial machinery. | Pros: Simple design, cost-effective. Cons: Limited load capacity compared to spiral gears. |

| Spiral Bevel Gears | Teeth are curved and angled, allowing smoother operation. | Aerospace, robotics, and high-speed applications. | Pros: Higher load capacity, quieter operation. Cons: More complex manufacturing process, higher cost. |

| Hypoid Gears | A type of spiral bevel gear with an offset between axes. | Automotive differential systems, heavy machinery. | Pros: High torque transmission, smooth engagement. Cons: Requires precise alignment, more expensive. |

| Crown Gears | Features a conical shape with teeth on the top surface. | Marine applications, right-angle drives. | Pros: Compact design, good for tight spaces. Cons: Limited power transmission capability. |

| Miter Gears | Similar in size and tooth count, used for 90-degree angle changes. | Conveyor systems, machine tools. | Pros: Simple design, easy to install. Cons: Lower load capacity, can be noisy. |

Straight Bevel Gears

Straight bevel gears are characterized by their straight teeth that align with the gear’s axis. They are commonly used in applications like automotive transmissions and various industrial machinery. For B2B buyers, the simplicity of design translates to a cost-effective solution, making them an attractive option for many applications. However, their limited load capacity compared to other gear types may necessitate consideration of operational demands before purchase.

Spiral Bevel Gears

Spiral bevel gears feature teeth that are curved and angled, which allows for smoother engagement and operation. They are widely used in high-speed applications such as aerospace and robotics. B2B buyers appreciate their higher load capacity and quieter performance, which can enhance machinery longevity. However, the complexity of their manufacturing process may result in a higher cost, making it essential for buyers to weigh budget constraints against performance needs.

Hypoid Gears

Hypoid gears are a specialized form of spiral bevel gears where the axes are offset. This design allows for efficient torque transmission and smooth engagement, making them ideal for automotive differential systems and heavy machinery. B2B purchasers should consider their advantages in high torque applications; however, the need for precise alignment can complicate installation and increase costs.

Crown Gears

Crown gears feature a unique conical shape with teeth positioned on the top surface, making them suitable for marine applications and right-angle drives. Their compact design is advantageous in tight spaces, which is a common requirement in various industrial settings. While they offer space-saving benefits, B2B buyers should be aware of their limited power transmission capability, which may restrict their use in high-load applications.

Miter Gears

Miter gears are designed to operate at 90-degree angles and are often of equal size and tooth count. They find applications in conveyor systems and machine tools. The straightforward design of miter gears makes them easy to install, which is beneficial for quick assembly processes. However, their lower load capacity and potential noise during operation may be factors for buyers to consider when selecting gears for specific applications.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of beveled gear

| Industry/Sector | Specific Application of beveled gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft control systems | Enhances reliability and safety in flight control | Compliance with aviation standards and certifications |

| Automotive | Transmission systems | Improves efficiency and performance of vehicles | Material quality, heat treatment processes, and precision |

| Mining | Conveyor systems for material handling | Increases operational efficiency and reduces downtime | Durability under heavy loads, corrosion resistance |

| Oil & Gas | Pumping and drilling equipment | Ensures reliable operation in harsh environments | Customization for specific applications and conditions |

| Industrial Machinery | Gearboxes in manufacturing equipment | Optimizes power transmission and reduces wear | Precision manufacturing and quality control processes |

Aerospace

In the aerospace sector, bevel gears are integral to aircraft control systems, including rudders and flaps. Their conical shape allows for efficient power transmission at various angles, which is crucial for precise control. International buyers must ensure that the gears meet stringent aviation safety standards and certifications. Quality assurance processes, including rigorous testing and compliance with specifications, are vital to mitigate risks associated with flight safety.

Automotive

Bevel gears play a critical role in automotive transmission systems, where they facilitate the transfer of power between the engine and wheels. This application demands high efficiency and performance, as any failure can lead to significant operational costs. Buyers in regions such as Europe and South America should prioritize sourcing gears that offer superior material quality and advanced heat treatment processes to withstand the stresses of everyday use. Precision in manufacturing is also essential to ensure compatibility with various vehicle models.

Mining

In the mining industry, bevel gears are commonly used in conveyor systems to transport materials efficiently. Their robust design helps to handle heavy loads and minimizes the risk of breakdowns, which can be costly. Buyers from Africa and the Middle East should focus on sourcing gears that exhibit exceptional durability and corrosion resistance due to the harsh operating conditions often encountered in mining environments. The ability to customize bevel gears for specific applications can also significantly enhance operational efficiency.

Oil & Gas

Bevel gears are crucial in oil and gas applications, particularly in drilling and pumping equipment. They help maintain reliable operation in extreme conditions, such as high pressure and corrosive environments. Buyers in this sector should consider sourcing gears that can be tailored to meet the specific demands of their operations, including customization for size and material. Ensuring that the gears are manufactured using advanced techniques can enhance their performance and longevity, reducing the frequency of maintenance and replacement.

Industrial Machinery

In industrial machinery, bevel gears are used in gearboxes to optimize power transmission. This application is vital for reducing wear and improving the efficiency of manufacturing processes. Buyers should seek suppliers that implement rigorous quality control measures during manufacturing to ensure precision and reliability. Additionally, understanding the specific operational requirements of the machinery will help in selecting the right bevel gears, ultimately leading to improved productivity and reduced operational costs.

Related Video: The World’s Largest Bevel Gear CNC Machine- Modern Gear Production Line. Steel Wheel Manufacturing

Strategic Material Selection Guide for beveled gear

Bevel gears are critical components in various mechanical systems, and selecting the right material is essential for optimizing performance and longevity. Below is a detailed analysis of four common materials used in the manufacturing of bevel gears, focusing on their properties, advantages, limitations, and considerations for international B2B buyers.

1. Steel Alloys

Key Properties:

Steel alloys, particularly carbon and alloy steels, exhibit high tensile strength, hardness, and wear resistance. They can withstand high temperatures and pressures, making them suitable for demanding applications.

Pros & Cons:

Steel alloys are highly durable and can be heat-treated to enhance their properties. However, they can be prone to corrosion if not properly treated or coated. Manufacturing complexity can vary based on the specific alloy and heat treatment processes required.

Impact on Application:

Steel bevel gears are compatible with a wide range of media, including oils and greases, making them ideal for automotive and industrial applications.

Considerations for International Buyers:

Compliance with standards such as ASTM AISI for steel grades is crucial. Buyers in Europe may prefer materials that meet DIN standards, while those in South America and Africa should consider local regulations regarding material specifications.

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance due to its chromium content, along with good mechanical properties. It maintains strength at elevated temperatures and has a relatively low thermal expansion coefficient.

Pros & Cons:

The primary advantage of stainless steel is its resistance to rust and corrosion, making it suitable for applications in humid or corrosive environments. However, it is generally more expensive than carbon steels and can be more challenging to machine.

Impact on Application:

Stainless steel bevel gears are ideal for food processing, pharmaceuticals, and marine applications where hygiene and corrosion resistance are paramount.

Considerations for International Buyers:

Buyers should ensure compliance with specific standards such as ASTM A276 for stainless steel grades. In Europe, EN standards may apply, and buyers should be aware of local sourcing capabilities to avoid delays.

3. Aluminum Alloys

Key Properties:

Aluminum alloys are lightweight and have good corrosion resistance. They exhibit moderate strength and can be anodized to enhance surface properties.

Pros & Cons:

The main advantage of aluminum is its low weight, which can reduce overall system weight and improve efficiency. However, aluminum gears may not handle high loads as effectively as steel, making them less suitable for heavy-duty applications.

Impact on Application:

Aluminum bevel gears are often used in applications where weight savings are critical, such as in aerospace and automotive industries.

Considerations for International Buyers:

Buyers should verify that aluminum alloys meet relevant standards, such as ASTM B221. In Europe, compliance with EN standards is also necessary, and buyers should consider the availability of specific aluminum grades in their region.

4. Composite Materials

Key Properties:

Composite materials, such as reinforced plastics or carbon-fiber composites, offer excellent strength-to-weight ratios and corrosion resistance. They can also dampen vibrations effectively.

Pros & Cons:

Composites are lightweight and can be tailored for specific applications, but they may not withstand high temperatures or loads as well as metals. Manufacturing complexity can be higher, requiring specialized processes.

Impact on Application:

Composite bevel gears are suitable for applications in electronics, robotics, and lightweight machinery where weight and noise reduction are priorities.

Considerations for International Buyers:

It is essential to ensure that composite materials comply with relevant industry standards. Buyers should also consider the specific performance characteristics required for their applications, as composites can vary widely in properties.

Summary Table

| Material | Typical Use Case for beveled gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | Automotive, Industrial Machinery | High strength and durability | Prone to corrosion without treatment | Medium |

| Stainless Steel | Food Processing, Marine Applications | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum Alloys | Aerospace, Automotive | Lightweight and good corrosion resistance | Moderate strength under high loads | Medium |

| Composite Materials | Robotics, Lightweight Machinery | Tailored properties and low weight | Limited high-temperature performance | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers seeking to enhance their bevel gear applications. Understanding the properties, advantages, and limitations of each material will facilitate informed decision-making and ensure compliance with relevant standards across different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for beveled gear

Bevel gears are essential components in various mechanical systems, and understanding their manufacturing processes and quality assurance protocols is crucial for international B2B buyers. This guide will provide insights into the typical manufacturing stages, key techniques, and quality control measures that ensure the reliability and performance of bevel gears.

Manufacturing Processes for Bevel Gears

The manufacturing of bevel gears involves several key stages that ensure precision and quality. Here’s a breakdown of these stages:

1. Material Preparation

The choice of material is foundational to the performance of bevel gears. Common materials include:

– Alloy Steels: Known for their strength and wear resistance, suitable for high-load applications.

– Stainless Steels: Ideal for environments where corrosion resistance is critical.

– Cast Iron: Often used for lower load applications due to its good machinability.

The material is typically received in bulk form and must undergo processes such as:

– Cutting: To obtain blanks of the required dimensions.

– Heat Treatment: Enhances material properties such as hardness and toughness, often through processes like quenching and tempering.

2. Forming

The forming stage involves creating the gear teeth and final shape. Key techniques include:

– Gear Cutting: This can be performed using various methods:

– Conventional Gear Cutting: Suitable for low to medium production volumes.

– CNC Gear Cutting: Offers high precision and flexibility, ideal for complex designs and high-volume production.

– Gear Grinding: Used to achieve tight tolerances and superior surface finish, particularly for high-quality applications.

3. Assembly

Once the gears are formed, they may be assembled with other components such as shafts and housings. The assembly process can involve:

– Press-fitting: Ensures tight connections between gears and shafts.

– Welding or Bolting: Depending on the application requirements, these methods provide structural integrity.

4. Finishing

Finishing operations are critical for enhancing the performance characteristics of bevel gears. These may include:

– Deburring: Removal of sharp edges to prevent wear and ensure smooth operation.

– Lapping: Improves surface finish and tooth contact patterns.

– Coating: Application of protective coatings to enhance corrosion resistance.

Quality Assurance in Bevel Gear Manufacturing

Quality assurance is vital to ensure that bevel gears meet industry standards and customer specifications. Here are the main aspects of quality control in the manufacturing process:

Relevant International Standards

- ISO 9001: A widely recognized standard that outlines the requirements for a quality management system, ensuring consistent quality in products and services.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for gears used in the oil and gas sector, ensuring they meet specific performance criteria.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Inspects raw materials for compliance with specifications before manufacturing begins.

– In-Process Quality Control (IPQC): Monitors production processes to catch defects early, using techniques such as dimensional checks and surface quality assessments.

– Final Quality Control (FQC): Comprehensive inspection of finished products, including:

– Dimensional Accuracy: Ensuring that all specifications are met using precision measuring tools.

– Tooth Profile Inspection: Verifying that the gear teeth are manufactured to design specifications.

Common Testing Methods

Testing methods play a crucial role in validating the quality of bevel gears:

– Coordinate Measuring Machines (CMM): Used for precise dimensional measurements.

– Gear Analyzers: Assess the tooth profile and contact patterns.

– Hardness Testing: Confirms that the heat treatment process has achieved the desired material properties.

Verification of Supplier Quality Control

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some strategies to ensure supplier compliance with quality standards:

Supplier Audits

Conducting regular audits of suppliers can help verify their adherence to quality standards. Audits should cover:

– Quality management systems in place.

– Compliance with international standards (e.g., ISO 9001).

– Processes for handling defects and non-conformances.

Requesting Quality Reports

Buyers should request detailed quality reports from suppliers, including:

– Results from IQC, IPQC, and FQC checkpoints.

– Certifications that validate compliance with relevant standards.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can include:

– Random sampling of produced gears.

– Verification of documentation and compliance with international standards.

Conclusion

Understanding the manufacturing processes and quality assurance practices for bevel gears is crucial for international B2B buyers. By paying attention to material preparation, forming techniques, assembly, and finishing, as well as implementing rigorous quality control measures, buyers can ensure that they source high-quality bevel gears that meet their specific application needs. With the right verification strategies in place, businesses can foster reliable supplier relationships and enhance their operational efficiency.

Comprehensive Cost and Pricing Analysis for beveled gear Sourcing

To effectively navigate the procurement of beveled gears, international B2B buyers must understand the intricate cost structure and pricing dynamics involved in sourcing these components. This section delves into the various cost components, price influencers, and offers actionable tips for buyers across Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials used in bevel gear manufacturing include steel, aluminum, and specialized alloys. The choice of material significantly impacts the price, with high-performance alloys costing more due to their enhanced properties like strength and corrosion resistance.

-

Labor: Labor costs are influenced by the skill level required for gear manufacturing, which often involves precision machining and quality control. Regions with higher labor costs may see increased pricing, while those with lower labor expenses can offer competitive rates.

-

Manufacturing Overhead: This encompasses the operational costs associated with running manufacturing facilities, including utilities, maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead, thus impacting the final price.

-

Tooling: Custom tooling is often required for specific bevel gear designs, which can represent a significant upfront investment. Buyers should consider the amortization of these costs over production volumes to assess their impact on unit pricing.

-

Quality Control (QC): Ensuring the gears meet stringent quality standards involves testing and inspection processes. The more rigorous the QC, the higher the associated costs, which will be reflected in the final price.

-

Logistics: Shipping costs can vary greatly depending on the destination, shipping method, and volume. Buyers should factor in potential tariffs and import duties when evaluating total costs.

-

Margin: Suppliers typically apply a profit margin based on their operational costs, market demand, and competitive landscape. Understanding the supplier’s cost structure can provide leverage during negotiations.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly influence pricing. Larger orders often lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Customized bevel gears, tailored to specific applications or performance requirements, will generally command higher prices. Standardized products are usually more cost-effective.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO standards) can elevate costs. Buyers should weigh the necessity of these factors against their budget and application needs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with proven track records may charge a premium, but often provide superior quality and service.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) can help buyers manage logistics costs. Incoterms define the responsibilities of buyers and sellers in shipping, impacting overall expenses.

Buyer Tips

-

Negotiation: Effective negotiation tactics can lead to more favorable pricing. Building long-term relationships with suppliers can also yield discounts on future orders.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as lifespan, maintenance, and performance when assessing value.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, local economic conditions, and potential trade agreements that could affect pricing.

-

Supplier Diversity: Engaging multiple suppliers can foster competition and provide options for better pricing and service levels.

-

Research and Benchmarking: Conduct thorough research and benchmarking against industry standards to ensure competitive pricing. Understanding the market landscape can empower buyers during procurement discussions.

Disclaimer: Prices for beveled gears can vary widely based on the factors discussed, and it is advisable to seek multiple quotes to gauge the market accurately.

Spotlight on Potential beveled gear Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘beveled gear’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for beveled gear

Bevel gears play a crucial role in various mechanical applications, from automotive to industrial machinery. Understanding their technical properties and trade terminology is essential for international B2B buyers seeking quality and reliability in their gear systems. This section outlines key specifications and industry terms relevant to bevel gears.

Key Technical Properties of Bevel Gears

-

Material Grade

– Definition: The material grade specifies the type of alloy or steel used in the manufacturing of bevel gears. Common materials include carbon steel, stainless steel, and alloy steel.

– B2B Importance: The choice of material affects the gear’s durability, load capacity, and resistance to wear and corrosion. Selecting the appropriate material is vital for ensuring the gear can withstand operational stresses in its intended application. -

Tolerance

– Definition: Tolerance refers to the permissible limits of variation in a gear’s dimensions, such as tooth spacing and overall size.

– B2B Importance: High tolerance levels are critical for ensuring proper meshing with other gears, minimizing noise, and enhancing operational efficiency. Buyers should prioritize suppliers who can meet stringent tolerance requirements to avoid mechanical failures. -

Tooth Profile

– Definition: The tooth profile describes the shape and design of the gear teeth, which can be straight, spiral, or helical.

– B2B Importance: The tooth profile impacts the gear’s efficiency, load distribution, and noise levels. Understanding the benefits of different profiles helps buyers select gears suited for specific applications, such as high-speed machinery or quiet operations. -

Heat Treatment

– Definition: Heat treatment processes, such as carburizing or quenching, enhance the hardness and strength of bevel gears.

– B2B Importance: Proper heat treatment is essential for increasing wear resistance and extending the gear’s lifespan. Buyers should inquire about heat treatment practices to ensure product longevity and reliability. -

Surface Finish

– Definition: Surface finish pertains to the texture of the gear’s surface, measured in Ra (roughness average).

– B2B Importance: A finer surface finish reduces friction and wear, contributing to smoother operation and longer service life. Buyers should assess surface finish specifications as part of their quality requirements. -

Load Capacity

– Definition: Load capacity indicates the maximum load that a bevel gear can handle without failure.

– B2B Importance: Understanding load capacity is crucial for ensuring the selected gear can perform under specific operational conditions. Buyers must match the gear’s load capacity with their application needs to avoid premature failure.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces components that are used in another company’s end products.

– Significance: For buyers, working with OEMs can guarantee that they receive high-quality parts designed specifically for their applications. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Significance: Understanding MOQ is essential for buyers to manage inventory costs and ensure they are purchasing sufficient quantities to meet their operational demands. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers to request pricing and terms for specific products or services.

– Significance: Buyers use RFQs to compare quotes from multiple suppliers, ensuring they receive the best price and conditions for their bevel gear needs. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions.

– Significance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost allocation, ensuring smooth transactions across borders. -

Lead Time

– Definition: Lead time is the time taken from placing an order to receiving the goods.

– Significance: Understanding lead time is crucial for effective supply chain management, allowing buyers to plan production schedules and inventory levels accordingly. -

Quality Assurance

– Definition: Quality assurance refers to the systematic processes put in place to ensure that products meet specific standards and specifications.

– Significance: For buyers, ensuring that suppliers have robust quality assurance processes is vital for receiving reliable and high-quality bevel gears.

In summary, grasping the essential technical properties and trade terminology surrounding bevel gears is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances the overall efficiency and effectiveness of their operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the beveled gear Sector

Market Overview & Key Trends

The global market for bevel gears is driven by several factors, including the increasing demand for efficient power transmission systems in various industries such as automotive, aerospace, and manufacturing. As economies in Africa, South America, the Middle East, and Europe continue to grow, there is a heightened need for advanced machinery that relies on high-quality bevel gears. Notably, the trend towards automation and the adoption of Industry 4.0 technologies are reshaping sourcing strategies. Buyers are increasingly looking for suppliers who can provide not only high precision but also flexibility in production volumes.

Emerging technologies such as 3D printing and advanced CNC machining are revolutionizing the bevel gear manufacturing process, allowing for rapid prototyping and customization. Buyers should consider suppliers that leverage these technologies to remain competitive. Additionally, there is a growing emphasis on digital platforms for procurement, enabling buyers to access a wider range of suppliers and products while facilitating better price comparisons and contract negotiations.

Illustrative Image (Source: Google Search)

Market dynamics are also influenced by geopolitical factors, particularly in regions like Europe and the Middle East, where trade agreements and tariffs can affect sourcing decisions. B2B buyers must remain aware of these factors to navigate the complexities of international procurement effectively. Understanding local market conditions and establishing relationships with regional suppliers can provide strategic advantages.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the bevel gear sector. The environmental impact of gear manufacturing—such as energy consumption, waste generation, and resource depletion—has prompted many companies to adopt more sustainable practices. Buyers should prioritize suppliers who implement eco-friendly manufacturing processes, such as using renewable energy sources and minimizing waste through recycling initiatives.

Ethical sourcing is equally important, as businesses face increasing scrutiny regarding their supply chains. Buyers should look for suppliers who adhere to ethical labor practices and are transparent about their sourcing materials. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the use of “green” materials—such as those with lower carbon footprints or derived from recycled sources—can enhance the sustainability profile of bevel gear products. As consumers and regulators demand greater accountability, aligning procurement strategies with sustainable and ethical standards will not only mitigate risks but can also enhance brand reputation and customer loyalty.

Brief Evolution/History

The evolution of bevel gears dates back to the late 18th century when they were first utilized in mechanical devices. Initially, these gears were crafted using rudimentary methods, leading to inefficiencies and inaccuracies. The advent of precision machining in the 20th century revolutionized the production of bevel gears, enabling manufacturers to create gears with tighter tolerances and better performance characteristics.

Today, bevel gears are integral to various applications, from automotive drivetrains to aerospace systems. Continuous advancements in materials science and manufacturing techniques have further enhanced their efficiency and durability. As the industry moves toward more sophisticated applications, understanding the historical context of bevel gear development can provide valuable insights into future trends and innovations in sourcing and manufacturing.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of beveled gear

-

What criteria should I use to vet suppliers of beveled gear?

When vetting suppliers, prioritize their experience and expertise in bevel gear manufacturing. Check for certifications such as ISO 9001, which indicates adherence to quality management standards. Review their production capabilities and technology, including CNC machinery and heat treatment processes. Additionally, assess their financial stability and reputation by examining customer reviews and case studies. It may also be beneficial to request references from other international clients, especially those within your industry. -

Can I customize bevel gears to meet specific requirements?

Yes, many manufacturers offer customization options for bevel gears. You can specify dimensions, tooth profiles, materials, and heat treatment processes based on your application needs. Ensure you provide detailed specifications and drawings to the supplier. It’s advisable to discuss your requirements early in the procurement process to clarify capabilities and timelines. Some suppliers may also provide prototype services for testing before committing to larger orders. -

What are the typical minimum order quantities (MOQ) and lead times for bevel gears?

MOQs for bevel gears can vary significantly based on the manufacturer and the complexity of the gear design. Generally, expect MOQs ranging from 50 to several hundred units. Lead times can also vary, typically ranging from 4 to 12 weeks, depending on customization, production capacity, and material availability. It’s essential to confirm these details with your supplier during negotiations to align expectations and plan your supply chain effectively. -

What payment terms should I expect when sourcing bevel gears internationally?

Payment terms can vary widely among suppliers. Common practices include advance payments, net 30, or net 60 terms. For large orders, consider negotiating payment plans based on milestones, such as a deposit upon order confirmation and the balance upon delivery. Ensure that payment methods are secure, and consider using letters of credit for additional protection in international transactions. Always clarify terms in the contract to avoid disputes later. -

How do I ensure quality assurance and certification for the bevel gears I purchase?

Request documentation of quality control processes and certifications from your supplier, such as ISO or other relevant standards. Inquire about their inspection methods, including the use of coordinate measuring machines (CMM) and gear analyzers. It’s also prudent to conduct periodic audits or inspections during the manufacturing process to verify compliance with your quality standards. Establish a clear agreement on acceptable tolerances and quality metrics in your contract. -

What logistics considerations should I keep in mind when importing bevel gears?

Logistics is crucial for the timely delivery of bevel gears. Ensure that your supplier has experience in international shipping and can manage customs clearance efficiently. Discuss shipping options, lead times, and costs upfront, including Incoterms to clarify responsibilities. Consider partnering with a logistics provider familiar with your target markets in Africa, South America, the Middle East, and Europe to streamline the import process and mitigate risks. -

How can I handle disputes with suppliers effectively?

To manage disputes, establish clear communication channels and document all agreements and changes in writing. Utilize a formal dispute resolution process outlined in your contract, which may include mediation or arbitration before escalating to legal action. It’s advisable to maintain a professional relationship and seek to resolve issues amicably. Additionally, consider including clauses in your contracts that specify jurisdiction and governing law relevant to both parties. -

What are the common challenges faced when sourcing bevel gears internationally?

Common challenges include language barriers, cultural differences, and varying quality standards. Fluctuations in currency exchange rates can also impact pricing. To mitigate these risks, invest time in building strong relationships with suppliers and ensure clear communication of expectations. Conduct thorough market research to understand local regulations and standards. Finally, consider sourcing from multiple suppliers to diversify your risk and ensure continuity of supply.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for beveled gear

In conclusion, the strategic sourcing of bevel gears is essential for international B2B buyers seeking to enhance operational efficiency and product performance. By understanding the intricate manufacturing processes—from design and engineering to heat treatment and finishing—buyers can make informed decisions that align with their specific application needs. Key takeaways include the importance of selecting suppliers with advanced capabilities in CNC machining and rigorous quality control measures, which are crucial for ensuring the durability and precision of bevel gears.

As the global market evolves, particularly with the rise of e-mobility and advanced manufacturing technologies, buyers must remain adaptable and proactive. Engaging with suppliers who can offer customized solutions and prototype development will be vital for innovation and competitiveness.

Moving forward, international buyers from Africa, South America, the Middle East, and Europe should actively seek partnerships with reputable gear manufacturers that prioritize quality and reliability. This strategic approach will not only secure high-performance bevel gears but also foster long-term success in an increasingly competitive landscape. Embrace the opportunities ahead—invest in strategic sourcing today for a more efficient tomorrow.